It’s a question that has been asked by many DIYers and handymen over the years – can a hacksaw really cut through metal? The answer, as with most things in life, is it depends. There are certain types of metal that a hacksaw can easily cut through, while other types of metal present more of a challenge. In this comprehensive article, we will answer all of your questions about using a hacksaw to cut metal, as well as provide helpful tips on how to get the job done right. Let’s get started!

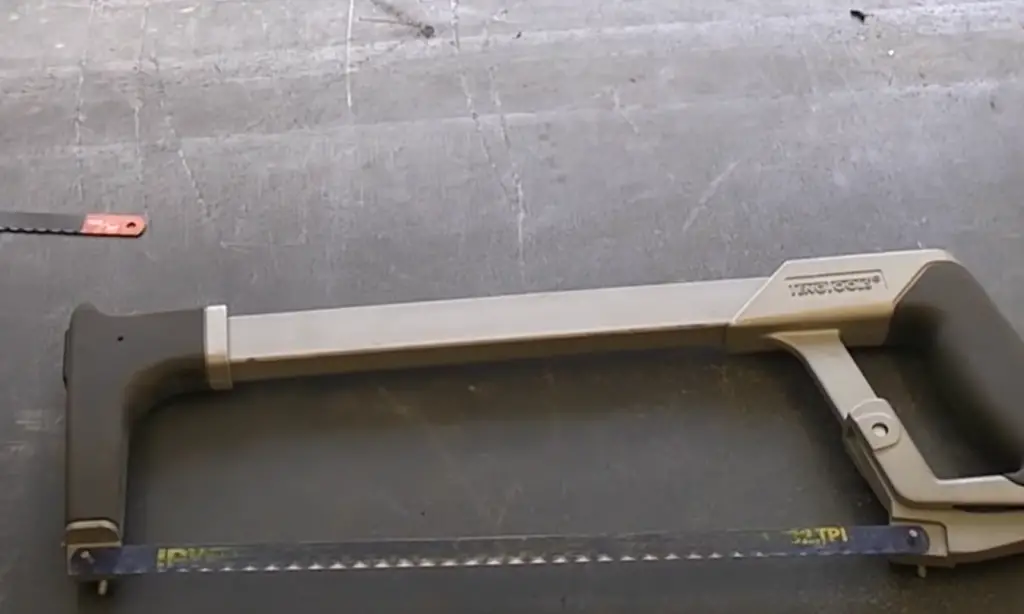

What Is a Hacksaw?

A hacksaw is a handheld tool that consists of a blade with sharp teeth that is used for cutting through materials like wood, plastic, and metal.

The blade is mounted in a frame that can be adjusted to change the blade’s tension, which in turn affects how easily the blade cuts through the material.

Parts of a Hacksaw

Hacksaw Frame

The hacksaw frame is the body of the saw. It is typically made of metal, although some frames are made of plastic. The blade is attached to the frame and tensioned with a screw or lever.

Hacksaw Blade

The hacksaw blade is the cutting element of the saw. It is a thin strip of metal with sharp teeth on one edge. The blade is attached to the frame and tensioned with a screw or lever.

The most important consideration when choosing a hacksaw blade is the material you will be cutting. Blades are available in a variety of materials, each designed for optimal performance on specific types of metal.

Carbon steel blades are the most common type of blade. They are suitable for cutting all types of metals, including ferrous and non-ferrous metals. However, carbon steel blades will quickly dull when used on harder metals such as stainless steel or cast iron.

High speed steel (HSS) blades are made of a high carbon steel alloy. They are designed for cutting harder metals such as stainless steel and cast iron. HSS blades will stay sharper longer than carbon steel blades, but they are more brittle and can break if bent too far.

Tungsten carbide tipped (TCT) blades are the most expensive type of blade, but they are also the longest lasting. TCT blades are made of a hard metal alloy with tungsten carbide teeth. They are designed for cutting extremely hard metals, such as aluminum and bronze.

What Materials Can A Hacksaw Cut?

A hacksaw is a hand saw that consists of a blade with teeth that’s stretched between two metal frames.

While a hacksaw can technically cut through any type of material, it’s not always the best tool for the job. For example, you would never use a hacksaw to cut through wood because it would be very difficult and time-consuming. The same goes for softer materials like plastic or aluminum.

In general, a hacksaw works best on harder materials like metals (including stainless steel and cast iron), as well as ceramics and glass. So, if you’re planning on doing some home improvement projects that involve cutting through metal, a hacksaw is a good tool to have on hand.[1]

What Thickness Of Metal Can A Hacksaw Cut?

Hacksaw Frame Depth

A hacksaw is a hand saw with a blade held in place by a frame, that is used for cutting thin pieces of metal. The blade is usually made of high-carbon steel, and is available in different sizes and shapes.

The size of the blade will determine the thickness of metal that it can cut through. For example, a 12-inch hacksaw blade can cut through metal up to 2 inches thick, while a 14-inch hacksaw blade can cut through metal up to 3 inches thick.

The depth of the hacksaw frame also plays a role in how thick of a piece of metal can be cut. A standard hacksaw frame has a depth of about 3 inches, which allows for a maximum cutting depth of about 2 inches. If you need to cut through metal that is thicker than 2 inches, you will need to use a deep-cut hacksaw frame, which has a depth of about 4.5 inches.[1]

Material Thickness

The thickness of the metal will also affect how easy it is to cut through with a hacksaw. Softer metals, such as aluminum or brass, will be easier to cut than harder metals, such as steel or cast iron.

If you are cutting through a piece of metal that is less than 1/8 inch thick, you can use a standard hacksaw blade. If the metal is thicker than 1/8 inch, you will need to use a blade that is designed for cutting thicker metal. These blades have more teeth per inch, which helps them to cut through the metal more easily.

Can A Hacksaw Cut Metal Screws?

For the most part, yes a hacksaw can cut through metal screws. However, it will take some time and effort on your part. The teeth on a hacksaw are not as sharp as those on a power saw, so it will require more work to get through the metal. In addition, you need to be careful not to damage the screw head.

Here are some tips for using a hacksaw to cut through metal screws:

- Use a fine-toothed blade for best results.

- Apply even pressure when sawing.

- Go slowly and be patient!

- Be extra careful not to damage the screw head.

Can A Mini Hacksaw Cut Metal?

A mini hacksaw is a great tool for anyone who needs to do some light cutting. However, you may be wondering if this little saw is up to the task of cutting metal.

The answer is: it depends.

While a mini hacksaw can cut through softer metals like aluminum or brass, it will struggle with harder metals like steel. If you’re trying to cut something like rebar or stainless steel, you’ll likely need a heavier-duty saw.

That said, there are ways to make metal cutting easier on a mini hacksaw. Applying some WD-40 or other lubricant to the blade can help it move more easily through the metal. And using a blade designed for cutting metal will also make the job easier.

So, while a mini hacksaw may not be the best tool for every metal-cutting job, it can certainly handle some lighter work. And with a few tips and tricks, you can make metal cutting easier on your little saw.

What Type Of Hacksaw Blade Cuts Metal?

High Carbon Steel

Bimetal blades are also HCS blades with a cobalt alloy tooth edge welded onto the body of the blade. This makes them ideal for cutting metals such as cast iron, stainless steel, non-ferrous metals, and alloys.[1]

High-Speed Steel

This is a common type of hacksaw blade that can cut through various types of metals, including stainless steel and cast iron.[1]

Bi-Metal Blades

This type of hacksaw blade is ideal for cutting through tougher metals such as stainless steel and cast iron. The blade is made from high carbon steel with a cobalt alloy tooth edge welded onto the body of the blade.

What Is Tpi On A Hacksaw Blade?

The TPI, or “teeth per inch” on a hacksaw blade, is a measure of how many teeth are on the blade. The more teeth there are, the finer the cut will be. For example, a 14 TPI blade will produce a much finer cut than a 10 TPI blade.

However, more teeth also means that the blade will wear out faster. So, if you’re going to be cutting a lot of metal, you may want to choose a lower TPI blade.

What Is The Best Blade For Cutting Metal?

When it comes to cutting metal, the type of hacksaw blade you use is important. There are three main types of blades:

- High carbon steel blades: These are the most common type of hacksaw blade and can be used on a variety of materials, including wood and plastic. They are also the least expensive option.

- Bi-metal blades: These blades are made of two different types of metal, which makes them more durable and better able to withstand heat. They are a good choice for cutting thicker metals.

- Tungsten carbide blades: The strongest and most expensive type of hacksaw blade, these are designed for cutting extremely hard materials like stainless steel.

How To Cut Metal With A Hacksaw?

Mount Blade on Frame

The first thing you need to do is take your hacksaw and mount it on the frame. To do this, you need to find the teeth of the blade and position it in such a way that they are pointing downwards.

After that, you should take the two bolts that come with the frame and screw them in place. Once they are tightened, your hacksaw should be securely mounted on the frame.[2]

Clamp Work Material

The next step is to take your work material and clamp it down. This is important because you need to make sure that the metal you are cutting is firmly in place. If it is not, then there is a chance that it might move while you are cutting, which can lead to accidents.

There are many different ways to clamp down your work material. The most common method is to use C-clamps. These are clamps that have a handle that you can squeeze in order to tighten them. Another popular method is to use vise grips. These are similar to C-clamps, but they have jaws that grip the work material more securely.[2]

Hold Hacksaw Correctly

Now that your work material is clamped down, you can start cutting. But before you do, it is important to make sure that you are holding the hacksaw correctly. The first thing you need to do is find the right grip. The most common grip is known as the pistol grip. To do this, you simply need to position your hand in such a way that it is similar to how you would hold a pistol.

Create Notch

Once you have the correct grip, you can start cutting. But before you start making long cuts, it is a good idea to create a notch in the work material. This will help to guide the blade and prevent it from wandering off course.

To create a notch, you simply need to position the blade of the hacksaw at the point where you want to start cutting. After that, you should make a few short strokes in order to create a groove for the blade to follow.

Cut Material

After you have created a notch, you can start making long cuts. To do this, you simply need to apply pressure to the handle of the hacksaw and push it forward. As you are doing this, make sure that you are following the line of the notch. If you veer off course, then you might end up with a crooked cut.

If you go too slow, then the blade will get hot and start to dull. On the other hand, if you go too fast, then the blade might break.[2]How Do You Make a Straight Cut in Metal Using a Hacksaw?

If you’re planning on using a hacksaw to cut through metal, there are a few things you should keep in mind to ensure a clean, straight cut. First of all, it’s important to use a sharp blade – a dull one will make it more difficult to get a precise cut. Secondly, you’ll need to apply even pressure as you saw back and forth; too much pressure can cause the blade to break, while too little won’t allow it to cut through the metal.

Finally, it’s helpful to use a guide (like a strip of wood) to help keep the blade steady as you cut.[1]

Tips for Using a Hacksaw

If you’ve decided that a hacksaw is the right tool for the job, there are a few things you can do to make sure you get the best results.

- First, consider the type of blade you’ll need. If you’re cutting thick metal, you’ll want a blade with more teeth per inch (TPI). For thinner metal, a lower TPI will do the trick.

- Second, make sure the blade is secured tightly in the frame. A loose blade will cause problems when cutting and can be dangerous.

- Finally, when using a hacksaw, be sure to use gentle, even strokes. Trying to force the blade through the metal will only damage the blade and could cause injury.[2]

When to Replace Your Hacksaw Blade

You might be surprised to know that you can actually cut through quite a bit of metal with a hacksaw before needing to replace the blade. However, there will come a time when even the sharpest blade will need to be replaced. Here are a few signs that it’s time for a new hacksaw blade:

- The blade is dull and is no longer cutting cleanly or quickly

- The teeth on the blade are damaged or missing

- The blade is bent or warped[2]

If you notice any of these issues, it’s time to get a new blade. Fortunately, they’re relatively inexpensive and easy to find at most hardware stores.

FAQ

How thick of metal can a hacksaw cut?

A hacksaw can cut through a variety of thicknesses of metal, but it will work best on thinner pieces. The thicker the metal, the more difficult it will be to cut through and the more likely you are to damage the blade.

Which hacksaw is best for cutting metal?

There are a few different types of hacksaws, but the one that is best for cutting metal is typically a standard hacksaw with a fine-toothed blade.

What is the easiest way to cut metal?

If you are looking for the easiest way to cut metal, you may want to consider using a power saw. Power saws can quickly and easily cut through metal of all thicknesses.

Can a hacksaw cut a bolt?

A hacksaw can cut through a bolt, but it will take some time and effort. You will need to use a saw blade that is designed for cutting metal. The thicker the bolt, the more difficult it will be to cut through.

Can a hacksaw cut off a lock?

A hacksaw can be used to cut off a lock, but it is not the ideal tool for the job. A power saw or bolt cutters would be a better option.

How do you cut steel with a hacksaw?

To cut steel with a hacksaw, you will need to use a saw blade that is designed for cutting metal. The thicker the steel, the more difficult it will be to cut through. It is important to make sure that the blade is sharp and that you are using the proper technique.

What are the 3 types of hacksaw?

The three types of hacksaws are standard, offset, and junior. Standard hacksaws have a straight blade that is attached to the frame in the center. Offset hacksaws have a blade that is offset from the center of the frame. Junior hacksaws have a smaller frame and are typically used for cutting small pieces of metal.

Useful Video:How To Cut Metal – Ace Hardware

Conclusion

Yes, you can cut metal with a hacksaw – but there are some things you need to keep in mind. Use a bi-metal blade for the best results, and take your time cutting through thicker pieces of metal. Be extra careful when cutting galvanized steel, as the zinc coating can be poisonous if inhaled. With a little patience and the right tools, you can make clean, precise cuts through metal with a hacksaw.

Have you ever cut metal with a hacksaw? What tips would you add? Let us know in the comments below!

References:

- https://www.finepowertools.com/hand-tools/hacksaw-for-metal/

- https://www.thespruce.com/how-to-use-a-hacksaw-5204960