Choose the Best Beginner Metal Lathe

Customer’s Choice: the Best Rated Beginner Metal Lathes

67 users answered this survey. Please help us improve this review!

Are you looking for the best beginner metal lathes on the market? If so, you’ve come to the right place. In this comprehensive guide, we will answer all of your questions and help you choose the perfect lathe for your needs. We’ll discuss the different features that you should look for in a beginner’s lathe, and we’ll provide reviews of some of the most popular models on the market. So whether you’re a seasoned woodworker or a complete novice, read on to find out everything you need to know about choosing a metal lathe!

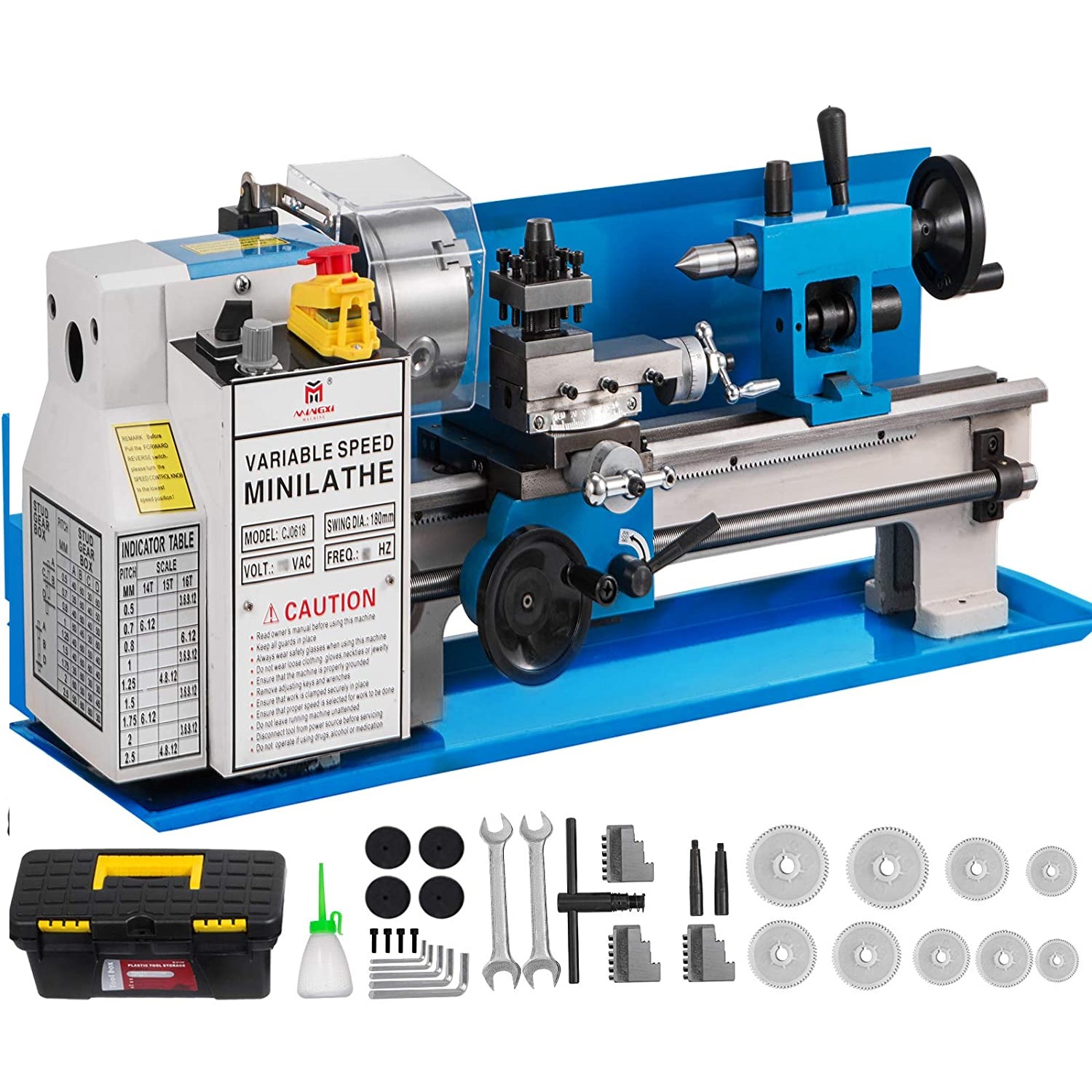

BestEquip Metal Lathe 7″ x 14″, Mini Metal Lathe

Looking for a mini metal lathe that offers both quality and value? Then check out the BestEquip Metal Lathe 7″ x 14″!

Looking for a mini metal lathe that offers both quality and value? Then check out the BestEquip Metal Lathe 7″ x 14″!

But the best part? This machine is also very affordable. So if you’re looking for a quality lathe without breaking the bank, this is the perfect option for those who are just starting.

If you’re looking for a metal lathe that’s cheap and functional, then the BestEquip Metal Lathe 7″ x 14″ is certainly worth considering. However, it’s important to be aware of its limitations before making a purchase. Firstly, the instructions that come with the lathe are very vague, so it may take some extra time for you to figure everything about the machine out. Secondly, the tolerance is quite poor, so you’ll need to be very precise when working with it. Thirdly, the tools are poorly aligned, which can make your work more difficult. Fourthly, the speed control is poor, so you’ll need to be careful when using it. Lastly, the build quality is also quite poor, so it’s not as durable as some other models.

Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe

Looking for a mini metal milling lathe that is perfect for hobbyists? Look no further than the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe. This top-quality lathe offers a smooth performance and great precision, making it the ideal choice for anyone who wants to do some precision metalworking.

Looking for a mini metal milling lathe that is perfect for hobbyists? Look no further than the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe. This top-quality lathe offers a smooth performance and great precision, making it the ideal choice for anyone who wants to do some precision metalworking.

This Erie Tools’ machine is designed for light-duty work, but it packs a lot of punch. Just be aware that it’s not as powerful as some of the other models on the market, and it can take some time to set up properly. Plus, the build quality could be better – tools have been known to come loose, and the instructions are poorly written. But if you’re looking for an affordable option that still delivers good results, this mini milling lathe is worth considering.

Sherline 3.5″ x 8″ lathe, inch

The Sherline 3.5″ x 8″ lathe is a versatile tool that can be used for a variety of modeling and machining projects. It comes with a highly-detailed manual, and is protected by a one year warranty. With its many accessories, the Sherline lathe is perfect for anyone looking to create detailed models or other small scale projects.

The Sherline 3.5″ x 8″ lathe is a versatile tool that can be used for a variety of modeling and machining projects. It comes with a highly-detailed manual, and is protected by a one year warranty. With its many accessories, the Sherline lathe is perfect for anyone looking to create detailed models or other small scale projects.

BestEquip 8″ x 16″ Benchtop Lathe

This sturdy and reliable lathe is perfect for a wide range of projects. It features metal gears for durability and has a swing range of 400mm.

This sturdy and reliable lathe is perfect for a wide range of projects. It features metal gears for durability and has a swing range of 400mm.

BestEquip 8″ x 16″ Benchtop Lathe is perfect for anyone who wants to do some simple woodworking or metalworking at home. However, keep in mind that this lathe does need to be adjusted before you can start using it, and it doesn’t have a very good build quality. Additionally, the instructions that come with it are quite vague. But if you’re just looking for a simple lathe to do some small projects around the house, this one could be a good option for you. Also, be aware that it doesn’t have any warranty backing it up.

TECHTONGDA 8X31” Precision Metal Lathe

This powerful metal lathe can churn out precision products with ease. With a 900W brushless motor, it has all the power you need to get the job done quickly and efficiently. Plus, the bed, security features, and gears are all made of metal for superior quality and durability.

This powerful metal lathe can churn out precision products with ease. With a 900W brushless motor, it has all the power you need to get the job done quickly and efficiently. Plus, the bed, security features, and gears are all made of metal for superior quality and durability.

This neat machine however uses metric units for all dials, so make sure you’re ready to do some conversions before getting started. And if you’re looking for a rotation direction switch, unfortunately you won’t find it in this lathe. It also will take some of your time to set this machine up, but besides that it is worth the money.

Buyers Guide

Definition of Metal Lathes

A metal lathe is a powerful machine tool that is used for shaping pieces of metal, wood, or other materials. Metal lathes can be operated manually or automatically.

Lathes as an instrument were first used in ancient Egypt and China. They were later improved upon by the Greeks and Romans. Metal lathes were not widely used in Europe until the 15th century. By the 19th century, they were an essential tool for factories and machine shops. They had a great impact on the Industrial Revolution as well.

Metal lathes come in a variety of sizes and styles. Some are small enough to fit on a workbench while others are large enough to require their own dedicated stand or floor space.

When Are Metal Lathes Used?

Today, metal lathes are still an essential tool for many industries. They are utilized in the manufacture of automotive parts, aircraft components, and machine tools. They are also used in woodworking, jewelry making, and model making, but mostly in the field of metalworking.

Metalworking can be done by hand or using machine tools. Machine tools are powered machines that use cutting tools to shape and form metal into desired shapes. Lathes are one type of machine tool used in metalworking.

Lathes use rotational force to shape material. The material is held in place while a cutting tool is passed along it to remove excess material and create the desired shape. Lathes can be used to create cylindrical, conical, or spherical shapes. They can also be used to cut threads, create tapers, and turn complex shapes. [1], [2]

Different Types of Metal Lathes

As with every tool, there is plenty of variety when it comes to metal lathes.

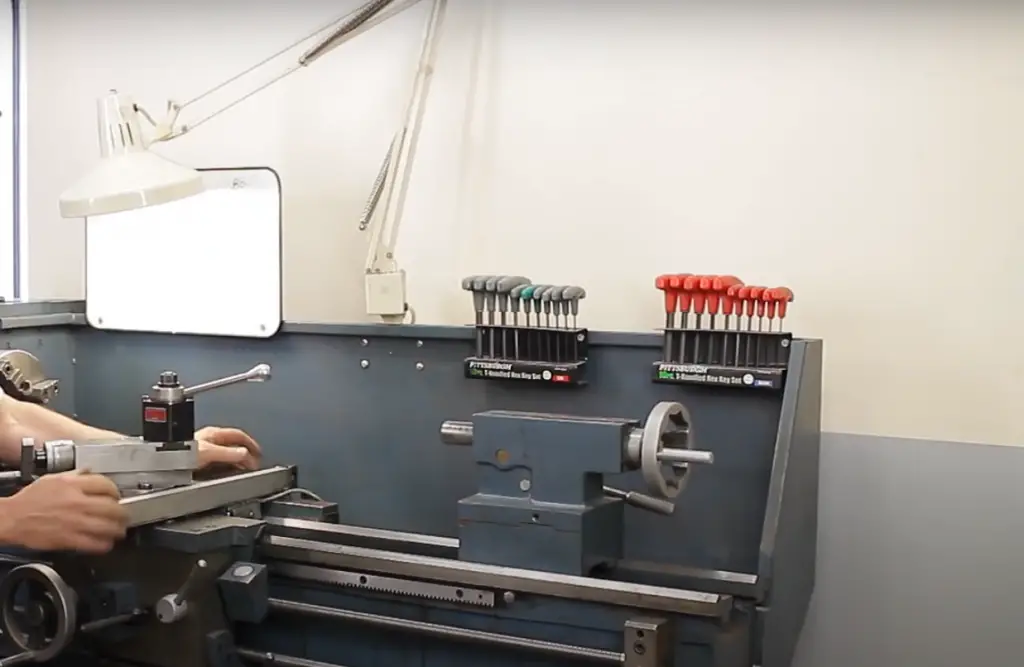

Benchtop lathes are one of them and as the name suggests, these lathes are small enough to be placed on top of a workbench. These are perfect for small projects and can be easily transported from one place to another.

Another type is the engine lathe which is a heavier duty machine that is mostly used in industrial settings. These lathes can handle larger projects and require more space than benchtop lathes.

CNC lathe is an interesting one as it is a computer-controlled machine. A CNC lathe can be programmed to create very precise and intricate shapes. These are mostly used in the aerospace and medical industries where accuracy is critical.

There are many other types of metal lathes available on the market today such as turret lathes, toolroom lathes, and gap bed lathes. Each type has its own advantages and disadvantages. It is important to choose the right type of lathe for the project at hand.

Metal lathes can be operated manually or automatically. Manual lathes require the operator to move the workpiece and tool by hand. CNC lathes use CNC (computer numerical control) to perform operations. CNC lathes can be programmed to perform repetitive tasks with high precision. [3]

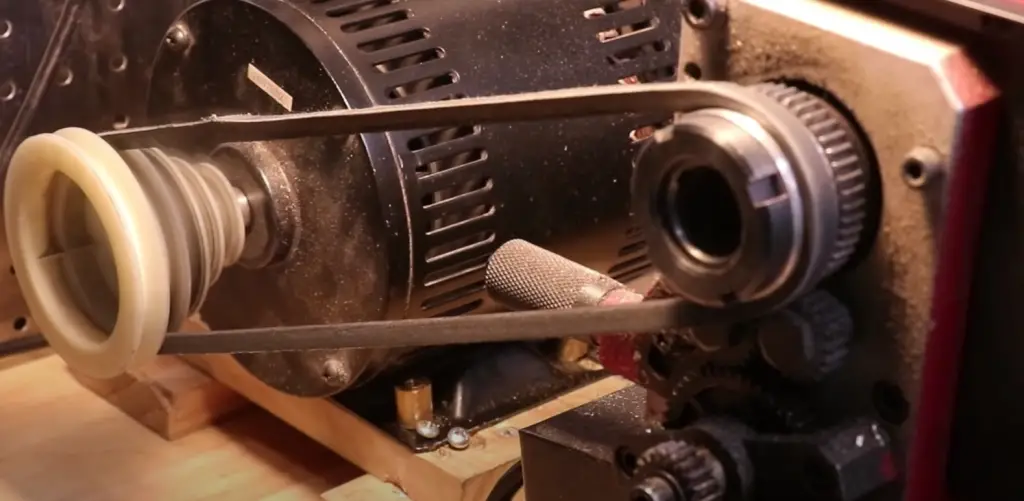

Construction of a Metal Lathe

A metal lathe consists of a bed, a headstock, and a tailstock. The bed is the main frame of the lathe. It provides support for the other parts of the lathe and houses the drive train. The headstock is mounted at one end of the bed. It contains the motor and spindle. The tailstock is mounted at the other end of the bed and is used to support long workpieces.

The headstock houses the motor and spindle. The motor provides power to rotate the spindle. The spindle is precision-machined to hold cutting tools securely while they are in use. It also has a chuck that can be used to mount workpieces.

The tailstock is adjustable and is used to support long workpieces. It has a quill that can be moved up and down. The quill is used to hold cutting tools and is precision-machined to ensure accuracy. [1]

How Beginner Friendly Are Metal Lathes?

Metal lathes can be very user-friendly, even for beginners. There are many different types and sizes of lathes available on the market today. Many manufacturers offer instructional manuals or videos to help users get started.

Operating a metal lathe does require some skill and knowledge. Users should have a basic understanding of how to use cutting tools and how to select the correct tool for the job at hand. They should also know how to properly mount workpieces and how to adjust the speed and feed rate of the lathe. With some practice, anyone can learn how to use a metal lathe safely and effectively.

You should mind that lathes are pricier than other machines and you should also have space to keep it. If you don’t have a workshop, your house’s garage might do the trick but make sure to clean it up before starting working. [4]

Are Metal Lathes Safe to Use?

Yes, metal lathes are safe to use when proper safety precautions are followed. Users should always wear eye protection and gloves when operating a lathe. They should also be aware of potential hazards, such as flying chips or sparks. To reduce the risk of injury, users should read the instruction manual before using the lathe and should practice safe work habits.

Another safety tip is to check if the workpiece is mounted securely before starting the lathe. Once the lathe is turned on, do not touch the workpiece or cutting tools until the lathe has come to a complete stop. A secure mount of the tools is important as well, to avoid flying tools.

Don’t forget to sharpen your tools regularly and to clean your lathe after each use. These simple maintenance tasks will help to extend the life of your lathe and ensure that it continues to operate safely and smoothly.

Do not wear loose clothing or jewelry that could become caught in moving parts. Tie back long hair to keep it away from the lathe.

When it comes to safety, it is always better to be over-cautious than sorry. If you are a beginner, or new to using metal lathes, it is best to seek help from someone who is experienced. [5]

Buyers Guide for the Best Beginner Metal Lathes

So, now that we provided you with reviews of five different beginner metal lathes, it’s time to help you choose the right one for your needs. Here are some things to keep in mind when making your decision.

Budget

The first thing you’ll want to consider is your budget. All of the lathes we reviewed are priced under $1000, but there is a range within that. The more expensive models will have more features and higher quality components, while the less expensive models may be a little more bare-bones.

Think about how much you’re willing to spend and what features are most important to you. If you’re just starting out, you may not need all the bells and whistles of the most expensive model. But if you have a little more experience, you might want to invest in a lathe that will grow with you as your skills improve. [6], [8], [11]

Workplace size

Another important consideration is the size of your workplace.

The last thing you want is to get your new lathe home and realize it’s too big for your workshop!In addition, the bigger the lathe, the harder it is to move around. If you think you might need to move your lathe around often, look for a smaller model that will be easier to transport.

Finally, keep in mind that metal lathes can be very loud. If you have neighbors close by or if you work late at night, you might want to choose a quieter model to avoid disturbing the peace. [6], [8], [9], [11]

Your skill level

Are you a total beginner? Or do you have some experience with metalworking or other types of lathes? If you’re just starting out, you’ll want to look for a lathe that is easy to use and has plenty of safety features. We will get to these below.

Keep in mind that you won’t need a lathe filled to the brim with features if you’re just starting out. You can always upgrade to a more advanced model later on.

On the other hand, if you’re more experienced, you might be able to get by with a less user-friendly lathe. However, even experienced users should make sure to read the manual carefully before using any new machine.

No matter your skill level, it’s always a good idea to practice on some scrap wood before moving on to metal. That way, you can get a feel for the machine and how it works without risking damage to your workpiece. [6], [11]

Presence of safety features

As we mentioned before, safety is an important consideration when choosing a lathe. Look for a machine that has guards to protect your hands and fingers from the spinning workpiece. Some models also have emergency stop buttons in case of accidents.

Another safety feature to look for is an automatic shut-off. This will turn the lathe off if it gets too hot, preventing fires and damage to the machine.

As we mentioned before, even experienced users should take care when using any new machine. Read the manual carefully and be sure to follow all safety instructions. [6], [7], [9], [10]

Durability of the build

When you’re working with metal, you need a machine that can stand up to the rigors of the job.

In addition, check to see how well-built the components are. Are the handles solid and well-attached? Are the gears properly lubricated? These are all signs of a high-quality machine that will last you a long time. It’s best to avoid plastic gears, as they can strip easily.

Finally, make sure to choose a model from a reputable brand. Some brands have been making metal lathes for decades and have a reputation for quality craftsmanship. [6], [7], [8]

User-friendliness

As we mentioned before, user-friendliness is important for beginners. Look for a lathe with clearly labeled controls and an easy-to-understand manual.

Some models also come with digital readouts, which can be very helpful. These displays show you the speed of the spindle, the depth of your cuts, and other important information.

If you’re looking for a more user-friendly lathe, you might want to consider one that comes with a built-in light. This will help you see your workpiece more clearly, making it easier to get precise results.

Finally, some lathes come with accessories like chucks and tool holders. These can make your life much easier by holding onto your workpiece for you. These features aren’t essential only for beginners, but for pros as well. No one wants their work to be harder than it has to be! [7], [8], [9], [11]

Motor Power

The power of the motor is another important consideration. You’ll want to make sure the lathe you choose has enough power to handle the material you’re working with.

For example, if you’re going to be working with heavy-duty materials, you’ll need a more powerful motor. On the other hand, if you’re only going to be working with lighter materials, you can get by with a less powerful motor.

As a complete beginner in metalworking however, we recommend you to choose a lathe with at least 550-600 watt brushless motor. This will give you enough power to work with most materials without being too much for you to handle.

In general, the more powerful the motor is, the more expensive the lathe will be. However, it’s worth paying extra for a machine that can handle anything you throw at it. After all, you don’t want your projects to be limited by your equipment!

You should also consider the speed of the spindle. If you’re going to be doing a lot of detailed work, a slower speed might be better. However, if you’re just looking to get the job done quickly, a higher speed might be what you need. [7], [9]

Warranty

When you’re choosing a lathe, it’s important to consider the warranty. After all, this is a big investment, and you want to be sure you’re covered in case something goes wrong.

Some companies offer very generous warranties, while others only offer limited coverage. Be sure to read the fine print so you know what’s covered and what isn’t.

This will ensure that you’re covered in case of any problems that might arise.

Finally, remember that even the best metal lathes can have issues from time to time. It’s always a good idea to keep a few spare parts on hand, just in case something breaks! [8], [9], [11]

FAQ

Are metal lathes a good tool for a metalworking beginner?

Metal lathes are an excellent tool for those who just start to dive into metalworking. They are relatively simple to use and can be used to create a wide variety of objects. As long as you follow safety precautions, a metal lathe can be a great introduction into the world of metalworking.

What is the ideal size of a metal lathe?

The size of the lathe depends on what you plan to use it for. If you just want to create small objects, a mini lathe would be sufficient. However, if you want to tackle larger projects, you might need a full-size lathe.

No matter what size lathe you choose, make sure that it is able to handle the type of metal you want to work with. Some metals are more difficult to work with than others and require a more powerful lathe.

What is a good beginner metal lathe?

One of the most important things to look for in a beginner metal lathe is ease of use. A lot of people are intimidated by power tools, but a good lathe will be easy to operate. Look for a machine with intuitive controls and clear instructions.

It’s also important to find a lathe that is versatile. You might not know what all you want to do with your new tool yet, but a versatile machine will give you the opportunity to explore different projects. Look for a lathe with various attachments and accessories as well.

Useful Video: MX-210V 8×16 Metal Lathe Review

Conclusion

So, if you are a beginner and don’t have the faintest idea of where to start, fret not! There are many kinds of lathes available. But if you’re just starting out in the workshop, it might be a good idea to consider a benchtop metal lathe. These machines are typically smaller and easier to use than engine or automated metal lathes.

We considered a variety of factors in our search for the best metal lathes for beginners and tried to provide a range of options depending on your budget and level of experience. Keep in mind that what is most important is finding a machine that you feel comfortable using – it should be easy to set up and use without too many complicated bells and whistles. And finally, always make sure to read the warranty before making your purchase. Happy crafting!

References:

- https://www.ametals.com/post/what-is-a-lathe-and-how-does-it-work

- https://machinefanatic.com/what-does-a-lathe-do/

- https://machineryfuture.weebly.com/knowledge/lathe-machine-04

- https://www.weldinggurus.com/best-metal-lathes/

- https://littlemachineshop.com/images/gallery/info/MiniLatheUsersGuide.pdf

- https://homemakerchic.com/best-metal-mini-lathe/

- https://handymansworld.net/best-mini-metal-lathes/

- https://www.architecturelab.net/best-metal-lathe/

- https://www.electronicshub.org/best-metal-lathes/

- https://www.sharpen-up.com/best-metal-lathe-money-top-5-reviewed/

- https://www.weldinggurus.com/best-metal-lathes/