Say hello to Hobart Handler 130 – your trusty welding sidekick! This welding machine is here to make your projects a breeze. It easily welds up to 3/16in. steel with flux-core wire, allowing you to take on any job you possibly can, no matter how big or small.

Say hello to Hobart Handler 130 – your trusty welding sidekick! This welding machine is here to make your projects a breeze. It easily welds up to 3/16in. steel with flux-core wire, allowing you to take on any job you possibly can, no matter how big or small.Hobart Handler 130 User Manual

Pros & Cons of Hobart Handler 130

Buyer’s Guide

Why Hobart?

When it comes to welding, Hobart has been a trusted name for years. The Handler 130 is no exception. This welder offers excellent performance and durability in an easy-to-use package. It’s ideal for light industrial and home use, with the ability to weld various materials including steel, stainless steel, aluminum, and cast iron.

Whether you need to repair a broken fence or build a new one, the Hobart Handler 130 is up for the job. It’s designed to be reliable and efficient so that you can complete your projects quickly and easily. Plus, it’s backed by a 3-year warranty from Hobart, giving you peace of mind.[2]

For Whom Hobart Handler 130 Designed For?

The Hobart Handler 130 is designed for the do-it-yourselfer and hobbyist who are looking for an economical way to get into welding. It is a reliable and durable machine that can help you complete your small-scale projects with ease. The Handler 130 is perfect for anyone just starting out in the world of welding, as it is not only easy to use but also relatively affordable. It is safe and comes with a variety of settings, making it suitable for most projects. Whether you’re repairing farm equipment or building furniture, the Handler 130 can help get the job done. Additionally, experienced welders might find the Handler 130 useful for certain lighter-duty projects.[2]

Hobart Handler 130 specs at a glance

The Hobart Handler 130 is one of the best MIG (metal inert gas) welders out there, designed to give hobbyists and professionals alike an easy-to-use tool for their welding projects. Here’s what you need to know about its specs:

- Input voltage: 115V / 230V AC

- Output range: 25-130A

- Duty cycle rating: 20% at 130A, 50% at 90A

- Processes: MIG (GMAW), flux cored (FCAW)

- Wire size: 0.030” – 0.035” steel and stainless steel; 0.

Design and Portability

The Hobart Handler 130 is a well-designed and easy to use welder that can be used for a variety of projects. Its portability makes it ideal for onsite work or in the shop, allowing you to take your welding needs with you wherever you go. The lightweight design and included shoulder strap make it simple to transport, even for long distances. The control panel is conveniently located for easy access, allowing you to quickly adjust amperage settings and turn the unit on and off. All in all, the Handler 130 makes welding an effortless task.

Performance

The Hobart Handler 130 is a great choice for hobbyists and light-duty projects.

It’s also compatible with most common electrode sizes ranging from 1/16″ to 3/32″.The arc is smooth and reliable, and excellent for out-of-position welding. The machine has a broad range of amperage settings that provide great control over the weld puddle. The five-way selector switch makes it easy to adjust parameters on the fly.[2]

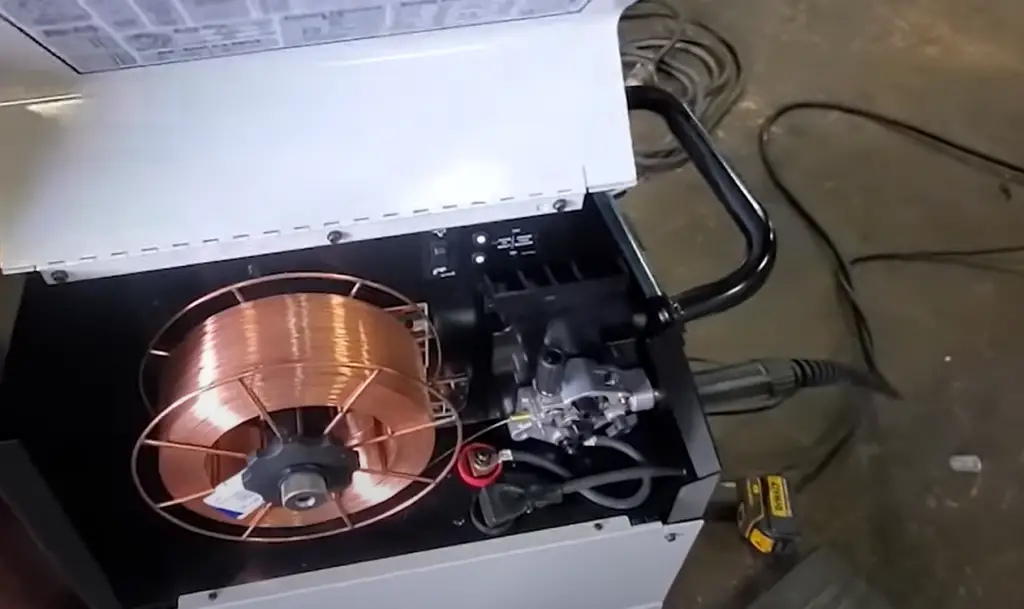

MIG welder unboxing

Unboxing the Hobart Handler 130 is a breeze! Once you unpack your welder from its box, make sure to check that everything is there. You should have:

- Welding gun and cable assembly

- Work clamp and cable

- Power cord

- Spool of self-shielded flux-core wire

- Contact tips

- Gasless nozzle

- Argon/CO2 regulator and hose assembly

Once you have all the components, it’s time to get your welding machine set up! With a few simple steps, you can have your Hobart Handler 130 ready for use. First, attach the work lead (clamp and cable) to a solid ground. Then connect the welding gun and power cord to the machine. Next, install the self-shielded flux-core wire spool onto the drive roll assembly. Finally, adjust your voltage and wire speed settings according to your project requirements.

Full-size MIG platform

The Hobart Handler 130 is a full-size MIG platform designed to deliver exceptional performance and durability. It features an industrial-style cast aluminum drive system, dual groove quick-change drive rolls, and infinite wire feed speed control.

The Hobart Handler 130 also features a spool gun capable feeding aluminum wire up to 3/64” thick. The Hobart Handler 130 is designed to deliver high quality welds on thicker materials and can handle a wide range of welding projects including automotive, farm/ranch, maintenance and repair applications.[2]

Making spatter

The Hobart Handler 130 is an ideal tool for making spatter-free welds. This versatile and durable MIG/TIG welder can be used on both steel and aluminum, so it’s perfect for a variety of welding projects. With its easy-to-use digital control panel, you can set the current and voltage to get a consistent spatter-free weld every time. The adjustable inductance control provides even more flexibility when welding aluminum, so you can create perfect spatter-free welds with ease. Additionally, its sleek design is both visually pleasing and easy to use.

Reversible drive rolls

The Hobart Handler 130 is equipped with a reversible drive that easily reverses the direction of travel when needed. This feature allows you to work on both sides of your project, making it much easier and more efficient. The reversible drive feature also helps minimize downtime due to stuck wire since the feed rolls can be reversed quickly. The kit includes two sets of reversing drive rolls, one for .023 and .030 inch wire. This ensures you have the right size feed rolls in place no matter what type of project you are working on. If you need to use a different sized wire, additional sets can be purchased separately.

Hinged door

The Hobart Handler 130 has a hinged door and drive system that makes welding easier. It utilizes an innovative and ergonomic design that allows for easy access to the weld area, eliminating the need to continuously open and close the hood during use. The handle on the back of the unit is height adjustable and easily fits into tight spaces, making it even more convenient to use. This allows you to maintain a constant flow of heat and improved weld quality. The hinged door also provides better visibility when welding, which is beneficial for precision and accuracy.

Power output

The Hobart Handler 130 is a powerful welder with an output of 30-130 amperes. This allows it to weld up to 1/4 inch thick steel in a single pass and 3/8 inch steel in multiple passes. The welder also has very good voltage and current stability, making it suitable for both mild steel and stainless steel welding. With its output, the Handler 130 can be used for MIG, flux-cored, gasless and Pulsed MIG welding projects.[1]

Weight and Transportation

The Hobart Handler 130 is a lightweight welding machine weighing just 54 pounds, making it easy to transport.

It also has a comfortable handle for easier carrying and an adjustable shoulder strap for longer hauls. The included 10-foot input power cable gives you plenty of room to reach the outlet.Wire Speed and Voltage Settings

The Hobart Handler 130 MIG Welder is designed to provide easy use of wire speed and voltage settings. The machine has a simple two-knob design that allows you to adjust the welding parameters quickly and easily. For more experienced users, these knobs can also be used to fine tune your welds.

The wire speed is adjustable from 30-180 inches per minute and the voltage ranges from 15-22 volts. This wide range of settings allows you to choose the best combination for a variety of different welding applications. Additionally, the machine has an infinite wire feed speed control so that you can get precise results with each weld.[1]

System setup

The Hobart Handler 130 is an easy-to-use, user-friendly welding system. It features a simple setup process with all of the necessary components included to get you up and running quickly.

The high frequency start allows for fast arc starts in any position and the 8 voltage settings provide greater control over your welds. With multiple welding processes including MIG, flux-cored and TIG, the Handler 130 is a perfect choice for hobbyists, small shop welders or any DIY enthusiast.[1]

Usability

The Hobart Handler 130 is designed for convenience and usability. It has a set up time of 5 minutes and you can get to work almost immediately. The user interface on the machine is simple with three knobs that control the wire feed speed, voltage, and amperage. This makes it incredibly easy to adjust settings quickly without any guesswork. The gun is comfortable to use and has an ergonomic design which helps reduce fatigue during long welding sessions. Lastly, the spool of wire is easy to load and there’s a quick-release lever that allows you to change out empty wires quickly.

Price

The Hobart Handler 130 is an affordable welding machine that is perfect for light-duty applications. It has a duty cycle of 20% at 130 amps, and can weld up to 5/16″ steel in a single pass. It comes with a gas regulator, MIG gun and 10′ cable assembly. The overall dimensions are 19″ x 11″ x 13″, making it lightweight and easy to move around. The price of the machine varies, but typically ranges from $650-$750 depending on where you buy it.

Warranty Options

The Hobart Handler 130 comes with a five-year warranty, so you can rest assured that your investment is protected. The warranty covers all manufacturer defects and any problems that may arise from normal wear and tear. Furthermore, the company offers an Extended Service Plan (ESP), which is an additional three years of protection against breakdowns caused by manufacturer defects. The ESP also includes coverage for parts and labor, as well as a complimentary annual inspection to ensure that your welder is operating correctly. If you’re looking for extra peace of mind, the Hobart Handler 130 is definitely worth considering.

Safety features

When working with the Hobart Handler 130, safety should always be taken into account.

Additionally, it features an overload protection circuit that detects when currents exceed safe levels and shuts down power to reduce further damage. This machine also has a metal cover for added protection and convenience. The Hobart Handler 130 is CSA listed, meeting the safety standards of Canada and the US. When you choose to buy this machine, you can rest assured that it has been rigorously tested to ensure safe operation.[1]Who Should Consider Getting a Hobart Handler 130 Welder?

The Hobart Handler 130 is an ideal welder for anyone who needs a reliable, easy-to-use welder that can handle mild steel and flux core welding. It is especially suited to hobbyists and DIY enthusiasts who want a lightweight yet powerful welder they can use with ease in their home or garage workspace. The Hobart Handler 130 is also great for professionals and small business owners who need a welder that can handle light-duty projects. It’s designed to be simple to use, so even novice welders can quickly become proficient with this machine.

Where to buy the Hobart Handler 130?

The Hobart Handler 130 can be purchased from a variety of online retailers, home improvement stores, and welding supply outlets. It is also available for purchase directly from the manufacturer’s website. Shopping around will help you get the best price and ensure that you get the model that best meets your needs. Look for deals on shipping or accessories to make the most of your purchase.[2]

What Happened to the Hobart Handler 130?

The Hobart Handler 130 is one of the most popular MIG welders ever produced by Hobart. It was first released in 2001 and quickly became a very popular choice for DIY welders. Unfortunately, it was discontinued in 2015 due to production costs and new EPA regulations which made its operation more difficult.

What should you know before buying the Hobart Handler 130?

The Hobart Handler 130 is an excellent choice for any novice or professional welder. It has a powerful motor that packs 140 amps of power and can handle heavy-duty welding jobs with ease.

This machine also features dual voltage capability, giving you the ability to plug into either 115V or 230V outlets. With its simple and intuitive design, the Hobart Handler 130 is easy to use and can be set up quickly. It’s an ideal machine for a variety of welding applications, from auto body work to metal fabrication.

FAQ

Why is aluminum not good for welding?

Aluminum is not ideal for welding because it has a low melting point and can oxidize quickly. This means that when welding aluminum, you have to take extra care to prevent overheating and contamination. Additionally, aluminum requires special equipment, such as a special torch tip designed to weld thin metals or an induction heating system. Overall, it’s best to stick with materials that have higher melting points and are easier to weld, such as steel or stainless steel.

What type of welder is best for aluminum?

MIG welders are the best type of welder for aluminum because they heat the metal quickly, which helps to reduce oxidation. When using a MIG welder for aluminum, you must use special shielding gas and wire specifically designed for this purpose. Additionally, make sure your machine has enough power to effectively weld aluminum.

What welding is best for aluminum?

TIG welding is the best type of welding for aluminum because it allows for precise control over heat input and puddle size. It also creates a strong, reliable weld with minimal distortion. However, TIG welding requires extensive practice to master and can be time consuming compared to other methods such as MIG or oxy-fuel welding. So if you’re just starting out, you may want to try other methods first.

Is it better to weld aluminum with MIG or TIG?

The choice between MIG and TIG welding for aluminum depends on your experience level and the type of project you’re working on. If you’re an experienced welder, then TIG is arguably the better option as it provides greater control over heat input and puddle size. However, if you’re just starting out, then MIG welding may be the better option as it’s generally easier to learn and requires less practice. Ultimately, the best type of welder will depend on your individual needs.

Video Guide: New Hobart Mig Welder Set Up & Welding

Conclusion

The Hobart Handler 130 is a great choice for those who are looking for an affordable and reliable MIG welding machine. It’s easy to use, has a wide range of features and comes with a free spool gun for more precise welding operations. The included user manual makes it easy to get started with the product, although more advanced users may need to purchase additional accessories for more detailed usage. We highly recommend the Hobart Handler 130 for novice and expert welders alike. With an unbeatable price tag and comprehensive features, it’s sure to meet all your needs. Thanks for taking the time to read our review of the Hobart Handler 130!

References:

- https://weldingpros.net/hobart-ironman-230-review/

- https://fixitmanblog.com/hobart-ironman-230-reviews/