Choose the Best Glues for Plastic To Metal

Customer’s Choice: the Best Rated Glues for Plastic To Metal

419 users answered this survey. Please help us improve this review!

When it comes to bonding plastic to metal, you want to make sure you’re using the right adhesive. Different glues work better for different applications, and not all glues are created equal. In this guide, we will discuss the different types of glue available and help you choose the best product for your needs.

There are two main types of glue for plastic to metal:

- Epoxy is a strong, permanent adhesive that is ideal for applications where you need a durable bond;

- Acrylic is a less-permanent adhesive that is perfect for projects where you need the ability to adjust or remove the pieces later on;

When choosing an adhesive, you also need to consider the type of plastic you’re working with. Some plastics are more difficult to bond than others, so it’s important to choose a glue that is specifically designed for the material you’re working with.

We’ll also provide tips on how to use each adhesive for optimal results. So whether you’re looking to bond a new part to your car or fix a broken one, we’ve got you covered!

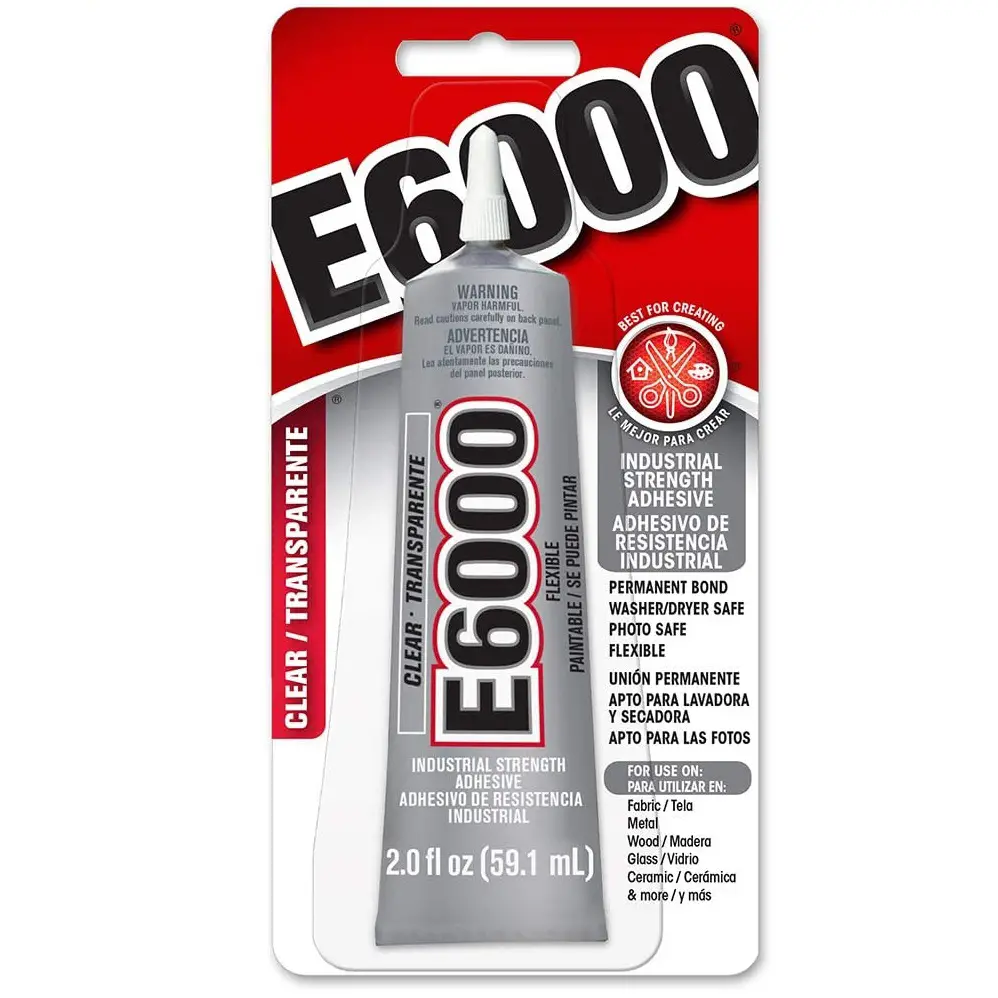

E6000 237032 Craft Adhesive – the Editor’s choice!

This amazing product is extremely strong and bonds instantly to almost any surface, metal or plastic. It’s also waterproof and flexible, so it can withstand extreme temperatures. Plus, it comes in three different colors (clear, white, black) so you can choose the perfect one for your project.

This amazing product is extremely strong and bonds instantly to almost any surface, metal or plastic. It’s also waterproof and flexible, so it can withstand extreme temperatures. Plus, it comes in three different colors (clear, white, black) so you can choose the perfect one for your project.

J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy – the best temperature resistance!

Are you searching for a quick and reliable way to bond metal, concrete, fiberglass, and other materials? J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy is your solution!

Are you searching for a quick and reliable way to bond metal, concrete, fiberglass, and other materials? J-B Weld 8276 KwikWeld Quick Setting Steel Reinforced Epoxy is your solution!

This easy-to-use epoxy dries in just 6 minutes, forming a strong bond that’s resistant to extreme temperatures and oils and gas. In addition, it can be ground and drilled like metal – perfect for automotive or industrial applications.

The J-B Weld 8276 is the strongest, quickest setting epoxy you will ever use! This dark grey epoxy sets in 6 minutes and cures in 4 hours. The J-B Weld 8276 is ideal for automotive, brick, fiberglass, metal, and concrete applications. The oil- and gas-resistant formula bonds to most materials and is non-toxic.

Gorilla Super Glue Gel – the best drying time!

Gorilla Super Glue Gel can be perfect for the fix-it-now mindset. It dries within 10 seconds, so there’s no need to wait around. In addition, it’s suitable for most metal surfaces, making it a versatile option for quick repairs.

Gorilla Super Glue Gel can be perfect for the fix-it-now mindset. It dries within 10 seconds, so there’s no need to wait around. In addition, it’s suitable for most metal surfaces, making it a versatile option for quick repairs.

Keep your metal surfaces looking shiny and new with our fast-drying, no-run formula! Suitable for indoor and outdoor use, this product is a budget-friendly option that dries within 10 seconds. The clog-proof cap prevents spills and the strong fumes dissipate quickly. The full cure time is 24 hours.

Amazing GOOP 160012 Adhesive – the best for automotive projects!

Need to fix your car? Amazing GOOP 160012 Adhesive can be a smart solution! This adhesive is designed specifically for automotive projects and can be used to protect battery terminals, seal auto parts inside and outside, and repair vinyl seats and floor mats.

Need to fix your car? Amazing GOOP 160012 Adhesive can be a smart solution! This adhesive is designed specifically for automotive projects and can be used to protect battery terminals, seal auto parts inside and outside, and repair vinyl seats and floor mats.

Just be sure to avoid using it on materials like wood or paper, as it won’t work as well on those surfaces. And don’t worry about the mess – this adhesive is easy to apply, but just make sure you give it enough time to cure before driving off!

This adhesive was designed specifically to bond glass, metal and plastic, making it the perfect choice for repairs both inside and outside your vehicle. It’s also ideal for insulating electrical wiring, and its strong adhesion will keep everything in place even under tough conditions.

J-B Weld 8267-S SteelStik Epoxy Putty Stick – the best for stainless steel!

If you’re looking for a top-quality epoxy putty stick that can handle even the toughest jobs, then look no further than the J-B Weld 8267-S adhesive.

If you’re looking for a top-quality epoxy putty stick that can handle even the toughest jobs, then look no further than the J-B Weld 8267-S adhesive.

Additionally, the J-B Weld product is chemical-resistant and has good temperature resistance, meaning it can stand up to even the most demanding conditions.

The J-B Weld 8267-S putty stick is the perfect way to fix stainless steel and non-corrosive metal surfaces. With a 900 PSI strength, it’s perfect for any job that needs a little bit of reinforcement. In addition, the chemical-resistant qualities make this one putty stick you can rely on.

The Buyer’s Guide

Types of Adhesives for Bonding Plastic to Metal:

Epoxy Adhesives

The first type of adhesive we will discuss is epoxy adhesives. Epoxy adhesives are two-part resins that cure to form a very strong bond. They are available in both liquid and gel form and can be used on a variety of surfaces including plastic, metal, glass, and ceramic[1].

One of the main benefits of using epoxy adhesives is that they can create a permanent bond. This means that once the epoxy has cured, it will not come apart unless you use solvents or mechanical force to break the bond.

Another benefit of using epoxy adhesives is that they have high resistance to heat and chemicals. This makes them ideal for bonding plastic to metal, as the bond will not be broken by exposure to these elements.

There are a few things to keep in mind when using epoxy adhesives. First,it is important to make sure that you mix the two parts of the resin together in the correct ratio. If you do not mix them correctly, the adhesive will not cure properly and will not create a strong bond.

Second, epoxy adhesives have a relatively long cure time, so you need to be patient when waiting for the adhesive to set. Once it has cured, however, the bond will be very strong and durable.

Epoxy adhesives are available at most hardware stores and home improvement stores. They are typically sold in small tubes or bottles, and you will need to purchase both the resin and the hardener.

Experts recommend using epoxy adhesives for projects where you need a strong, permanent bond, such as bonding plastic to metal. If you are looking for a quick-setting adhesive, however, epoxy is not the right choice.

Cyanoacrylates

Cyanoacrylates are a type of fast-setting adhesive that is available in both liquid and gel form. The term “super glue” is a generic name for the most well-known super glues. Everyone knows that this sort of glue bonds in seconds, and you must act quickly to arrange your goods. Is it possible to superglue plastic to metal? This is when knowing which super glue to use becomes crucial, as there are several types available[2].

This means that you can complete your project quickly without having to wait for the adhesive to set.Another benefit of using cyanoacrylate adhesives is that they can be used on a variety of surfaces, including plastic, metal, glass, and ceramic.

There are a few things to keep in mind when using cyanoacrylate adhesives.

First, it is important to work quickly as the adhesive sets very quickly.

Second, you need to be careful when applying the adhesive as it can cause skin irritation.

Cyanoacrylate are typically sold in small tubes or bottles.

Experts recommend using cyanoacrylate adhesives for projects where you need a quick-setting adhesive. If you are looking for a strong, permanent bond, however, cyanoacrylate is not the right choice.

Silicone Adhesives

Silicone-based adhesives are a good choice for bonding plastic to metal because they create a strong, permanent bond[3].

One of the main benefits of using silicone adhesives is that they have high resistance to heat and chemicals. This makes them ideal for bonding plastic to metal, as the bond will not be broken by exposure to these elements.

Silicone is a versatile material that can be molded and cooled rapidly. It maintains its flexibility even after it has been hardened. You will have to wait for the silicone to cure, unlike instant glue. It’s not unusual for a job to last anywhere from 24 hours to a few days. This is for bigger repair work, but it isn’t for smaller craft projects.

Hot Glue Gun

Hot glue guns are a popular choice for bonding plastic to metal because they are quick and easy to use. Hot glue is applied using a gun that heats the glue until it is melted. The melted glue is then applied to the surfaces that need to be bonded together.

If you’re working with any sort of repairs, a glue gun that’s been designed for manufacturing rather than a simple craft glue gun is ideal. Glue sticks are available in a variety of forms and adhesives, so be sure to check your local hardware store or a DIY shop for them.

Certain glue sticks may not adhere to metal or plastic, so look at the materials they bond to when selecting. Hot melt glue sticks are also known as acrylic, polyamide, or ethylene-vinyl acetate (EVA) hot melt sticks and include several varieties.

One of the main benefits of using hot glue is that it sets very quickly. This means that you can complete your project quickly without having to wait for the adhesive to set.

Another benefit of using hot glue is that it can be used on a variety of surfaces, including plastic, metal, glass, and ceramic.

Polyurethane Adhesives

Polyurethane adhesives are a good choice for bonding plastic to metal because they create a strong, permanent bond.

One of the main benefits of using polyurethane adhesives is that they have high resistance to heat and chemicals. This makes them ideal for bonding plastic to metal, as the bond will not be broken by exposure to these elements.

Polyurethane is a versatile material that can be molded and cooled rapidly. It maintains its flexibility even after it has been hardened. You will have to wait for the polyurethane to cure, unlike instant glue. It’s not unusual for a job to last anywhere from 24 hours to a few days.

The PU adhesive is a very tough substance that may be used on many surfaces. It’s especially effective at bonding materials that aren’t comparable, such as plastic to metal.

You can also paint and sand polyurethane once it has cured.UV Cure Adhesives

UV light is required to generate a strong and permanent bond in these adhesives. UV curable adhesives are effective on a wide range of substrates, including metal, plastic, glass, and wood. This adhesive may also be used in a variety of mixed materials.

One of the main benefits of using UV cure adhesives is that they have high resistance to heat and chemicals. This makes them ideal for bonding plastic to metal, as the bond will not be broken by exposure to these elements.

Another benefit of using UV cure adhesives is that they are set very quickly. This means that you can complete your project quickly without having to wait for the adhesive to set.

The main disadvantage of UV curable adhesives is that they require special equipment for the curing process, such as a UV lamp or LED light.

Main Features:

Multi-Purpose Adhesives

Non-porous materials like plastic, metal, and glass are difficult to combine because they are non-absorbent.

The glue that forms a high-strength bond, particularly if you want to connect two materials like metal and plastic, is important. Looking for a glue that works on multiple surfaces should be effective and more adaptable.

Most experts recommend products that offer a strong bond on various surfaces for general-purpose projects.

Drying Times

The drying time is an additional critical factor to consider when selecting the best glue for your project. You don’t want to be stuck waiting around for hours or even days for the adhesive to dry.

So, it all depends on what you’re doing and how long you need the drying to last. Epoxy, which takes longer to cure, produces a stronger and more durable connection than super glue.The drying times for all adhesive goods should be stated on their labels.

Keep in mind that some glues require more time than others to set and cure, so it’s essential to read the label before making your purchase.

If you need a quick-drying option, there are many products on the market that can meet your needs. All you have to do is choose the right one for your project.

Easy to use

Most users require a product that is simple to use, and many adhesives may be simply used and left; others, on the other hand, require more work. Many epoxy products, for example, must be combined before being applied and failure to do so may result in an ineffective bond.

Another aspect to consider is the application. For little, precise work, a precise nozzle is required.

Other adhesives may need brushes, sponges, or other equipment to distribute the glue. Some adhesives are more hazardous than others, and some require special safety equipment when utilized, which makes things a little more difficult and expensive.

Adhesive Properties

The properties of the adhesive are another critical factor to consider.

Different adhesives have different properties, such as heat resistance and water resistance. Depending on your project, you may need an adhesive that can withstand high temperatures or one that is waterproof.

Make sure to select an adhesive with the required properties for your project. Otherwise, you run the risk of the bond not lasting as long as you need it to or not being strong enough.

When shopping for the best glue for your project, keep an eye out for these three features:

- Bonds multiple surfaces including plastic, metal, glass, ceramic, wood;

- Flexible once dried;

- Stainless/waterproof;

These are important factors to look for when choosing a product because they will help ensure your project’s longevity and success. In addition, we recommend avoiding adhesives that require heat or clamps to set as these can be difficult to use and may not be as durable.

How to Glue Plastic to Metal:

1) Prepare the surface

The first step is to clean the surface of both the plastic and the metal. This will help the glue to adhere better and create a stronger bond. Use a mild soap and water solution to clean the area, then dry it completely with a soft cloth.

2) Decide how strong you need the bond to be

The next step is to decide how strong you need the bond to be. For example, if you are gluing a plastic toy together, you might not need a very strong bond. However, if you are gluing something like a plastic pipe to metal, you will need a stronger bond.

3) Choose a suitable adhesive

There are different types of glue that can create different levels of strength. For example, epoxy glue is one of the strongest types of glue. If you need a very strong bond, this is the type of glue that you should use.

4) Be wary of plastics with low surface energy

Some plastics have low surface energy, which means that it can be difficult to get the glue to adhere to them.  If you are having trouble getting the glue to stick, you can try using a primer or sanding the plastic to rough up the surface.

If you are having trouble getting the glue to stick, you can try using a primer or sanding the plastic to rough up the surface.

5) Test a glue if you’re unsure

If you are unsure about which type of glue to use, it is always a good idea to test it on a small area first. This will help you to avoid any mistakes that could ruin your project.

FAQ

What is a control applicator?

A control applicator is a device that helps you apply the glue evenly. It can be as simple as a cotton swab or a toothpick, or it can be a more sophisticated tool like a syringe.

Some adhesives come with a control applicator built-in. If not, you can usually find them at your local hardware store. Control applicators are particularly useful when working with small or delicate pieces.

Wear gloves when working with adhesives to avoid skin contact. If you do get adhesive on your skin, try acetone or nail polish remover to remove it.

How to avoid skin spills?

Wear gloves when working with adhesives to avoid skin contact. If you do get adhesive on your skin, try acetone or nail polish remover to remove it.

If you are working with a strong adhesive, consider wearing a face mask to avoid inhaling fumes.

Finally, be sure to work in a well-ventilated area.

Does Gorilla glue work on plastic to metal?

The short answer is yes, Gorilla glue will work on plastic to metal. However, it’s important to note that not all Gorilla glues are created equal. The original Gorilla glue is designed for woodworking and won’t provide a strong bond on its own for plastic to metal.

Luckily, Gorilla now offers a product specifically designed for bonding dissimilar surfaces like plastic to metal. This product, called Gorilla Super Glue Gel, can create a strong bond in just seconds [5].

What is the difference between plastic glue and Super Glue?

Plastic glue is a general term for any adhesive that can bond plastic to another surface. Super Glue, on the other hand, is a specific brand name and product. While there are many types of Super Glue, they all share certain characteristics like being water-resistant and bonding quickly.

Plastic glue will produce a far more solid connection (it will melt the plastic parts together considerably). Super glues are often quite brittle, thus some experts would advise using plastic glue [6].

Does silicone stick plastic to metal?

Yes, silicone will bond plastic to metal. In fact, it’s one of the best materials you can use for this purpose. Silicone is flexible, water-resistant, and can withstand high temperatures.

It’s also easy to find and relatively inexpensive. You can find silicone adhesives at most hardware stores or online retailers.

Just make sure to choose a product that is specifically designed for bonding plastic to metal. Some silicones are better suited for other applications like sealing gaps or creating a waterproof seal.

What does Gorilla glue not stick to?

Gorilla glue is an incredibly versatile adhesive and will bond most materials. However, there are a few things that it doesn’t work well with.

Gorilla glue won’t adhere to surfaces that are already wet or oily. It also doesn’t work well with polypropylene or polyethylene plastics.

If you’re not sure whether Gorilla glue will work for your project, it’s always best to test it on a small area first.

How do you glue PVC to steel?

PVC pipe won’t stick to the metal pipe of any sort. Only PVC cement creates a solvent bond with plastic and does not adhere to metal. The pipe may be inserted into a rubber seal that fits inside the hub, then sealed in place with a sealant specifically formulated for this purpose [7].

Does Elmer’s glue work on metal?

Elmer’s glue can adhere to a variety of materials, including paper, cardboard, styrofoam board, canvas, fabric, felt, pottery and ceramic wood, and leather. But it won’t perform well on non-porous surfaces like metal or polycarbonate [8].

How long does Gorilla Glue last once opened?

A fully opened bottle of any cyanoacrylate adhesive (Gorrila GLue included) lasts 6 to 8 weeks before the remaining adhesives on the outside of the application tube join together [9].

Does Loctite work on plastic and metal?

Loctite 425 is a fast-curing, low-strength cyanoacrylate adhesive for locking metal and plastic fasteners. It cures in less than 2 minutes on plated metal and plastic fasteners, allowing fixture speed to be boosted with Loctite 7113 [10].

Is surface preparation required for bonding plastic to metal?

For the best results, it’s always best to clean and roughen up the surfaces that you’ll be bonding together. This will help the adhesive to better grip the surface and create a stronger bond.

You can clean the surfaces with isopropyl alcohol or another solvent-based cleaner. For roughening up the surface, you can use sandpaper or a file.

Useful Video: JB Weld SteelStik Review-Real Life Use

Final thoughts

So, what’s the best adhesive for bonding plastic to metal? Well, that depends on your needs. If you’re looking for a permanent fix, epoxy is probably your best bet. But if you need something that’s easy to remove and reusable, hot glue might be a better option. No matter what you choose, make sure you read the instructions carefully and follow them closely. With the right adhesive, bonding plastic to metal can be a breeze!

References:

- https://resin-expert.com/en/guide/best-glue-for-metal-to-plastic

- https://3dinsider.com/how-to-glue-metal-to-plastic/

- https://craft-art.com/best-glue-for-metal-to-plastic/

- https://craft-art.com/best-glue-for-metal-to-plastic/

- https://www.gorillatough.com/product/gorilla-super-glue/

- https://www.dakkadakka.com/dakkaforum/posts/list/362907.page

- https://www.mcall.com/business/real-estate/mc-diy-sunday-real-estate-1012-20141010-story.html

- https://survivalfreedom.com/9-surfaces-elmers-glue-works-on-and-3-it-doesnt/

- https://www.gluegun.com/blogs/adhesive-reviews/what-average-shelf-life-cyanoacrylate-glue

- https://www.ellsworth.com/products/adhesives/cyanoacrylate/henkel-loctite-assure-425-plastic-fastener-threadlocker-blue-20-g-bottle/