Choose the Best Dremel Bit for Cutting Metal

Customer’s Choice: the Best Rated Dremel Bits for Cutting Metal

66 users answered this survey. Please help us improve this review!

Dremel is a brand that is well-known for its rotary tools. But did you know that they also make a great line of bits specifically designed for cutting metal? In this article, we will discuss the different types of Dremel bits available and what each one is best suited for. We will also provide some tips on how to get the most out of your Dremel when cutting metal. So, whether you are a hobbyist who likes to work with metal or a professional who needs to do some occasional metal cutting, this article is for you.

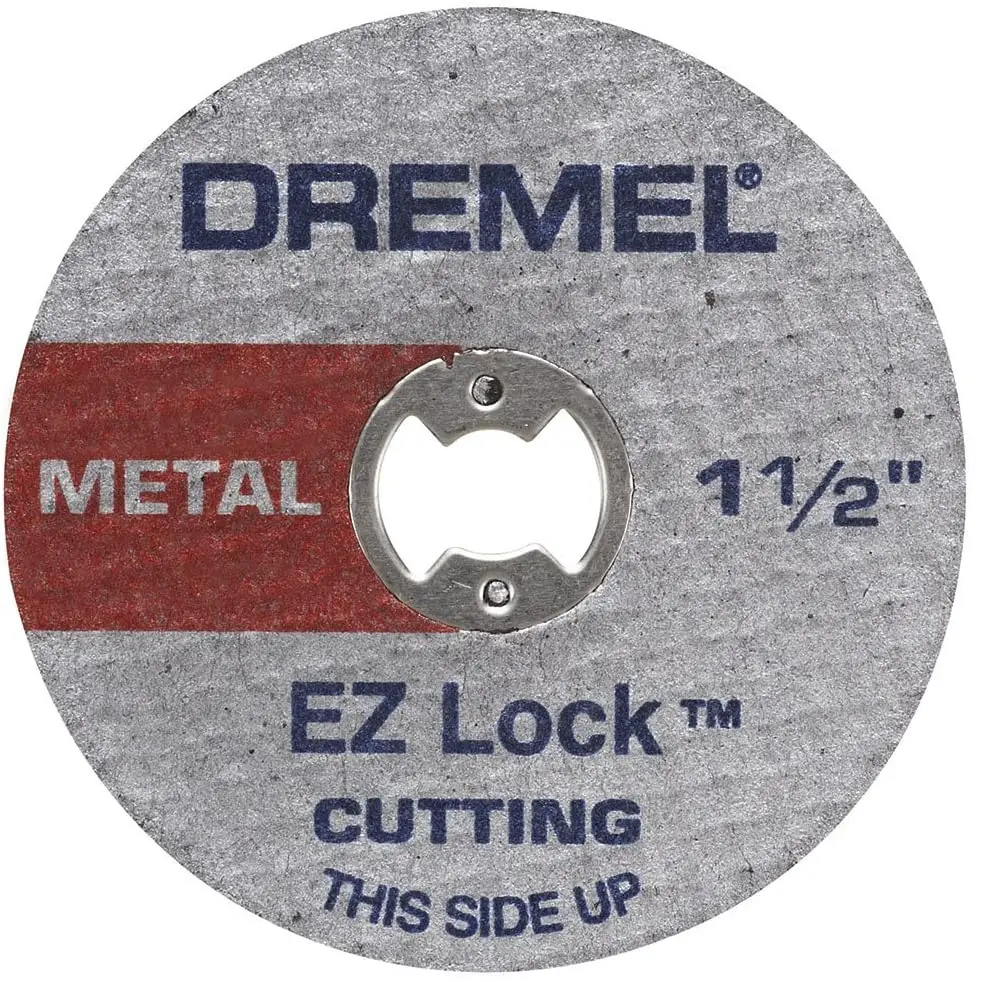

Dremel EZ406-02 Cut-off Wheels – Long-Lasting, Labeled Cut-Off Wheels!

The Dremel EZ406-02 Cut-off Wheels are the perfect tool for a wide variety of metal cutting projects. With a 1-1/2 In. (38.1 mm) wheel diameter and 0.045 In. (1.1mm) thick blade, these highly-durable cut-off wheels offer long-lasting performance on even the toughest materials.

The Dremel EZ406-02 Cut-off Wheels are the perfect tool for a wide variety of metal cutting projects. With a 1-1/2 In. (38.1 mm) wheel diameter and 0.045 In. (1.1mm) thick blade, these highly-durable cut-off wheels offer long-lasting performance on even the toughest materials.

Overall, the Dremel EZ406-02 Cut-off Wheels are an excellent choice for a wide variety of metal cutting projects. The high durability and long lasting performance make them a great choice for even the most challenging applications. The patented EZ Lock system makes accessory changes quick and easy, so you can keep your projects moving forward with minimum interruption. If you are looking for a versatile and reliable metal cutting solution, the Dremel EZ406-02 Cut-off Wheels are a great option to consider.

Dremel 420 Cut-off Wheels – Ideal For Cutting All Kinds Of Metal!

If you’re looking for a rotary tool that can double as a cutting machine, the Dremel 420 is a great option. The 420 features a 15/16 In. (23.8 mm) wheel diameter and 0.04 In. (1.0 mm) thick blade, making it ideal for slicing, making straight cuts, and slots in all kinds of metal, including hardened steel, sheets metal, and aluminum. [2]

If you’re looking for a rotary tool that can double as a cutting machine, the Dremel 420 is a great option. The 420 features a 15/16 In. (23.8 mm) wheel diameter and 0.04 In. (1.0 mm) thick blade, making it ideal for slicing, making straight cuts, and slots in all kinds of metal, including hardened steel, sheets metal, and aluminum. [2]

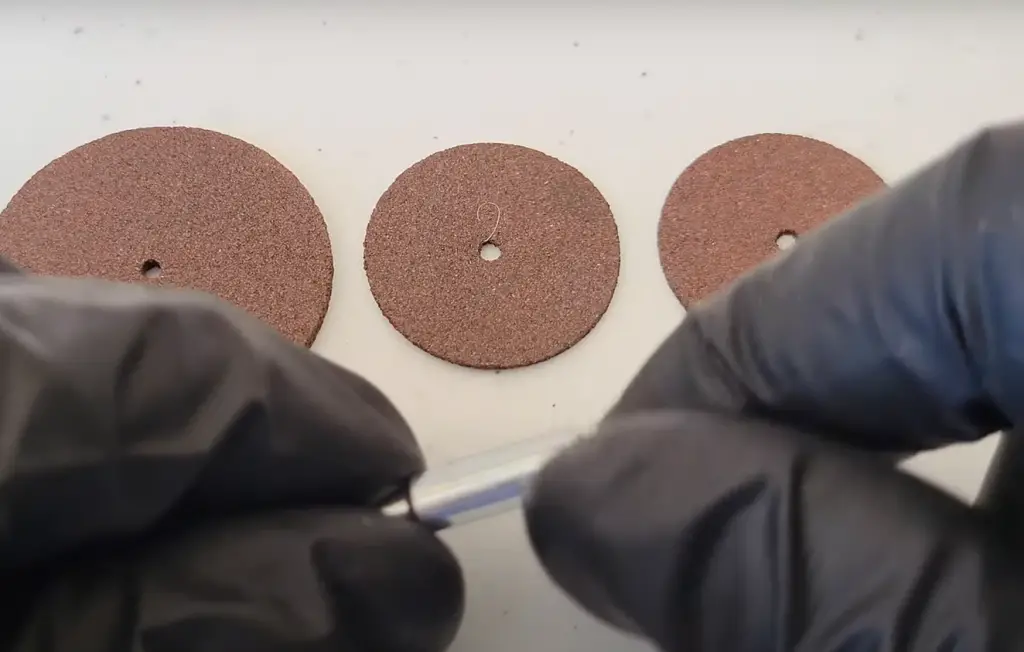

Dremel EZ456 Cut-off Wheels – Safety First!

The Dremel EZ456 Cut-off Wheels are reinforced with fiberglass for increased durability, making them ideal for cutting or slotting bolts, screws, or sheet metal. They also work great for thin wood, ceramic, and plastic. With a working diameter of 1-1/2″, these cut-off wheels will last 2X longer than other brands.

The Dremel EZ456 Cut-off Wheels are reinforced with fiberglass for increased durability, making them ideal for cutting or slotting bolts, screws, or sheet metal. They also work great for thin wood, ceramic, and plastic. With a working diameter of 1-1/2″, these cut-off wheels will last 2X longer than other brands.

So if you’re looking for a reliable, easy-to-use set of cut-off wheels that can handle just about anything, look no further than the Dremel EZ456 Cut-off Wheels!

Dremel 426 Cut-off Wheels – Top Quality!

The Dremel 426 Cut-off Wheels are the perfect solution for all your cutting, grooving and trimming needs. Made of a hard abrasive and reinforced with fiberglass, these wheels are 0.045″ (1.2 mm) thick with a diameter of 1 1/4″ (32.0 mm). [4]

The Dremel 426 Cut-off Wheels are the perfect solution for all your cutting, grooving and trimming needs. Made of a hard abrasive and reinforced with fiberglass, these wheels are 0.045″ (1.2 mm) thick with a diameter of 1 1/4″ (32.0 mm). [4]

Overall, the Dremel 426 Cut-off Wheels are an excellent choice for a variety of applications. So, if you’re looking for a reliable and affordable option, then these are the wheels for you!

Dremel 426B Cut-off Wheels – Editor’s Choice!

The Dremel 426B Cut-off Wheels are the ideal tool for quickly and easily cutting or slotting bolts, screws or sheet metal. These durable cut-off wheels are reinforced with fiberglass for increased durability and can easily handle even the most hardened steel.

The Dremel 426B Cut-off Wheels are the ideal tool for quickly and easily cutting or slotting bolts, screws or sheet metal. These durable cut-off wheels are reinforced with fiberglass for increased durability and can easily handle even the most hardened steel.

The Buyer’s Guide

The Basics Of Cutting Wheels

Types Of Cutting Wheels

There are three types of cutting wheels: abrasive, bimetallic, and diamond. Each type has its own benefits and drawbacks that you should consider before making a purchase.

Abrasive Cutting Wheels: Abrasive cutting wheels are the most common type of wheel used for cutting metal. They are made from a variety of materials, including aluminum oxide, silicon carbide, and zirconia.

However, they do wear down more quickly than other options and can create more dust and debris.Bimetallic Cutting Wheels: Bimetallic cutting wheels are made from two different metals bonded together. The most common combination is an aluminum oxide core with a steel outer layer. Bimetallic wheels are more durable than abrasive wheels and can be used on tougher materials. However, they are also more expensive and can create more sparks when used on metal.

Diamond Cutting Wheels: Diamond cutting wheels are the strongest and most durable type of wheel available. They are made from a diamond-coated metal or composite material and can cut through even the hardest metals. Diamond wheels are also the most expensive option and can produce more heat and sparks than other types of wheels.

Characteristics Of Dremel Bits

Dremel Bits are considered as one of the most versatile tools. It can be used for various purposes such as cutting, grinding, polishing, and carving. However, what sets it apart from other power tools is its ability to cut metal. [7]

Types Of Dremel Bits

Before you start using a Dremel Bit to cut metal, it is important to understand the different types of Dremel Bits available and their specific purpose. There are three main types of Dremel Bits for Cutting Metal:

- High-Speed Steel (HSS) Bits: These bits are the most common type of Dremel Bits used for cutting metal. They are made of high-speed steel which makes them durable and ideal for various applications.

- Titanium Coated Bits: Titanium coated bits are designed for durability and long life. They are perfect for use on hardened metals and can withstand higher temperatures.

- Carbide Bits: Carbide bits are the strongest type of Dremel Bits available. They are perfect for use on very hard metals and can withstand high temperatures.

Dremel cutting wheels materials

Dremel cutting wheels are made of different materials. The most common ones are grains, bonds and fiberglass. [6]

The type of material you choose will depend on what you’re cutting and your personal preferences.

Grain: Grain is the abrasive material that actually does the cutting. The most common grains used in Dremel cutting wheels are aluminum oxide and zirconium oxide.

Bond: The bond is what holds the grain together. The most common bonds used in Dremel cutting wheels are resinoid, rubber, shellac and vitrified.

Fiberglass: Fiberglass is often used as reinforcement for the other two materials. It provides strength and durability to the wheel.

Selecting Dremel Bits Based On Material

When choosing a Dremel cutting wheel, it’s important to consider the material you’ll be working with. Different materials require different types of wheels.

For example, if you’re cutting through metal, you’ll need a wheel with a harder bond and sharper grain.

Here are some general guidelines to help you choose the right Dremel cutting wheel for your project:

- If you’re cutting through soft materials like wood or plastic, use a wheel with an abrasive grain like aluminum oxide or zirconium oxide.

- If you’re cutting through hard materials like metal, use a wheel with a harder bond and sharper grain like resinoid or vitrified.

- If you’re looking for extra durability, choose a wheel with a higher concentration of abrasive grain.

- If you need a wheel that can be used on multiple materials, choose a universal wheel like resinoid or vitrified.

Keep these guidelines in mind when selecting a Dremel cutting wheel for your next project. With the right tool, you’ll be able to easily cut through any material.

Selecting Cutting Wheel Size

Now that we know the different types of materials Dremel can cut, let’s talk about selecting the right size cutting wheel.

Size: The diameter of the cutting wheel is an important factor to consider. The most common diameters are 16mm, 20mm and 22mm. Choose a size that will give you the best visibility and control while cutting.

Thickness: Cutting wheel thickness can range from 0.35mm to 0.80mm. A thicker wheel will last longer, but a thinner wheel will provide better visibility and control.

Dremel also offers a variety of thicknesses for its metal cutting wheels, so you can find the perfect one for your needs.

Now that we know how to choose the right size and thickness for our cutting wheel, let’s look at some safety tips.

Stay Safe Using A Cut-Off Wheel

As always, safety should be your number one priority when using any power tool. When using a Dremel to cut metal, be sure to wear eye protection and follow these safety tips:

- Inspect your cut-off wheel before each use to make sure it is not damaged

- Secure the workpiece so it cannot move while you are cutting

- Use a vice or clamp to hold the workpiece if necessary

- Keep your hands and fingers away from the cutting area

- Wear gloves if necessary to protect your hands [8]

- Use the right type of cutting wheel for the material you’re cutting (we’ll get into more detail on that later).

- Don’t force the tool – let it do the work.

- Be aware of kickback (when the wheel suddenly grabs the metal and throws it back at you).

- Following these safety tips will help you avoid accidents and injuries while using your Dremel to cut metal.

Proper Positioning And Other Tips

- When cutting metal with your Dremel, always use a cutting wheel that is specifically designed for metal. These wheels are usually made of high-speed steel or tungsten carbide and will stay sharp much longer than a standard abrasive wheel.

- To extend the life of your cutting wheel, use it only on one type of metal. Cutting different types of metals can cause the wheel to break down prematurely.

- Always use eye protection when using your Dremel. Flying metal shavings can cause serious injury to your eyes.

- If you’re having trouble cutting through a particularly thick piece of metal, try using a grinding stone attachment instead of a cutting wheel. The grinding stone will wear down the metal more slowly, but it will eventually get the job done.

- If you need to make a precise cut, use a cutting guide attachment. This attachment will help you to make straight, clean cuts every time.

Try to remember these tips and tricks the next time you use your Dremel to cut metal. With a little practice, you’ll be able to make perfect cuts every time!

When To Replace Dremel Bits For Cutting Metal

Dremel bits for cutting metal can last a long time if they are taken care of properly. However, there will come a time when they will need to be replaced. The following are signs that it is time to replace your Dremel bits for cutting metal:

- The bit is not cutting as cleanly as it used to

- The bit is starting to wear down and is not as sharp as it used to be

- You have been using the same bit for a long time and it is starting to show signs of wear and tear

- You are not getting the results you want with your current bit

If you notice any of these signs, it is time to replace your Dremel bits for cutting metal.

There are a few things you need to keep in mind when replacing Dremel bits for cutting metal.

First, you need to make sure you get the right size bit.

Second, you need to make sure the bit is compatible with your Dremel tool.

And third, you need to choose a material that is durable and will last long.

Following these tips will help you to safely replace your Dremel bits for cutting metal.

FAQ

How do I choose a cut-off wheel?

There are a few things you’ll want to keep in mind when choosing a cut-off wheel for your Dremel. The first is the material you’ll be cutting. If you’re only going to be cutting soft metals like aluminum or brass, you can get away with a lower grit wheel. However, if you’re planning on cutting harder metals like steel or stainless steel, you’ll need a higher grit wheel.

The second thing to consider is the thickness of the metal you’ll be cutting. Thicker metals will require a thicker cut-off wheel. You don’t want to use a thin wheel on thick metal, as it will just break under the pressure.

Finally, you’ll want to think about what kind of finish you want on your cut. If you’re looking for a clean, precise cut, you’ll want to go with a higher grit wheel. However, if you’re just looking to quickly get through a piece of metal, a lower grit wheel will do the trick.

What shouldn’t you do with a cut-off wheel?

Don’t use a cut-off wheel to grind or sand. The abrasive material is designed for cutting only. If you use it for grinding or sanding, the wheel will wear down quickly and unevenly.

Don’t use a cut-off wheel on aluminum. The soft metal clogs the abrasive material and makes the wheel ineffective.

Don’t force the cut-off wheel. It should cut easily without putting too much pressure on the tool. If you find yourself having to force it, stop and get a new wheel.

Don’t use a damaged cut-off wheel. If the wheel is cracked, chipped, or otherwise damaged, it could break while you’re using it and cause serious injury. Always inspect your wheels before use and discard any that are damaged.

Following these tips will help you get the most out of your cut-off wheels and stay safe while using them.

What is a metal cutting wheel made of?

A metal cutting wheel is made of an abrasive material, such as aluminum oxide or silicon carbide. The abrasive is bonded to a metal (usually steel or aluminum) plate with a resinous binder. The bonding agent determines how quickly the wheel wears down and how much heat it can withstand.

There are two types of metal cutting wheels: those for ferrous metals and those for nonferrous metals. Ferrous metals, such as iron and stainless steel, are harder than nonferrous metals, such as aluminum and copper. As a result, ferrous-metal-cutting wheels are usually made of harder materials, such as aluminum oxide or zirconia alumina. They’re also usually reinforced with fiberglass or other composite materials to help them hold up to the high temperatures generated by cutting hard metals.

Non Ferrous-metal-cutting wheels are made of softer materials, such as silicon carbide or cubic boron nitride. They’re not reinforced because they don’t have to withstand the high temperatures generated by cutting ferrous metals.

What is the difference between a cutting wheel and grinding wheel?

A cutting wheel is a thin, circular disc that is used to cut materials like metal and tile. A grinding wheel is a thicker, cylindrical disc that is used to grind down surfaces or remove excess material.

So, which one should you use when you need to cut metal?

In general, a cutting wheel will give you a cleaner cut and will be less likely to cause damage to the material you’re cutting. However, they can wear down more quickly than grinding wheels.

Grinding wheels are better for heavier-duty tasks, like removing rust or paint from metal surfaces. They can also be used to create a smooth finish on your workpiece. However, they can be more difficult to control and may cause more damage to the material if you’re not careful.

What causes cut-off wheels to break?

Cut-off wheels can break for a variety of reasons. The most common is probably due to misuse, such as trying to cut through material that is too thick or using the wrong type of wheel for the material you’re trying to cut. Sometimes, however, it’s simply because the wheel was defective to begin with.

If you’re having trouble with your cut-off wheels breaking, there are a few things you can do to try to prevent it. First, make sure you’re using the right type of wheel for the material you’re trying to cut. Second, don’t force the wheel – let it do the work. And finally, if possible, use a slower speed setting on your Dremel tool.

If you’re still having problems, it might be time to switch to a different type of cutting wheel altogether. There are many different types of Dremel bits available, so there’s sure to be one that will suit your needs.

Do cut-off wheels expire?

You might be wondering if cut-off wheels have an expiration date. The answer is no, they don’t expire. However, it’s important to inspect your cut-off wheels before each use and replace them if they show any signs of wear or damage.

What is the difference between Type 1 and Type 27 cut-off wheels?

The main difference between Type 27 and Type 01 cut wheels is the former has a depressed center while the latter has a raised one. This means that when you attach each type of wheel to your Dremel, they will protrude in different ways. With a Type 27, less of the wheel will be exposed, so it’s great for when you need more control over your cuts. On the other hand, because more of the Type 01 is sticking out, it can work faster on tougher materials.

So which should you use? If you’re not sure or are working with a particularly difficult material, go for the Type 27. If you want to make quick work of something simpler, like aluminum sheeting, the Type 01 is probably your best bet.

Can you use a cut-off wheel on an angle grinder?

A cut-off wheel can be used on an angle grinder. However, it is important to note that a cut-off wheel is not the same thing as an abrasive disc. A cut-off wheel is made of hard materials such as aluminum oxide or silicon carbide and is designed for cutting only. An abrasive disc, on the other hand, is made of softer materials such as ceramic or glass and is designed for grinding and finishing.

What grinder wheel is best for cutting metal?

For cutting metal, you want to use a grinding wheel that is made of abrasive material. The most common abrasive materials are aluminum oxide and silicon carbide. Aluminum oxide is the more durable of the two, but it is also more expensive. Silicon carbide is not as durable as aluminum oxide, but it is less expensive.

If you are only going to be cutting metal occasionally, then you can get away with using an aluminum oxide grinding wheel. If you are going to be doing a lot of metal cutting, then you will want to use a silicon carbide grinding wheel.

Useful Video: How to cut with a drilling machine using a bolt/Drilling machine cutter life hacks

Conclusions

After reading this guide, you should have a much better understanding of the different types of Dremel bits that are available for cutting metal. You also know what to look for when shopping for these bits, as well as some tips for using them. We hope that you found this guide helpful and informative. Thanks for reading!

References:

- https://www.amazon.com/gp/product/B000FBLRVA/

- https://www.amazon.com/dp/B00004UDH3

- https://www.amazon.com/dp/B000FBLRVK

- https://www.amazon.com/dp/B00004UDH9

- https://www.amazon.com/Dremel-426B-4-Inch-Reinforced-Cut-Off/dp/B000PDWEDS

- https://www.weilerabrasives.com/cutting-wheel-guide/

- https://www.finepowertools.com/grinders/dremel-bits/

- https://www.empireabrasives.com/blog/portable-cutoff-wheel-safety-dos-donts-safe-practices/