The angle grinder is a versatile tool that is beloved by both hobbyists and professionals. This trusty tool can quickly and easily handle all of your metal-cutting needs. You can use an angle grinder to cut metal, but there are a few things you need to keep in mind before you get started. In this blog post, we will discuss the best way to use an angle grinder to cut metal, as well as some of the potential hazards involved in this process. Let’s get started!

What Is an Angle Grinder?

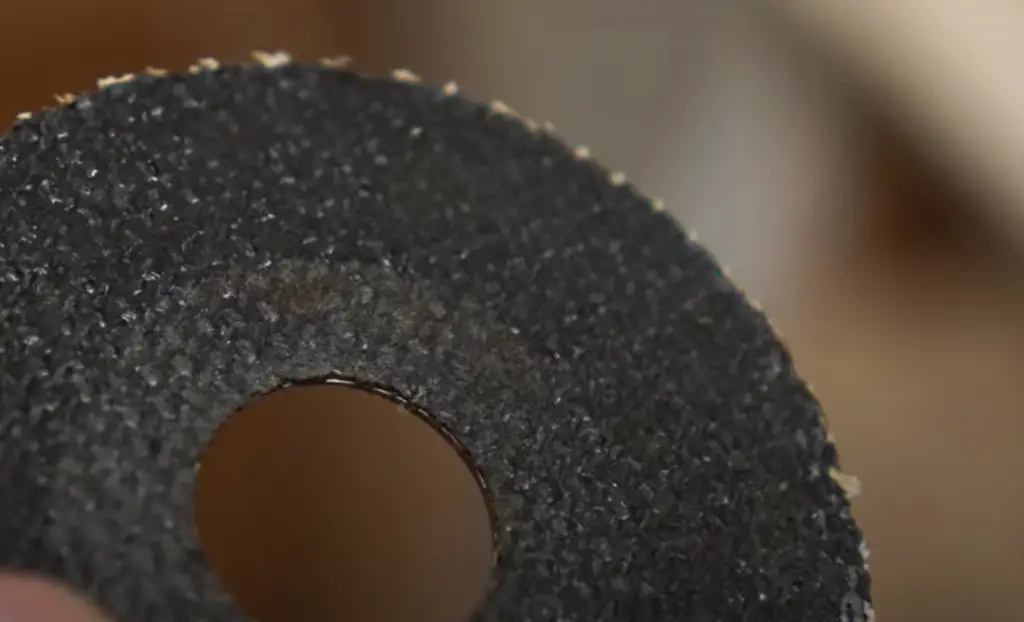

An angle grinder is a versatile tool that can be used for numerous projects. Angle grinders are not only for grinding metal; you can use them for polishing and sanding, too. Angle grinders typically have a disc that is made of abrasive material, such as aluminum oxide or diamond.

Why Use an Angle Grinder to Cut Metal?

Angle grinders are useful for many different projects, but they’re especially adept at cutting metal. Metal is a difficult material to cut through, so it requires more energy.

An angle grinder is able to provide that power thanks to its electric motor. Additionally, angle grinders typically have a higher speed than other types of saws, which makes them ideal for cutting through metal.

How to Cut Metal with an Angle Grinder

Now that you know the advantages of using an angle grinder to cut metal, let’s go over the steps required. There are a few things to remember when using an angle grinder on metal.

First, make sure that you are using the correct disc. For most metal cutting applications, you will want to use a disc that is made of abrasive material like aluminum oxide or diamond.

Second, ensure that the disc is securely attached to the angle grinder.

Third, always use gloves and eye protection when operating an angle grinder.

When cutting metal, always start with the angle grinder turned off. Once the blade is touching the surface of the metal, you can then turn on the power.

With these tips in mind, let’s go over a few specific examples of how to cut metal with an angle grinder. [2]

Angle Grinder Safety

Using the Correct Blades Cutting techniques

Angle grinders are handheld power tools that can be used for a multitude of purposes. While they are mostly used for grinding down or cutting through metal, they can also be used for other materials such as wood or plastic. A common question people have angle grinders is if they can be used to cut metal. Cutting metal with an angle grinder is possible and even fairly simple to do. Although angle grinders are versatile, there are a few things you should remember before cutting metal.

First and foremost, you need to make sure that you are using the correct blades. Angle grinders come with a variety of different blades and each one is designed for a specific purpose.

Using the wrong type of blade can not only damage your angle grinder, but it can also be extremely dangerous.Utilizing the Safety Guard

Be sure to attach the safety guard before beginning to cut. The safety guard is there for a reason and it is there to protect you from the blades.

If the blades were to come into contact with your skin, they could cause serious injury or even death.

Ensuring Workspace Safety

Another important safety tip is to make sure that your workspace is clear and free of any debris. The last thing you want is for something to get caught in the blades while you are cutting metal. This could cause serious damage to both your angle grinder and your workspace.

Use in a Ventilated Area

Because angle grinders create a lot of dust and debris, it is important to use them in a well-ventilated area. If possible, try to do your cutting outdoors so that the debris has a place to go. If you must do your cutting indoors, be sure to open up all of the windows and doors to ensure proper ventilation. [3]

Wear Appropriate Protective Gear

Finally, be sure to wear the appropriate protective gear when using an angle grinder. This includes eye protection, ear protection, and gloves. Angle grinders can be very loud and the blades can cause serious injury if they come into contact with your skin. Wearing the appropriate protective gear will help to keep you safe while you are using your angle grinder.

Wear Personal Protective Equipment

Eye Protection – Wear safety glasses or goggles, or a face shield (with safety glasses or goggles). Some models are equipped with an integrated dust collection system to reduce exposure.

Hearing Protection – Use earplugs or earmuffs. Angle grinders can be very loud.

Gloves – Wear gloves to protect your hands from flying debris and sparks.

Dust Mask – If the grinding tool is not equipped with a dust collection system, wear a dusk mask to avoid inhaling the dust.

Long Sleeves – Wear long sleeves to protect your arms from flying debris.

Closed-Toe Shoes – Wear closed-toe shoes to protect your feet from flying debris.

Choosing the Right Cut Off Disc

Disc Composition

Angle grinders come with different disc compositions, each designed for a specific type of cutting.

There are also discs made from zirconia alumina, which are good for cutting stainless steel, stone, brick, and ceramic tile. To select the right disc for your needs, consult your angle grinder’s user manual to see what types of discs it can accommodate.

You can also ask an employee at your local hardware store for recommendations.

Durability

Another factor to consider when choosing a cut off disc is durability. If you’ll be using your angle grinder for heavy-duty cutting, you’ll need a disc that can stand up to the tough material. For example, if you’re cutting through concrete or stone, you’ll need a disc made from abrasive materials like silicon carbide or diamond. These discs are more expensive than those made from aluminum oxide, but they’re also much more durable and will last longer.

Cutting Speed

When selecting a cut off disc, it’s important to consider the speed at which it will cut through the material. Some discs are designed to cut quickly, while others are better suited for making precision cuts.

Disc Thickness

The thickness of the disc also plays a role in the speed of the cut. A thinner disc will require less pressure to cut through the material, which means it will cut faster. However, a thinner disc is also more likely to break under heavy-duty use. If you’ll be using your angle grinder for heavy-duty cutting, you’ll need a thicker disc that can withstand the added pressure.

How Deep You Need To Cut

Another factor to consider is how deep you need to cut. Some discs are designed to make shallow cuts, while others can cut up to 3/4 of an inch deep. If you’re not sure how deep you need to cut, it’s best to err on the side of caution and choose a disc that can make deeper cuts. That way, you’ll be able to make shallow cuts if necessary without having to replace the disc.

Disc Type

When you’re shopping for a cut off disc, you’ll also need to decide what type of disc you want. The most common type is the standard, which is designed for general-purpose cutting. There are also thin discs, which are good for making precise cuts, and turbo discs, which are designed for cutting through tough materials.

Size

Finally, you’ll need to select the right size disc for your needs. Angle grinders come with different size discs, so be sure to choose one that will fit your machine. You can usually find this information in the angle grinder’s user manual.

What Can Be Used to Cut Metal?

There are a few different tools that can be used to cut metal. These include:

- Abrasive cutoff wheels

- High-speed steel (HSS) saw blades

- Carbide-tipped saw blades

- Reciprocating saw blades

Of these options, the most commonly used tool for cutting metal is the abrasive cutoff wheel. This type of wheel is made from a hard, abrasive material that can quickly and easily cut through metal.

The Mechanism of an Angle Grinder

An angle grinder is a handheld power tool that uses abrasive wheels to cut, grind, and polish. The wheels are attached to the grinder with a threaded spindle. The user holds the grinder with both hands and presses the wheel against the workpiece to cut, grind, or polish.

Angle grinders are available in a variety of sizes and styles, so choosing the right one for your needs is important. Smaller angle grinders are best suited for light-duty tasks like sharpening tools or removing rust from metal, while larger angle grinders can handle heavier-duty jobs like cutting concrete or tile. [4]

Can an Angle Grinder Cut Steel?

An angle grinder can be used to cut steel, but it will require a disc that is specifically designed for cutting metal. These discs are usually made from abrasive materials like silicon carbide or diamond. Abrasive cutoff wheels are the most common type of disc used for cutting metal.

To use an angle grinder to cut steel, you’ll need to attach a metal cutting disc to the grinder. Once the disc is in place, you can begin cutting through the steel. Be sure to use caution and go slowly to avoid damaging the material or injuring yourself.

When cutting steel with an angle grinder, it’s important to keep the following tips in mind:

- Wear eye protection to avoid injury from flying debris.

- Wear gloves to protect your hands from the sharp edges of the metal.

- Use a cutting guide to help you make straight, precise cuts.

- Go slowly and use light pressure to avoid damaging the material.

With these tips in mind, you can safely and effectively cut steel with an angle grinder. [5]

FAQ

How thick of metal can an angle grinder cut through?

Angle grinders are not designed to cut through very thick metal. In most cases, they will be able to cut through metal that is up to four inches thick. However, this will vary depending on the power of the angle grinder and the type of blade that is being used.

What types of metal can an angle grinder cut?

Angle grinders can cut a variety of different metals, including steel, aluminum, and stainless steel. However, they should not be used on softer metals, such as copper or brass.

Can an angle grinder be used to cut tile?

No, angle grinders should not be used to cut tile. This is because they can create too much heat, which can damage the tile.

Can an angle grinder be used to cut concrete?

The answer is yes, an angle grinder can be used to cut concrete. However, it is important to note that there are a few things you need to keep in mind when using an angle grinder to cut concrete. First, you need to make sure that the blade you are using is designed for cutting concrete. Second, you need to take extra care when cutting concrete with an angle grinder as the concrete can easily chip and break. Finally, you may want to consider using a diamond blade when cutting concrete with an angle grinder.

What metal can not be cut by an angle grinder?

There are a few metals that can not be cut by an angle grinder, such as aluminum and stainless steel. However, there are special blades that can be used to cut these metals. If you are trying to cut aluminum or stainless steel with an angle grinder, you may want to consider using a specialized blade.

Can an angle grinder be used as a cutter?

Yes, an angle grinder can be used as a cutter. However, it is important to note that the blades on an angle grinder are not as sharp as those on a traditional cutter. This means that you will need to use more pressure when cutting with an angle grinder. Additionally, you may want to consider using a diamond blade when cutting with an angle grinder.

Can an angle grinder be used to cut wood?

No, you should not use an angle grinder to cut wood. The blades on an angle grinder are designed for cutting metal and concrete, not wood. If you try to cut wood with an angle grinder, you will likely damage the blade and the wood.

What kind of blade do you use on a grinder to cut metal?

There are a few different types of blades that can be used to cut metal with an angle grinder. The most common type of blade is a standard metal cutting blade. However, you may also want to consider using a diamond blade or a carbide-tipped blade.

What to avoid when using an angle grinder?

An angle grinder is a powerful tool that can cut through metal. However, there are certain things you should avoid when using an angle grinder. Here are four things to avoid when using an angle grinder:

- Don’t use an angle grinder on wood or plastic. These materials can clog the abrasive disc and cause it to overheat.

- Don’t use an angle grinder if you’re not familiar with how to operate it safely. Be sure to read the instruction manual before using this tool.

- Don’t apply too much pressure when using an angle grinder. Let the weight of the tool do the work for you.

- Don’t use an angle grinder on rusty or dirty metal. The abrasive disc can become clogged with debris, which can cause it to overheat.

If you follow these four simple tips, you’ll be able to safely and effectively use an angle grinder on metal.

What is the difference between an angle grinder and a cut off grinder?

An angle grinder is a handheld power tool that can be used for a variety of different applications. An angle grinder features an abrasive disc that is mounted on a spindle. The user holds the angle grinder with both hands and uses the abrasive disc to cut, grind or polish a variety of materials. A cut off grinder is also a handheld power tool that can be used for a variety of different applications. A cut off grinder also features an abrasive disc that is mounted on a spindle. However, the major difference between an angle grinder and a cut off grinder is that a cut off grinder only has one grinding wheel as opposed to two like an angle grinder. This makes it much more difficult to use a cut off grinder for tasks such as cutting or grinding metal.

What material can not be cut with a grinder?

There are a few materials that can not be cut with an angle grinder or a cut off grinder. These materials include concrete, stone and metal. If you try to cut these materials with a grinder, the results will be very unsatisfactory. The best way to cut these materials is with a saw.

Useful Video: How I Make Straight Accurate Cuts With The Angle Grinder

Conclusion

As you can see, an angle grinder is a versatile tool that can be used for a variety of different projects. While it is not the ideal tool for every job, it can certainly be used to cut metal. When using an angle grinder to cut metal, it is important to use the correct blade and take all safety precautions. With proper care and safety precautions, an angle grinder can be a great addition to your tool collection.

References:

- https://www.nortonabrasives.com/en-gb/resources/expertise/why-angle-grinder-essential-tool

- https://ronixtools.com/en/blog/the-best-angle-grinders-to-cut-metal/

- https://metexonline.com/news/angle-grinder-safety/

- https://ronixtools.com/en/blog/key-parts-of-an-angle-grinder/

- https://fantastichandyman.com.au/blog/what-is-an-angle-grinder/