Purple tungsten is a rare metal that can be used for a variety of purposes. It is often used in jewelry and other decorative items, but it also has several industrial uses. This metal features a striking violet hue, which makes it a popular choice for ornamental pieces. Additionally, its high melting point and low coefficient of thermal expansion make it ideal for use in electrical contacts and other components that need to withstand extreme temperatures. This blog post will discuss some of the most common uses for purple tungsten. It will also talk about why this metal is so special, and why it is becoming more popular every day!

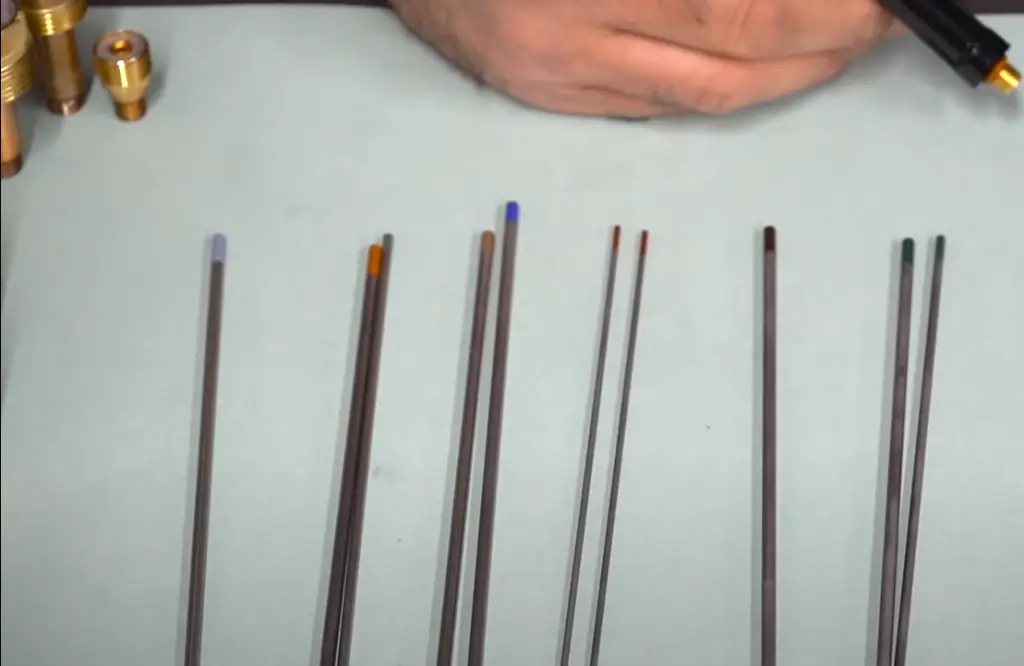

Tungsten Color Coding: What’s the Deal?

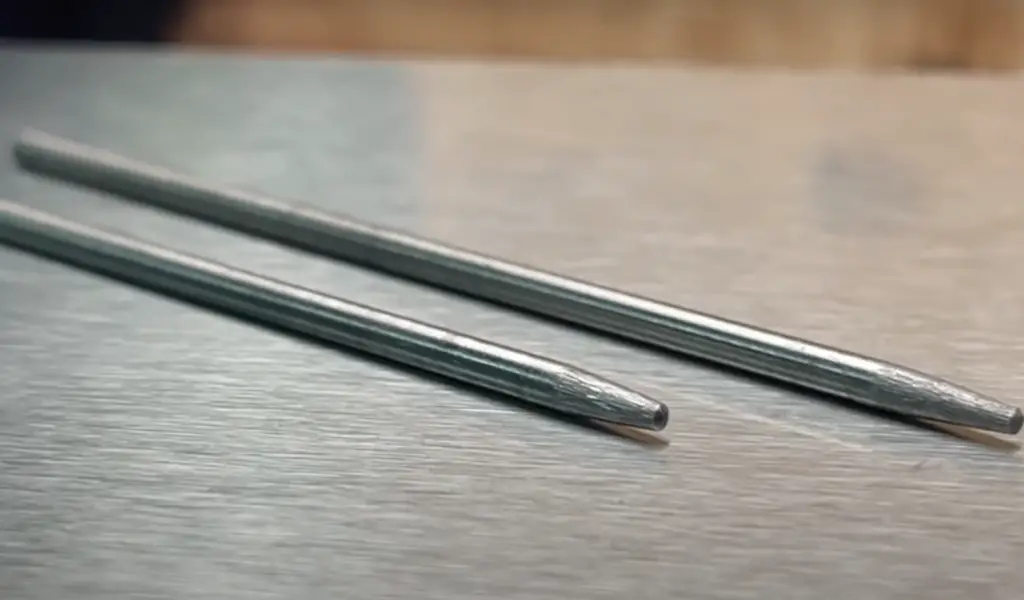

When it comes to selecting tungsten for TIG welding, the color coding system is a great starting point. Different colors are used to indicate various alloys and sizes of tungsten electrodes for the specific type of welding job at hand.

Green – Thoriated tungsten, also known as Red Tungsten (2% thorium)

These electrodes contain 2% thorium, which helps create higher temperatures when welding than other types of tungstens.

This makes them ideal for high-amperage welding projects where heavy penetration is needed as well as general-purpose AC/DC welding jobs.

Gold/Yellow – Pure Tungsten (WP)

Pure tungsten can be used for a variety of AC/DC welding projects, including those that require soft penetration.

Yellow – Ceriated Tungsten (CeO2)

These electrodes contain 1% cerium oxide, making them ideal for lower amperage TIG welding jobs on thin materials like stainless steel, aluminum, and magnesium. CeO2 is also the preferred choice when welding with DC current since it maintains a stable arc at both low and high speeds.

Gray – Lanthanated Tungsten (La2O3)

Lanthanated tungsten contains 2% lanthanum oxide, which provides extra arc stability and a higher current carrying capacity than other types of tungsten. It is often used with both AC/DC welding projects, making it an extremely versatile choice for many welders.

Red – Zirconiated Tungsten (ZrO2)

This type of tungsten contains 1% zirconium oxide, which helps to reduce arc wander and spatter. It is a great choice for welding aluminum, magnesium, and stainless steel with AC current.

White – Rare Earth Tungsten

Also known as Multi-Strike tungsten, this type of electrode combines three rare earth oxides – cerium, lanthanum, and yttrium – to create increased electrical conductivity and arc stability without overheating or damaging the base material. It works well on both AC/DC welding projects.

Orange – Silicon Tungsten (Si2O3)

These electrodes contain 2% silicon oxide, making them ideal for AC welding jobs on stainless steel, aluminum, and magnesium. Silicon tungsten also works well with DC current and is often used by beginning welders due to its low burn-off rate.

Brown -Rare Earth Molybdenum (RE 2 O3)

These electrodes contain 2% rare earth oxides, making them a great choice for welding aluminum and magnesium. They provide increased arc stability and electrical conductivity, as well as improved resistance to wear. RE 2 O3 is also a good option for TIG welding with DC current.

Purple -Tungsten-Lanthanum (La2O3)

This type of electrode contains 1% lanthanum oxide, making it a great choice for TIG welding on aluminum and stainless steel. It is often used with both AC/DC welding projects, making it an excellent all-purpose tungsten.

Understanding the different colors associated with each type of tungsten will help you choose the right electrode for your TIG welding job.

With this knowledge in hand, you’ll be able to confidently select the perfect tungsten electrodes for any TIG welding job [1].What is Purple Tungsten used for?

Purple tungsten is most commonly used in a variety of industrial and commercial applications. Its unique color allows it to stand out from other metals, making it ideal for decorative purposes, such as jewelry and watch parts. It is also used in the production of electrical contact points and components, such as switches and connectors.

Additionally, purple tungsten is an effective material for radiation shielding due to its high density and superior corrosion resistance. Furthermore, purple tungsten can be used in various forms of welding and machining operations because of its strength and durability.

Finally, it is sometimes employed as a protective coating on many items that require additional protection from elements such as moisture or heat. As you can see, there are numerous uses for purple tungsten in a variety of different industries.

This versatile metal has the potential to be a powerful force in many applications, so it is worth considering if you need an effective material that is both durable and attractive. Purple tungsten can provide an interesting way to add color and texture to your project while providing practical benefits. With its strength, longevity, and stylish appearance, this could be the perfect choice for your next project [2]!

Effects of Different Tungsten Components

Tungsten can be used to create a variety of products and components, each of which has its unique effects.

Its extreme hardness makes it ideal for making precision parts that require intense wear resistance.Tungsten alloys are composed of tungsten combined with other metals such as nickel, iron, or cobalt. These alloys are extremely strong and durable and are ideal for use in high-temperature applications due to their excellent thermal conductivity.

Another common component made from tungsten is tungsten wire. Tungsten wire is used in a variety of industrial and medical applications due to its extremely high melting point, making it resistant to extreme heat.

Finally, tungsten can also be used to create filaments for light bulbs. Tungsten filaments are an efficient choice because they burn brighter than other types of filaments while using less energy.

Overall, tungsten components have many unique benefits depending on their application. From machining operations to lighting applications, each type of tungsten component has its own set of advantages and disadvantages that should be taken into consideration when selecting the appropriate material for your needs [3].

Green vs Purple Tungsten

Tungsten is a hard, brittle metal found in various alloys and used for different applications. It has a wide range of uses in industry and has been utilized for centuries as a material for jewelry, tools, and more. As one of the strongest metals available, it has many advantages over other materials, such as its ability to maintain an extremely high temperature without becoming soft or altering its molecular structure.

Green tungsten is the result of adding oxygen to the compound during manufacturing. When exposed to air, green tungsten oxidizes quickly and may form discolored layers on its surface. This oxidation can cause an uneven finish on the material that makes it difficult to work with. However, green tungsten also provides greater resistance to corrosion than regular tungsten.

In comparison, purple tungsten is created by adding sulfur and phosphorus during manufacturing instead of oxygen. It has a higher melting point and more tensile strength than green tungsten, making it more suitable for applications that require extreme heat or pressure. Purple tungsten also offers superior electrical conductivity, making it an excellent choice for electrodes in various equipment used in the electronics industry. Additionally, purple tungsten is highly resistant to corrosion and tarnishing, so it can last much longer without any significant deterioration.

Overall, although both green and purple tungsten have their advantages and disadvantages, they are both important materials used extensively in the industrial world today. Whether you need a durable material for your jewelry or dependable electrodes for precision equipment, both green and purple tungsten are excellent choices. Ultimately, the best option for you will depend on your specific needs and requirements.

DIY projects that need purple tungsten

You may need purple tungsten for different DYI projects. One way that purple tungsten can be used is in jewelry making. Purple tungsten can be used to create beautiful rings, necklaces, and earrings. It is a striking color that adds a unique touch to any piece of jewelry. Additionally, purple tungsten is extremely durable and long-lasting due to its hardness. This makes it an excellent choice for pieces of jewelry that you want to last for years to come.

Another use for purple tungsten is in woodworking projects. It can be used as an inlay or edging material for furniture and cabinets, giving them a distinctive look. It can also be used as an accent on small wooden objects such as boxes or trays. In addition, purple tungsten is a very versatile material and can be used for many different types of projects.

Finally, purple tungsten can also be used for arts and crafts projects. It can be used to create unique decorations or as an accent color in paintings or prints. Its rich hue will add depth and interest to any project, giving it a luxurious look that’s sure to impress. With its versatility and long-lasting durability, purple tungsten is the perfect material to use for your next DIY project.

Advantages of Purple Tungsten

In addition to its stunning appearance, purple tungsten has many other advantages that make it an ideal choice for jewelry and other decorative items.

First, purple tungsten is highly durable and scratch resistant. This makes it ideal for use in a wide range of wearables, from watches to rings and bracelets. Its hardness also ensures that your jewelry will not easily become scratched or damaged with everyday wear.

Second, purple tungsten is hypoallergenic, making it a great choice for those with sensitive skin who are looking for beautiful jewelry pieces without the worry of an allergic reaction.

Finally, purple tungsten has a very low thermal conductivity which makes it perfect for both cold and warm climates; this allows you to enjoy your jewelry no matter the season! Additionally, its non-toxic properties make it a safe option for jewelry and decorative pieces.

Overall, purple tungsten is an ideal choice for those looking to add a unique and stunning splash of color to their wardrobe. With its durability and low maintenance requirements, it makes the perfect addition to any collection.

FAQ

Can purple tungsten be used for mild steel?

No, purple tungsten cannot be used for mild steel. This type of tungsten is typically used for aluminum and magnesium alloys because it has a higher melting point than other tungsten grades. It can also be used for hard-facing applications where high abrasion resistance is required.

However, due to its higher melting point, it would not be suitable for welding mild steel as the heat generated would risk warping or damaging the material. For welding mild steel, a standard grey grade of tungsten should be used instead.

Can you use purple tungsten to weld aluminum?

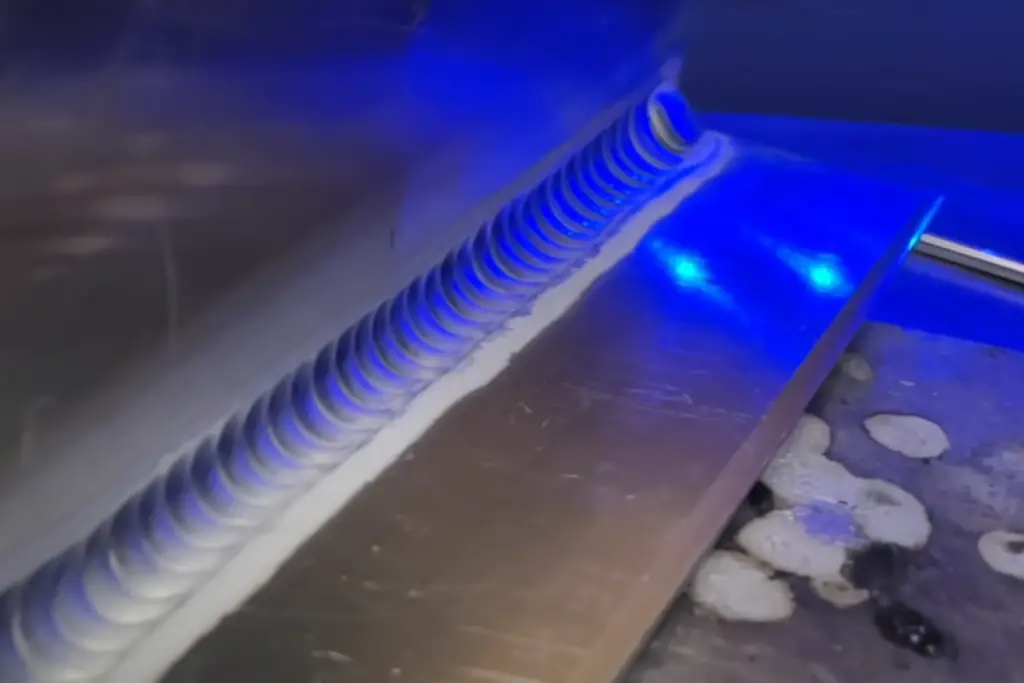

Yes, purple tungsten is a great choice for welding aluminum. Its higher melting point makes it ideal for the temperatures required to weld aluminum alloys. Additionally, because it has a higher abrasion resistance than other grades of tungsten, it can help reduce tip erosion during extended use and ensure better consistency in the welds.

What grade of tungsten should be used for stainless steel?

For welding stainless steel, a Ceriated or Lanthanated grade of tungsten should be used instead of purple tungsten. Ceriated and Lanthanated grades have lower melting points than purple tungsten which make them more suitable for welding stainless steel material without risking damage from excessive heat generated by the arc. Additionally, these grades also have better current carrying capacity than other tungsten grades which helps with maintaining a stable arc.

What is the best way to maintain and care for purple tungsten?

To ensure optimal performance and life span of your purple tungsten, proper maintenance and handling are key. First and foremost, always use the correct grade of tungsten for your specific application. Secondly, be sure to keep it clean from any debris or foreign particles that could contaminate the weld. Finally, properly store your purple tungsten in a dry place away from extreme temperatures when not in use – this will help it last longer and perform better when you need it most!

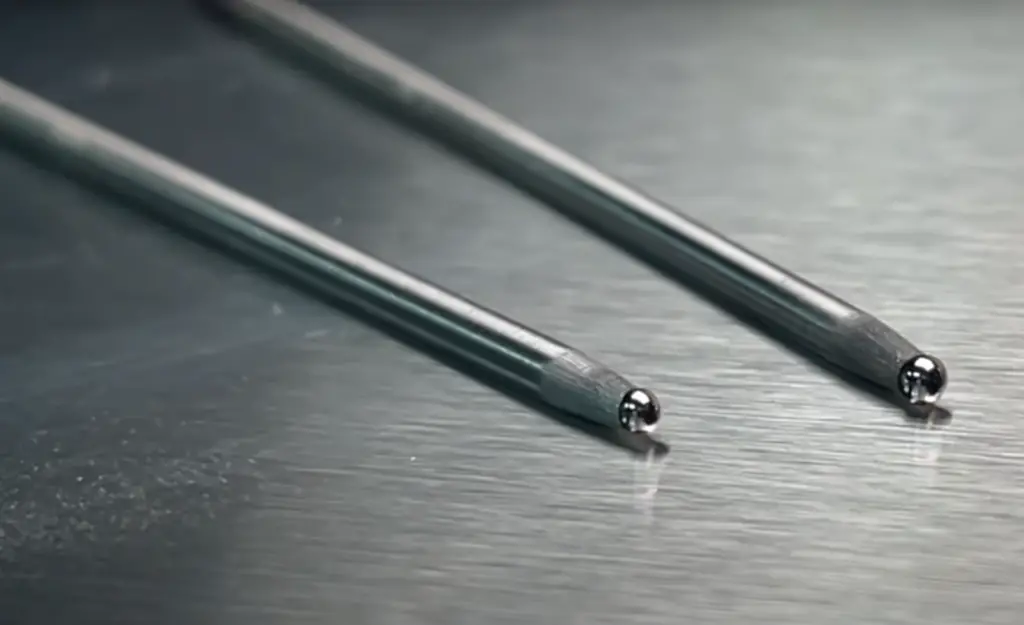

What is a purple TIG electrode?

A purple TIG electrode is a type of tungsten electrode that is specifically designed for use in Tig welding applications. It has a higher melting point than other types of tungsten electrodes which makes it better suited to welding aluminum and magnesium alloys, as well as hard-facing applications where high abrasion resistance is required. Additionally, purple tungsten electrodes also have higher arc stability than standard grey-grade electrodes due to their increased current carrying capacity.

What are the benefits of using a purple tungsten electrode?

The primary benefit of using a purple tungsten electrode over standard grey-grade electrodes is its higher melting point which allows it to handle the elevated temperatures necessary for welding aluminum and magnesium alloys without causing warping or damage to the material. Additionally, its higher current carrying capacity and abrasion resistance make it ideal for hard-facing applications as well as providing better arc stability and consistency in the welds.

Are purple tungsten electrodes more expensive than standard grey-grade electrodes?

In general, purple tungsten electrodes will often be more expensive than their gray-grade counterparts due to their increased performance capabilities. However, this cost may be offset by the improved quality of the weld produced as well as the fact that less electrode tip erosion is experienced during use due to its higher melting point. As such, many welding professionals believe that purple tungsten electrodes are worth the additional investment when compared to grey-grade electrodes.

Is purple tungsten radioactive?

No, purple tungsten is not radioactive. It does contain trace amounts of thorium and carbon, but these are present in such small quantities that they do not pose any health or safety hazard to those working with the material. Purple tungsten has been used for medical imaging and radiation therapy for several decades due to its low-level radioactivity. As such, it is perfectly safe to work with when handled correctly and stored away from extreme temperatures.

What color is pure tungsten?

Pure tungsten is actually a silver-grey color. It can range from darker shades of grey to almost white depending on its purity and the manufacturing process used. Additionally, some manufacturers may coat their tungsten electrodes with other materials such as ceramic or diamond which can give them a variety of different colors. Purple TIG electrodes are usually composed of a mixture of thorium and carbon which gives them their distinctive purple color.

What color tungsten is best for stainless steel?

For welding stainless steel, grey-grade tungsten electrodes are generally the best choice. Grey-grade electrodes have a lower melting point than purple tungsten and thus will not overheat the material during welds.

Alternatively, if you need higher current carrying capacity and abrasion resistance for your welds, a purple tungsten electrode may be preferable as it can handle these conditions better than a grey-grade electrode. Ultimately, the decision of which type of tungsten electrode to use should be based on your specific application requirements.

What can Purple tungsten weld?

Purple tungsten electrodes are suited to welding aluminum and magnesium alloys, as well as hard-facing applications where high abrasion resistance is required. Additionally, they can also be used to weld steel and other ferrous metals depending on the specific application requirements. As with any type of TIG welding, it is important to use the correct amperage setting for the particular material being welded to produce a strong weld that is free from defects or imperfections.

What is pink tungsten used for?

Pink tungsten electrodes are a type of tungsten electrode composed of thorium and cerium, which gives them their distinctive pink color. They are typically used for welding low alloy steels, stainless steel, and cast iron. Pink tungsten electrodes offer increased arc stability and better weld characteristics than grey-grade or purple tungsten due to the lower melting point of their alloy composition. Additionally, they can also be used on aluminum alloys where a higher current carrying capacity is required.

What color of tungsten for aluminum?

For welding aluminum, a purple tungsten electrode is the best choice. This type of electrode has a higher melting point which means it will not overheat the material while welding. Additionally, its increased abrasion resistance makes it ideal for hard-facing applications where high wear and tear is expected. When using any type of tungsten electrode, it is important to select an amperage setting that is appropriate for the specific material being welded in order to achieve optimal results.

What is orange tungsten for?

Orange tungsten is a type of tungsten electrode composed of thorium and lanthanum, which gives it its distinctive orange color. It is primarily used for welding high-temperature materials such as copper alloys and stainless steel. Orange tungsten electrodes offer improved arc stability and better weld characteristics than other types of tungsten due to the lower melting point of their alloy composition. Additionally, they can also be used on aluminum alloys where a higher current carrying capacity is required.

How to choose tungsten according to its color?

When selecting the right tungsten electrode for your welding applications, it is important to consider the color of the tungsten as well. Generally, grey-grade electrodes are best suited for carbon steel and stainless steel, purple electrodes are suitable for aluminum and magnesium alloys, pink electrodes can be used on low alloy steels and cast iron, and orange electrodes are ideal for copper alloys and stainless steel.

Additionally, always ensure that you use an amperage setting that is appropriate for the material being welded to achieve optimal results. Finally, keep in mind that some manufacturers may coat their tungsten electrodes with other materials such as ceramic or diamond which can give them a variety of different colors so make sure to double-check the electrode’s composition before making your selection.

Useful Video: Ep. 22 What is Tungsten Used for?

Conclusion

Purple tungsten is a unique and versatile material with many potential applications. Its properties make it an attractive option for use in a variety of industries, particularly those that require precise temperature control or electrical conductivity. The ability to tailor the color of this material makes it even more desirable, allowing companies to create products with a distinct and custom look. With further research and development, purple tungsten could become an invaluable resource for businesses around the world.

References:

- https://www.kovinc.com/welding/color-of-a-tungsten-electrode

- https://benchmarkabrasives.com/blogs/news/what-is-purple-tungsten-used-for

- https://www.memuk.org/infrastructure/fabrication/a-guide-to-tungsten-electrodes-60506