Choose the Best Laser Engravers for Metal

Customer’s Choice: the Best Rated Laser Engravers for Metal

29 users answered this survey. Please help us improve this review!

Are you in the market for a laser engraver for metal? If so, you’re in luck. In this comprehensive guide, we will answer all of your questions and help you find the best laser engraver for your needs. We’ll start by discussing the different types of laser engravers available on the market, and then we’ll provide reviews of some of the best models currently available. Finally, we’ll give you some tips on how to choose the right laser engraver for your business. So without further ado, let’s get started!

BobsCNC Evolution 3 CNC Router Kit

Looking for an easy-to-assemble CNC router kit that can handle wood and softer metals? Look no further than the BobsCNC Evolution 3. This light-weight kit comes with many accessories and detailed instructions, making it perfect for any DIY enthusiast.

Looking for an easy-to-assemble CNC router kit that can handle wood and softer metals? Look no further than the BobsCNC Evolution 3. This light-weight kit comes with many accessories and detailed instructions, making it perfect for any DIY enthusiast.

The BobsCNC Evolution 3 CNC Router Kit is a great choice for woodworkers who want to add routing capabilities to their shop without spending a lot of money. However, there are some drawbacks that potential buyers should be aware of. First, the precision of this router is not as good as more expensive models. And second, it’s not as durable as some other routers on the market, because it’s entirely made of wood. The gantry flexes a bit, and the screws can come loose over time. But if you’re willing to overlook these minor flaws, the BobsCNC Evolution 3 CNC Router Kit is a great addition to any woodworking shop.

Genmitsu CNC 3018-PRO Router Kit

Looking for a great value on a CNC router kit? Check out the Genmitsu CNC 3018-PRO. This easy-to-assemble router kit is perfect for anyone looking to get into CNC routing.

Looking for a great value on a CNC router kit? Check out the Genmitsu CNC 3018-PRO. This easy-to-assemble router kit is perfect for anyone looking to get into CNC routing.

The Genmitsu CNC 3018-PRO Router Kit is a great choice for those looking to get into the world of CNC routing. However, there are a few things to be aware of before making your purchase. First, the instructions can be unclear and assembly can be messy, so bring the vacuum cleaner to your workplace. Secondly, finding compatible CAM software can be difficult. And finally, the spindle speed is relatively slow and there are no limit switches. Despite these potential drawbacks, the Genmitsu CNC 3018-PRO Router Kit is a great machine that offers a lot of value for its price.

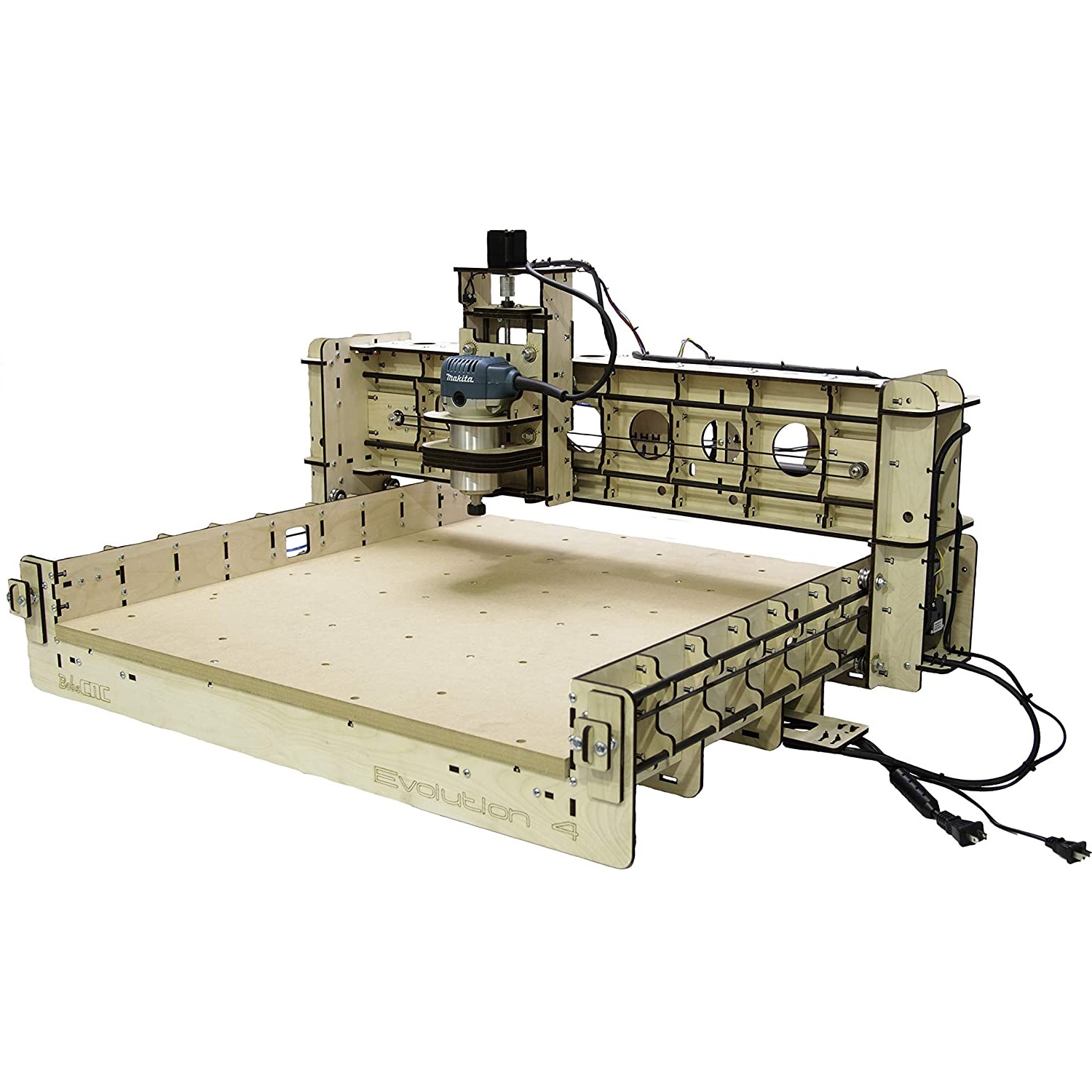

BobsCNC Evolution 4 CNC Router Kit

Are you looking for a top-quality CNC router kit that is easy to use and perfect for hobbyists? Then look no further than the BobsCNC Evolution 4 CNC Router Kit. This incredible machine comes with detailed instructions and easy-to-use open source software, making it perfect for anyone who wants to get into CNC routing.

Are you looking for a top-quality CNC router kit that is easy to use and perfect for hobbyists? Then look no further than the BobsCNC Evolution 4 CNC Router Kit. This incredible machine comes with detailed instructions and easy-to-use open source software, making it perfect for anyone who wants to get into CNC routing.

The BobsCNC Evolution 4 CNC Router Kit is not for everyone. It requires a purchase of additional devices, like a dust collector, and regular maintenance. It also takes a long time to assemble, even up to two full days. It’s only for experienced users who are willing to put in the effort to get amazing results. But once you get it up and running, there’s nothing this machine can’t do. Just be warned that loose bearings are a common issue, so be ready to take care of that accordingly.

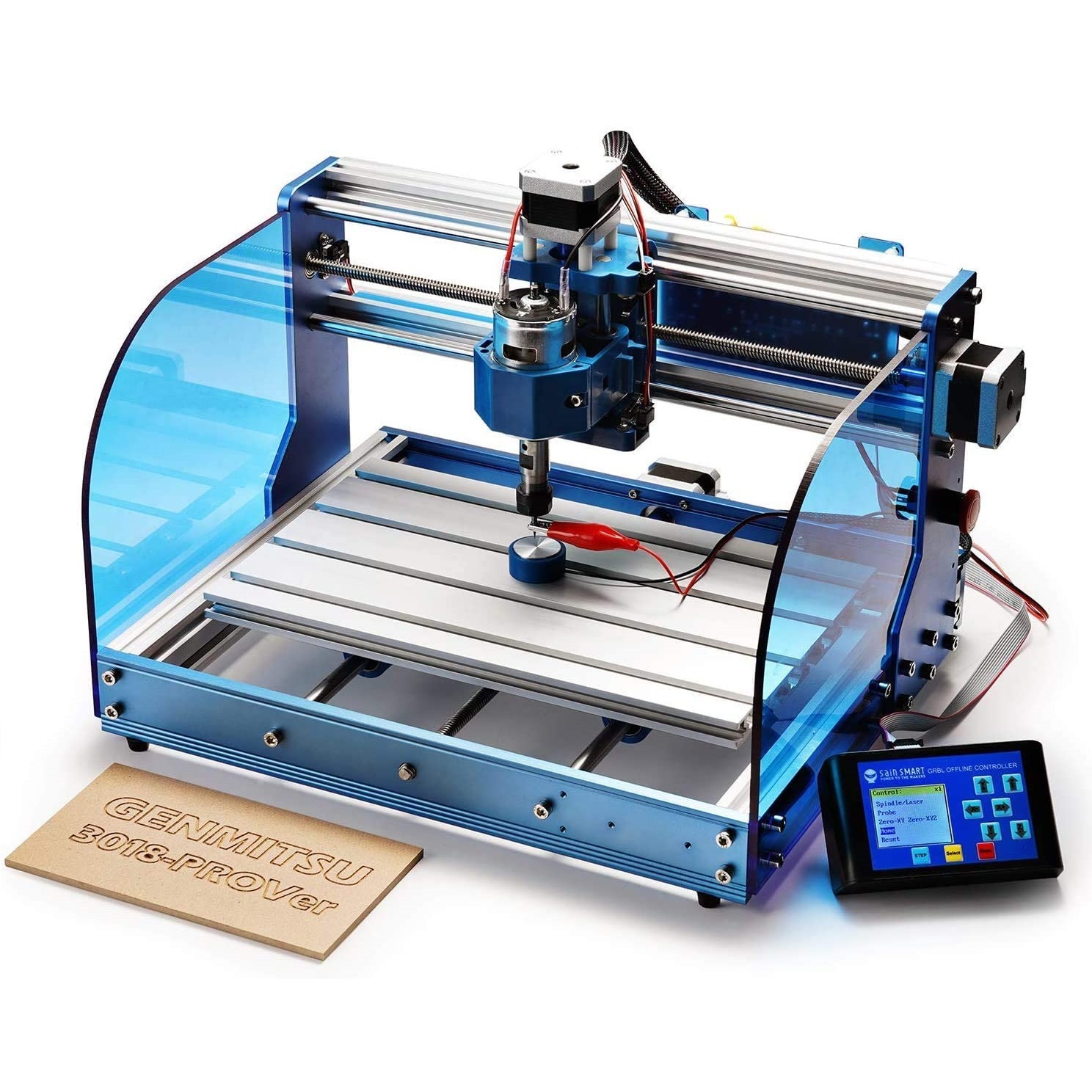

SainSmart Genmitsu 3018-PROVer Desktop CNC Router Machine

The SainSmart Genmitsu 3018-PROVer Desktop CNC Router Machine is an excellent choice for those looking for a high-quality, but cheap machine.

The SainSmart Genmitsu 3018-PROVer Desktop CNC Router Machine is an excellent choice for those looking for a high-quality, but cheap machine.

The SainSmart Genmitsu 3018-PROVer Desktop CNC Router Machine is a great choice for anyone looking for an affordable CNC router. However it has a very small working area, different from what was promised. The screws also come in different sizes, which can make work harder for you. Additionally, the offline controller is unresponsive, making it hard to control the machine. And finally, the wire management is poor, making it difficult to keep the wires organized.

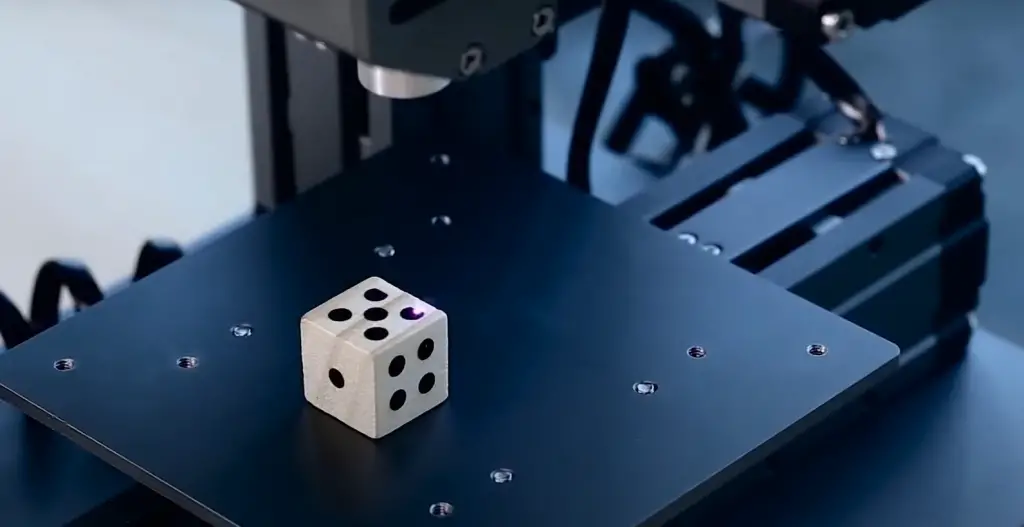

DIY CNC Router Kit, 24x17cm, Mini Milling Machine

This DIY CNC Router Kit is great for anyone who wants to get into the world of CNC machining. It’s a compact little machine that can cut through thin metal sheets, making it perfect for small projects.

This DIY CNC Router Kit is great for anyone who wants to get into the world of CNC machining. It’s a compact little machine that can cut through thin metal sheets, making it perfect for small projects.

Unfortunately, it doesn’t have the power to cut through thicker materials, so if you’re looking to work with heavier gauge metals, this isn’t the machine for you. Additionally, the assembly process is quite difficult and requires a fair amount of skill and knowledge. And to top it all off, the machine doesn’t come with a manual, so good luck trying to figure out how to use it! Overall, this machine is way too expensive for the quality it offers.

Buyers Guide

Now that you know the ins and outs of laser engravers, it’s time to find the perfect one for your needs. With so many different models on the market, it can be tough to make a decision. But don’t worry, we’re here to help with this neat guide.

What is Metal Engraving?

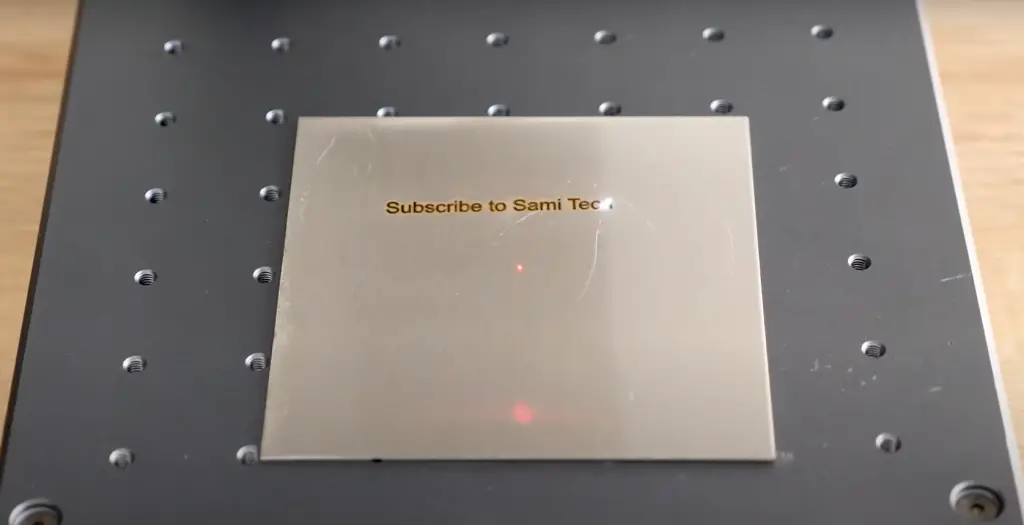

Metal engraving is the process of carving a design or message into a hard, durable material using a laser. Laser engravers are precise and efficient tools that can be used on a variety of metals, including aluminum, brass, stainless steel, and more.

There are many reasons why you might want to engrave metal. Perhaps you’re looking to add a personal touch to jewelry or gifts. Or maybe you need to mark industrial components with important information like serial numbers or part numbers. Whatever your reason, there’s a laser engraver out there that’s perfect for the job. [1]

Metal Engraver Lasers and How Are They Used?

Metal engraving lasers are powerful tools that can quickly and easily carve designs into metal surfaces.

Laser engravers work by focusing a beam of high-powered laser light onto the surface of the metal. The heat from the laser causes the metal to vaporize, carving out your design.

They are very flexible and can be used to create intricate designs, text, and even photographs. But using some of them may require some skill from you.

No matter what type of metal engraving you need to do, there’s a laser engraver out there that will suit your needs. [1],[2]

Types of Metal Engravers

There are three main types of metal engravers: CO₂, fiber and crystal. Let’s talk about them in detail.

CO₂ Laser Engravers

CO₂ laser engravers are the most common type of metal engraver. They’re affordable and easy to use, making them a great choice for hobbyists and small businesses.

CO₂ lasers emit a beam of gas that is then amplified by a series of mirrors. This creates a powerful laser beam that can be focused onto the surface of the metal. CO₂ lasers can be used on a variety of coated metals, including aluminum, brass and copper.

However they aren’t strong enough to cut even the softest of metals. But if you’re looking for an affordable and user-friendly option, a CO₂ laser engraver is a great choice.

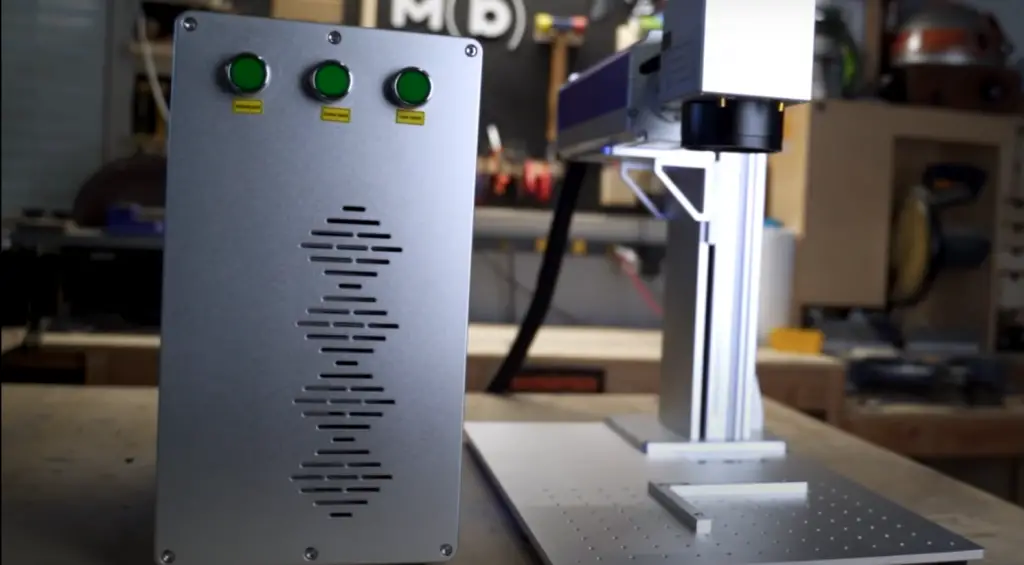

Fiber Laser Engravers

Fiber laser engravers are one of the most used types in metalworking. They’re fast, efficient, and can be used on a variety of metals.

Fiber lasers use a glass fiber to generate the laser beam. The advantage of this is that it allows for very high-powered beams without generating too much heat.

Fiber lasers are also very low maintenance and have a long lifespan.

One downside of fiber lasers is that they’re not as effective at engraving thicker metals. If you’re looking to engrave these types of surfaces, you’ll need to use a different type of laser.

Crystal Lasers

Crystal lasers are the newest type of laser engraver on the market.

Crystal lasers use a synthetic crystal as their gain medium, which allows them to produce a very high-quality beam of light. This makes them ideal for engraving smaller, more detailed designs.

However, because they’re so new, crystal lasers are still relatively rare and can be difficult to find, and they won’t work as well on metals.

But be prepared to pay a premium for this cutting-edge technology. [1],[2],[2],[4]

Laser Engraving Techniques

Engraving

As we already mentioned, engraving is the process of carving something into the metal surface. There are two main techniques for laser engraving metal: vector carving and raster engraving.

Vector carving is the most common type of engraving. It’s perfect for simple 2D designs and text. Vector carving works by following a path that you’ve created in your design software. The laser will follow this path to carve out your design. If you just want to create something not too complex, it’s the way to go.

Raster engraving is best suited for detailed images or designs with shading. Raster engraving works by scanning the surface of the metal with the laser beam, much like a printer scans a page of text. The advantage of this method is that it can create more complex designs than vector carving. This is the main reason why it is primarily used for 3D reliefs or complex logos.

Engraving usually cuts up to 0.125′ into the metal, so it’s important to be careful with your design. If you’re not sure how deep you want your engraving to be, start with a shallow depth and slowly increase it until you get the results you’re looking for. [5]

Etching

Etching is a type of engraving that uses a lower-powered laser to remove the top layer of metal, they usually make a small cut up to 0.02mm deep. This technique is perfect for creating detailed designs or small hobby projects. It is usually a preferred technique for softer metals, like aluminum.

Etching is also a great way to add texture to your design. By etching different patterns into the surface of the metal, you can create a unique, one-of-a-kind look for your project.

If you’re looking for more than just a simple engraving, etching is a great option.

Marking

Marking is an engraving style that uses a high-powered laser to create a permanent mark on the surface of the metal. This is done with the help of an oxidation process. This technique is often used for identifying and branding purposes.

Marking can be used on a variety of metals, including aluminum, brass, copper, and stainless steel. And because the marks are so permanent, they’ll withstand even the most extreme conditions.

Marking is a great way to add a permanent and durable mark to your metal project. But because it uses such high-powered lasers, it’s important to be very careful with your design. Make sure you know exactly where you want your mark to be before you start engraving.

What Kind of Metals Can You Engrave With Laser?

The answer to this question is not as simple as it might seem at first. In principle, any metal can be engraved with a laser – from the softest aluminum alloys to the hardest steels. But in practice, there are a few nuances that you need to take into account when choosing a laser engraving machine for metal.

It is worth considering what material you will be working with most often. If you plan to engrave only relatively soft metals such as brass or aluminum, then any laser engraver will do the job just fine. But if you also want to be able to work with harder materials like stainless steel or titanium, then you will need a more powerful laser engraver with higher power and better cooling. Same goes for metal thickness. But in theory, you can work on anything as long as you adjust your laser properly!

Now that you know more about how lasers work and the different types available, let’s take a closer look at some of the best laser engravers on the market!

Laser Engravers Buyers Guide

Now that you know the ins and outs of laser engravers, it’s time to find the perfect one for your needs. With so many different models on the market, it can be tough to make a decision. But don’t worry, we’re here to help with this neat guide.

Type of laser

The first step is to decide which type of laser engraver you need. Do you want a CO₂ engraver or a fiber laser? If you’re not sure, here’s a quick overview of the main differences:

CO₂ models are better for thicker materials, while fiber lasers are more precise and can engrave on thinner sheets up to 0.5 inches.

Fiber models are also faster and more energy-efficient, so they’ll save you money in the long run. [1],[3],[4]

Size of the bed

The bed is the platform on which you’ll be engraving your materials. So, it’s important to make sure that the bed of your laser engraver is large enough to accommodate your needs. If you’re working with larger pieces of material, then you’ll need a machine with a large bed. But if you’re only working on smaller projects, then you can get away with a smaller machine.

Additionally, keep in mind that the size of the bed will also affect the overall size of the machine. So, if you’re limited on space, then you might want to opt for a smaller model. [1],[2],[3],[4]

Price

The other thing you just can’t ignore when looking for a laser engraver is your budget. Laser engravers can range in price from a few hundred dollars to several thousand, so it’s important to find one that fits your needs and budget. If you’re just starting out, we recommend going with a cheaper model so you can get a feel for how they work before investing in a more expensive one. [2],[4]

Power of the Laser

The next thing to look at is the wattage, the power of the laser. A higher wattage will mean that the machine can engrave faster and deeper, but it also means that the machine will be more expensive. For thicker materials, you’ll need a machine with at least 40 watts of power. But if you’re just working on thinner sheets of material, then a lower-powered machine will suffice, although you never know when you may need to work with something thicker.

In general, metal requires more power than other materials.

Thicker sheets will require even more power. [1],[2],[3],[4]Longevity of the laser

The lifespan of the laser is one of the most important factors to consider when purchasing a laser engraver. The average lifespan of a laser is around 2,000 hours. But that is only average. We mind you. Better quality lasers can last up to double that. And the best ones on the market? They can engrave for up to 10,000 hours without any problems whatsoever.

Now, of course, you’re not going to be using your laser 24/07. But it’s still important to consider how long the laser will last. After all, you don’t want to have to replace your machine every few months. [4]

Automation

You also need to consider what kind of automation you need. If you’re looking for a machine that can handle large projects with ease, then you’ll want one that is fully automated. These machines are more expensive, but they will save you time and money in the long run. On the other hand, if you only need a machine for small projects, then a semi-automatic or manual engraver will suffice. [3]

Upgradability

One of the most important things to consider when purchasing a laser engraver is whether or not it can be upgraded. Many entry-level machines are incapable of being upgraded, which means you’ll have to buy a new one every time you want to add a new feature or improve performance.  But if you invest in a machine that’s upgradable, you can save yourself a lot of money in the long run. Just be sure to check what kind of upgrades are available before making your purchase.

But if you invest in a machine that’s upgradable, you can save yourself a lot of money in the long run. Just be sure to check what kind of upgrades are available before making your purchase.

Software Availability and Compatibility

One of the most important things to consider when choosing a laser engraver is the software compatibility. Not all engravers will be able to work with every type of software, so it’s important to do your research and make sure that the model you’re interested in is compatible with the software you’re using. Additionally, some software is only available for certain operating systems, so if you’re not using a Windows or Mac computer, you’ll need to make sure that the engraver you choose can work with your OS. [1],[2],[3],[4]

Connection Options

The last but not least thing you need to consider is how you want to connect your engraver to your computer. There are three main types of connection: USB, Bluetooth, and WiFi.

Bluetooth is less common, but it’s perfect for engravers that are going to be used wirelessly. WiFi is the least common type of connection, but it’s ideal for large engravers that need to be connected to a network. [2]

FAQ

Do laser engravers work on metal?

Laser engravers can be used on a variety of materials, including metal. However, the type of laser engraver you use will determine the results you get. For example, CO₂ lasers are well-suited for engraving thicker metals because they produce a beam strong enough. Fiber lasers on other hand aren’t that ideal for most thicker metals, but will do a great job on gold or thicker steel.

How strong of a laser do you need to engrave metal?

The power of the laser is one of the most important factors to consider when choosing a laser engraver for metal. The stronger the laser, the deeper it can engrave into the metal.

If you’re looking for a machine that can handle heavy-duty projects, you’ll need at least a 50-watt laser. For lighter projects, a 30-watt laser should be sufficient.

Keep in mind that more powerful lasers will be more expensive to purchase and operate. They also require more maintenance and safety precautions.

If you’re not sure how much power you need, it’s best to err on the side of caution and choose a more powerful machine. You can always scale back your projects if necessary.

What laser can engrave steel?

The best laser engravers for metal can handle a variety of materials, including steel. Many lasers will have no problem engraving on steel, but if you’re looking to do more than just engrave your logo onto a few products, you’ll want to consider a machine that can handle thicker pieces of metal and has higher wattage.

In terms of power, it’s recommended to go with an engraver around 30-40 watts. This is enough power to etch or mark most metals, including thicker ones without going overboard.

Can CO2 lasers engrave metal?

CO₂ lasers can engrave metal, but the process is a bit different than with other materials. CO₂ lasers work by vaporizing the top layer of the material, so when engraving metal, you need to make sure that the laser is powerful enough. Otherwise, it will just leave a mark on the surface.

Useful Video: Genmitsu CNC 3018-PRO Router Kit GRBL Control review and tutorial

Conclusion

So, there you have it – our picks for the best laser engravers for metal on the market. All of these machines are great choices for businesses and hobbyists alike who need to etch designs into a variety of metals. If you’re still not sure which machine is right for you, be sure to check out our buyer’s guide. In short, when choosing the right laser engraver for your business, make sure to consider the type of laser being used, its longevity, horsepower and size, as well as software compatibility. Of course, this is just a starting point; when choosing the right machine for your needs. Thanks for reading!

References:

- https://www.cncsourced.com/laser-engravers/metal-laser-engravers-cutter/

- https://woodymanreviews.com/best-laser-engraver-for-metal/

- https://handtoolsforfun.com/the-best-laser-engraver-for-metal-review/

- https://www.omnicoreagency.com/best-laser-cutter-engraving-machines/

- https://laserengravingtips.com/is-raster-or-vector-better/