Having a stuck spark plug in the aluminum head of an engine can be a frustrating and time-consuming problem. When it happens, it may seem impossible to remove it using conventional methods. But there are some tried-and-true ways to get that stubborn spark plug out without damaging the engine or its components. Read on for tips on how to safely and effectively remove a stuck spark plug from an aluminum head.

Why Spark Plugs Get Stuck

One of the most common problems car owners face is a stuck spark plug in the aluminum head. It happens when an engine has been running for too long or has not been properly maintained.

The buildup of carbon and other deposits on the spark plug surfaces can cause it to become increasingly difficult to remove, making it even more important to take preventive action before this issue arises.

The Top 8 Factors Contributing To Stuck Spark Plugs In Aluminum Heads

Here are eight factors that can contribute to a stuck spark plug in an aluminum head [1]:

- Improper Torque: Over-tightening or under-tightening the spark plug can lead to stripping or cross-threading, which makes removal difficult;

- Corrosion: Rust and corrosion can occur if the spark plug is exposed to water or other corrosive liquids;

- Carbon Buildup: Excessive carbon buildup on the threads of a spark plug can create a strong bond that makes removal difficult;

- Vibration: Constant vibrations from the engine can cause some parts to become loose, including the spark plug;

- Thread Stripping: Over time, threads may become stripped due to improper installation or corrosion, making it impossible to remove without damaging the spark plug or head;

- Heat Transfer Compounds: If heat transfer compounds are not applied correctly or if they are left on for too long, they can form an impenetrable seal around the threads of a spark plug and prevent its removal;

- Seized Bolts: Rust and corrosion can cause bolts to become seized, which means they cannot be loosened or removed without causing damage to the spark plug or head;

- Cylinder Head Damage: If the cylinder head is damaged due to over-tightening of the spark plug, it can make removal difficult or impossible.

Potential Risks of Leaving a Stuck Spark Plug Unaddressed

Here are some of the potential consequences you may face if a stuck spark plug is left unaddressed [2]:

- Poor Engine Performance: A stuck spark plug can lead to misfires, poor fuel economy, and decreased engine performance;

- Poor Fuel Consumption: The engine may not be able to combust fuel efficiently if a spark plug is stuck in place, leading to a decrease in fuel economy;

- Damage to Components: If the spark plug is stuck for too long, it can cause damage to other components, such as the cylinder head or valve stem;

- Excessive Wear: Repeated attempts to remove a stuck spark plug can lead to wear and tear on the threads of the spark plug or cylinder head;

- Premature Spark Plug Failure: A damaged spark plug may fail prematurely if not removed in time, leading to increased maintenance costs and wasted time;

- Broken Parts: If parts are broken during the attempted removal of a stuck spark plug, the repair costs could be significant and require replacement parts that may be expensive or hard to find;

- Engine Damage: If a stuck spark plug is not addressed quickly, it could lead to engine damage due to increased pressure or heat levels;

- Seized Engine: In extreme cases, the engine may seize up if the spark plug is left in place for too long. It can be catastrophic and lead to expensive repairs that may be difficult to complete.

Preparing for the Removal Process

Before you remove a stuck spark plug from an aluminum head, you should prepare and gather the necessary tools and materials. Taking safety precautions to prevent damage is also essential, as an improperly removed spark plug can cause damage to the engine and its components:

Gathering the Necessary Tools and Materials

The first step in removing a stuck spark plug is to gather the necessary tools and materials. It includes items like penetrating oil, an adjustable wrench or ratchet set, pliers, heat-resistant gloves, and protective eyewear.

Taking Safety Precautions to Prevent Damage

Take safety precautions when removing a stuck spark plug from an aluminum head. Ensure the area where you work is clear of debris or other potential hazards that could cause harm or injury. Wear protective eyewear and gloves to protect yourself from burns or other injuries caused by the spark plug or heat generated during removal. Ensure no flammable liquids are present in the area.

By properly preparing for the removal process, taking safety precautions, and gathering the necessary tools and materials, you can safely and effectively remove a stuck spark plug from an aluminum head without causing damage. With these tips in mind, you can avoid costly repairs and get your engine running again.

Step-By-Step Guide: Methods to Remove Stuck Spark Plugs

You can use several methods to remove a stuck spark plug from an aluminum head. Here is a step-by-step guide outlining the most common methods [3]:

Method 1: Soaking with Penetrating Oil

It includes the following steps:

Choosing the Right Penetrating Oil

When selecting a penetrating oil for removing a stuck spark plug, you should pick one that is suitable for aluminum surfaces and will not cause damage. It’s best to use an oil-based product like WD-40 or Liquid Wrench that can penetrate through rust and corrosion and help loosen the stuck spark plug.

Preparing and Applying the Penetrating Oil

Before applying the penetrating oil, make sure that the remaining debris on the spark plug is removed by wiping it off with a clean rag.

It will give the oil time to penetrate through rust or corrosion that may be preventing the removal of the stuck spark plug.Tools and Techniques for Removing the Stuck Spark Plug

Once you have applied the penetrating oil to the stuck spark plug, there are a few techniques and tools that can help in its removal. An adjustable wrench can be used to try and loosen the spark plug by gently rocking back and forth while applying pressure counterclockwise on the bolt head. A ratchet set may also be helpful if an adjustable wrench is unavailable. If these methods are unsuccessful, a rubber hammer can be used to gently tap around the edges of the spark plug to help loosen and remove it.

If the spark plug still does not budge, a stronger penetrating oil may be necessary or you can try using heat on the bolt head to further soften rust or corrosion that is preventing its removal. It is important to avoid applying too much heat, as it could damage the threads of the cylinder head or other engine components.

Once the stuck spark plug has been successfully removed, it is important to inspect it for wear and tear before replacing it with a new one. The threads of the spark plug and cylinder head should also be cleaned off before re-installing a new spark plug. Lastly, apply an anti-seize compound to ensure proper installation and prevent future sticking issues.

Method 2: Utilizing Heat

Applying heat to loosen the stuck spark plug is a useful method for removing a stuck spark plug from an aluminum head. Before proceeding, make sure the necessary safety precautions are taken to prevent potential damage.

Precautions to take while using heat

When applying heat to loosen a stuck spark plug, it is important to be mindful of the temperature range and how long the heat should be applied.

Applying too much heat can cause damage to the engine components or cylinder head threads, so it is best to use a low-temperature torch like a propane torch set on its lowest setting and only apply heat in short bursts until the spark plug loosens.

Tips for a successful removal process

When attempting to remove a stuck spark plug from an aluminum head using heat, the following tips should be kept in mind for a successful removal process:

- Make sure the area where you are working is clear of debris or potential hazards;

- Wear protective eyewear and gloves to protect yourself from potential burns or other injuries caused by the spark plug or heat generated during removal;

- Select a penetrating oil that is suitable for aluminum surfaces and will not cause damage;

- Apply the penetrating oil to the spark plug threads and let it soak for at least 15 minutes before trying to loosen the stuck spark plug;

- Use an adjustable wrench, ratchet set, or rubber hammer to try and loosen the stuck spark plug;

- If these methods fail, use a low-temperature torch in short bursts until the sparks plug loosens;

- Inspect the spark plug for wear and tear before replacing it with a new one

- Clean the threads of the spark plug and cylinder head before re-installing a new spark plug;

- Apply an anti-seize compound to ensure proper installation and prevent future sticking issues;

- If all else fails, take your car to a professional who can remove the stuck spark plug safely without causing damage.

Method 3: Utilizing a Spark Plug Removal Tool

It covers the following points:

Introduction to spark plug removal tools

A spark plug removal tool is an effective and efficient way of removing a stuck spark plug from an aluminum head. The tool works by threading the end of the tool into the cylinder head and gripping the stuck spark plug so that it can be safely and easily removed. This method requires less effort than other methods such as applying heat or using penetrating oil, which makes it ideal for those who don’t have access to specialized tools or materials.

Step-by-step instructions for using a removal tool

Using a spark plug removal tool is relatively straightforward. Here are some step-by-step instructions for efficiently and safely removing a stuck spark plug using a removal tool:

- Choose the correct size of the spark plug removal tool for your engine. Most engines use an M14 or M18 size spark plug removal tool;

- Apply some light lubricant such as oil to the threads of the cylinder head before inserting the removal tool. It will help ensure the threads on the cylinder head and tool do not get damaged during installation;

- Insert the threaded end of the removal tool into the cylinder head and turn it counter-clockwise until it grips the stuck spark plug;

- Gently wiggle and pull on the exterior handle of the removal tool while turning it counter-clockwise to loosen and remove the spark plug;

- Once the spark plug is removed, inspect it for wear and tear before replacing it with a new one.

Essential tips for efficient and safe removal

When using a spark plug removal tool to remove a stuck spark plug, following some essential safety tips can help ensure that the process goes smoothly:

- Make sure you are wearing safety goggles and gloves while attempting to loosen or remove a stuck spark plug;

- Select an appropriate size of removal tool for your engine’s cylinder head thread size;

- Apply a light lubricant such as oil to the threads of the cylinder head before inserting the removal tool;

- Be careful not to over-tighten the removal tool, as it could damage the threads of both the cylinder head and removal tool;

- Ensure that there are no flammable liquids present in the area where you are working before attempting to use the removal tool;

- If all else fails, take your car to a professional who can remove the stuck spark plug safely without causing damage;

- Clean the threads of both the spark plug and cylinder head before re-installing a new spark plug;

- Apply an anti-seize compound to ensure proper installation and prevent future sticking issues.

These tips should help you safely and efficiently remove a stuck spark plug from an aluminum head using a removal tool. Remember to always take the necessary safety precautions when attempting kind of repair or maintenance work on your engine. If in doubt, seek professional assistance.

Troubleshooting Common Challenges

If you are having trouble removing a stuck spark plug from an aluminum head, here are some common challenges to look out for [4]:

Dealing with broken spark plug porcelain or electrode

If the spark plug porcelain or electrode has broken off in the cylinder head, it can be tricky to remove. First, try using a spark plug extractor tool to grasp the broken piece of porcelain or electrode. If it fails, you may need to use a drill bit and drill out the broken piece from the cylinder head.

It should be done with caution to avoid damaging the threads of the cylinder head. Once you have removed the broken piece, use a tap and die set to clean up the threads of the cylinder head before reinstalling a new spark plug.

Extracting a broken or damaged spark plug

If the spark plug is stuck in the cylinder head due to corrosion or other damage, it may need to be extracted using a special tool such as an impact wrench or extractor socket for added torque. To do it, insert the appropriate-sized socket into your drill and attach it to the stuck spark plug. Then, turn on your drill and apply pressure until you feel the spark plug loosen. Once the spark plug is loosened, use an adjustable wrench or ratchet set to finish turning and removing it from the cylinder head.

Addressing stripped or damaged threads in the aluminum head

If you have stripped or damaged threads in the aluminum head when trying to remove a stuck spark plug, you may need to use a tap and die set to repair them. First, insert the appropriate-sized tap into your drill and carefully thread it into the damaged area of the cylinder head until all of the debris has been removed.

Then, use a die of matching size and thread it onto the cylinder head to restore its original shape and threading pattern. Clean the area with a solvent and lubricant before reinstalling a new spark plug.

FAQs

Can I use WD-40 to remove a stuck spark plug?

No, you cannot. WD-40 is not a suitable lubricant for removing a stuck spark plug. It can cause corrosion and other damage to the threads of the cylinder head, making it difficult to remove [5].

Do spark plugs need anti-seize in aluminum heads?

Yes, it is recommended to use an anti-seize compound on spark plugs in aluminum heads. It will help ensure proper installation and prevent future sticking issues.

How tight should spark plugs be in aluminum heads?

Spark plugs should be tightened to the manufacturer’s specifications in aluminum heads. It will ensure proper installation and prevent leaks or other issues [6].

Can I use penetrating oil on stuck spark plugs?

Yes, you can use penetrating oil on stuck spark plugs. It will help to loosen the plug from the cylinder head and make it easier to remove. Make sure to apply a light coat of oil to the threads of the cylinder head before inserting the removal tool.

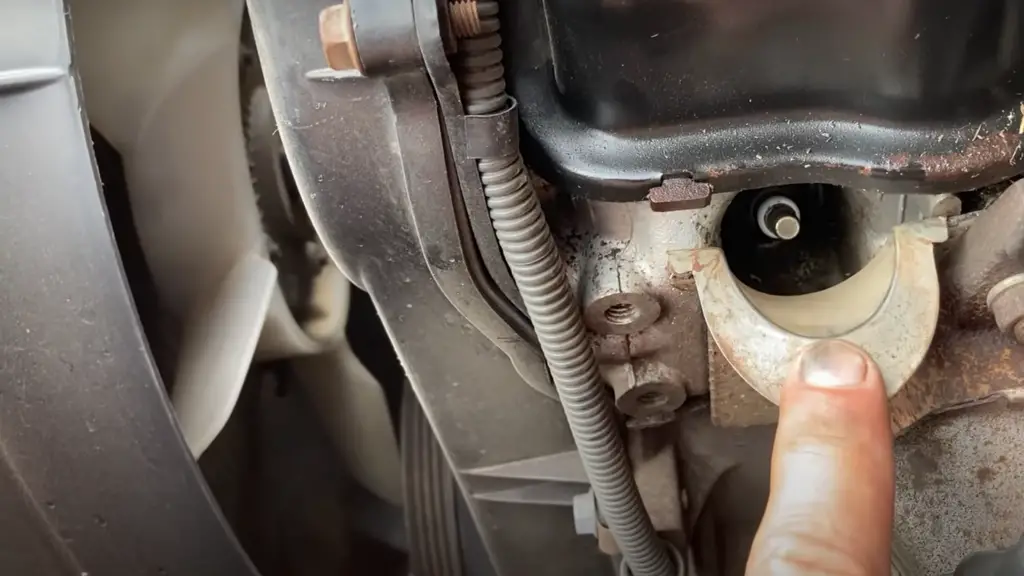

Useful Video: How To: Remove Seized Spark Plugs

Conclusion

Removing a stuck spark plug from an aluminum head can be challenging without the right tools and safety precautions. Using a spark plug removal tool is the safest and most effective way to remove a stuck spark plug, but it is important to select an appropriate size of removal tool for your engine’s cylinder head thread size. Use the tips above to safely and efficiently remove a stuck spark plug from an aluminum head using a removal tool. Remember to always take the necessary safety precautions when attempting kind of repair or maintenance work on your engine.

References:

- https://vehiclefreak.com/how-to-remove-a-stuck-spark-plug-stubborn-seized-and-fused-plugs/

- https://www.startribune.com/an-engine-in-a-sticky-situation-dealing-with-a-stuck-spark-plug/125912833/

- https://drivenowautomotive.com/how-to-remove-spark-plugs-that-are-stuck/

- https://www.underhoodservice.com/spark-plug-replacement-problems-and-preventive-measures/

- https://www.housedigest.com/1331575/use-wd-40-hack-for-removing-spark-plugs/

- https://ngksparkplugs.com/en/resources/spark-plug-installation/