Are you looking for a durable and reliable material to use for your construction projects? Look no further than the titanium nail. Often used in medical, aerospace, and military fields for its strength and resistance to corrosion, titanium nails have recently become a popular choice for construction projects as well. However, if you’re new to using titanium, you may be wondering where to start. In this beginner’s guide, we’ll explore the benefits of using a titanium nail in construction and provide tips on how to use it effectively.

Titanium: Why It Is The Best Option

Titanium is a metal that has been growing in popularity over the past few years. It has become a popular option for numerous industries because of its unique characteristics. Many industrialists and designers are starting to appreciate the advantages of titanium in comparison to some other metals like aluminum and steel. In today’s blog post, we will check some facts which prove titanium to be the best option and why it should be your go-to metal for various applications.

- Strength and Durability. One of the primary reasons why titanium is the best option is its strength and durability. It is one of the strongest and most robust natural metals, as a result it is really useful for long-lasting applications. This metal is also really durable and can resist high levels of wear and tear.

- Lightweight. Another significant advantage of using titanium is that it is lightweight. This property makes it a popular option for products like sports equipment, aircraft parts, and other applications where weight is a crucial factor. In comparison, some other metals such as steel and aluminum are substantially heavier, making them less suitable for some industries.

- High-Temperature Resistance. Titanium is also highly resistant to high temperatures and can operate in environments where temperatures reach up to 1650 degrees Celsius. This makes it the perfect material to use in high-temperature industries like the aerospace and automotive industries. It can also work in harsh environments without the risk of breaking down, such as oil rigs and other industrial plants.

- Critical Medical Applications. Many researchers and medical professionals have also been researching and finding the advantages of using titanium for various medical applications. Titanium is highly biocompatible and is not rejected by the body. This makes it ideal for creating medical implants, such as bone replacement, knee, and hip implants. It is also successful in surgical instruments like dental instruments.

- Environmental-Friendly. Titanium differs from other metals,as it is recyclable and environmentally friendly. Recycling titanium saves money and energy while reducing the environmental impact. It can be remelted, processed, and reused in the manufacture of other products, reducing the cost of further production and waste disposal.

Titanium is unquestionably the best option for various industrial, medical, and commercial applications. From its strength and durability to its high-temperature resistance, lightweight, and biocompatibility, it has unique advantages that make it unmatched when it comes to many applications. Additionally, it is cost-effective and environmentally friendly. It is no wonder that its prospects in various industries continue to grow. So, if you’re thinking of using a metal that will offer you durability, strength, lightweight, biocompatibility, and environmental-friendliness, titanium is the best option for you!

Properties of Titanium

Titanium is a fascinating metal known for its unique properties and abilities. It is highly valued for its strength, durability, and resistance to corrosion, making it an ideal choice for a variety of applications. From the aerospace industry to medical implants, titanium has become an essential material for many fields. Let’s explore the properties and features of titanium that make it one of the most sought-after metals in the world.

High Strength and Low Density

One of the most significant properties of titanium is its strength-to-density ratio. It has the highest strength-to-weight ratio of any metal, allowing it to withstand extreme pressures and loads while remaining light. Titanium’s strength also improves with temperature, making it an excellent choice for high-temperature applications. Its low density means that it is easy to work with, making it suitable for a wide range of manufacturing processes.

Corrosion Resistance

Another advantage of titanium is its exceptional resistance to corrosion. This property is mainly due to the formation of a protective oxide layer on the surface of the metal when exposed to air or water. This layer prevents the metal from reacting with its environment and breaking down over time. As a result, titanium can withstand long-term exposure to harsh chemicals, saline environments, and high temperatures without degrading.

Biocompatibility

The medical industry has embraced titanium for its biocompatibility, which means it is inert and non-toxic to the human body. It is an excellent choice for medical implants, such as dental implants, because it can bond with human bone and tissue. Additionally, titanium has been used in prosthetics, pacemaker cases, and orthopedic implants due to its robustness and ability to withstand the harsh internal environment of the body.

Ductility and Workability

Titanium is highly ductile, which means it can be shaped, bent, and formed without cracking or breaking. This quality makes it an ideal metal for manufacturing products that require intricate designs. Titanium is also easy to work with, and it can be cut, welded, and machined using conventional tools and techniques. As a result, it is a popular material for applications that require complex shapes and designs. [1]

Thermal Stability

Titanium has excellent thermal conductivity, making it a popular metal for applications that require heat transfer. It can withstand high temperatures without melting or degrading, making it an ideal material for jet engine and gas turbine components. Its ability to dissipate heat quickly also makes it a popular material for cookware and other kitchen appliances.

Titanium is a versatile metal with a unique set of properties and abilities that make it ideal for a wide range of applications. Its strength, corrosion resistance, biocompatibility, ductility, workability, and thermal stability have made it a popular choice for use in the aerospace, medical, automotive, and industrial sectors. As we explore new frontiers and develop new technologies, titanium is sure to play a vital role in supporting our needs and advancing our capabilities.

The Application of Titanium Nails

Among the latest advancements in construction materials are titanium nails, which have been found to be much stronger than traditional nails made of steel, copper, or aluminum.

First, let’s review some of the key properties of titanium that make it such a great choice for construction. Titanium is incredibly strong and resistant to corrosion, which means it can withstand harsh conditions, even in coastal areas or high-traffic buildings. It’s also lightweight, so it’s easier to handle and less likely to add unwanted weight to a structure. When it comes to nails, titanium is particularly useful because it has a high strength-to-weight ratio, which means it’s much stronger than other metals at the same weight.

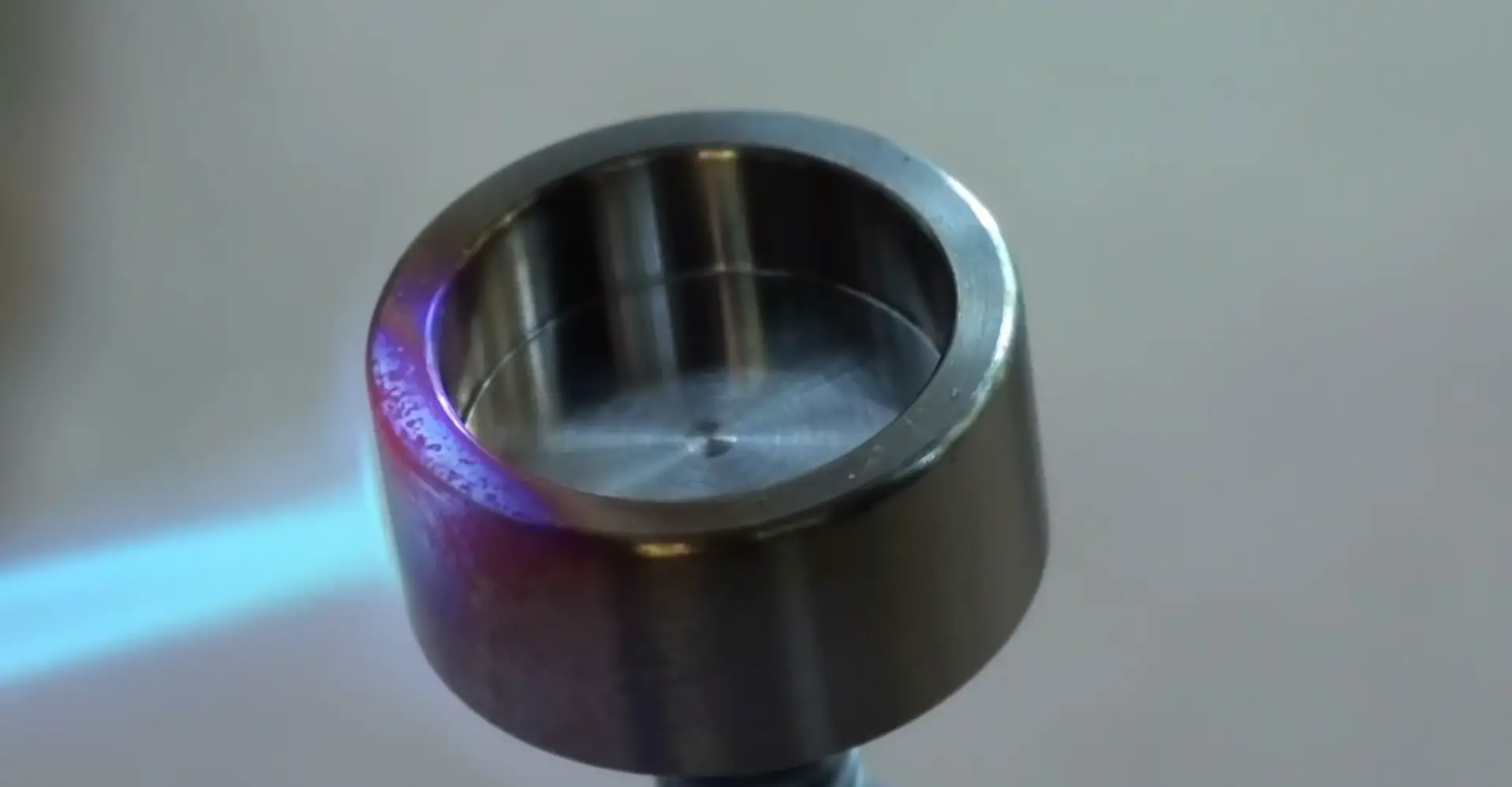

So, how do titanium nails work? The process is fairly simple: a titanium wire is drawn and rolled into the shape of a nail, which is then heat-treated to harden the metal. The result is a nail that is incredibly strong, with a much higher resistance to bending and breaking than traditional nails. For contractors and DIY enthusiasts alike, this means that they can use fewer nails per board or beam since each nail can hold more weight and withstand greater tension.

But what about the cost? While titanium nails are generally more expensive than traditional nails, they offer significant cost savings over time due to their longevity. They’re much less likely to corrode or break, which means that they don’t need to be replaced as often as other types of nails. Additionally, because fewer titanium nails are needed per board or beam, labor costs may also be lowered. In the end, investing in titanium nails can pay off in the long run through lower maintenance and replacement costs.

Even though titanium nails are relatively new to the construction industry, they’re quickly gaining popularity due to their many advantages. By using titanium nails, contractors and DIY enthusiasts can take advantage of the strength, durability, and safety that titanium provides. Though it may be a bit more expensive upfront, it’s well worth the investment given their long lifespan and reduced need for replacements. In the end, it’s clear that titanium nails are the future of construction.

The Complete Guide to Using a Titanium Nail for Construction

In the world of construction and carpentry, having the right tools is crucial to achieving quality results in your work. One such tool that has become increasingly popular in recent times is the titanium nail. This durable and corrosion-resistant nail is a game-changer in the world of construction, offering a level of accuracy and strength that other nails cannot match. However, using a titanium nail requires some know-how, and that’s where this guide comes in.

Understanding the properties of titanium nails

Before you can use titanium nails effectively, it’s important to understand their properties. Titanium nails are incredibly strong, durable, and corrosion-resistant, making them an excellent choice for construction and carpentry work. They are also lightweight and easy to handle, allowing for precise placement and minimal errors. Additionally, titanium nails are perfect for work in high-temperature environments, as they do not become brittle or melt under intense heat.

Preparing surfaces for titanium nails

Before you start using titanium nails, it’s crucial to ensure that the surfaces you’re nailing into are clean and free of debris. This will ensure that the nail can be inserted correctly, reducing the chance of damage to the nail or the surface it’s being nailed into. If the surface is rough or uneven, you may need to sand it down or use a leveling compound to create a smooth, even surface for the nail.

Inserting and positioning the nail

When using titanium nails, it’s important to take care when inserting them into the surface. Hold the nail firmly and position it at the desired angle, then gently tap it into the surface using a hammer or nail gun. If you’re using a hammer, be sure to hold it at the right angle and use just enough force to avoid bending the nail or damaging the surface.

Securing and finishing the nail

Once the nail is in place, use a finishing nail to secure it in place. This will ensure that the nail stays in place and does not loosen over time. You can then use a filler or putty to cover up any gaps or holes around the nail, achieving a smooth and seamless finish. Finally, sand down the surface to create an even finish, and paint or finish as desired.

Maintenance and care for titanium nails

Like any other tool, titanium nails require proper maintenance to perform effectively. After use, clean the nail thoroughly to remove any debris or dirt. If the nail becomes damaged or bent, replace it with a new one to avoid placing unnecessary strain on the nail or the surface it’s placed into. Store your titanium nails in a dry and clean location, away from moisture, to prevent rust or corrosion.

Using a titanium nail for construction requires a bit of patience, skill, and knowledge. However, with some practice and a thorough understanding of the properties and usage of titanium nails, you can achieve excellent results in your work. By using this guide, you can ensure that you’re maximizing the potential of your titanium nail and creating quality finished projects in your work. Start using your titanium nail today with confidence and become a master in your construction tasks!

Benefits And Drawbacks of Titanium Nails

Titanium is a highly popular metal used in various industries, including construction. One of the most common ways in which titanium is used in construction is in the form of nails. Titanium nails are known for their exceptional strength, durability, and resilience, making them a popular choice among builders, contractors, and homeowners. However, like any other material, titanium nails also have their fair share of drawbacks.

Benefits of titanium nails:

Titanium nails offer several advantages over traditional nails made from steel or other metals. First and foremost, titanium nails are incredibly strong and can withstand a great deal of pressure and weight. They are designed to hold up against various environmental factors, including harsh weather conditions, high humidity, and extreme temperatures. This strength and durability make titanium nails a preferred choice in construction, especially in areas that are prone to natural disasters such as earthquakes and hurricanes.

Finally, one of the most significant benefits of titanium nails is their lightweight. Titanium is much lighter than steel or other metals, making it an ideal choice for construction projects where weight is an issue. Lighter nails can reduce the overall weight of the structure, making it easier to transport, install, and move if necessary. The lightweight property of titanium nails also makes them easier to handle and use, which can reduce the risk of injury during construction.

Drawbacks of titanium nails:

One of the primary drawbacks of using titanium nails is their cost. Titanium is an expensive metal, and so titanium nails are more expensive than traditional nails made from steel or other metals. This added cost can deter some builders and contractors from using titanium nails, especially if they are working within a tight budget. Additionally, titanium nails can be difficult to find, as they are not as common as traditional nails.

While titanium nails are durable and resilient, they are also more challenging to work with than traditional nails. Titanium is a hard metal, which makes it difficult to drive nails into wood or other building materials. This can make it challenging for builders and contractors to work with titanium nails, especially those who are not experienced in using them. Additionally, it takes longer to install titanium nails than traditional nails, which can add to the overall cost of the project.

FAQ

How do titanium nails work?

So, how exactly do titanium nails work? To put it simply, they work just like regular nails, but with the added benefits of titanium. Titanium is a metal that is incredibly strong and corrosion-resistant, meaning that it won’t rust or weaken over time. This makes it an ideal material for use in construction, where the elements can take a toll on traditional materials like steel. In addition to their strength and durability, titanium nails are also much lighter than traditional steel nails.

How are titanium nails made?

The process begins with a piece of raw titanium that is heated up and forged into the desired shape. The nails are then cut to size and polished before being packaged and sold. Because of the strength and durability of titanium, these nails can last for years without needing to be replaced.

Can you overheat titanium?

While titanium is a highly resilient material that is well-suited for high-temperature applications, it is not invincible to overheating. By understanding the factors that influence the heat resistance of titanium, as well as the potential consequences of overheating, engineers and other professionals can take steps to prevent damage and ensure optimal performance of titanium components. Whether you’re working with titanium in aerospace, medical, or industrial applications, it’s important to be aware of the risks of overheating and take appropriate precautions to avoid them.

At what temperature does titanium soften?

Understanding the softening temperature of titanium is crucial to ensure its mechanical properties are maintained even at high temperatures. Factors such as its composition, impurities, and manufacturing process can affect the softening temperature of titanium. Combining its unique properties, high strength-to-weight ratio, and good corrosion resistance, titanium can be used in various applications and industries. Its high cost may deter some manufacturers from using it, but its unique properties make it the ideal choice for many critical applications.

Does heat weaken titanium?

The answer is yes, depending on the type of titanium and the environment in which it is used. Titanium alloys such as Ti-6Al-4V and Ti-6Al-4V ELI can handle higher temperatures than pure titanium, but even they can weaken and become susceptible to alpha-case layer formation if exposed to temperatures exceeding 300°C. When using titanium in high-temperature environments, it is essential to consider the specific application and to ensure that the metal is properly heat-treated and protected from oxidation or contamination. Heat treatment can be an effective way to enhance titanium’s performance, but it must be done correctly to avoid weakening or other defects.

Useful Video: 7 Things You Didn’t Know About Titanium | GCN Tech Does Science

Conclusions

If you’re looking for a strong, durable, and corrosion-resistant material for your construction projects, consider using a titanium nail. With the right preparation, installation, and maintenance, a titanium nail can provide long-lasting and reliable performance for your project. Whether you’re fastening, anchoring, or tying down materials, a titanium nail can provide the strength and security you need. So, next time you’re planning a construction project, remember to explore the benefits of using a titanium nail.

References:

- https://corelamps.com/en/elements/properties-of-titanium/#Physical_properties_of_titanium