Stainless steel 21-6-9, commonly referred to as Nitronic 40, is a nitrogen-hardened high magnesium component. Thanks to its exceptional combination of toughness, high heat tolerance and anti-corrosion properties, it has become a favorite material for a variety of manufacturing sectors. This versatile alloy is found in a wide range of applications in the aviation, automotive, and general industrial sectors, where its excellent weldability and formability make it ideal for a variety of engineering needs. Whether it’s withstanding harsh environments or providing long-term strength, this steel delivers superior performance that exceeds expectations.

What is 21-6-9 stainless Steel?

As mentioned earlier, this grade is a high-quality variant of alloy steel. It is characterized by high durability, high resistance to hot temperatures, stress resistant properties, and great formability, making it a popular selection in a variety of industries.

This exceptional type of alloy steel is made up of 21% Cr, 6% Ni and 9% Mn, which gives it high toughness and superior wear resistance. Its highly tolerant temperature stability allows it to maintain its structural integrity even under extreme conditions, making it perfect for use in challenging settings.

In addition, the outstanding properties of steel corrosion protection make it ideal for use in aggressive environments such as salt water, acidic solutions and chemical plants. Resistance to spot corrosion, crevice corrosion and strain corrosion cracking further guarantees durability and reliability.

Furthermore, the superior formability of this variant of SS enables it to be easily shaped and fabricated into various components, making it versatile for a variety of manufacturing processes. This, combined together with its outstanding properties, makes it a preferred choice in industries that require high-performance materials.

In this way, the Nitronic 40 is an excellent material that combines toughness, temperature stability, corrosion tolerance and formability. Its exceptional qualities also make it an indispensable tool in various sectors where reliability and performance are of paramount importance.[1]

21-6-9 Stainless Steel Composition

Natural steel is renowned for the outstanding performance characteristics that can be attributed to its special structure. This brand of steel is primarily made up of a combination of Chromium, Nickel and Manganese, as well as other minor components such as Carbon, Silicon, Phosphorus, Sulphur and Nitrogen. These carefully balanced elements work in harmony to give steel its remarkable benefits.

The significant content of both Cr and Ni provides this metal with superior wear and heat stability, meaning it is an outstanding selection for uses that require durability in challenging environments. In addition, the high content of both Mn and N further strengthens the material, improving its overall technical characteristics.

Among the most significant characteristics of this steel is its outstanding stability against oxidation and rust, even at elevated temperatures. This exceptional corrosion stability makes it very suitable for uses where exposure to corrosive substances or harsh conditions is unavoidable.

In conclusion, the precisely matched combination of elements in that particular type of SS results in a superior product that combines toughness, temperature and wear tolerance, and is highly resistant to rust.These characteristics make it the preferred material for many industries, from auto and space to sea and pharmaceuticals.[1],[2]

21-6-9 Stainless Steel Properties

Mechanical Properties

High-grade steel, also known as UNS S21900, is a versatile alloy that demonstrates excellent structural properties. Due to the excellent combination of superior tensile and yield stress, this grade demonstrates outstanding resistance to deformation and failure even under substantial stress.

Moreover, its excellent ductility allows for easy stretching and the ability to be drawn into fine wire without the risk of tearing.These superior characteristics make this alloy an ideal material for a variety of different kinds of jobs requiring strength, durability and reliability.

Thermal Properties

When it comes to the temperature characteristics, this type of alloy steel has a high level of heat development and exceptional heat resistance. This unique combination makes it particularly suitable for applications that are often exposed to extreme temperatures or rapid temperature fluctuations. Whether it’s the scorching heat of a furnace or the sudden cooling of a cryogenic environment, it remains steadfast, retaining its own properties even under the most challenging temperature conditions. This superior resistance and adaptability makes it a versatile choice for a wide range of high-quality metal handling tasks, providing optimum performance and durability in demanding environments.

Physical Properties

Physically, 21-6-9 stainless steel is a remarkable material known for its exceptional strength and durability. With a hefty weight-to-strength ratio, it offers unparalleled performance in demanding conditions. Not only is it highly resistant to wear and abrasion, but it also exhibits excellent corrosion resistance, making it an ideal choice for components subjected to high friction during operation. Additionally, its high density and magnetic permeability contribute to its exceptional magnetic responsiveness, making it an excellent option for applications that require precise magnetic control and sensitivity. Overall, this stainless steel stands out as a versatile material that combines strength, durability, and magnetic properties to meet the demanding needs of various industries.

21-6-9 Stainless Steel Equivalent

While 21-6-9 steel possesses a unique set of properties that distinguishes it from other alloys, there are several alternatives available, each with its own set of characteristics that can be considered depending on the specific requirements of the application. Alloys such as 304L and 316L stainless steel, for example, are often regarded as viable options due to their similar corrosion resistance and mechanical properties. However, it is crucial to understand that these alternatives, although comparable in certain aspects, may not fully replicate the particular combination of strength, formability, and high-temperature stability that characterizes 21-6-9 SS.

Therefore, when seeking an equivalent alloy, it is strongly recommended to consult with a materials expert who can provide comprehensive guidance to ensure that the alternative alloy satisfies all the necessary requirements of the intended application, thus guaranteeing optimal performance and reliability.[2]

21-6-9 Stainless Steel Uses

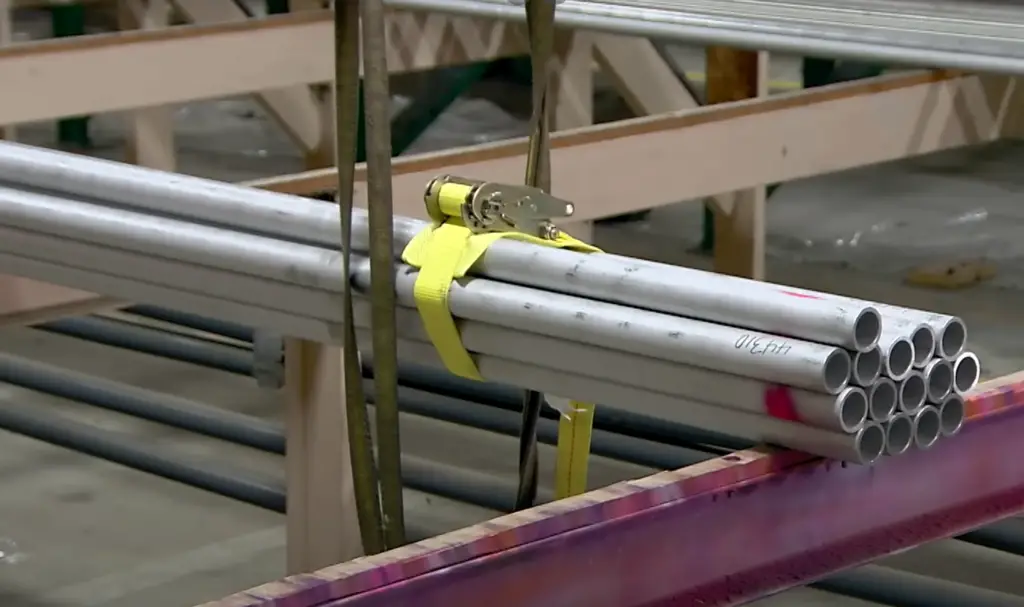

The exceptional set of properties exhibited by stainless steel makes it extremely versatile for a wide range of applications. In the aerospace industry, this alloy is frequently selected for the manufacturing of critical aircraft components that are exposed to extreme temperatures and high-pressure environments, ensuring optimal performance and reliability. Similarly, in the marine industry, its exceptional resistance to corrosion and pitting makes it the preferred choice for various seawater applications, including shipbuilding and offshore structures. Additionally, in the industrial sector, this stainless steel grade finds extensive use in chemical and petrochemical processing equipment, where its excellent resistance to corrosive substances and high temperatures is crucial for maintaining operational efficiency and safety. Moreover, it is also widely employed in the manufacturing of high-strength, high-temperature equipment used in demanding industrial processes, providing durability and reliability in harsh operating conditions.

21-6-9 Stainless Steel Welding

Welding 21-6-9 is typically straightforward due to its excellent weldability. This alloy, known for its exceptional corrosion resistance and mechanical properties, is widely used in various industries. It is compatible with a variety of standard welding methods, including Tungsten Inert Gas (TIG), Metal Inert Gas (MIG), and resistance welding techniques.

One of the key advantages of this stainless steel is its high Nitrogen content, which enhances its resistance to intergranular corrosion during the welding process. As a result, the need for pre-heating or post-weld heat treatment is usually eliminated. This not only saves time and energy but also simplifies the welding procedure.

To ensure the corrosion resistance and overall integrity of the alloy, it is crucial to select appropriate filler materials and shielding gases. This helps to maintain the alloy’s properties and prevent any potential degradation or compromise in performance.

While this type of stainless steel offers excellent weldability, it is always recommended to have a professional or someone with adequate training conduct the welding process. This ensures the best results and helps to maintain the quality and integrity of the material, meeting the highest standards of fabrication and performance requirements.[3]

Fabrication

Fabrication of 21-6-9 stainless steel is relatively simple due to its excellent formability and machinability. This versatile alloy can be easily cut, molded, and shaped into a variety of forms, allowing for its widespread use in numerous applications across industries. Whether it’s in the automotive, aerospace, or medical field, it’s proven to be a reliable choice.

To ensure optimal results, it’s crucial to employ adequately cooled and lubricated high-speed tools during the machining process. This precautionary measure helps prevent work hardening, a common challenge that arises when working with stainless steel. By carefully considering these factors, manufacturers can achieve precise and efficient fabrication while maintaining the desired mechanical properties of the material.

Machinability

21-6-9 steel is renowned for its exceptional machinability, providing a significant advantage in various manufacturing processes. This alloy can be efficiently machined using traditional methods such as cutting, drilling, turning, and milling. It’s important to note that due to its high work-hardening rate, careful planning and execution of the machining process are crucial. To ensure optimal results, machine tools must be maintained in prime condition and operated at appropriate speeds. Additionally, implementing effective cooling and lubrication during machining can help minimize the risk of overheating and work hardening. Despite these considerations, the overall machinability of this stainless steel not only facilitates high production rates but also delivers exceptional surface finish, making it a prime choice for a wide range of industrial applications. Whether it’s for precision components or intricate parts, this stainless steel alloy proves to be a reliable and versatile option, ensuring superior performance and durability in demanding manufacturing environments.

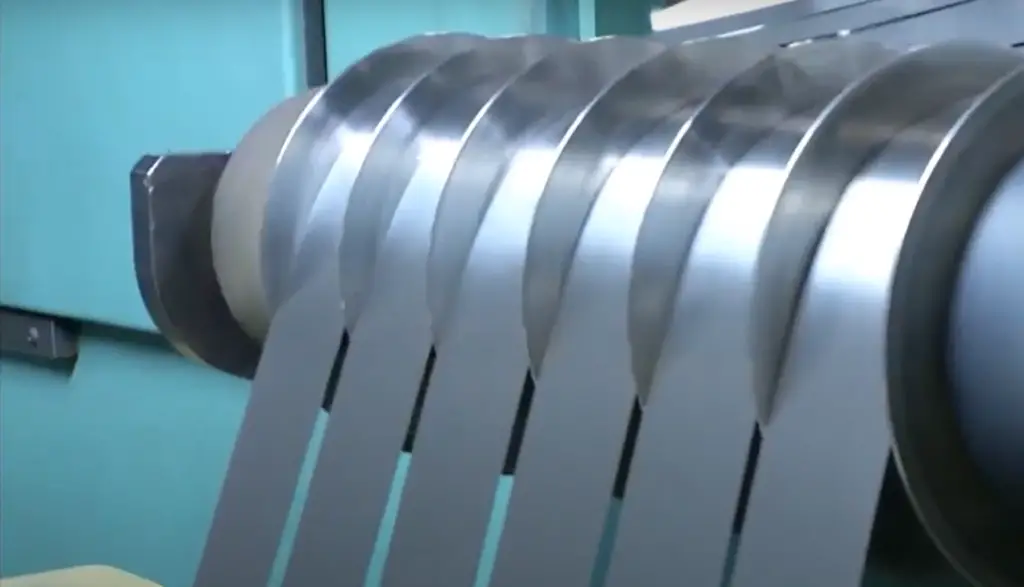

Forming

Forming 21-6-9 steel is an efficient and versatile process, thanks to the alloy’s excellent ductility and formability. This material can be successfully shaped into various forms using standard forming methods, including bending, rolling, and stretching. However, it’s important to note that the high work-hardening rate of 21-6-9 stainless steel necessitates meticulous planning and execution of forming processes.

To ensure optimal results, adequate lubrication and precise control of forming speeds are crucial. These measures help minimize the risk of cracking or tearing during the forming process, ensuring the integrity of the final product. Despite these considerations, the alloy’s superior formability opens up possibilities for creating intricate and complex shapes and structures, expanding its utility across diverse industries.

With its exceptional combination of strength, corrosion resistance, and formability, stainless steel continues to be a preferred choice for applications that demand both durability and aesthetic appeal. Whether in architectural design, automotive manufacturing, or aerospace engineering, this alloy’s versatility and reliability make it an invaluable material for shaping the future.

Heat Treatment

The heat treatment of 21-6-9 is a critical step in optimizing its mechanical properties. This process involves carefully controlling the material’s temperature, duration of heating, and rate of cooling. By subjecting the steel to specific heat treatment parameters, such as precise temperature and controlled cooling, we can achieve desirable outcomes.

During the heat treatment, the steel’s hardness is increased, its tensile strength is enhanced, and its resistance to wear and tear is augmented. This ensures that the stainless steel is well-suited for various applications, providing durability and reliability in demanding conditions.

It is essential to emphasize the meticulous monitoring and adjustment of heat treatment parameters to avoid any undesired alteration in the material’s properties. The specific details of the heat treatment procedure are contingent upon the desired mechanical properties and the anticipated application of the stainless steel.

By implementing a carefully tailored heat treatment process, we can optimize the performance of 21-6-9 stainless steel, making it an ideal choice for a wide range of applications that demand high mechanical strength and durability.

Cold Working

Cold working, also known as cold deformation, is a process used to shape and strengthen metals at temperatures significantly below their recrystallization point. When it comes to 21-6-9 stainless steel, a versatile alloy with excellent ductility and formability, various cold working techniques like rolling, drawing, or stretching can be effectively applied. These processes can result in improved tensile strength and hardness of the material, enhancing its overall mechanical properties.

However, it’s important to consider that just like other stainless steel alloys, 21-6-9 steel exhibits a high work-hardening rate. This means that with each cold working process, the alloy’s strength and hardness increase while its ductility decreases. To strike the right balance and prevent excessive hardening, a careful and well-planned approach to cold working is crucial.

In addition to cold working, it may be necessary to perform stress relief or annealing procedures after the deformation process. These techniques help reduce residual stresses and restore the desired level of ductility in the material, ensuring its optimal performance.

By understanding the intricacies of cold working and implementing appropriate strategies, it is possible to harness the full potential of 21-6-9 stainless steel while maintaining the desired mechanical properties.

Annealing

Annealing is a heat treatment process used to alter the physical and sometimes chemical properties of a material. In the case of 21-6-9 stainless steel, annealing is primarily employed to reduce hardness, increase ductility, and relieve internal stresses.

During annealing, the steel undergoes a fascinating transformation. As the steel is heated, the atoms within its crystalline structure become energized, enabling them to migrate and rearrange themselves. This rearrangement results in a softened and more workable material. Additionally, any stresses induced by previous processes are relieved, ensuring the steel’s stability and integrity.

To achieve the desired results, careful control of temperature and cooling rates is vital. Precise monitoring and adjustment of these variables allow for the controlled transformation of the steel’s microstructure, ensuring optimal properties for its intended application. By employing the correct annealing parameters, undesirable changes in the material’s properties can be prevented, guaranteeing the highest quality and performance.

In summary, annealing plays a crucial role in enhancing the characteristics of 21-6-9 stainless steel. Through controlled heating and cooling, the steel’s crystalline structure is modified, resulting in a more malleable and stress-relieved material. The meticulous control of annealing parameters ensures the desired properties are achieved, making it a vital process in material science and engineering.

Tempering

Tempering is an essential heat treatment process employed to enhance the toughness and ductility of hardened steel, such as the renowned 21-6-9 stainless steel, while simultaneously reducing its hardness. This meticulous procedure involves carefully heating the steel to a temperature slightly below its critical point, followed by a controlled cooling process. The primary objective of tempering is to alleviate the internal stresses that may have been induced by prior processes like quenching.

For the exceptional 21-6-9 SS, tempering plays an even more significant role by further augmenting its corrosion resistance, which is crucial for various applications. Additionally, this process contributes to a well-balanced combination of strength, hardness, and ductility, thereby enhancing its overall mechanical properties. It is worth mentioning that achieving the desired improvements in mechanical properties without any unintended alterations requires precise control over the tempering temperature and cooling rate.

By meticulously applying the tempering process, manufacturers can ensure that the hardened steel possesses the ideal characteristics for its intended use, making it a versatile and dependable material in various industries.

Hardening

Hardening of 21-6-9 stainless steel is achieved through two primary methods: strain hardening and heat treatment. Strain hardening, also known as work hardening, occurs during various forming processes where the steel is plastically deformed, leading to the creation of dislocations in its metallic structure. This increase in dislocations enhances the steel’s hardness and strength.

On the other hand, heat treatment hardening involves heating the steel to a specific temperature and then rapidly cooling it through quenching. This rapid cooling process results in the formation of a hardened crystalline structure in the steel.

For this stainless steel, these hardening processes play a crucial role in significantly improving its strength and wear resistance, thus making it highly suitable for demanding applications.

Therefore, it becomes essential to adopt a balanced approach in order to optimize the material’s properties based on its intended application, taking into consideration the desired level of strength, ductility, and corrosion resistance.[3]FAQ

What is the highest grade of stainless steel?

The highest grade of stainless steel is the 904L or 1.4539 stainless steel, an austenitic alloy renowned for its exceptional resistance to uniform corrosion. This is primarily attributed to its high content of nickel and chromium. Additionally, the addition of Copper to this grade provides excellent resistance to strong reducing acids, particularly sulphuric acid. These remarkable properties, combined with its improved strength and excellent formability, make it an ideal choice for use in harsh environments and critical applications, such as in the chemical processing, petrochemical, and pharmaceutical industries.

It is important to note that the definition of the “highest” grade can vary depending on the specific requirements of the application. Different grades of stainless steel may excel in different areas, including strength, corrosion resistance, or ease of fabrication. Therefore, careful consideration must be given to selecting the most suitable grade based on the desired characteristics for each particular use case.

What number is standard stainless steel?

The number most commonly associated with standard stainless steel is 304, also known as 1.4301. Stainless steel 304 is an austenitic grade that can be severely deep drawn, making it a very popular choice for the manufacture of drawn stainless parts such as sinks, hollow-ware, and saucepans. Its excellent deep drawing capability allows for the creation of intricate shapes and designs, providing versatility in the production of various kitchenware and utensils.

In addition to its superior formability, stainless steel 304 offers a good balance of strength, corrosion resistance, and fabricability. This combination of properties makes it a versatile material suitable for a wide range of applications in various industries, including architecture, automotive, and food processing. Its corrosion resistance ensures durability and longevity, even in harsh environments or exposure to corrosive substances.

However, it’s essential to note that the term “standard” can be misleading as the most suitable grade of stainless steel will depend largely on the specific requirements of the application. Other commonly used grades, such as 316 and 430, offer unique properties that cater to specific needs. For example, stainless steel 316 provides enhanced corrosion resistance, particularly in chloride-rich environments, making it ideal for marine applications or coastal areas. On the other hand, stainless steel 430 possesses improved heat resistance and is often used in applications where high-temperature exposure is a concern, such as in automotive exhaust systems.

By understanding the distinct characteristics of different stainless steel grades, manufacturers and designers can select the most appropriate material to meet their specific needs, ensuring optimal performance, longevity, and cost-effectiveness.

What does 21 0 stainless steel mean?

The term “21-0 stainless steel” refers to a specific grade of stainless steel known for its unique composition. This grade is characterized by the absence of Nickel, which sets it apart from other stainless steel alloys.

This composition gives the stainless steel its distinct properties.This grade of stainless steel, often referred to as ferritic stainless steel, exhibits excellent resistance to oxidation and possesses magnetic properties. However, it is important to note that due to the absence of nickel, 21-0 stainless steel has a lower corrosion resistance compared to other grades, such as the widely-used 304 grade.

Despite its limitations, 21-0 stainless steel finds utility in various applications, particularly in situations where high temperature resistance is required. Its unique composition and properties make it a valuable material in specific industries and settings.

What is the better grade of stainless steel?

The notion of a “better” grade of stainless steel is subjective and largely depends on the specific application and environmental conditions. For instance, grade 304 stainless steel, with its excellent formability and resistance to most forms of corrosion, is often considered a high-quality choice for general use. However, in environments with high chloride exposure, grade 316, which contains molybdenum for enhanced corrosion resistance, might be a better option. Similarly, for applications that require exceptional strength and hardness, the 440 series, known as high-carbon stainless steels, may be preferred.

Moreover, when considering the selection of stainless steel grades, it’s crucial to take into account other factors such as heat resistance, weldability, and cost-effectiveness. For instance, grade 310 stainless steel exhibits superior heat resistance and is suitable for applications where exposure to high temperatures is expected. On the other hand, grade 430 stainless steel offers good corrosion resistance and is often chosen for applications that require affordability and moderate corrosion resistance.

Ultimately, the selection of the most suitable grade of stainless steel depends on finding the optimal balance of properties required for a specific application. Factors such as resistance to corrosion, mechanical properties, fabricability, heat resistance, and cost, among others, should all be considered. Understanding the demands and requirements of the specific use-case is essential to ensure the appropriate grade of stainless steel is chosen, ensuring optimal performance and longevity.

What is the cheapest grade of stainless steel?

The 400 series, specifically grade 409 stainless steel, is widely recognized as one of the most affordable options available in the market. It falls under the category of ferritic stainless steel, characterized by its lower corrosion resistance compared to other grades. However, despite this limitation, grade 409 is still well-suited for numerous applications, particularly those that require high heat resistance.

The cost-effectiveness of grade 409 stainless steel can be attributed to its lower chromium content and the absence of Nickel. These factors make it a popular choice for cost-sensitive applications, such as automotive exhaust systems. It offers reliable performance while keeping material costs low. However, it is important to note that when selecting a grade of stainless steel, factors beyond material costs should also be taken into consideration. These factors include the expected lifetime of the application, maintenance requirements, and potential replacement costs.

By carefully evaluating the specific requirements of your application and considering various factors, you can make an informed decision regarding the most suitable grade of stainless steel to meet your needs.

What is the healthiest grade of stainless steel?

When it comes to health considerations, grade 316 stainless steel, also known as marine-grade stainless steel, is widely recognized as the healthiest choice. This is primarily due to its exceptional corrosion resistance, which is achieved by the addition of molybdenum to its composition. The presence of molybdenum enhances its ability to resist a wide range of corrosive chemicals, including various acids commonly found in food items and the corrosive effects of salt in sea air. As a result, grade 316 stainless steel is an ideal material for cookware, cutlery, and other kitchen utensils, as it significantly reduces the risk of metal leaching into food.

Moreover, grade 316 stainless steel offers additional benefits. It exhibits remarkable resistance to heat damage and warping, ensuring not only the longevity of the product but also the safety and hygiene of the users. This durability and resilience make it a reliable choice for kitchenware that withstands the test of time.

However, it is always advisable to exercise caution and ensure that any stainless steel product that comes into contact with food has a food-safe rating or certification. This provides an extra layer of assurance and guarantees that the product meets the necessary safety standards for food preparation.

Useful Video: Steel Types – Stainless Steel Vs Carbon Steel Explained.

Conclusion

21-6-9 stainless steel, also known as UNS S21900, is a high-alloy stainless steel renowned for its exceptional resistance to corrosion and high-temperature environments. This remarkable grade of stainless steel contains 21% Chromium, 6% Nickel, and 9% Manganese, which not only contribute to its enhanced formability and weldability but also ensure superior resistance to pitting and crevice corrosion, even in challenging marine environments.

Moreover, the presence of nickel and manganese, in conjunction with the high chromium content, grants 21-6-9 stainless steel remarkable strength and durability, making it a preferred choice for applications in aerospace and other industries where elevated temperatures are prevalent. Its ability to withstand high-temperature conditions without compromising its structural integrity makes it an invaluable material for critical components and parts subjected to extreme thermal stresses.

However, it is essential to consider the cost and availability of 21-6-9 stainless steel. While it offers distinctive advantages over common grades like 304 and 316, it may not be as widely accessible or cost-effective. Therefore, when selecting this grade, like any other stainless steel variant, it is crucial to carefully analyze the specific requirements and weigh the trade-offs to ensure an optimal choice for the intended application.

References:

- https://www.techsteel.net/alloy/stainless-steel/21-6-9

- https://blog.thepipingmart.com/grades/21-6-9-stainless-steel-uns-s21900-composition-properties-and-uses/

- https://www.suppliersonline.com/propertypages/21-6-9.asp\