Titanium is a remarkable metal which is increasingly used in various applications, such as medical, automotive, aerospace sphere, among others. However, drilling titanium can be tricky and challenging, even for experienced machinists. The material is notorious for its toughness, which can cause premature tool wear, chip clogging, and poor surface finish. In this blog post, we will provide you with essential tips and techniques to drill titanium more efficiently and effectively.

Titanium And Its Common Use

Titanium is a versatile metal that can be found in a variety of products we use every day. It is durable and lightweight, and as a result it is a perfect option for industries from aerospace to healthcare. In this guide, we’ll delve into the various ways titanium is used and why it is such a popular choice in manufacturing.

Aerospace Industry

Titanium is known to be a popular choice in aircraft manufacturing because it is strong as well as able to withstand high temperature. It is used to create some parts and structural components. Because of the fact that titanium is lightweight it is a great choice for space exploration, as it ensures that a spacecraft is lighter, thus making it more fuel-efficient.

Medical Industry

Titanium is highly biocompatible and is used to create medical implants such as hip replacements, dental implants, and spinal implants. This biocompatibility ensures that the material doesn’t reject the patient’s body and is also corrosion-resistant making it last longer inside the human body.

Jewelry Industry

Jewelry designers love to work with titanium due to its durability, light-weightness, and hypoallergenic properties. It is often used in making engagement rings because it can be easily customized, and it is also resistant to scratches and dents.

Sports Equipment

Titanium is used in sports equipment because it is really lightweight and strong which makes it a great choice for high-performance gear. Examples of equipment made from titanium include tennis rackets, bicycle frames and golf clubs. [2]

Automotive Industry

Automobile companies use titanium in the manufacturing of turbochargers, high-performance exhaust systems, and engine valves, among other components. Titanium’s strength and ability to resist corrosion mean that it’s ideal for building parts designed to last the life of a vehicle. [2]

In summary, the list of applications of titanium in various industries is extensive. From spacecraft to medical implants and jewelry, sports equipment, and automotive industry, titanium’s benefits have made it a desirable material. As sustainable technologies continue to emerge, titanium is expected to play a significant part.

Drilling Titanium: Step-By-Step Process

Drilling titanium can be a challenging task. Titanium is a tough and durable metal, and it requires a specific method to be drilled. If you are planning to drill titanium, you must follow a particular process to achieve the desired results.

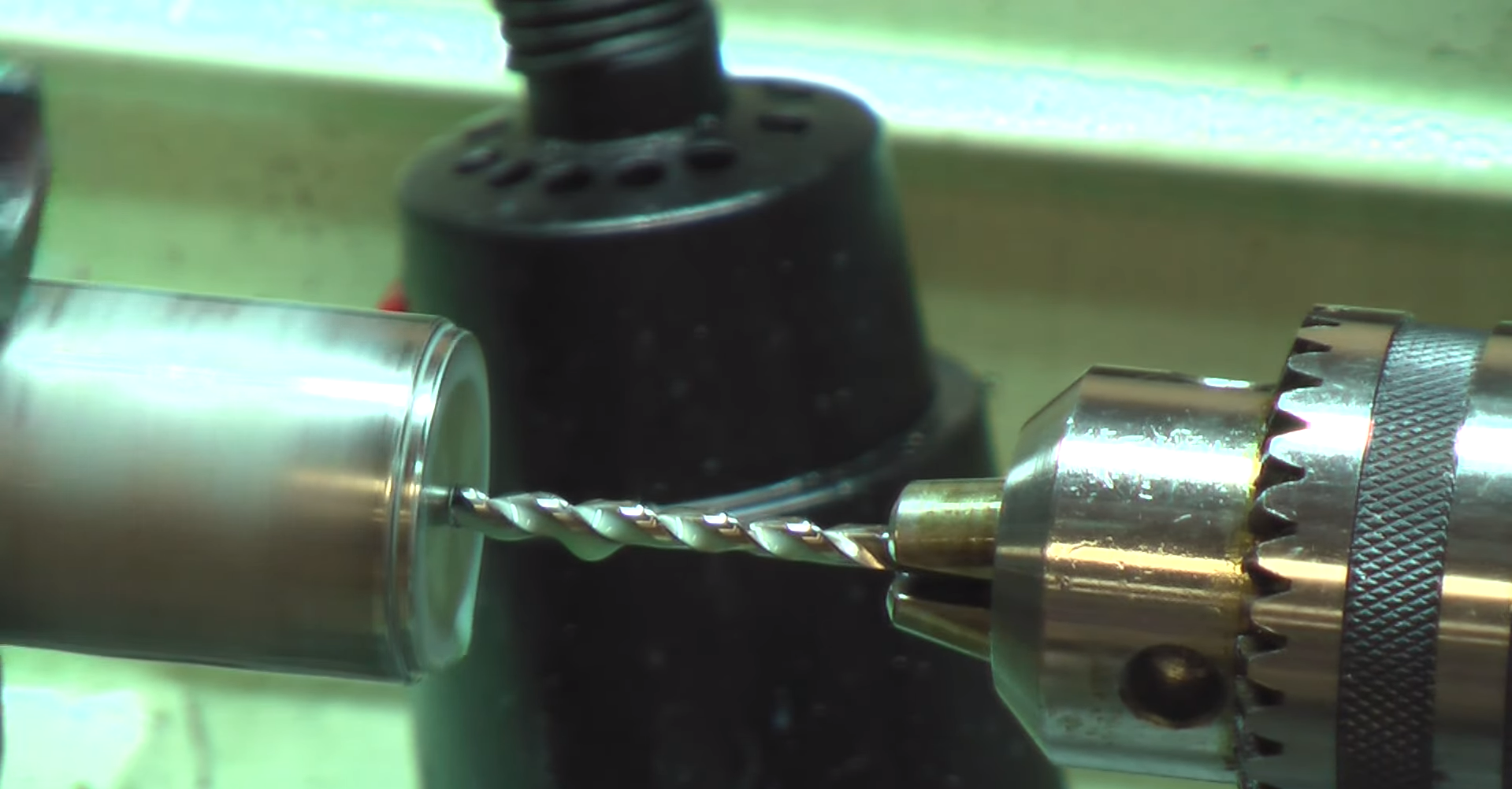

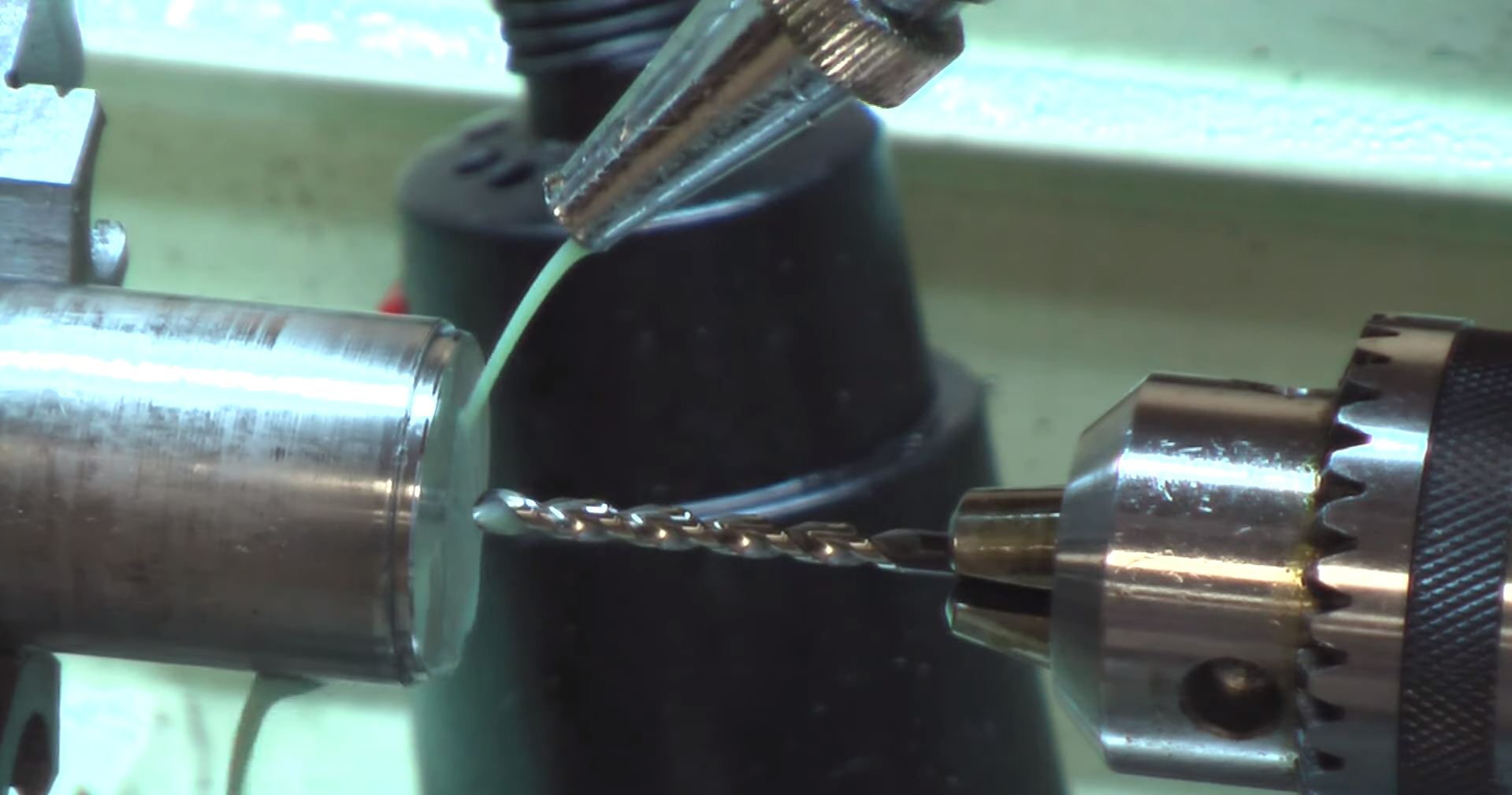

Step 1. Find the suitable drill bit

Titanium is a bit different from the rest of metals, as it needs a drill bit with a sharp and strong tip to cut through its tough surface. The best options here could be a high-speed steel drill and a carbide tipped one. You have to pay attention to its size as well, because if the size is bigger than needed the bit can dull, and if the size is smaller – the bit can break down.

Step 2. Prepare the titanium

Before drilling the titanium, it must be prepared. Cleaning the surface of the titanium is essential to eliminate any dust, debris, or rust that could damage the drill bit or disrupt the drilling process. Using sandpaper, clean the surface of the titanium to make it smooth and free of any imperfections. Also, make sure the titanium piece is clamped tightly to the workbench to avoid any movement.

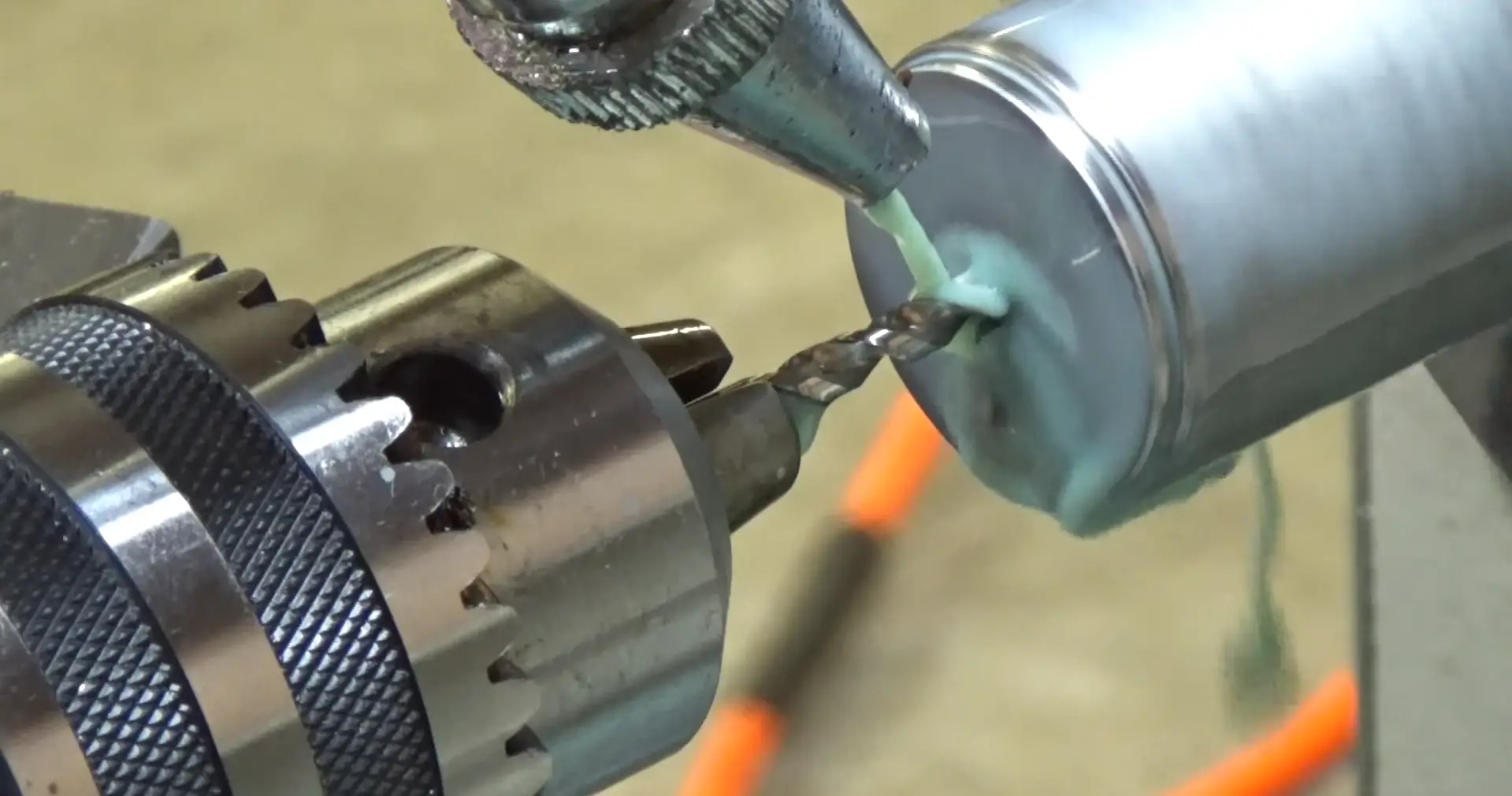

Step 3. Lubricate the drill bit

If you don’t want the drill bit to overheat or wear out too quickly, lubrication is crucial while drilling titanium. Applying cutting oil or a coolant can also extend its lifespan, and ensure that the drilling process goes smoothly. Make sure to apply the lubricant often during the drilling process.

Step 4. Drill slowly and smoothly

Drilling titanium requires the drill to be operated at a slow speed. The high density of titanium makes it prone to overheating and ultimately causing the bit to simply break down. Therefore, it’s better to set your drill at a low speed and pressure to reduce heat and friction while drilling. It’s also essential to keep the drilling process smooth and consistent, as any jerky or sudden movements can break your bit.

Step 5. Clean and inspect

Once the drilling process is complete, it’s time to clean and inspect the drilled holes. Use a brush or air gun to remove any debris or dust from the drilled hole. Inspect the drilled hole to ensure its size and quality. If the holes are not the desired size or have any cracks or impurities, the drilling process may need to be repeated.

Drilling titanium is a demanding process that requires specific techniques and equipment to achieve the best results. Finding the suitable drill bit, preparing the titanium, lubricating the drill bit, drilling slowly and smoothly, and cleaning and inspecting the drilled holes are all crucial steps in the process. By following these steps carefully, you can drill titanium successfully and efficiently. Titanium is a long-lasting and durable material, that’s why it is a great option for application in various industries. So, it’s popularly used in places like aerospace, automotive, and marine applications. Finally, it’s essential to follow safety guidelines while drilling to prevent any accidents or injuries.

TOP Tips on How to Drill Titanium

Although it is an incredibly difficult material to drill through, titanium is gaining popularity in the manufacturing and industrial sector. This is because of its durability, strength, and high resistance to heat and corrosion. However, it is important to understand the proper techniques when drilling through titanium to avoid damage to the material, the drilling bit, and most importantly, the workers. Now let’s discuss some top tips on how to drill titanium effectively and safely.

Use high-quality drill bits: Finding the suitable drill bit is the most important step when it comes to drilling through titanium. The material is prone to overheating and can be quite tough, so it is crucial to opt for a bit that can withstand the high heat that is generated during the drilling process. Ideally, your drill bit should be made of cobalt or carbide material that has a high resistance to heat and is able to maintain its sharpness for longer. With a high-quality bit, you’ll be able to achieve a cleaner, more precise hole, and reduce the risk of damaging the titanium. [1]

Keep the drill bit cool: Titanium is known to cause drill bits to overheat during the process of drilling, and this can even cause it to break. To prevent this, you need to use a coolant when drilling through titanium. The most commonly used coolant is cutting oil, which helps to lubricate the drill bit and reduce the temperature generated by the friction. You can also use water or air to cool down the bit, but ensure you’re not using too much water or oil as this can damage the material.

Secure the material: A secure grip on the material you’re drilling is essential when it comes to drilling through titanium. This is because the material can be very tough and may require a heavy amount of pressure when drilling. Securing the material in place with clamps or a vise will reduce vibrations and improve accuracy, which is crucial when drilling through titanium.

Wear protective gear: Finally, it is important to wear adequate protective gear when drilling through titanium. This is because the material and the drill bit generate significant heat and metal shavings that can be hazardous to your eyes, skin, and lungs. Wear gloves, safety glasses, dust masks, and other protective gear depending on the situation. This will not only protect you but also make the drilling process safer and more efficient.

Drilling through titanium is no easy feat, but with the right tools, techniques, and protective gear, it can be done safely and effectively. By following these top tips, you’ll be able to drill through the tough material with precision and avoid damaging the material and drill bits. Remember to choose high-quality drill bits, keep the bit cool, choose the right drilling speed, secure the material, and wear adequate protective gear. With these tips in mind, you’ll be able to drill through titanium as easily as through any other material.

Challenges of Titanium Drilling

Titanium is a durable and lightweight material that is used in an array of industrial applications. Industries ranging from aerospace and automotive to medical and marine rely heavily on titanium for its numerous benefits. However, drilling holes in titanium can be challenging as it is a tough and heat-resistant material. Here we explore the challenges of titanium drilling and provide insights on how to overcome them.

- Titanium’s High Heat Resistance. The high melting point of titanium makes it difficult to drill, especially when using traditional drilling methods. During the drilling process the high heat is generated and it can cause increased wear and tear on the drill bits and reduce their lifespan. Additionally, heat produced during the process can cause titanium to harden, potentially causing cracks to form. Overcoming these challenges, it is essential to have the suitable drill bits for the job. It is recommended to start with high-speed steel drills, which are fast and durable and have a special coating that helps them to handle the higher temperatures that occur when drilling titanium.

- Difficult-to-cut Material. Titanium is a difficult-to-cut material, making it challenging to drill without reducing the lifespan of the drill bit. This material has a very low thermal conductivity, meaning that heat generated during the drilling process is not quickly dispersed. As a result, if the drill bit is not meant to drill titanium, it tends to overheat quickly. To overcome this challenge, manufacturers now produce drills that are specifically designed for titanium drilling. These drills come with special coatings that reduce friction and wear and tear on the drill bit, leading to increased durability and tool life.

- Proper Coolant and Lubrication. When drilling through titanium, the use of proper coolant and lubrication techniques is essential, as it can significantly impact the quality of the final product. The high heat generated during drilling can make titanium brittle, causing it to crack. Applying coolant and lubricant when drilling will eliminate warping of the material. Additionally, use a coolant that is suitable for titanium materials, this compound must have a low viscosity, excellent cooling and lubricating properties, and should be free from harmful chemicals.

- High Work Hardening. Titanium is known for its work hardening properties, meaning that it becomes harder as it gets deformed. This property can lead to a phenomenon called “drill skating.” This occurs when the drill bit starts to skate or spiral out of control, making it challenging to drill straight holes. To overcome this challenge, it is essential that the steel drill bits have a 135-degree split point for a precision start and to drill in short bursts rather than long, constantly applying pressure, allowing the bits and material to cool more frequently.

- Proper Tool Management and Operator Training. Titanium is a challenging material to drill, and it’s important to use the right tools and techniques to avoid damaging the material, wasting time, and increasing costs. Proper tool management strategies, such as cleaning, sharpening, and replacing tools regularly, reducing the cost of maintenance and the risk of failure. Additionally, operator training and education on the properties of titanium are essential. It would be best if you always considered the best safety protocols when working with this material.

In conclusion, each of the challenges of titanium drilling has a solution, and with proper techniques and tools, it is possible to drill titanium to meet the requirements of a specific project. That said, it is important to understand the properties of titanium and use the proper tools, safe technologies, along with the guiding protocol with vast experience and knowledge to complete the project optimally. The solution to drilling titanium is timeless and straightforward, know your tools, and choose always based on the working requirement. Choose wisely.

Safety Precautions When Drilling Titanium

Drilling is a critical aspect of construction and metalwork, and knowing how to drill titanium is crucial, given its unique properties and strength. However, drilling titanium can pose a safety risk if the right precautions are not taken. Regardless of whether you are an industrial worker or DIY enthusiast, it is vital to understand the safety measures involved when drilling titanium. Here we highlight the essential safety precautions to observe when drilling titanium.

Wear Personal Protective Equipment

The first and foremost safety tip to observe when drilling titanium is to wear appropriate personal protective equipment. This includes goggles or safety glasses to protect your eyes from flying debris, safety gloves to protect your hands and protect against potentially hazardous chemicals, and respiratory protection if working in a confined space. These tools are necessary to protect against dust, chemicals, heat, and debris when drilling titanium.

Use the Appropriate Tools and Bits

You must use the most suitable drill bit, proper cutting speeds, and feeds when drilling titanium. The right tool selection and setup will improve the drilling efficiency and reduce your chances of injury. For instance, using a step bit instead of a reduced-shank HSS twist drill bit can help prevent “walking” as you drill and reduce the risk of breaking a bit. Additionally, you should avoid using aggressive or worn-out bits, and use lubricants such as oil or water to reduce the friction and heat generated when drilling.

Take Precautions to Prevent Overheating or Ignition

Titanium is sensitive to heat, and drilling releases significant amounts of thermal energy that can result in overheating or, in some instances, ignition. Therefore, it is essential to keep the titanium cool when drilling. A simple way to do this is to use coolant/lubricant, such as oil, or keep the drill and material constantly wet to prevent heat buildup. Additionally, avoid using compressed air to blow away debris, as doing so can introduce oxygen that may result in combustion if the titanium dust is in contact with a heat source.

Cabin or workspace environment

When drilling titanium in a confined space, it is crucial to consider the workspace environment. Ensure the environment is well ventilated to remove dust and fumes quickly. Ideally, you should have a dust/ventilation system or blower fan installed to remove titanium dust and other pollutants quickly. Additionally, make sure to clean up regularly and remove any titanium debris, as they can lead to slips, trips, and falls.

Proper training and supervision

Finally, it is essential to undergo proper training on the safe handling of equipment and tools. Supervision during the drilling and training on proper equipment handling techniques and practices will go a long way in preventing accidents and injuries. Safety measures can be put into place such as providing comprehensive safety manuals, equipment-specific safety information, or online training tools.

Drilling titanium is a technical task that requires skill, knowledge, and the right tools to get the job done correctly and safely. Observing essential safety precautions is crucial to avoid injury, mishaps, or damage to the material. It is vital to wear personal protective equipment and use proper drilling equipment and techniques to reduce risks. Prevent heat buildup by using coolant or keeping the material wet, and work in a well-ventilated area. With these tips in mind, you can effectively and safely use drilling tools on titanium in a variety of scenarios, whether it’s for personal or commercial applications.

FAQ

Will carbide drill through titanium?

Titanium is a tough material that can quickly wear down carbide tools if not used correctly. It’s essential to use carbide tools with sharp edges, an optimized geometry, and a high-performance coating to achieve the best results. Additionally, using a coolant or lubricant can help prolong the life of carbide tools and minimize the heat generated during drilling.

What is the best coating for drilling titanium?

There are several types of coatings available for drilling through titanium, including TiCN, TiAlN, and TiN. Each type of coating has unique properties that can enhance its performance in specific applications. For example, TiCN is great for drilling hard materials, while TiAlN is ideal for drilling at high speeds and with large cutting depths. TiN works well in a wide range of drilling applications. It’s essential to choose a coating that matches your specific drilling needs, the type of titanium you’re drilling, and your budget.

What is the world’s strongest drill bit?

The world’s strongest drill bit is made from polycrystalline diamond (PCD) material, which is a synthetic diamond that’s stronger than natural diamonds. These drill bits are ideal for high-speed drilling, and they can last up to 100 times longer than traditional carbide drill bits. Although PCD drill bits are more expensive than other types of drill bits, their long life and superior performance make them a popular choice for tough drilling applications.

Is titanium stronger than a diamond?

It’s not stronger than a diamond. In fact, diamonds are the hardest natural material known to man, with a score of 10 on the Mohs hardness scale. Titanium, on the other hand, scores around 6 on the same scale. This means that diamond is more than twice as hard as titanium, making it much more difficult to drill through.

Useful Video: How to Drill Titanium With HSS

Conclusions

Drilling titanium can be a daunting task for many machinists, but with the right tools, techniques, and know-how, it is possible to drill this tough material effectively. By using the correct drill bit, lubrication, peck drilling, and maintaining the tool, you can reduce drilling time, minimize tool wear and tear, and achieve a high-quality surface finish. We hope that the tips and techniques mentioned above will help you successfully drill titanium in your next project.

References:

- https://ruko.shop/blogs/ruko-shop-blog/how-to-drill-titanium

- https://www.hit-tw.com/newsdetails.aspx?nid=300