Jethete M-152 is a highly acclaimed type of stainless steel that is widely recognized for its exceptional strength and outstanding resistance to corrosion. This weather-hardened steel is specially designed for high-stress applications where durability and resistance are of utmost importance. The unique composition, which includes elements such as Chromium, Nickel and Molybdenum, imparts this alloy with superior properties, making it an outstanding choice for a variety of demanding industrial applications. With its superior strength, excellent heat resistance, and remarkable resistance to oxidation, Jethete M-152 finds extensive usage in critical sectors such as aeronautics, power generation, and many other industries that require robust and reliable materials to withstand extreme conditions and ensure optimal performance.

What is Jethete M152?

Jethete M152 is a highly sought after grade that belongs to the family of weather hardened jet stainless steels. Renowned for its exceptional strength and remarkable resistance to corrosion, this alloy is composed of Chromium, Nickel, and Molybdenum, which synergistically contribute to its outstanding performance. Its ability to withstand elevated temperatures and extreme pressure conditions makes it an optimal choice in critical sectors such as aerospace, power generation, and other high-stress environments.

With its exceptional durability and robust mechanical properties, including high tensile strength and good ductility, M152 has become an indispensable component in numerous industrial applications. Its solid execution and long-lasting endurance make it a trusted choice for demanding conditions where reliability and longevity are paramount. Whether it’s in the aerospace industry, power generation plants, or other high-stress applications, Jethete M152 continues to deliver exceptional performance, ensuring the highest standards of quality and safety.[1]

Jethete M152 Composition

M152 is a highly regarded SS alloy, known for its exceptional strength and durability.

In addition to these key elements, trace amounts of Carbon, Silicon, Manganese, and Phosphorus further contribute to its general ability to perform. The presence of Chromium not only enhances the steel’s corrosion resistance but also improves its hardenability, making it suitable for various high-stress applications. The addition of Nickel significantly increases the alloy’s toughness, ensuring it can withstand demanding conditions. Furthermore, Molybdenum plays a decisive role in enhancing the steel’s strength and resistance to heat, making it ideal for use in extreme environments. This unique combination of elements provides Jethete M152 with unparalleled resilience, making it a preferred choice for applications requiring exceptional performance under challenging conditions.[2]Properties

The properties of Jethete are directly influenced by its unique chemical composition, which consists of a precise combination of elements. This type of alloy not only showcases excellent tensile and yield strength, even at high temperatures, but it also exhibits outstanding resistance to deformation and fracture. These qualities make it well-suited for use in demanding industrial environments where strength and durability are paramount.

In addition to its mechanical properties, M152 possesses remarkable resistance to oxidation and corrosion. This means that it can effectively withstand exposure to harsh and corrosive elements, maintaining its structural integrity even in the most extreme conditions. The alloy’s ability to resist oxidation also contributes to its long-term reliability and longevity.

Furthermore, Jethete M152 can be further enhanced through a heat treatment process, which enables it to be hardened and strengthened. This treatment not only increases its durability but also enhances its resistance to wear and tear, ensuring its longevity in demanding applications.

Another notable characteristic of this alloy is its consistent magnetic response in all conditions. This makes it particularly suitable for applications where a stable and reliable magnetic performance is required.

In general, this steel is a versatile and highly efficient natural grade that offers exceptional tensile strength, stress resistance and temperature stability. This valuable combination of qualities makes it an excellent match for a huge range of commercial applications where reliability and durability are of paramount importance.[2]

Jethete M 152 Uses

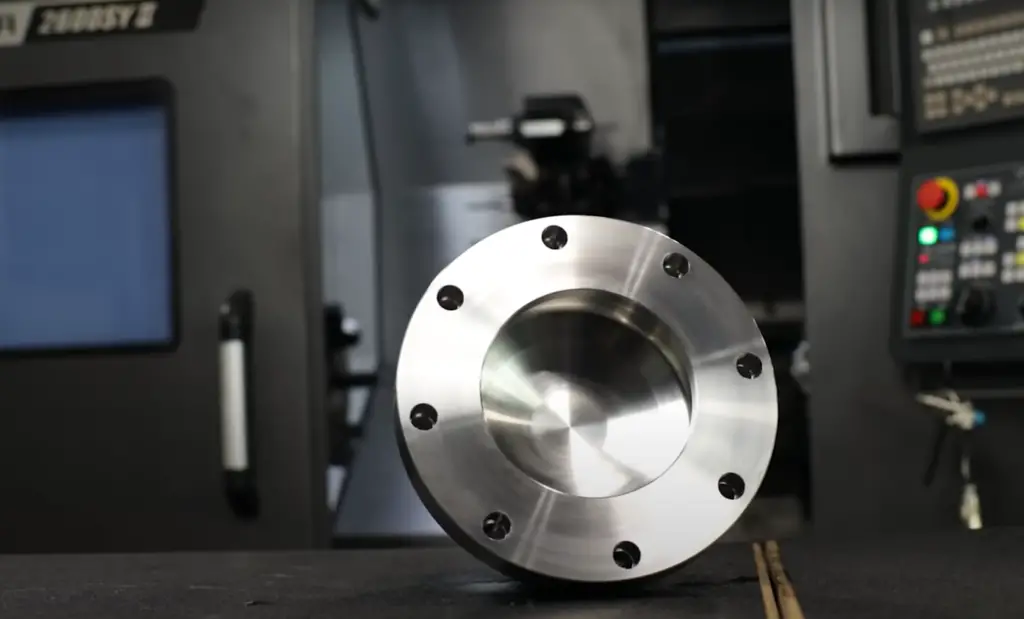

The exceptional properties and resilience of Jethete M152 make it an indispensable material in a broad spectrum of sectors. In the aerospace sector, this high-performance alloy is extensively utilized in the manufacturing of gas turbine engine parts, thanks to its remarkable ability to withstand extreme high-temperature conditions. Its outstanding durability and unmatched resistance to corrosion make it the ideal choice for the production of fasteners, bolts, and other critical components in the aviation industry.

Moving on to the power generation sector, Jethete M152’s excellent heat resistance and exceptional strength make it highly suitable for intricate components like turbine blades, discs, and rings. Its exceptional resistance to corrosion, even under the harshest conditions, positions it as a reliable option for crucial components in nuclear power plants, ensuring long-lasting performance and safety.

In the automotive industry, Jethete M152 finds its application in high-performance vehicles where superior strength and heat resistance are essential, particularly in engine valves and gear components. Moreover, its remarkable ductility and impact resistance make it an ideal choice for safety-critical components, ensuring reliability and durability even under demanding conditions.

In summary, Jethete M152’s exceptional properties and versatility make it an extremely valuable material for various industrial applications, promising unparalleled performance, longevity, and reliability. With its unique combination of strength, heat resistance, corrosion resistance, and impact resistance, Jethete M152 continues to be at the forefront of innovation, driving advancements in multiple industries.[1]

Jethete M152 Corrosion Resistance

Jethete M152, a high-performance alloy, exhibits exceptional corrosion resistance, making it an ideal choice for harsh and demanding environments. This remarkable resilience against corrosion is primarily attributed to its high Chromium content, which reacts with oxygen to form a thin, protective layer on the steel’s surface. This layer acts as a shield, effectively preventing further oxidation and corrosion. It provides robust protection against a wide range of corrosive substances, including acids, alkalis, and salts.

Moreover, the addition of Molybdenum further enhances the resistance of Jethete M152, especially in high-temperature conditions. The combination of Chromium and Molybdenum ensures that the alloy maintains its structural integrity and performance, even when exposed to corrosive elements for prolonged periods. This makes Jethete M152 an excellent choice for applications in challenging industrial settings where durability and longevity are paramount.

With its exceptional corrosion resistance and ability to withstand harsh conditions, Jethete M152 stands out as a reliable and durable solution for industries that require high-performance materials.[3]

Heat Treatment

The heat treatment process is a critical and intricate aspect of working with Jethete M152, as it plays a significant role in enhancing the alloy’s properties and overall performance. This stainless steel can be effectively hardened and strengthened through a meticulously controlled process that involves precise heating and cooling.

The process commences with a vital step known as solution treatment. During this stage, the alloy is heated to a high temperature and then rapidly cooled, resulting in the dissolution of the alloying elements into a homogeneous solid solution. This essential action significantly improves the alloy’s corrosion resistance and toughness, ensuring its durability in challenging environments.

Following the solution treatment, the alloy undergoes another crucial phase called aging. In this procedure, the alloy is heated to a lower temperature, allowing for the precipitation of intermetallic phases. These intermetallic phases play a pivotal role in enhancing the alloy’s strength and hardness, contributing to its exceptional performance under high-stress conditions.

It is important to note that the specific temperatures and timings for these processes can vary depending on the desired mechanical properties.

By meticulously adhering to the precise conditions, an optimal balance of strength, hardness, and toughness can be achieved, making Jethete M152 an ideal choice for demanding, high-temperature industrial applications.In conclusion, through proper heat treatment, Jethete M152 attains exceptional mechanical properties, making it highly suitable for rigorous industrial applications. The intricate process of heat treatment ensures that the alloy possesses the necessary strength, hardness, and toughness to withstand extreme conditions, thereby enhancing its overall performance and reliability.[2]

Machining

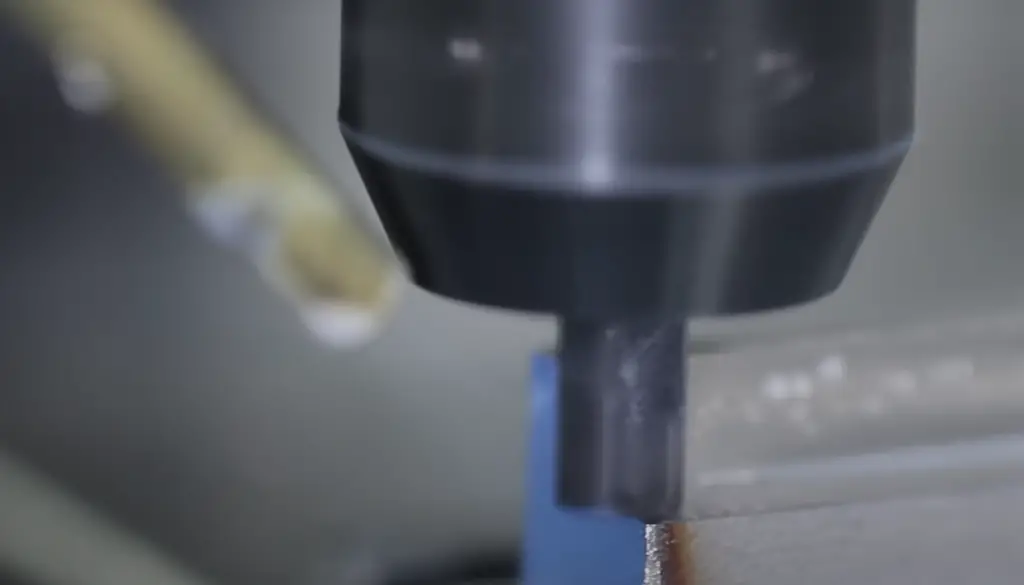

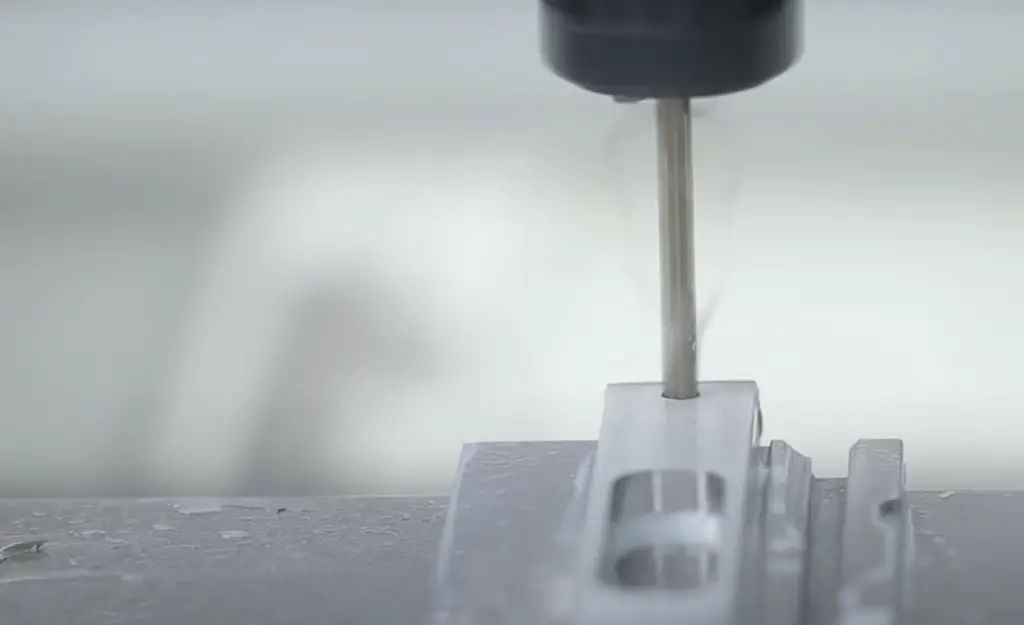

Working with Jethete M152 requires special care and precision during machining due to its high strength and work-hardening rate. The alloy’s unique properties demand a meticulous approach to ensure optimal results.

When it comes to shaping and manipulating Jethete M152, the selection of appropriate tools, lubricants, and techniques is paramount. By employing the right tools and employing the correct machining techniques, this alloy can be successfully transformed into various forms and sizes, catering to a wide range of industrial applications.

For cutting operations, carbide-tipped tools are highly recommended due to their exceptional hardness and wear resistance. These tools excel in high-speed cutting conditions that Jethete M152 often requires, ensuring efficient and precise machining.

When turning the alloy, positive rake angles and large relief angles are typically suggested to minimize the work-hardening effect. Carefully controlling the cutting speed is crucial to prevent overheating, which can compromise both the tool’s effectiveness and the alloy’s surface finish.

Jethete M152 can also be effectively drilled, milled, and ground using conventional methods. However, the work-hardening property of the alloy necessitates a steady feed and speed to maintain tool integrity. By utilizing coolants and lubricants during these processes, heat dissipation and friction reduction can be achieved, thereby prolonging tool life and enhancing the surface quality of the machined components.

In summary, while machining Jethete M152 can pose challenges due to its unique physical properties, with the correct approach, tools, and techniques, it can be effectively machined for a wide range of industrial applications. The careful selection of tools and the implementation of appropriate machining strategies are key to unlocking the full potential of Jethete M152 in various manufacturing processes.[3]

Welding

Welding Jethete M152 requires a distinct approach due to its specific physical and chemical characteristics. The alloy, known for its exceptional strength and corrosion resistance, can be welded by most standard methods, including tungsten inert gas (TIG) and metal inert gas (MIG) welding. However, it’s crucial to consider its high work-hardening rate and tendency towards weld decay to ensure a successful weld.

Before welding, meticulous preparation is essential. The material should be thoroughly cleaned to remove any contaminants that could negatively affect the weld quality. This includes removing dirt, grease, and oxide layers that may be present on the surface. Moreover, preheating the alloy before welding can help to reduce thermal stresses and prevent cracking, ensuring a more robust and reliable weld joint.

When it comes to filler material, it’s highly recommended to use a filler of similar composition to ensure compatibility and maintain the alloy’s properties in the weld area. This promotes optimal metallurgical bonding and minimizes the risk of creating weak points in the weld. Additionally, the use of shielding gases like argon during the welding process can help prevent oxidation and ensure a cleaner weld, further enhancing the integrity of the final product.

This usually involves a combination of solution treatment and aging, similar to the initial heat treatment process. The specific heat treatment parameters should be determined based on the desired mechanical properties and the intended application of the welded component.In sum, with the right precautions and techniques, Jethete M152 can be effectively welded for various high-performance applications. Its unique combination of strength, corrosion resistance, and weldability ensures that the final product exhibits optimal performance and durability, even in demanding environments.

FAQ

What is specification of M152?

Jethete M152 is a precipitation hardenable stainless steel, known for its exceptional properties and versatility. With a Сhromium content of 12%, it exhibits a martensitic structure that provides excellent strength and durability. Designed to meet the rigorous standards of the British Standard Aerospace series, specifically the BS S151 specification, this alloy is highly regarded in the industry.

Composed of carefully balanced elements, Jethete M152 includes Сarbon (0.08-0.13%), Сhromium (10.5-12.5%), Silicon (0.50% max), Manganese (0.50% max), Nickel (5.0-6.0%), Molybdenum (0.80-1.20%), Sulfur (0.030% max), Phosphorus (0.030% max), and a balance of Iron. Its seamless tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon, and wire forms make it readily accessible for various applications.

What sets M152 apart is its remarkable performance across a wide range of temperatures. It exhibits excellent strength and resistance even at high temperatures, while also maintaining good toughness and ductility in sub-zero conditions. This makes it a reliable choice for critical applications in aerospace, power generation, and automotive industries.

In summary, Jethete M152 stands as a reliable and versatile material, offering exceptional strength, durability, and adaptability. Its adherence to strict standards and its ability to excel in demanding environments make it an ideal choice for a wide array of applications.

What is the equivalent of M152?

The equivalent of Jethete M152 in other standards can vary depending on the system used. For example, in the Unified Numbering System (UNS), the equivalent grade for M152 is identified as UNS S64152. While the American Iron and Steel Institute (AISI) does not have a direct equivalent, a similar grade that comes close is AISI 660. In the European Standard (EN), the equivalent designation is EN 1.4935. In Germany, under the Deutsche Industrie Normen (DIN), the corresponding grade is labeled as X12CrNiMoV12-3.

It’s important to note that although these grades are considered equivalents, there might be slight variations in the percentages of individual alloying elements. Hence, it is always recommended to cross-check the specific material properties before selecting an equivalent grade for a particular application. Taking this precaution ensures that the chosen grade will meet the desired specifications and performance requirements.

What is the AMS 5719 specification?

The AMS 5719 specification, issued by the Society of Automotive Engineers (SAE), is a comprehensive document that specifically applies to Jethete M152. This specification not only covers the physical and mechanical properties of the alloy but also provides detailed guidelines for its heat treatment, forging, and machining processes.

To achieve the desired strength and hardness, the AMS 5719 specification mandates a specific procedure. It stipulates that the alloy should undergo a solution treatment at 980°C (1800°F) followed by aging at 550°C (1022°F). This meticulous process ensures that Jethete M152 attains optimal performance characteristics.

Furthermore, the AMS 5719 specification sets out stringent standards for testing the properties of the alloy, including tensile strength, yield strength, elongation, and reduction of area. These tests ensure the alloy meets the highest quality requirements for various industrial applications.

In addition to outlining the physical and mechanical aspects, the AMS 5719 specification also specifies inspection procedures that manufacturers must follow to ensure the highest level of quality and consistency in the production of Jethete M152.

In summary, the AMS 5719 specification serves as an indispensable guide for both manufacturers and users of Jethete M152. It not only ensures the alloy’s performance aligns with the demanding requirements of various industries but also guarantees the highest level of quality and consistency in its production.

What is Jethete?

Jethete, also known as Jethete M152, is a widely recognized term in the field of materials science. It refers to a specific type of stainless steel that boasts remarkable properties and characteristics. Its unique martensitic structure, featuring a body-centered cubic crystal lattice, sets it apart from other stainless steels.

One of the standout features of Jethete M152 is its exceptional strength, particularly at high temperatures. This makes it an ideal choice for applications in industries like aerospace, power generation, and automotive, where operating conditions can be demanding. Not only does it exhibit impressive strength, but it also demonstrates remarkable toughness and ductility, even when subjected to sub-zero temperatures.

This versatile material is widely appreciated for its conformance to the British Standard Aerospace series, specifically the BS S151 specification. Its composition and properties have been meticulously engineered to meet the rigorous standards of the aerospace industry. Engineers and manufacturers rely on Jethete M152 for its high work-hardening rate, which ensures superior performance and durability in critical applications.

It’s worth noting that due to its specific composition, Jethete M152 requires careful consideration when it comes to machining and welding. Its tendency towards weld decay necessitates distinct approaches to ensure optimal performance and longevity. By adhering to proper machining and welding techniques, the full potential of Jethete M152 can be realized.

In summary, Jethete M152 is a remarkable stainless steel alloy that excels in strength, toughness, and ductility. Its versatility and adherence to aerospace specifications make it a preferred choice in various industries. With its outstanding properties and careful handling, Jethete M152 continues to contribute to advancements in engineering and technology.

Useful Video: The MOST SHOCKING Stainless Steel Milling Ever!!! *YOU MUST SEE THIS*

Conclusion

In conclusion, Jethete M152 stands out as a truly exceptional and versatile stainless steel alloy, possessing a myriad of highly advantageous properties. Notably, its exceptional strength at high temperatures ensures superior performance under demanding conditions, while its commendable toughness at sub-zero temperatures guarantees reliability even in extreme cold environments. Additionally, its good ductility allows for ease of shaping and forming, further enhancing its usability across various applications.

Moreover, Jethete M152 exhibits impressive resistance to creep, ensuring long-term structural integrity and stability. Its superior hardenability enables precise and controlled heat treatment, resulting in optimal mechanical properties tailored to specific requirements. This alloy’s adherence to various international standards further attests to its exceptional quality and reliability, providing reassurance to industries worldwide.

Furthermore, Jethete M152 showcases remarkable adaptability, demonstrating its ability to withstand diverse environmental conditions encountered in real-world applications. Its excellent corrosion resistance safeguards against degradation and ensures longevity, while its effective heat dissipation properties prevent overheating and maintain efficient operation.

Given its wide-ranging capabilities and outstanding performance, Jethete M152 continues to be an invaluable material in numerous industries, including aerospace, automotive, and power generation. Its unrivaled combination of strength, durability, and versatility makes it an optimal choice for critical components and demanding environments.

References:

- https://alloysintl.com/inventory/nickel-cobalt-alloys/jethete_m152/

- https://www.techsteel.net/alloy/stainless-steel/jethete-m-152

- https://blog.thepipingmart.com/grades/jethete-m152-composition-properties-and-uses/