When it comes to conducting heat, different metals have different levels of efficiency. Some are better than others at transporting heat energy from one place to another. But which metal is the best conductor of heat? To answer this question, we must examine the properties and characteristics of different metals and their ability to conduct heat. By comparing their thermal conductivity values, we can determine which metal is the most efficient in transferring heat. We’ll also look at other factors that can affect a metal’s ability to conduct temperature changes, such as melting point, density, resistivity, and more. Finally, we will look at how these materials may be used in everyday life where efficient energy dissipation is essential for optimum operation.

Heat Exchangers

Heat exchangers are devices for transferring heat from one medium to another. They are often used in industries where efficient heat transfer is essential for optimal performance. They work by exploiting the difference between two liquids or materials on either side of the device. By circulating one material and allowing energy to be shared between the two, heat exchangers can be incredibly efficient in the transfer of electrical energy.

They are a common component of many industrial systems, such as those used in chemical plants and refineries, electrical power plants, air conditioners, and HVAC systems.

Heat coils can be in parallel or counterflow configurations, depending on the application for which they will be used. Parallel-flow designs assume that both fluid flows move in the same general direction, while counter-flow designs have both fluids moving in opposite directions. This design makes it possible to increase the effectiveness of heat transfer between the two media, as well as to better control the temperature. Heat transfer tubes can also be made from a variety of metals, which include Steel Alloys, Stainless Steel and Titanium Alloys, which offer a good level of strength and corrosion resistance while retaining a high level of conduction, making them ideal for use in extreme temperatures or corrosive environments.[1]

Industrial Facilities

Heat exchangers are commonly found in industrial facilities, providing efficient and effective transfer of heat energy for a variety of uses. They are widely used in synthetic chemical plants, oil refineries, power plants, air conditioning and heating systems to transfer heat from one medium to another. Heat exchangers can be made of various metals, such as Copper and Aluminum, which have excellent thermal conductivity, making them ideal for efficiently transferring temperature changes. Steels, Stainless Steel and Titanium Alloys can also be used depending on the requirements of the application, as they provide a good degree of durability and corrosion resistance while maintaining a high level of thermal conductivity for optimal performance in extreme temperatures or corrosive environments.

The two most common types of heat exchanger designs are parallel flow and counterflow. Parallel flow involves having both media streams travel in the same direction whilst counterflow has both streams flowing in opposite directions. This setup allows for a higher efficiency of thermal energy transfer between the two substances as well as better temperature control than traditional methods. Heat exchangers are essential components in many industrial processes as they are able to quickly move large amounts of heat with precision and accuracy while mitigating risks associated with high pressure environments or extreme temperatures.

Solar Thermal Water Systems

Solar thermal water systems are becoming increasingly popular due to their ability to provide a safe, efficient, and cost-effective way of heating water. These systems use the sun’s energy to heat up water in a solar collector. The heated water is then transferred into an insulated storage tank either through direct circulation or thermal siphoning. In direct circulation systems, pumps circulate the heated water from the solar collector through pipes directly into the insulated storage tank. Alternatively, in thermal siphoning systems, gravity is used to move the heated water from the collector to a tank located above it.

Heat exchangers play an important role in solar energy storage tanks because they help maintain the temperature balance in the system by transferring heat energy between two fluids (in this case, between the incoming cold water and the outgoing hot water). As a result, they provide efficient heat transfer with minimal energy loss, which allows for a constant temperature to be maintained without the extra electricity and other fuels that would otherwise be required to achieve that temperature. In addition, the heat coils provide enhanced freeze protection by allowing cold winter air to reach only the outside of the jacketed tank, while keeping the internal components warm and operational.

Gas Water Heaters

Gas water heaters are becoming increasingly popular due to their efficient operation and cost-saving potential. Compared to electric water heaters, gas powered units are able to heat up the same amount of water in a shorter period of time while consuming less energy which can lead to significant savings on energy bills over time. Gas powered models are available in either tankless (on-demand) or traditional tank-style varieties, both of which use heat exchangers to efficiently transfer heat between the incoming cold water and gas burner within the unit.

Tankless gas powered systems provide an endless supply of hot water on demand as they draw in and instantly heat up cold water from a pipe whenever needed without any preheating required. This makes them ideal for large households or commercial facilities with high demand for hot water such as hotels or restaurants since users can expect consistent temperatures without waiting times even at higher workloads. Traditional tank-style models operate by storing large amounts of already heated up hot water in an insulated storage tank from which it is then drawn whenever needed; however, these systems typically require more energy than their on-demand counterparts due to the amount of energy needed to keep the stored hot water warm at all times.

Forced Air Heating and Cooling

Forced air heating and cooling systems are becoming increasingly popular among both homeowners and businesses due to their efficiency, cost-saving potential, and wide range of safety features. In comparison to other HVAC systems, forced air units operate by circulating air throughout a given space via air ducts, which helps to evenly distribute heat or cool air throughout the entire area. This makes it an ideal choice for climates that experience extreme temperatures whether hot or cold since users can expect consistent levels of temperature control over time regardless of outside weather conditions.

Overall, forced air heating and cooling systems provide reliable comfort for both homeowners and businesses alike due to their efficient operation and cost saving potential along with added safety features that make them a preferred choice when considering HVAC options.

Why It’s Important to Look at Metals That Conduct Heat Well

When choosing the best material to use for any project that requires heat conduction, it is important to consider which metals are best suited for the task. This is because different metals have varying levels of thermal conductivity, which is a measure of how quickly and easily heat energy can be transferred through them. As such, choosing the wrong metal could mean investing in a product that does not perform as expected or fails completely due to the inability of the metal to efficiently transfer heat.

The two main categories of heat-conducting metals are thermally conductive and thermally resistive. Thermally conductive metals have high levels of thermal conductivity and can easily absorb and dissipate large amounts of heat such as Copper and Aluminum. On the other hand, thermally resistive metals like iron and steel have lower levels of thermal conductivity thus making them better suited for applications where low levels of heat need to be conducted such as radiators or convection ovens.

It is also important to take into consideration the environmental conditions in which a particular metal will be used when deciding on which type to choose such as whether it will be exposed to extreme temperatures or corrosive materials like saltwater. For example, certain types of stainless steel can be ideal for outdoor applications since they are more resistant against corrosion compared with other forms of metal while copper may not be suitable in this situation due to its susceptibility to degradation over time due to exposure to air and moisture.[2]

Metals That Conduct Heat the Best

The best metals for conducting heat are those with high thermal conductivity, such as Copper, Aluminum, Silver, and Gold. In general, different types of heat conductors have different levels of thermal conductivity depending on their individual composition, which should be taken into account when choosing a material for a particular application. By thoroughly researching each type in advance, including their respective prices, users can ensure that they choose the most suitable option while still obtaining optimal performance levels compared to other alternatives available on the market today.

Silver

Silver has slightly higher thermal conductivity levels than Aluminum which makes it a suitable choice for certain industrial applications such as cookware or laboratory equipment that require precise temperature control over extended periods of time. However, silver is much more expensive than both aluminum and copper so this should be taken into consideration when making purchasing decisions based on cost alone.

Copper

When it comes to metals that conduct heat the best, Copper is often regarded as the Gold standard. Copper’s high thermal conductivity and low cost make it an ideal choice for a variety of applications such as electrical wiring, plumbing, and heating systems.

In terms of thermal efficiency, Copper also offers greater effectiveness than other more expensive metals such as Silver or Gold due to its ability to rapidly dissipate large amounts of heat quickly. It can also be easily molded into various shapes and sizes to fit any desired application making it a very versatile material for use in many different projects.

Aluminum

Aluminum is another excellent conductor of heat due to its relatively low cost compared to other metals and its excellent thermal properties. Aluminum has a higher melting point than copper at 660 degrees Celsius which makes it both durable and resistant to extreme temperatures allowing it to remain highly efficient over long periods of time.

Aluminum’s ability to quickly dissipate heat also means that it is less likely to retain damaging levels of temperature within enclosed spaces which could present a safety risk if not properly managed.

Gold

Finally, Gold has one of the highest levels of thermal conductivity among all metals currently available on the market but its price tag reflects this accordingly making it an impractical option for most applications unless cost isn’t an issue. Despite this fact, Gold has seen increased use within recent years due to its ability to accurately transfer temperatures across long distances without any noticeable energy loss thus making it suitable for certain medical procedures such as laser surgery or therapeutic treatments where precise temperature control is required at all times.

Other Factors Affecting Heat Conduction

Other factors that can affect the thermal conductivity of a given metal include its physical properties, such as weight, density, and surface area. Generally speaking, the lighter and denser a metal is, the better it will be at transferring and dissipating heat rapidly due to its increased ability to absorb more energy in a shorter amount of time. On the other hand, heavier metals with a larger surface area tend to reflect more energy, resulting in slower heat transfer. Furthermore, certain metals may be more suitable for use in certain environments than others due to their individual level of resistance to corrosion or oxidation, which can affect their thermal conductivity over time.

Another major factor to consider when selecting the best material for any application involving thermal conductivity is its electrical conductivity. While most alloys have a high level of thermal transmittance due to their atomic structure, some are much better than others at conducting electric current, making them ideal for uses such as wiring or printed circuit boards where low levels of resistance must be maintained for proper operation. When considering this aspect, it is usually best to choose materials such as Copper or Aluminum, as they are known for having some of the lowest levels of electrical resistance available on the market today, as well as having impressive thermal properties.[3]

Applications for Conductive Metals

Copper is one of the most popular materials among the thermally conductive metals, as its thermal conductive properties make it an ideal choice for a wide range of applications. It is often used in electronics because it does not generate excessive noise or vibration, making it an ideal material for use in areas where precise temperature control and noise reduction are paramount. It can also be found in electric motors, radiators, air conditioners, and refrigeration systems due to its excellent ability to transfer temperature over long distances without noticeable energy loss.

Aluminum is another metal with excellent conductive properties, making it suitable for both commercial and industrial applications. This metal is highly resistant to corrosion and oxidation, making it perfect for use outdoors where exposure to environmental pollutants can be a problem, and it also provides impressive levels of performance when transferring heat or cold over long periods of time. It is commonly found in kitchenware such as pots and pans, as well as in laboratory equipment that requires precise temperature control over long periods of time.

Silver has one of the highest levels of thermal conductivity on the market, making it a suitable choice for certain industrial applications, such as high-end audio equipment or medical devices that need to maintain accurate temperatures at all times. Unfortunately, this material is quite expensive compared to other metals, but its impressive thermoelectric properties make it worth considering if price is not an issue. Also, you can find it in many electronic components, such as printed circuit boards, that require low resistance levels to work properly, as silver has one of the lowest resistance levels available today.

Lastly, Gold is known for its impressive conductivity among all the metals available on the world market, but its price reflects this accordingly, making it an impractical option for most applications unless cost is a factor. Despite this, in recent years, it has been increasingly used due to its ability to accurately transmit temperature over long distances without noticeable energy loss, making it suitable for certain medical procedures such as laser surgery or therapeutic treatments where constant precise monitoring of temperature is required. Gold can also be used in more luxurious items, such as jewelry or artwork, due to its attractive appearance and aesthetic properties when combined with other materials such as wood or stone.[3]

FAQ

Why is metal the best conductor of heat?

Metal is the best conductor of heat because it has a very low thermal resistance, which means it can transfer large amounts of heat energy from one place to another quickly and efficiently. This is due to the structure of atoms in metal, which have a comparatively high electrical conductivity and dense arrangement, which allows heat to pass through them quickly with minimal resistance.

Which metal holds heat the longest?

Gold is the metal that retains heat the longest due to its high thermal transmittance. It has one of the highest levels of thermal conductivity on the bullion market, making it a suitable choice for certain industrial applications, such as high-end audio equipment or medical devices that need to maintain a precise temperature at all times. In particular, it is resistant to corrosion and oxidation, making it a great material for outdoor use where exposure to contaminants is high. However, its price reflects this accordingly, making it an impractical variant for most applications unless cost is a factor. That said, Gold has been used more and more in recent years due to its superior thermal conductivity.

What metals heat up faster?

Lighter metals, such as Aluminum, tend to heat up faster than heavier metals, such as Gold. This happens as lighter metals have a higher electrical conductivity. Aluminum also has a higher specific heat capacity than heavier metals, which means it can absorb more energy before releasing it.

Is Gold the best conductor of heat?

No, Gold is not the best conductor of heat as it has one of the highest levels of thermal conductivity on the market. Other metals such as Aluminum and Silver may be more suitable depending on the application. In addition, lighter metals tend to absorb more energy, while heavier metals with a larger surface area tend to reflect more energy. Therefore, when choosing a metal for efficient thermal conductivity, you should consider not only cost, but also other factors such as weight, surface area, and corrosion/oxidation resistance.

What material holds heat best?

When it comes to which material retains heat the best, the most commonly used materials are ceramic, brick, concrete, glass, and metal. Ceramic and brick materials have a high thermal mass, which helps them absorb and retain heat more efficiently than other materials. This can be useful for certain applications, such as brick-built ovens, where you need to maintain a constant temperature for a long time.

Similarly, glass has a low thermal mass, so it heats up quickly but loses heat just as quickly, making it less suitable for applications where a constant temperature needs to be maintained over a long period of time. Metal is the most thermally conductive of these materials.Which metal is a bad conductor of heat?

Lead is a metal that is a poor conductor of heat compared to other metals. Due to its heavy atomic weight, it has one of the lowest thermal conductivity values on the market. Additionally, its melting point is much higher than other metals, meaning it can absorb more energy before it gets too hot and releases heat quickly.

The low thermal conductivity combined with the high melting point make lead a poor choice for applications where precise temperature control is required or where the temperature needs to be maintained for a long time. In addition, Lead is very susceptible to corrosion and oxidation, making it impractical for outdoor use despite its relatively low cost compared to other metals. So, while it can be a cost-effective choice in certain situations due to its low price and high resistance to erosion, its overall low thermal conductivity makes it unsuitable for most applications.

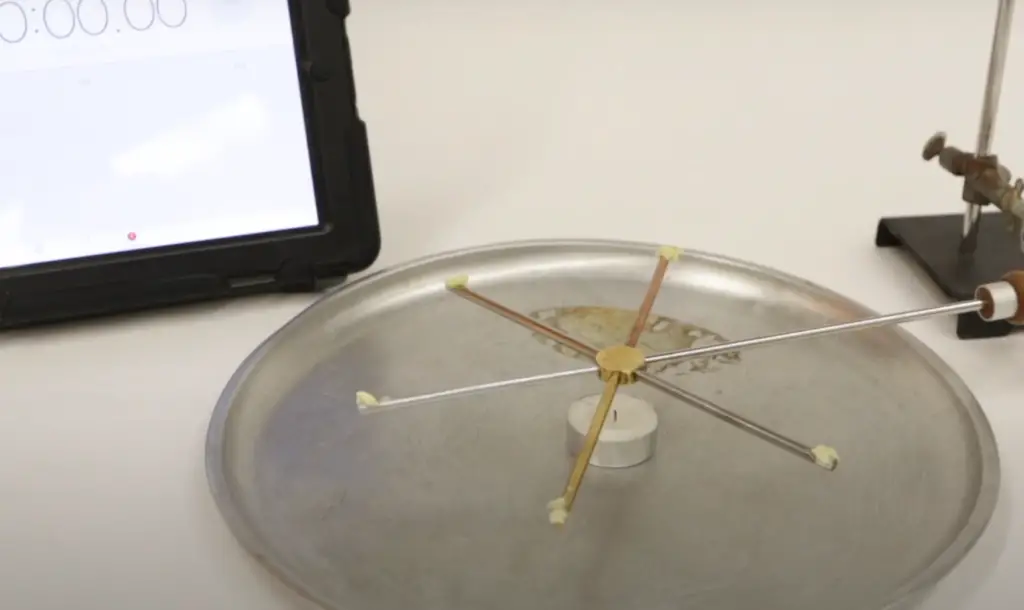

Useful Video:Which metal is the best conductor of heat?

Conclusion

Consequently, metal alloys are essential for modern manufacturing and engineering. They offer a wide range of advantages, such as increased strength, durability and corrosion resistance compared to all-metal materials. In addition, non-metallic alloys can be tailored with greater control over composition to meet specific requirements or performance criteria, making them an invaluable resource for engineers. Regardless of the application, choosing the right alloy is key to ensuring optimal results! By understanding how different metals work together in different proportions, you can create quality products at an affordable price that will withstand any challenges that come along the way.

References:

- https://www.metalsupermarkets.com/which-metals-conduct-heat-best/

- https://markhammetals.com/what-are-the-best-metals-for-conducting-heat/

- https://www.industrialmetalsupply.com/blog/best-metals-conducting-heat