How Much Does a Metal Fabricator Make?

In today’s economy, it’s important to know what kind of salary you can expect from different career paths. If you’re considering a career in metal fabrication, you’re probably wondering how much money you can make. Here’s a look at the average salary for metal fabricators.

What Does a Metal Fabricator Do?

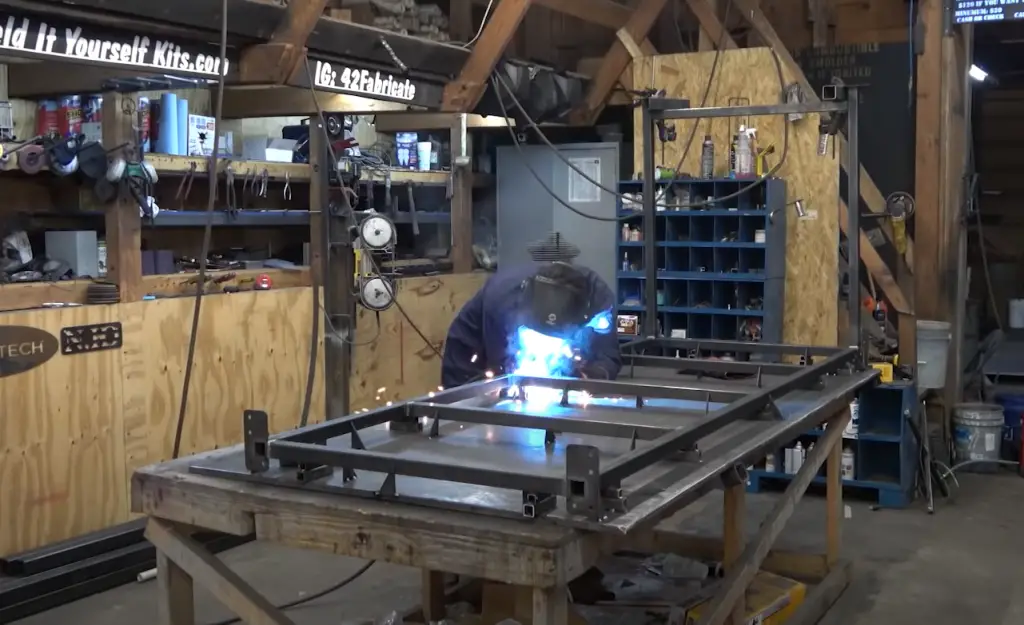

A metal fabricator is a skilled tradesperson who works with various metals and machinery to construct, repair, or manipulate products. Fabricators typically have experience in welding, cutting, and using power tools as well as manual labor techniques such as filing and grinding. They may be responsible for overseeing the entire production process from design to completion.

The job of a metal fabricator involves the use of many different materials including sheet metal, stainless steel, brass, aluminum, plastics and composites. A fabricator must know how to properly measure these pieces of material to create precise cuts and shapes that fit within their blueprinted design. Additionally they must be familiar with the properties of each type of metal in order to determine the best way to join them together. Fabricators must also be able to use various power tools safely and efficiently, as well as hand tools such as files and grinders.

Fabricators may work in a shop environment or onsite at a customer’s location depending on the project requirements. They are often responsible for planning out the production process from start to finish, including troubleshooting any problems that may occur along the way. Additionally, metal fabricators must ensure that all safety regulations are being followed and that their projects meet all quality standards before completing them. [1]

How Much Does a Metal Fabricator Make?

Metal fabricators make a wide range of salaries, depending on factors such as their experience and the type of work they do.

Metal fabricators who specialize in certain types of fabrication may also command higher wages than those who only take general jobs.Other factors that affect salary include location, type of employer (manufacturer versus custom shop) and benefits packages. In some cases, employers may offer bonuses or other incentives for completing certain projects or staying with the company for a set period of time. Ultimately, the amount that a metal fabricator earns is largely determined by the individual’s skill level, the type of work they do and the market in which they work.

Metal fabricators can also increase their earning potential by continuing to learn new skills and techniques, such as welding or machining. This type of training typically requires additional classes or certifications, but it can help metal fabricators stand out from others in their field and command higher wages. Additionally, experienced metal fabricators may be able to find a job with a company that offers better benefits packages than others in the industry. With a combination of experience, education and dedication, metal fabricators can maximize their earning potential. [2]

Pros and Cons of Working in Metal Fabrication

Working in metal fabrication can be a rewarding and challenging career for those who enjoy working with their hands. On the plus side, metal fabricators are well-paid, often earning an average of $50,000 to $60,000 per year depending on experience and location. They also get to work with a variety of materials such as aluminum, stainless steel, brass and copper.

On the downside, however, metal fabrication can be physically demanding work that requires strength, stamina and precision. The environment is often loud due to power tools and machinery being used throughout the day and there is always a risk of injury due to heavy lifting or careless use of equipment.

In addition, secondary safety concerns such as respiratory issues may arise from exposure to weld fumes or other hazardous materials. Additionally, workers must be aware of the dangers associated with working with electricity when using certain tools and machines.

Overall, metal fabrication is a rewarding career for those who are able to handle the physical demands and safety risks that come with it. It is important for those considering entering this field to weigh all aspects before making a decision. With proper training and experience, metal fabricators can enjoy stable employment and excellent wages in a variety of industries.

Metal Fabricator Responsibilities

A metal fabricator is responsible for designing and constructing metal products out of materials such as steel, aluminum, iron, copper, and other metals. They use a variety of techniques, such as welding, cutting, machining, and forming to create the finished product. Metal fabricators typically work in production shops, where they are required to follow precise instructions for the design and construction process.

In addition to fabrication work, metal fabricators are often responsible for maintaining tools and machinery used in their respective shops. It’s important that a fabricator has good problem-solving skills in order to troubleshoot any issues that may arise during production.[3]

Metal Fabricator Requirements

The specific requirements for becoming a metal fabricator vary depending on the employer. Most employers seek metal fabricators who have at least a high school diploma or equivalent, along with experience in metal fabrication and welding. Some positions may require certification in welding or other related specialties.

Additionally, physical strength and endurance are important qualities to possess as metal fabricators must be able to lift and move heavy objects. Generally, employers prefer applicants with strong mechanical aptitude and good problem-solving skills.

Furthermore, it is helpful if they can read blueprints and diagrams associated with the job.

Other necessary skills include manual dexterity and attention to detail, as well as familiarity with tools such as welding torches, saws, grinders, drills, hydraulic presses and other machinery used in metal fabrication. Computer skills and the ability to use software specifically designed for metal fabrication are beneficial as well.

Overall, employers prefer applicants with a combination of education, experience and technical skills that make them knowledgeable about their craft and able to work safely. Therefore, those seeking to become a metal fabricator should strive to develop their credentials in order to increase their chances of success. [4]

What is Structural Metal Fabrication?

Structural metal fabrication is the process of constructing structures out of metal components. This type of work requires strong technical skills, as it involves cutting and forming metal into a variety of shapes and sizes to create structural components such as beams, columns, girders and more.

Structural metal fabricators also use welding techniques to join pieces together securely and accurately. The end product can vary significantly depending on the project, but may include bridges, towers or other large infrastructure projects. Metal fabricators typically operate heavy machinery including saws, drills, shears, grinders and presses to complete their tasks.

In addition to these tools they may utilize hand-held measurement devices such as calipers or micrometers in order to ensure accuracy when shaping materials.

What is Commercial Metal Fabrication?

Commercial metal fabrication is a process used to create large-scale fabricated metal products and components. It involves the use of different tools and techniques, such as welding, cutting, forming, punching and machining, to shape metals into desired shapes and sizes. The items made through this process are often found in commercial buildings, industrial facilities and other infrastructure projects. Commonly produced products include structural steel frames for buildings, staircases, railings, columns and beams.

Metal fabricators are typically employed by companies that specialize in the production of these products but may also be hired by general contractors for specific projects. In addition to their technical skills related to creating custom metal products from sheet materials or other forms of raw material stock, metal fabricators must also understand the principles and safety practices related to commercial metal fabrication. In order to be successful in this field, metal fabricators need to have an excellent understanding of the entire fabrication process from start to finish.

Is Fabrication The Same As Welding?

No, fabrication is not the same as welding.

Fabrication can refer to any process in which materials are cut, formed and assembled into larger structures or products. This may include cutting sheets of metal into certain shapes, bending and folding the pieces into 3-dimensional shapes, and then assembling all the components.

In addition to welding, other processes such as soldering, riveting, bolting and screwing may also be used during fabrication. Generally speaking, welders will focus on joining metals while fabricators will produce more complex parts from scratch using multiple processes. Both roles require similar skill sets, but fabricators typically require a more well-rounded skill set. For this reason, metal fabricators are usually paid higher salaries than welders as they have to be able to handle a wide variety of tasks. [5]

FAQ

What is the meaning of metal fabricator?

A metal fabricator is a person or company that cuts, shapes, and forms metal components to create products. They are often employed by engineering firms to produce custom parts used in the construction of machinery or other devices.

How much does a metal fabricator make?

This depends on their experience level and location, as wages can vary greatly from region to region. According to PayScale, the average pay for a metal fabricator ranges between $30,000 and $60,000 per year in the United States. Those with more experience may earn higher salaries up to $83,000 annually.

What kind of job duties does a metal fabricator have?

Metal fabricators usually begin by reading blueprints to understand the specifications of the part they are making. They then use machines to cut and shape the metal according to those instructions. Other duties include welding, forming parts with a press brake, grinding edges, and performing quality control tests on final products.

What kind of qualifications do you need to become a metal fabricator?

Most employers require applicants for metal fabrication positions to have at least a high school diploma or GED. Some employers may also request certifications in various areas such as welding or machining. In addition, experience working with metal fabrication tools is often preferred by employers.

Is fabrication the same as welding?

No, fabrication refers to the entire process of building products from metal components. Welding is one part of this process, but it does not encompass the whole thing. Fabrication requires knowledge and skill in both welding and other areas such as cutting, shaping, and forming pieces with a press brake.

What are some common tools used by metal fabricators?

Metal fabricators usually use a variety of machines to carry out their job duties. These include items such as lathes, drill presses, plasma cutters, shears, welding machines, and press brakes. They may also use hand tools such as hammers and chisels for more precise work.

What are three types of fabrication?

Metal fabrication is the process of constructing metal parts and components for a variety of uses. It involves cutting, bending and assembling processes to create items such as machine frames and parts, structural supports, tanks, containers and other objects. There are three main types of metal fabrication: welding, machining and assembly. Welding is the process of joining two pieces of metal by melting them together with an electrical or gas arc. This type of fabrication requires specialized tools and training to ensure safety in the workplace. Machining involves cutting away material from a block or component using tools such as lathes and mills. This can also include drilling holes into metals for fastening purposes. Lastly, assembly includes joining pre-made components by riveting, bolting or welding into a finished product.

Useful Video: How much do sheet metal fabricators make?

Conclusion

In conclusion, the salary of a metal fabricator is highly dependent on the amount of experience they possess, their specialized skill set and their geographic location. Someone with an advanced degree in metal fabrication may expect to make more than entry-level workers in the field. On average, metal fabricators can expect to earn between $35,000 – $50,000 per year depending on experience. With the right combination of skill and determination, a metal fabricator may be able to find employment with higher wages or even better job opportunities elsewhere.

It is important for any aspiring metal fabricator to understand that this type of work requires hard physical labor as well as technical knowledge and training in order to be successful. As long as individuals are willing to put in the time and effort to learn the trade, there is a good chance they can find a career in metal fabrication that is both satisfying and lucrative.

References:

- https://www.salary.com/research/salary/posting/metal-fabricator-hourly-wages

- https://www.indeed.com/career/metal-fabricator/salaries

- https://money.usnews.com/careers/best-jobs/fabricator/salary

- https://www.tws.edu/blog/skilled-trades/what-does-a-metal-fabricator-do/

- https://skillpointe.com/careers/construction/metal-fabricator