Choose the Best Sawzall Blade for Metal

Customer’s Choice: the Best Rated Sawzall Blades for Metal

103 users answered this survey. Please help us improve this review!

You can find saw blades at any woodworking shop. Nowadays a lot of different types and sizes of saw blades appear on the market, and each one has its own set of pros and cons. In this guide, we will broach the subject of saw blades: what are they, their working capacities, the different types that market gives, and what you need to consider before purchasing one. We will also compare some popular brands and models to help you make the best decision for your needs!

BOSCH reciprocating Saw Blades for Metal cutting – the Editor’s choice!

The BOSCH RM6 5 Pack set reciprocating Saw Blades are perfect for any metal cutting needs you may have. With a thick kerf and tall body, these blades from the world-leading manufacturer of linear edge tools can make easy cuts through metal with precision and accuracy.

The BOSCH RM6 5 Pack set reciprocating Saw Blades are perfect for any metal cutting needs you may have. With a thick kerf and tall body, these blades from the world-leading manufacturer of linear edge tools can make easy cuts through metal with precision and accuracy.

Irwin Reciprocating Saw Blades, 11-Piece Set – the best for composition materials!

The Irwin Saw Blades is a great choice for anyone who needs an adaptable and long-lasting blade set. The blades are made with a use of bi-metal material, which makes them resistant to wear and tear. They also feature precision-set teeth that ensure slick and fast cuts.

The Irwin Saw Blades is a great choice for anyone who needs an adaptable and long-lasting blade set. The blades are made with a use of bi-metal material, which makes them resistant to wear and tear. They also feature precision-set teeth that ensure slick and fast cuts.

DEWALT Reciprocating Saw Blades 6-Piece – the best for durability!

Looking for a prolonged life of your reciprocating saw blades? The DEWALT brand has a great option for your needs. With 24 teeth that are compatible with both metal and wood, these blades will make quick work of any project you’re working on. Plus, the teeth are patented and have an optimization form for chip removal and are more efficient while cutting.

Looking for a prolonged life of your reciprocating saw blades? The DEWALT brand has a great option for your needs. With 24 teeth that are compatible with both metal and wood, these blades will make quick work of any project you’re working on. Plus, the teeth are patented and have an optimization form for chip removal and are more efficient while cutting.

WORKPRO 32-Piece Reciprocating Saw Blade Set – the best for coarse wood!

Looking for a set that is reliable and has versatility for many materials? Check out the WORKPRO 32-Piece Reciprocating Saw Blade Set. The set is made of durable Cr-V steel construction, these saw blades have an option to cut through a coarse wood with a thickness of 20-175mm – all without hitting any nails.

Looking for a set that is reliable and has versatility for many materials? Check out the WORKPRO 32-Piece Reciprocating Saw Blade Set. The set is made of durable Cr-V steel construction, these saw blades have an option to cut through a coarse wood with a thickness of 20-175mm – all without hitting any nails.

Diablo DS0908CF 9″ Steel Demon Carbide Recip Blade – the best for thick metal!

The Diablo brand is the perfect solution for cutting thick metal. The blades set a great example of impact resistance and upright cuts with smoother work and less vibration. Don’t bother about your blade slipping off the working table!

The Diablo brand is the perfect solution for cutting thick metal. The blades set a great example of impact resistance and upright cuts with smoother work and less vibration. Don’t bother about your blade slipping off the working table!

Buyer’s Guide

Saw blades: what you need to know

Saw blades are cutting tools that are used to cut through different types of materials, including wood, metal, plastic, and stone. Power tools are the best way to get a job done, but if you’re not experienced with them there’s no shame in hand tools. You can find them in many shapes and sizes so even those who think they don’t need power equipment can find something for themselves at home.

The world of construction has changed dramatically over recent years. New technologies allow us greater control than ever before- whether this means operating heavy machinery by ourselves or using simpler methods like chisels and hammers instead!

As to the saw blades, they are typically made from high-carbon steel or tungsten carbide.

Usually saw blades fall into two main categories: hand saws and power saws. Hand saws are smaller in size and usually have teeth that are less than an inch long. They are used for making precise cuts in small pieces of wood or other materials. Power saws, on the other hand, are larger in size and have longer teeth that can reach up to several inches in length. They are typically used to make rough cuts in larger pieces of wood or other types of materials.

There are a variety of types of saw blades currently available on the market, and each one is designed for a specific purpose.

The most popular types of saw blades include

Rip saws

Rip saws have teeth that are arranged in a straight line. They are used for making rip cuts, which are cuts that are made along the grain of the wood.

Crosscut saws

Crosscut saws have teeth that are arranged in a cross pattern. They are used for making crosscuts, which are cuts that are made across the grain of the wood.

Combination saws

Combination saws have teeth that are arranged in both a straight line and a cross pattern. They are used for making both crosscuts and rip cuts..

Plywood saws

Plywood saws have teeth that are designed specifically for cutting plywood. They typically have more teeth than other types of saw blades, that helps to prevent the blade from getting bogged down in the material.

Metal-cutting saws

Metal-cutting saws have teeth that are made from tungsten carbide or another type of hard metal. They are used for cutting through metals such as steel, aluminum, and copper.

Stone-cutting saws

Stone-cutting saws have diamond-tipped teeth that are designed for cutting through stone.

It is the only type of saw blades that are used for cutting through stone.

The best way to know if you’ve chosen a suitable saw blade for your project might be figuring out how much power you need.

The use of saw blades

Saw blades have a variety of options, but they will only work in the arms of skilled craftsman. Their task includes:

- Cutting wood

- Cutting metal

- Cutting stone

- Cutting plastic

- Making precise cuts

- Making rough cuts

Saw blades can be operated by hand or by power tools. Hand saws are typically used for making precise cuts in small pieces of wood or other materials. Power saws, on the other hand, are typically used for making rough cuts in larger pieces of wood or other materials.

Think ahead when choosing a saw blade. If you are not sure which type you need exactly, consult with a professional or read the instructions that came with your power tool. The wrong type of blade can damage your material or even injure you.

Now that we have a better understanding of what saw blades are and how to use them in your work, let’s see why they’re a necessity in your toolbox. [2]

Why should you have one

Saw blades are an essential part of any woodworking or metalworking project. They come in a wide range of sizes and shapes and can be operated by hand or by power tools. Saw blades are typically made from high-carbon steel or tungsten carbide.

There are many different types of saw blades available on the market, each one designed for a specific purpose. With the help of saw blades, you can do a different job at your workshop. Let’s review some popular models which are in an A-list of many workers who are using saw blades.

Popular models in demand

As we mentioned earlier, these are the top 4 on the list of the most popular ones.

Rip saws

The teeth on a rip saw are arranged in an orderly, straight line. This particular type of cut is made by running the tool along with grain direction for incisions that will result deep enough to reach what’s called “true wood.”

Crosscut saws

Crosscut saws have teeth that are arranged in a cross pattern. The advantage to this type of cut is it can be made across the grain, which means less work for you!

Combination saws

The blade of a combination saw is made up of both straight-line and cross patterned teeth. This makes it useful for cutting wood in different ways, like when you need to make ripped cuts or notches at an angle (like building decks).

Plywood saws

When you need to cut plywood, a wider tooth design is going to be best for your job. These blades have more points on them than other types of saws do which helps avoid getting caught up in the material and bogs down while cutting quickly!

Materials

Saw blades are typically made from high-carbon steel or tungsten carbide.

It is a relatively strong material that is often used for making tools and machine parts. Tungsten carbide, on the other hand, is a type of metal that contains both tungsten and carbon. It is an extremely hard material that can only be machined using diamond-tipped tools.The type of material of your saw blade will determine its price and how long it will last. Generally, saw blades made from tungsten carbide are more high-priced compared to those made from carbon steel. However, they will last longer and be harder, so you know what you are paying for.

If you are only going to be using your saw blade for occasional projects, then a carbon steel blade should be sufficient. However, if you plan on using your saw blade frequently, then a tungsten carbide blade may be a better investment.

Performance comparison

There are many factors that you should consider when looking for a saw blade. These include the type of material you will be cutting, the size of the project, and your budget.

Type of material: The type of material you will be cutting will determine the type of saw blade you need. For example, if you are only going to be cutting wood, then a rip saw or crosscut saw should suffice. However, if you plan on also cutting metal or stone, then you may need a different type of blade.

Size of project: The size of your project will also dictate which type of saw blade to use. If you are only working on small projects, then a smaller blade may be all you need.

Budget: Think about how much money you are ready to spend on a tool. Generally, saw blades that are made from tungsten carbide are more expensive than those made from carbon steel. However, they are also much harder and will last longer.

Additional characteristics

Let’s take a look at other characteristics of a saw blade that are also important to consider, when choosing the right one for you. These include the following:

The type of saw

Some blades are only compatible with certain types of saws. For example, circular saws use different blades than reciprocating saws. Make sure to check that the blade you want is compatible with your saw before making a purchase.

The size of the blade

The size of the blade will determine how deep and how wide it can cut. Larger blades can make deeper cuts but may be more difficult to control. Smaller blades can make shallower cuts but may be easier to maneuver. Choose the size that best suits your needs.

The number of teeth

The number of teeth on the blade will determine how fast it can cut. More teeth mean a slower cut, but a smoother finish. Fewer teeth mean a faster cut, but a rougher finish. Choose the number of teeth based on the type of project you are working on.

The material

Saw blades are made from different materials, including carbon steel, tungsten carbide, and diamond. Each material has its own advantages and disadvantages. Consider the material that best suits your needs before making a purchase.

Now that you know what to look for in a saw blade, you can make an informed decision about which one is right for you. With so many options on the market, there is sure to be a blade that meets your needs.

Prices

Prices for saw blades can range from a few dollars to over one hundred dollars. The price will depend on the quality of the blade, the material it is made from, and the brand. Some brands are more expensive than others, but this does not necessarily mean that they are of better quality. Look at the prices and compare them before making a purchase.

Prices at the market are quite different and it all depends on the quality and characteristics of the saw blade. The average price for a good-quality saw blade is about $30.

There are many factors to consider before the purchase.

After all the research you surely will be able to find the right tool.When it comes to saw blades, you get what you pay for. Cheaper blades will not last as long and may not be as durable. If you plan on using your blade frequently, it is worth investing in a higher-quality blade that will last longer and perform better. However, if you only need a blade for occasional use, a cheaper option may be sufficient.

Manufacturers

There are many manufacturers of saw blades. Some of the most popular brands include Bosch, Dewalt, Irwin, and Milwaukee. These brands offer a variety of different blade types and sizes to suit your needs. Do some research to find the brand that best suits your needs before making a purchase.

Bosch is one of the leading manufacturers when it comes to saw blades. The company offers a wide range of products for different applications. Their blades are made using high technology, so they show good characteristics and quality. Dewalt is another popular manufacturer of saw blades. Their products are known for their quality and performance.

Irwin is a trusted name in the saw blade industry. Their blades are designed for precision and accuracy, making them perfect for any project. The manufacturer offers a high range and variety of products, so it will be easier to find the type that you are looking for. Milwaukee is a leading manufacturer of saw blades. Their products are known for their durability and performance.

Tips for choosing the best saw blade

Now that you know what to look for in a saw blade, you can make an informed decision about which one is right for you. With so many options on the market, there is sure to be a blade that meets your needs. Here are a few tips to help you choose the best saw blade for your working project:

- Read reviews: Before making a purchase, read reviews of the different brands and models of blades. This will give you an idea of which ones are the best quality and which ones to avoid.

- Compare prices: Prices can vary greatly between different brands and models of blades. So check them before making a final decision.

- Choose the right size: The size of the blade you need will depend on the type of saw you are using. Make sure to choose a blade that is the right size for your saw.

- Consider the material: The material of the blade is important to consider. Some materials are better suited for certain projects than others. Choose a blade made from a durable material that can handle your project.

- Check the warranty: When making a purchase, be sure to check the warranty. This will give you peace of mind in knowing that you are covered in case anything goes wrong with the product.

With these tips in mind, you should be able to find the perfect saw blade for your needs.

FAQ

What are the three types of saw blades?

The three types of saw blades are circular, reciprocating, and jigsaw.

Circular saw blades are the most popular type of blade. They are used with a handheld circular saw or a table saw. Reciprocating saw blades are used with a reciprocating saw. They have teeth that move back and forth to cut through the material. Jigsaw blades are used with a jigsaw. They have teeth that move up and down.

Each type of blade is designed for different applications. Choose the type of blade that is best suited for your project.

How many teeth should my saw blade have?

The number of teeth on a saw blade varies depending on the type of blade and the application.

Circular saw blades typically have between 24 and 80 teeth. Reciprocating saw blades usually have between 18 and 24 teeth. Jigsaw blades can have anywhere from 14 to 36 teeth.

The number of teeth will affect the speed, smoothness, and accuracy of the cut. Choose a blade with the right number of teeth for your project.

What blade is best for cutting wood?

A circular saw blade with between 24 and 80 teeth is best for cutting wood. A reciprocating saw blade with 18 to 24 teeth can also be used for cutting wood.

For a smoother, more precise cut, choose a blade with more teeth. For a faster, rougher cut, choose a blade with fewer teeth.

Also, be sure to select a blade that is the right size for your saw. Using a blade that is too big or small for your saw can damage the tool and cause injuries.

When cutting wood, it is important to use the right type of blade. Be sure to choose a circular or reciprocating saw blade with the right number of teeth for your project. Also, make sure the blade is the right size for your saw. Using the wrong type of saw blade or the wrong size blade can cause damaging of the tool and injuries.

With so many different types of saw blades on the market, it can be difficult to know which one to choose. Use this guide to help you find the best saw blade for your needs. With a little research, you can find the perfect blade for your next job. [3]

How long does a saw blade last?

The lifespan of a saw blade depends on the type of blade, the material it is made from, and how often it is used.

A circular saw blade can last anywhere from one to two years with regular use. A reciprocating saw blade typically lasts six to twelve months with regular use. And a jigsaw blade can last up to three years with regular use.

It is important to inspect your blades regularly and replace them when they become worn out. Using a dull or damaged blade can damage your saw and cause injuries.

Be sure to check your blades often and replace them when needed to keep your saw in good condition.

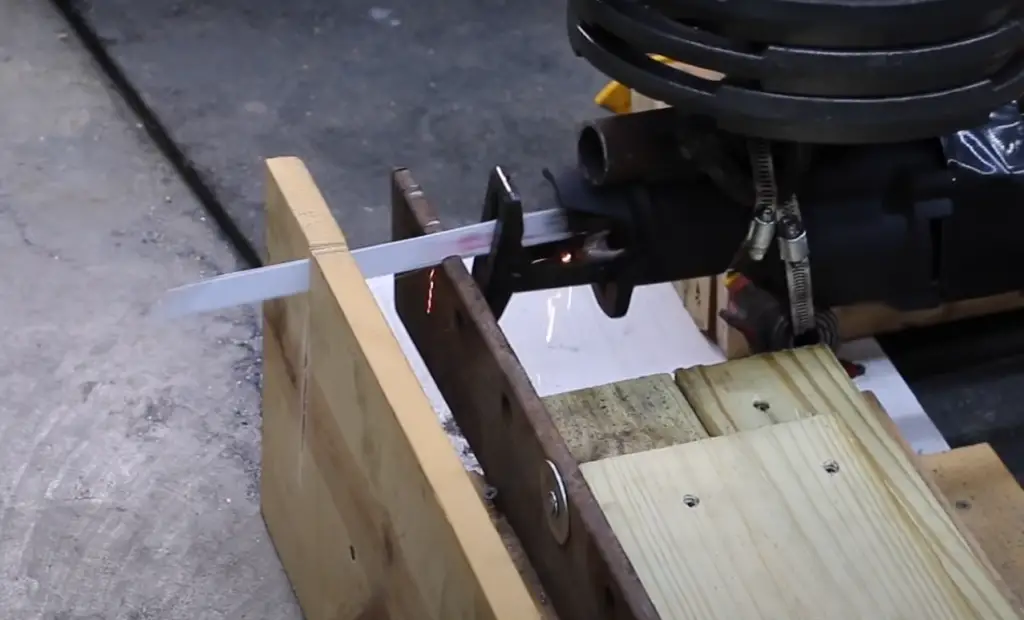

Useful Video: Best CARBIDE Thick Metal Sawzall Blade Brand? Let’s find out!

Conclusion

So, how do you choose the best saw blade for your needs? Start by considering the type of material you need to work with. If you’re working with metal or hard plastics, you will need a different blade than if you are working with wood. Next, think about the thickness and hardness of the material. The harder the material, the more teeth per inch (TPI) your blade should have. Finally, consider how much money you want to spend on blades versus how often you plan to use them. Keep in mind that high-quality saw blades can last many years if properly cared for. Armed with this information, choosing the right saw blade is easy!

References:

- https://www.toolstoday.com/g-44-circular-saw-and-blades-a-basic-overview

- https://www.globalspec.com/learnmore/manufacturing_process_equipment/cutting_tools/saw_blades

- https://www.familyhandyman.com/list/best-circular-saw-blades