Choose the Best Head Gasket for Aluminum Head

Customer’s Choice: the Best Rated Head Gaskets for Aluminum Heads

191 users answered this survey. Please help us improve this review!

As the market for aluminum heads has continued to grow, so too has the demand for quality head gaskets designed specifically for these applications. There are a number of different factors that you need to take into account when choosing a head gasket for an aluminum head engine, and this article is designed to help you make the right decision. In this article, we will discuss the different types of head gaskets available and provide reviews of some of the best products on the market. We will also offer some tips on how to choose the right head gasket for your needs.

Evergreen HS B2000 Cylinder Head Gasket Set Head Bolt

It’s important to keep your engine in top shape, and our Evergreen HS B2000 Cylinder Head Gasket Set Head Bolt is designed to help you do just that. This gasket set is made of high-quality materials and engineered to meet or exceed all original equipment specifications for proper sealing.

It’s important to keep your engine in top shape, and our Evergreen HS B2000 Cylinder Head Gasket Set Head Bolt is designed to help you do just that. This gasket set is made of high-quality materials and engineered to meet or exceed all original equipment specifications for proper sealing.

FEL-PRO HS 26415 PT-1 Head Gasket Set

Introducing the FEL-PRO HS 26415 PT-1 Head Gasket Set – the perfect choice for sealing surfaces that aren’t perfect. This gasket set is designed specifically for the repair environment, and features a unique combustion seal that can accommodate high cylinder pressures and head movement.

Introducing the FEL-PRO HS 26415 PT-1 Head Gasket Set – the perfect choice for sealing surfaces that aren’t perfect. This gasket set is designed specifically for the repair environment, and features a unique combustion seal that can accommodate high cylinder pressures and head movement.

GM Genuine Parts 12622033 Cylinder Head Gasket

Looking for a reliable and durable cylinder head gasket for your GM vehicle? Look no further than the GM Genuine Parts 12622033 Cylinder Head Gasket.

Looking for a reliable and durable cylinder head gasket for your GM vehicle? Look no further than the GM Genuine Parts 12622033 Cylinder Head Gasket.

MAHLE Original 54450A 6.0L Ford Power Stroke Cylinder Head Gasket

Looking for a top-quality cylinder head gasket for your 6.0L Ford Power Stroke engine? Look no further than the MAHLE Original 54450A 6.0L Ford PowerStroke Cylinder Head Gasket.

Looking for a top-quality cylinder head gasket for your 6.0L Ford Power Stroke engine? Look no further than the MAHLE Original 54450A 6.0L Ford PowerStroke Cylinder Head Gasket.

MAHLE Original is the world’s leading manufacturer of gaskets and sealing products, so you can be sure that this gasket will provide superior performance and long-lasting durability. Trust the experts at MAHLE.[4]

Cometic (H1796SP7051S) Head Gasket

The Cometic Head Gasket is designed to provide exceptional performance in the most demanding racing environment.

The Cometic Head Gasket is designed to provide exceptional performance in the most demanding racing environment.

Buyer’s Guide

How do I choose a head gasket?

There are a few factors you need to take into consideration when choosing a head gasket. The most important factor is the material of the head gasket. Head gaskets are typically made from either steel or copper. Steel head gaskets are less expensive and offer a good seal, but they are not as durable as copper head gaskets. Copper head gaskets cost more, but they offer a better seal and are more durable. Another factor to consider is the thickness of the head gasket. Thicker head gaskets can handle higher compression ratios and provide a better seal, but they also require longer bolts and may be difficult to install. You should also consider the application for which you will be using the head gasket. If you are using the head gasket on a street car, you will not need as much sealing power as you would for a race car. Finally, make sure to check the compatibility of the head gasket with your engine block and heads. Different engine designs require different types of head gaskets, and using the wrong type of head gasket can result in serious damage to your engine.[8]

Head gasket designs

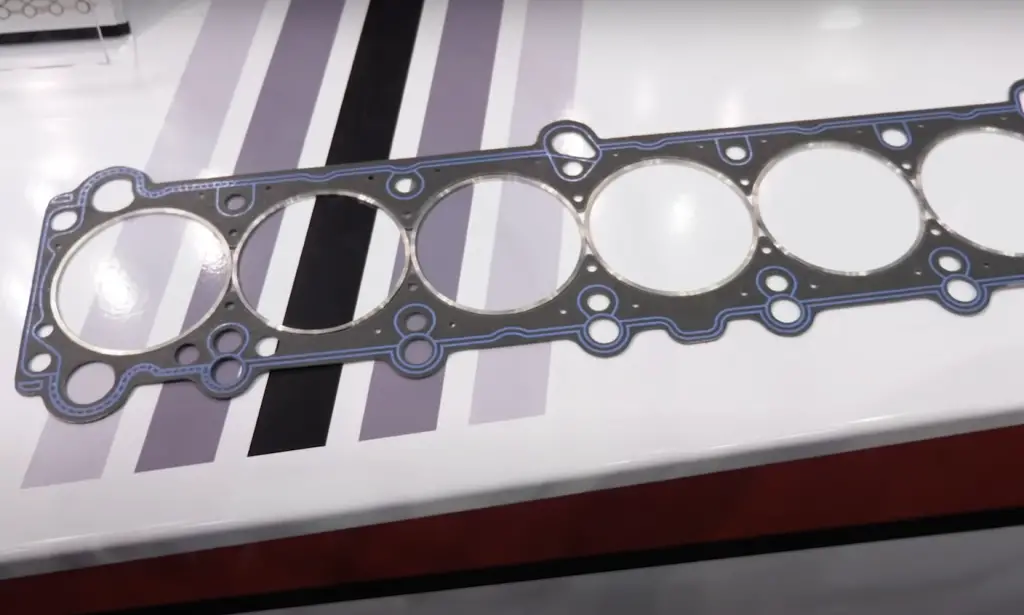

There are two basic designs of head gaskets: the one-piece head gasket and the multi-layer steel (MLS) head gasket. One-piece head gaskets are made from a single piece of material, typically steel or copper. MLS head gaskets are composed of multiple layers of steel with a composite elastomer core. MLS head gaskets offer superior sealing power and durability, but they are also more expensive.

For street cars, a one-piece head gasket will suffice.

Multi-layer steel (MLS) head gaskets are designed to handle high cylinder pressures and can be used in both street and racing applications. They offer several benefits over other types of gaskets, such as:

- Increased durability: MLS gaskets can withstand higher temperatures and pressures than other types of gaskets.

- Better sealing: MLS gaskets create a tighter seal between the head and block, which can help prevent oil and coolant leaks.

- Improved performance: MLS gaskets can provide a slight increase in power due to their ability to handle higher cylinder pressures.

One final note on choosing a head gasket: many aftermarket companies offer “universal” head gaskets that are supposed to fit a wide range of engine applications. We do not recommend using these gaskets. It is always better to use a head gasket that is specifically designed for your engine. Universal head gaskets may not seal properly and could cause serious engine damage.[9]

Compatibility

There are many factors to consider when choosing the best head gasket for your aluminum heads. The most important factor is compatibility. You need to make sure that the head gasket you choose is compatible with the materials used in your cylinder heads and block. Aluminum heads are typically made from either cast aluminum or extruded aluminum. Cast aluminum heads are softer and more brittle, while extruded heads are stronger and more durable. Choose a head gasket that is compatible with the type of aluminum used in your heads.

Another important factor to consider is the thickness of the head gasket. The thicker the head gasket, the higher the compression ratio you can run without blowing out the gasket. If you are running high compression pistons or a turbocharger, you will need a thicker head gasket to prevent blown head gaskets. Thicker head gaskets also provide additional support for cylinder heads with big valve springs. If you are not sure what thickness head gasket to use, consult a professional.

When choosing a head gasket, it is also important to consider the bore size of your engine. The bore size is the diameter of the cylinder in which the piston travels. A larger bore engine will require a thicker head gasket to prevent blowing out the gasket. If you are not sure what bore size your engine is, consult a professional.

Finally, you need to consider the type of engine you have. There are two types of engines, interference and non-interference. Interference engines have valves that come into contact with the piston when it is at top dead center. Non-interference engines do not have this problem. If you are not sure what type of engine you have, consult a professional.[7]

Head gasket coatings

If you want to get the most out of your aluminum heads, you should consider using a head gasket with a coating. A head gasket coating will help to create a seal between the head and block, as well as protect the gasket from heat. There are many different types of coatings available, so be sure to do your research before choosing one.

There are two main types of coatings: graphite and MLS (multi-layer steel). Graphite is the more traditional option and has been used for many years. MLS head gaskets are newer and offer some advantages over graphite gaskets, such as increased durability and better heat resistance. Ultimately, the decision of which type of coating to use is up to you.[6]

No matter which type of coating you choose, be sure to follow the installation instructions carefully. Applying too much or too little coating can affect the performance of the gasket.

Head gasket installation tips

If you’re installing a new head gasket on an aluminum head, there are a few tips to keep in mind. First, be sure to clean the surface of the head and block thoroughly before installation. Any dirt or debris on the surface can cause the gasket to leak. Second, use a torque wrench to tighten the bolts to the proper specification.

Over-tightening can damage the gasket or cause it to leak. Finally, if you’re using an aftermarket head gasket, be sure to follow any special installation instructions that come with it.[6]

Inspecting head gaskets for damage

If you’re unsure whether your head gasket is damaged, there are a few things you can look for. First, check the coolant level in the radiator and overflow tank. If it’s low, that could be a sign of a leak. You should also check for any visible leaks around the engine. Finally, if your engine is running hotter than normal or if the temperature gauge needle fluctuates erratically, that could be an indication that coolant is leaking into the cylinders and causing overheating.[6]

If you suspect your head gasket is damaged, it’s important to have it checked out by a mechanic as soon as possible. A blown head gasket can cause serious engine damage if left untreated.

Types of head gaskets

Multilayer steel

These are the most common type of head gasket and are made from multiple layers of stainless steel with an elastomer core. They are designed to seal between the cylinder head and engine block, as well as withstand high temperatures and pressures. MLS head gaskets can be used with both aluminum and cast iron heads.

Advantages:

- Can be used with a variety of materials including aluminum and cast iron

- Withstand high temperatures and pressures

Disadvantages:

- Not as durable as other types of head gaskets[7]

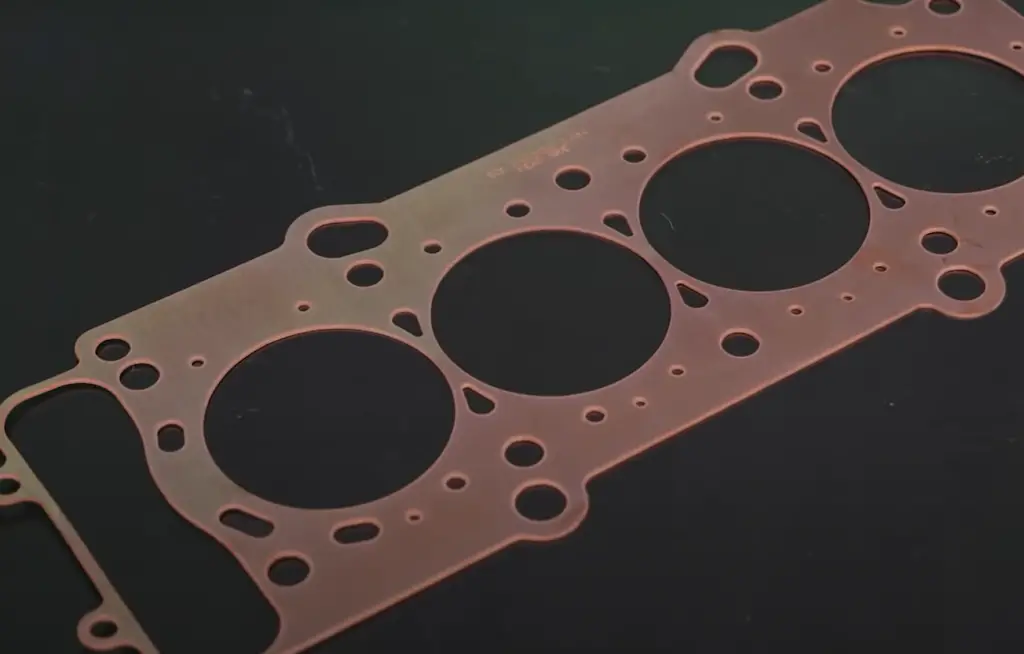

Copper vs. Stainless Steel

There are two primary types of metal used in head gaskets: copper and stainless steel.

Stainless steel is stronger and can withstand higher temperatures, making it a good choice for high-performance applications. However, both metals have their drawbacks. Copper is susceptible to corrosion and can leak over time, while stainless steel is more likely to cause engine damage if it cracks or tears.To decide which type of head gasket is right for your engine, you need to consider the operating conditions. If you’re using your vehicle in a hot climate or doing a lot of stop-and-go driving, stainless steel is a better choice. For street vehicles and those driven in moderate conditions, copper is a good option.[7]

If you’re still not sure which type of head gasket to choose, consult with a qualified mechanic or engine builder. They can help you select the best head gasket for your specific application.

Composite

If you are looking for a quality head gasket that will not break the bank, then a composite style gasket is a great option. These gaskets are made from multiple layers of steel and an elastomeric material, which makes them very durable.

Composite style gaskets also have excellent sealing properties and can handle high temperatures and pressures.

Elastomeric

If you are looking for a good quality head gasket that will seal well and last long, then an elastomeric head gasket is a good choice.

Elastomeric head gaskets also have good resistance to chemicals and heat, making them ideal for use in high-performance engines. However, they can be difficult to install correctly, so it is important to follow the instructions carefully.

If you are unsure about whether an elastomeric head gasket is right for your engine, then you can always ask a mechanic or head gasket specialist for advice.

Which gasket should I use for aluminum heads?

The best gasket to use for aluminum heads is an MLS (multi-layer steel) gasket. These gaskets have a much higher sealing ability than traditional head gaskets, and can better withstand the high temperatures found in aluminum engines. [6]

Comparison of Indicators for Choosing Head Gaskets for Aluminum Heads

When selecting head gaskets for aluminum heads, it is crucial to consider various indicators that affect performance, durability, and compatibility. The following table provides a comparison of key indicators to help you make an informed decision when choosing head gaskets.

| Indicator | Definition | Importance | Considerations |

|---|---|---|---|

| Material | The material used for the head gasket | High | Choose gaskets specifically designed for aluminum heads to ensure compatibility and prevent damage |

| Thickness | The thickness of the head gasket | Medium | Select an appropriate thickness based on the engine’s compression ratio and desired sealing capability |

| Compression Ratio | The ratio of the cylinder’s maximum volume to its minimum volume | High | Consider the engine’s compression ratio and select a head gasket that can handle the pressure without compromising the seal |

| Sealing Capability | The ability of the head gasket to maintain a reliable seal under various conditions | High | Look for head gaskets with excellent sealing properties to prevent leaks and maintain engine performance |

| Compatibility | The compatibility of the head gasket with the engine and other components | High | Ensure the head gasket is designed for your specific engine and works well with other components like coolant and oil passages |

| Heat Resistance | The ability of the head gasket to withstand high temperatures | Medium | Consider the engine’s operating temperature range and select a head gasket that can handle the heat without deteriorating |

| Price | The cost of the head gasket | Medium | Balance the cost with the desired quality and performance to find the best value for your needs |

Explanation of the table:

- Material: This indicator refers to the material used for the head gasket. It is important to choose gaskets specifically designed for aluminum heads to ensure compatibility and prevent damage.

- Thickness: The thickness of the head gasket plays a role in sealing capability. It is necessary to select an appropriate thickness based on the engine’s compression ratio and desired sealing capability.

- Compression Ratio: The compression ratio is the ratio of the cylinder’s maximum volume to its minimum volume. It is crucial to consider the engine’s compression ratio and select a head gasket that can handle the pressure without compromising the seal.

- Sealing Capability: This indicator represents the ability of the head gasket to maintain a reliable seal under various conditions. Look for head gaskets with excellent sealing properties to prevent leaks and maintain engine performance.

- Compatibility: Compatibility refers to the head gasket’s compatibility with the engine and other components. Ensure the head gasket is designed for your specific engine and works well with other components like coolant and oil passages.

- Heat Resistance: Heat resistance indicates the head gasket’s ability to withstand high temperatures. Consider the engine’s operating temperature range and select a head gasket that can handle the heat without deteriorating.

- Price: Price represents the cost of the head gasket. It is important to balance the cost with the desired quality and performance to find the best value for your needs.

FAQ

Do thicker head gaskets seal better?

Yes, thicker head gaskets will usually seal better than thinner ones. This is because they have a higher compression ratio, which helps to fill any gaps in the surface of the head and block. Thicker gaskets also tend to be more durable, so they can withstand repeated cycles of heating and cooling without losing their shape or becoming damaged.

Of course, there are some exceptions to this rule. If you’re using an aftermarket cylinder head that has been milled down to increase compression, you may need to use a thinner gasket in order to prevent leaks. Always consult your engine builder or mechanic before choosing a head gasket thickness.

Are metal head gaskets better?

Metal head gaskets are usually made from materials such as steel, copper, or titanium. They’re designed to seal better than traditional paper or composite gaskets, and can withstand higher temperatures and pressures. Metal head gaskets also have the advantage of being reusable, so you can remove and install them multiple times without damaging the gasket or engine.

However, metal head gaskets are usually more expensive than other types of gaskets. They may also require special installation tools, so it’s important to consult your mechanic or engine builder before choosing a metal head gasket.

In general, metal head gaskets are best suited for high-performance applications where reliability is paramount. If you’re just looking for a gasket that will seal your engine and prevent leaks, a traditional paper or composite gasket will probably suffice.

Are copper head gaskets better?

Copper head gaskets are often thought to be better for aluminum heads because they’re more pliable. This allows them to conform to irregularities in the surface of the head, creating a better seal. Copper gaskets also have good heat-dissipating properties, which is important in an engine that runs hot.

However, copper gaskets can be difficult to install and require special tools. They’re also more expensive than other types of gaskets. If you’re not experienced with installing copper gaskets, it’s best to leave this job to a professional mechanic.

Are graphite head gaskets good?

Graphite head gaskets are popular among engine builders because they offer good sealing and are resistant to corrosion. However, graphite head gaskets can be difficult to install and require special tools. If you’re not careful, it’s easy to damage the head gasket while installing it.

Another downside of graphite head gaskets is that they don’t always seal as well as other types of head gaskets. If you’re using a high-performance engine with aluminum heads, you may want to consider another type of head gasket.

What type of gasket is commonly used with aluminum cylinder heads and cast iron blocks?

The most common type of gasket used with aluminum heads and cast iron blocks is the MLS (multi-layer steel) gasket. These types of gaskets have a steel outer layer that is embossed with a sealing bead around the combustion chamber and water jacket openings. An inner layer of stainless steel or coated with an elastomeric material such as graphite or asbestos completes the construction of these gaskets.

While MLS gaskets are the most popular type used with aluminum heads, there are other options available on the market today. Copper head gaskets, for example, offer excellent sealing capabilities and are often used in high performance applications. If you’re using aftermarket cylinder heads or block that have been machined for O-rings, then an O-ring head gasket is likely your best bet.

Whichever type of gasket you choose, be sure to follow the manufacturer’s recommendations for installation and torque specs. With a little care and attention to detail, you can be confident that your engine will have a good seal and be able to make plenty of power.

Can you use stock head bolts on aluminum heads?

Yes, you can use stock head bolts on aluminum heads. However, it is important to check the torque specifications for your particular engine to ensure that you are not over-tightening the bolts. It is also a good idea to use a thread sealer on the threads to help prevent leaks.

If you are using aftermarket heads, it is important to check the instructions that come with the heads to see if there are any special requirements for installation. Some aftermarket heads require the use of special studs or bolts that are different from the stock hardware.

When installing head gaskets on aluminum heads, it is important to use a quality gasket set that includes silicone bead seals around the water jackets. These bead seals help to prevent coolant leaks.

It is also a good idea to use hardened washers under the head bolts to help prevent the bolts from stripping out the threads in the aluminum heads.

What is the best head gasket material?

There are a few different types of materials that can be used for head gaskets, but the most common are graphite, asbestos, and metal. Graphite head gaskets are generally considered to be the best option because they’re able to seal better than other materials and they don’t corrode like metal gaskets can. Asbestos head gaskets are also popular because they’re very durable, but they’re not as effective at sealing as graphite gaskets.

If you’re looking for a head gasket that will seal well and last long, then a graphite head gasket is probably your best bet. However, if you’re looking for a more affordable option, then an asbestos head gasket may be a good choice.

How do I choose a head gasket?

The first thing you need to do is identify what engine you have. There are many different types and sizes of engines, so it’s important to know which one is in your vehicle. Once you know the make and model of your engine, you can start narrowing down your options for head gaskets.

There are a few things to keep in mind when choosing a head gasket:

- The material the gasket is made from (metal, composite, etc.)

- The thickness of the gasket

- The size of the engine (small block, big block, etc.)

You also need to decide whether you want an OEM (original equipment manufacturer) gasket or an aftermarket gasket.

Are MLS (Multi-Layer Steel) head gaskets suitable for aluminum heads?

Yes, MLS head gaskets are commonly used with aluminum heads. They provide excellent sealing properties and can handle the differential expansion rates between aluminum heads and engine blocks.

Can I reuse a head gasket on aluminum heads?

It is generally not recommended to reuse a head gasket, especially on aluminum heads. The gasket’s ability to seal properly may be compromised after the initial installation, increasing the risk of leaks or engine damage. It is best to use a new head gasket whenever the cylinder head is removed.

What is the recommended torque specification for head bolts on aluminum heads?

The torque specification for head bolts on aluminum heads varies depending on the specific engine and manufacturer. It is crucial to follow the manufacturer’s recommended torque values to ensure proper clamping force without risking damage to the aluminum head or gasket.

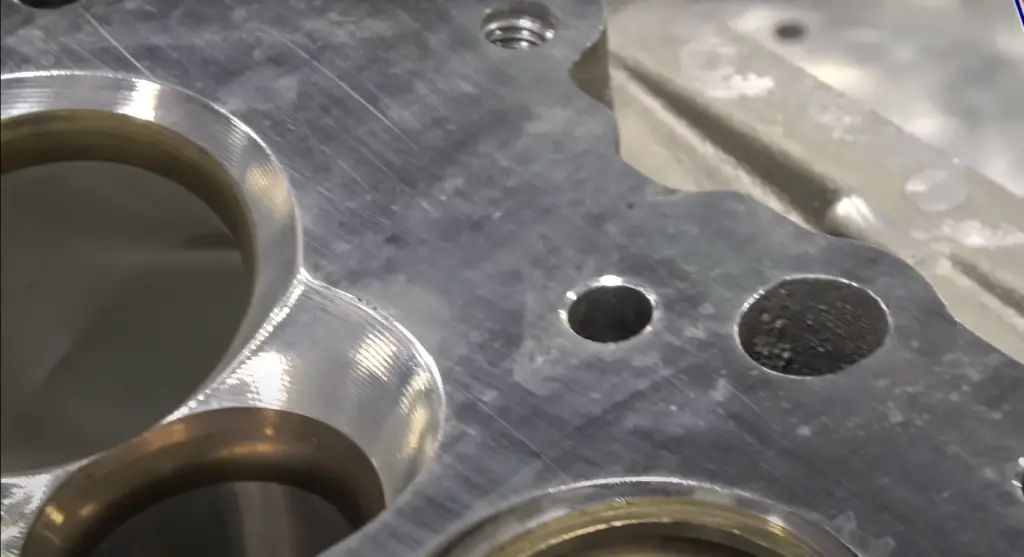

Can aluminum heads be resurfaced?

Aluminum heads can be resurfaced, but it requires careful attention to maintain their flatness and integrity. If the head gasket has failed or there are signs of warping, it is advisable to have a professional machine shop handle the resurfacing process to ensure accurate and proper results.

What is the role of a head gasket in an engine with aluminum heads?

The head gasket plays a crucial role in sealing the combustion chamber, coolant passages, and oil passages between the cylinder head and engine block. In engines with aluminum heads, the gasket helps compensate for the different expansion rates of the aluminum head and the cast iron block, ensuring a reliable seal under varying operating temperatures.

Can I use a composite head gasket with aluminum heads?

Composite head gaskets, typically made of non-asbestos materials, can be used with aluminum heads in certain applications. However, it is essential to consider the specific engine requirements and manufacturer recommendations to ensure compatibility and proper sealing.

How can I detect a blown head gasket on aluminum heads?

Common signs of a blown head gasket on aluminum heads include white exhaust smoke, coolant mixing with engine oil, overheating, loss of coolant without visible leaks, and compression or combustion gases entering the cooling system. If you suspect a blown head gasket, it is advisable to have a professional mechanic perform a thorough inspection and diagnose the issue.

Are there any special considerations when installing head gaskets on aluminum heads?

When installing head gaskets on aluminum heads, it is important to follow the manufacturer’s instructions and torque specifications precisely. Additionally, ensure the surfaces of the cylinder head and engine block are clean, flat, and free from debris or damage. Using a suitable sealant or lubricant as recommended by the manufacturer can also aid in achieving a proper seal.

Can aluminum head gaskets be used in high-performance or forced induction applications?

Yes, aluminum head gaskets can be used in high-performance or forced induction applications. However, it is crucial to select gaskets specifically designed for these conditions, considering factors such as increased cylinder pressures, higher combustion temperatures, and potential movement or flexing of the cylinder head.

What are the advantages of using MLS head gaskets for aluminum heads?

MLS head gaskets offer several advantages for aluminum heads, including excellent sealing properties, resistance to high temperatures and pressures, durability, and the ability to compensate for the differential expansion rates between aluminum heads and engine blocks. They are a popular choice for performance engines and applications that demand reliable sealing.

Useful Video: Gasket Material and Surface Roughness—and How they Relate

Conclusion

After reading this article, we hope you feel better informed about the best head gaskets for aluminum heads on the market. We know there are a lot of options out there, and it can be tough to choose the right one for your needs. Keep in mind the factors we discussed – material, thickness, price, and brand – and you should be able to find a great gasket that will serve you well.

Do you have any experience with using head gaskets on aluminum heads? Let us know in the comments below! And if you found this article helpful, please share it with your friends or fellow gearheads. Thanks for reading!

References:

- https://www.amazon.com/Evergreen-HSHB2000-Cylinder-Head-Gasket/dp/B007P747FU

- https://www.amazon.com/Fel-Pro-HS-26415-PT-1-Cylinder/dp/B00FADEIF0

- https://www.amazon.com/ACDelco-12622033-Original-Equipment-Cylinder/dp/B014MVAFYI

- https://www.amazon.com/MAHLE-Original-54450A-Stroke-Cylinder/dp/B00BBDZQBI

- https://www.amazon.com/Cometic-Gasket-H1796SP7051S-Head/dp/B00HSF7EYU

- https://www.speedwaymotors.com/the-toolbox/cylinder-head-gasket-replacement-buyers-guide/28652

- https://www.jbtools.com/blog/the-4-types-of-automotive-head-gaskets/

- https://www.partinfo.co.uk/articles/245