Do you need to drill into metal studs? If so, you’re in luck! This blog post will teach you the right way to do it. Metal studs are becoming increasingly popular due to their many benefits. They are strong, durable, and can be used for a variety of applications. However, drilling into them can be tricky if you don’t know what you’re doing. In this post, we will teach you the proper techniques for drilling into metal studs. So read on and learn how to get the job done right!

Why Do You Need to Drill?

Before getting started, it’s important to ask yourself why you need to drill into the metal stud in the first place. If you’re hanging a picture or piece of artwork, you can usually find an alternative method that doesn’t require drilling.

But if you’re mounting a heavy shelf or piece of hardware, drilling into a metal stud is often the best way to ensure that your item is securely attached.

How to Drill Into Metal Studs?

Now that you know why you need to drill into metal studs, let’s take a look at how to do it. The process is actually quite simple, but there are a few things you’ll need to keep in mind to make sure everything goes smoothly.

Locate the Stud

The first step is to find the stud. In most cases, the stud will be located along the wall where you need to drill. To find it, use a stud finder or simply knock on the wall until you hear a solid sound. Once you’ve found the stud, mark its location with a pencil so you know where to drill.

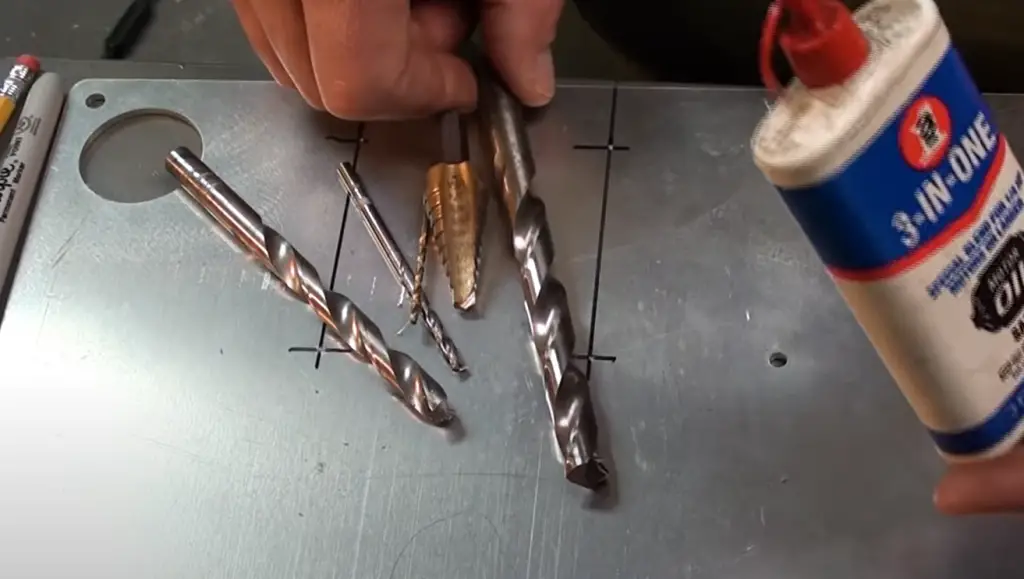

Choose the Right Drill Bit

The next step is to select the right drill bit for the job. For most applications, a standard metal drill bit will suffice. But if you’re dealing with particularly hard metals, you may need to use a carbide-tipped drill bit. These bits are more expensive, but they’re also much sharper and more durable.

Find the Edge, Then the Center

Once you’ve selected the right drill bit, it’s time to start drilling. But before you do, it’s important to find the edge of the stud. The easiest way to do this is to use a small nail or screw. Simply hold the nail or screw against the wall and then slide it until it hits the stud. Once you’ve found the edge of the stud, mark that location with a pencil. [1]

Screw vs. Gauge

Now that you’ve found the center of the stud, it’s time to decide whether you want to use a screw or a gauge to start your hole.

These bits are so sharp that they can easily cut through metal without much effort. But if you’re using a standard metal drill bit, a gauge may be a better option.Create the Pilot Hole

With the help of your chosen starting tool, create a small pilot hole in the center of the stud. This hole doesn’t need to be very big—just big enough for your drill bit to fit through.

Attaching Trim

Now that you’ve drilled your hole, you’re ready to attach your trim or hardware. To do this, simply insert a screw or nail into the hole and then screw or hammer it into place.

Plumbing and Electrical Holes

If you’re drilling a hole for plumbing or electrical work, the process is a little different. These holes need to be much larger than traditional pilot holes, so you’ll need to use a different drill bit. We recommend starting with a 1/2-inch spade bit.

Hole Saw

For even larger holes, you may need to use a hole saw.

Hole saws are specialized drill bits that can create large, circular holes in metal—perfect for plumbing and electrical work. [2]

Metal Stud Punch

If you’re working with particularly thin metal, a metal stud punch may be the best option. These tools are designed to create small pilot holes in metal without the need for a drill.

When to Use a Drill Press?

Most people don’t have a drill press in their home workshop. If you’re one of those people, don’t despair, you can still complete many woodworking projects without one. However, there are some circumstances where a drill press would be very useful. For example, if you need to make a lot of holes that are exactly perpendicular to the surface, it’s much easier to use a drill press than a handheld drill. This is especially true if the holes are small. It’s also easier to get a more consistent depth of hole with a drill press. If you’re drilling large holes (over 1/2 inch), or if you’re drilling through hardened steel, a drill press will give you better results than a handheld drill.

Pros of Using Metal Studs

There are several reasons to use metal studs in construction and renovation projects. Metal studs are:

- Lighter weight than wood, making them easier to work with

- More fire resistant than wood

- Non-conductive, so they’re ideal for electrical projects

- Resistant to pests like termites and carpenter ants

- Eco-friendly since they can be recycled

Cons of Using Metal Studs

Despite the benefits of using metal studs, there are also a few drawbacks to consider. Metal studs are:

- More expensive than wood studs

- Require special tools for cutting and drilling

- May be more difficult to find in some hardware stores

Types of Metal Studs

There are three primary types of metal studs: cold-formed steel, hot-rolled steel, and stainless steel. Each type has its own benefits and drawbacks that you should be aware of before beginning any project.

Cold-Formed Steel Studs

Cold-formed steel studs are the most common type of metal studs used in construction. They are crafted from thin sheets of steel that have been cold-rolled into shape. Cold-formed steel studs are strong and lightweight, making them easy to work with. However, they’re also more susceptible to damage from moisture and heat than other types of metal studs. [3]

Hot-Rolled Steel Studs

Hot-rolled steel studs are made from thicker sheets of steel that are heated and then rolled into shape. These studs are more expensive than cold-formed steel studs, but they’re also more durable. Hot-rolled steel studs are less likely to be damaged by moisture and heat, making them a good choice for projects that will be exposed to the elements.

Stainless Steel Studs

Stainless steel studs are made from an alloy of steel and chromium. This makes them more resistant to corrosion than other types of metal studs.

However, stainless steel studs are more expensive than other types of metal studs.Are Metal Studs Stronger than Wood?

Metal studs are stronger than wood studs, but they’re also more expensive. If you’re choosing between metal and wood for your project, consider the strength of the material you’ll be using.

Metal is a good choice for projects that require extra support, such as load-bearing walls. However, wood is a better choice for projects where aesthetics are important, such as shelving or trim.

Do Steel Studs Rust?

Steel studs can rust, but they’re less likely to than other types of metal studs. Stainless steel studs are the least likely to rust, followed by hot-rolled steel studs. Cold-formed steel studs are the most likely to rust, so if you’re using them in a project that will be exposed to moisture, make sure to paint or seal them to protect them from the elements.[4]

How Far Should A Screw Go Into A Stud?

Most screws should be driven into the stud until the head is level with the surface of the wood. This will ensure that the screw is driven far enough into the stud to create a strong connection, but not so far that it protrudes through the other side of the stud and becomes a tripping hazard.

Can A Cordless Drill Go Through Metal?

You want to hang a picture or mirror but there are no studs in the wall where you want to put it. You could use drywall anchors, but those only work if there’s something solid behind the drywall. If not, the anchor will just pull out of the drywall, taking your picture (or mirror) with it.

The next best thing is to drill into a metal stud. But can a cordless drill go through metal?

The answer is yes, but it’s not as easy as drilling into wood. You’ll need to use a different type of bit and drill at a lower speed. With the right tools and techniques, you can successfully drill into metal studs without damaging your drill or the studs. [5]

Things to Avoid When Drilling Into Metal Studs

- Do not use a dull drill bit. This will cause the metal to overheat and discolor.

- Do not use too much pressure when drilling. This can cause the drill bit to slip and damage the metal studs.

- Do not use an impact drill when drilling into metal studs. This can damage the studs and cause them to break.

- Do not use a power drill when drilling into metal studs. Not only does this method damage the studs, but it also increases the likelihood of them breaking.

- Do not use a hand drill when drilling into metal studs. This can be hazardous and might result in the studs shattering.

Where to Use Metal Studs?

Metal studs are most commonly used in commercial construction, but they have also been gaining popularity in residential applications in recent years. They offer a number of advantages over traditional wood framing, including increased fire resistance, termite resistance, and mold resistance. Metal studs are also much lighter than wood, so they’re easier to handle during the construction process.

Drilling into metal studs is different from drilling into wood, and if you don’t do it correctly, you could damage the studs or even injure yourself.How to Avoid Hurting Yourself?

One of the biggest dangers of drilling into metal studs is that the drill bit can slip and hit you in the hand or arm. To avoid this, always use a drill with a chuck that can grip the bit tightly. If you’re using an older drill that doesn’t have a locking chuck, wrap a piece of tape around the bit to keep it from slipping.

Another danger is that the metal can create sparks when it’s being drilled. To avoid being hit by flying sparks, wear safety glasses or a face shield while you’re working.

FAQ

Is it OK to drill into metal studs?

Yes, it is perfectly fine to drill into metal studs. In fact, drilling into metal studs is often necessary when hanging pictures or other items on a wall. The key is to use the proper type of drill bit and to exercise caution so that you don’t damage the wall.

How do you drill through a metal stud?

There are a few different ways that you can drill through a metal stud. The best way will depend on the type of metal stud that you’re dealing with. If the metal stud is made from steel, then you’ll need to use a carbide-tipped drill bit. For aluminum studs, you can use a regular drill bit.

How do I know if I have a steel or aluminum stud?

The easiest way to tell the difference between steel and aluminum studs is by their weight. Steel studs are much heavier than aluminum studs. Another way to tell the difference is by looking at the surface of the stud. Aluminum studs will have a smooth, shiny surface, while steel studs will have a dull, matte finish.When drilling into metal studs, it is important to use the proper type of drill bit. For steel studs, you will need to use a carbide-tipped drill bit. For aluminum studs, you can use a regular drill bit. It is also important to exercise caution so that you don’t damage the wall.

What screws do you use on metal studs?

There are a variety of different screws that you can use on metal studs.

The type of screw that you use will depend on the weight of the item that you’re hanging and the type of metal stud that you’re dealing with. For lighter items, you can use drywall screws. For heavier items, you’ll need to use toggle bolts or tapcon screws.

Can you screw into metal framing?

Yes, you can screw into metal framing – but you’ll need to use the right type of screws and drill bit. If you’re hanging anything heavy on your walls, it’s important to drill into a stud. But what if there’s no stud where you need to hang something? You can still get the job done by drilling into metal framing. With the right type of screws and drill bit, you’ll be able to get a secure hold in any metal surface. Just follow these steps:

- Choose the right drill bit. For most applications, a standard twist drill bit will do the trick. But if you’re working with harder metals like stainless steel, you may need to use a carbide-tipped drill bit.

- Use the right type of screws. For most applications, you’ll want to use screws that are specifically designed for metal surfaces. These screws will have a sharp point that can penetrate metal without slipping.

- Drill slowly and steadily. When drilling into metal, it’s important to go slowly and steady your hand to avoid stripping the screw or damaging the material. Start by drilling a small pilot hole, then gradually increase the size of the hole until it’s big enough for the screw to fit through.

- Apply pressure evenly. When screwing into metal, apply pressure evenly to avoid stripping the threads. If you’re using a power drill, start on a low setting and increase the speed gradually until the screw is tight.

- Use a lubricant. To make it easier to drill into metal, you can apply a lubricant like WD-40 or cooking oil to the drill bit. This will help prevent the bit from overheating and damaging the material.

What drill bit should I use for metal?

For most applications, a standard twist drill bit will suffice. But if you’re working with harder metals like stainless steel, you may need to use a carbide-tipped drill bit.

Is it better to drill fast or slow through metal?

When drilling into metal, it’s important to go slowly and steady your hand to avoid stripping the screw or damaging the material. Start by drilling a small pilot hole, then gradually increase the size of the hole until it’s big enough for the screw to fit through.

Useful Video: How To Drill Through Metal (DIY)

Conclusion

When it comes to drilling into metal studs, there are a few things you need to keep in mind. First, make sure you have the right type of drill bit. Second, use a slow and steady speed when drilling. And finally, be careful not to damage the studs. With these tips in mind, you should be able to drill into metal studs like a pro!

References:

- https://www.hunker.com/13418484/how-to-drill-into-metal-studs

- https://topcordlesstools.com/blog/how-to-drill-into-metal-studs/

- https://iron-eng.com/blog/cold-formed-steel-framing-guide/

- https://www.thespruce.com/reasons-to-reconsider-steel-studs-1822847

- https://www.amazon.com/ask/questions/Tx39513W0NMT1N8/ref=ask_ql_ql_al_hza