If you are looking for a new tool to help your workshop or factory run more efficiently, a CNC machine could be the answer! With its accuracy and precision, a CNC machine is one of the most versatile tools available on shop floors today.

But before you make any big purchasing decisions, it’s important to understand how much such a powerful machining process can cost.

In this blog post, we will look at all of the things that make a CNC machine cost money – from the materials it is made of to the type of machine it is and how much automation it has. By the end, you will know if investing in a CNC machine is right for your business.

Factors Affecting the Price of a CNC Machine

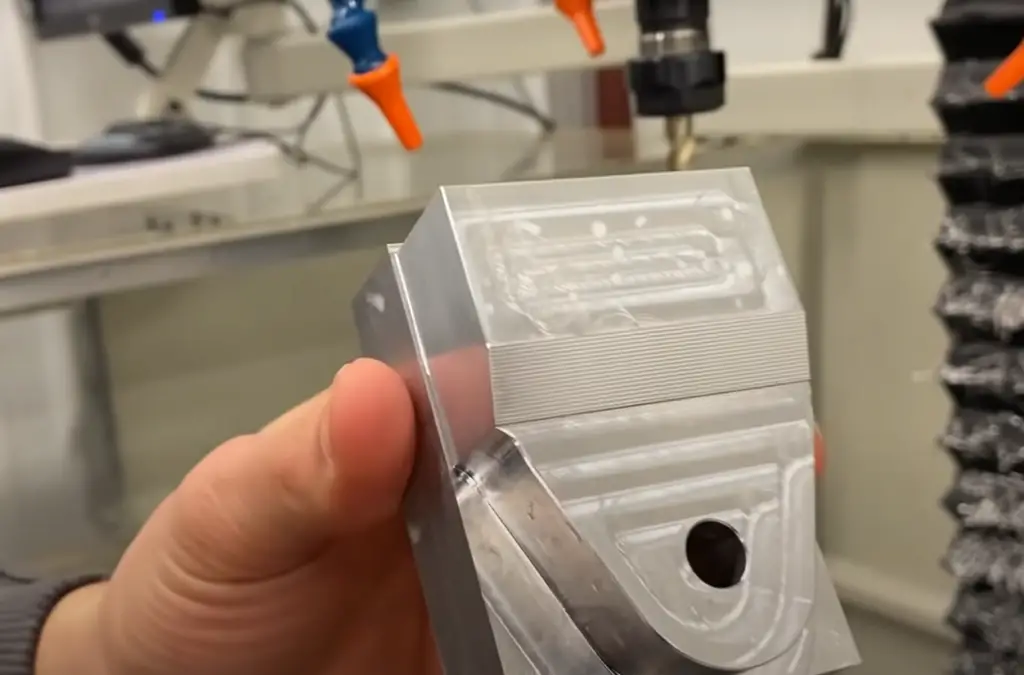

1. Materials Used: The materials used to create a CNC machine vary depending on the type of machine and brand. Many modern machines are made from aluminum or other metals, which can increase the cost.

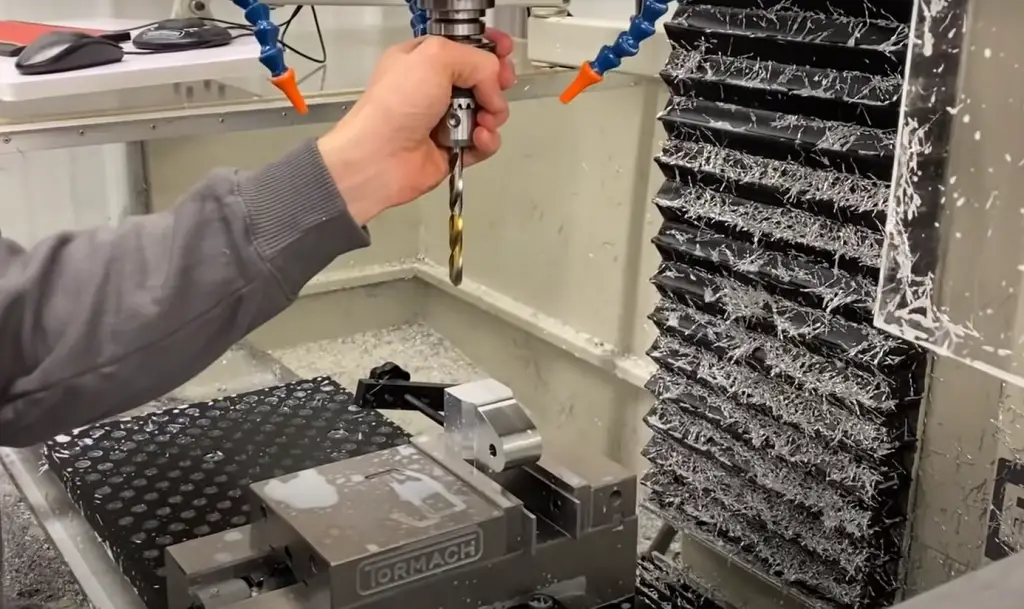

2. Type of Machine: There are four main types of CNC machines – router, milling, lathe and EDM.

3. Automation: The amount of automation included with your CNC machine will also affect its price tag. A fully automated machine may be more expensive than one without any automation, as it will require extra programming and setup.

4. Brand: Finally, the brand of CNC machine you choose to purchase can also play a role in how much it costs. Some better-known brands may be more expensive than lesser-known ones, but may offer better performance and reliability.

5. Size of Machine: The size of a CNC machine also affects how much it costs. If the machine is large, it will be more expensive because it requires more materials and parts to build. A smaller CNC machine may work better for precision tasks like cutting or drilling, while a larger one can do multiple jobs at the same time more quickly and accurately.

6. Speed and Accuracy: The speed and accuracy of a CNC machine will also affect its cost. Machines that go faster and are more accurate tend to be more expensive because they need better quality materials and parts. If you need to be very precise for your projects, it is worth it to get a machine that is faster and more accurate.

7. Power Requirements: The power requirements of a CNC machine will also play a role in its price. Machines that are powered by electricity or compressed air cost more to purchase and operate than manual ones, so make sure you factor this into your budget. [1]

Category-wise Cost of CNC Machines

The cost of a CNC machine can vary widely depending on its type, size and power requirements. Here is a list of average prices for each category:

- Router – $2,000 to $4,000

- Milling – $20,000 to $50,000

- Lathe – $10,000 to $20,000

- EDM – $30,000 to $60,000

It’s important to note that these price ranges are just averages and can vary depending on the specific machine you choose.

Other costs (or Hidden costs) of a CNC Machine

There are other things you need to budget for when you buy a CNC machine, not just the machine itself.

You’ll need to factor in things like maintenance and repairs, software upgrades, training and programming fees, shipping fees, and more. Make sure you know all of the costs before deciding which machine to buy.

Cost of used CNC Machines

If you don’t have a lot of money, buying a used CNC machine can be a good option. They are usually cheaper than new machines. But it is important to buy from someone who is well-known and trust-worthy. Make sure the machine is in good shape before you buy it.

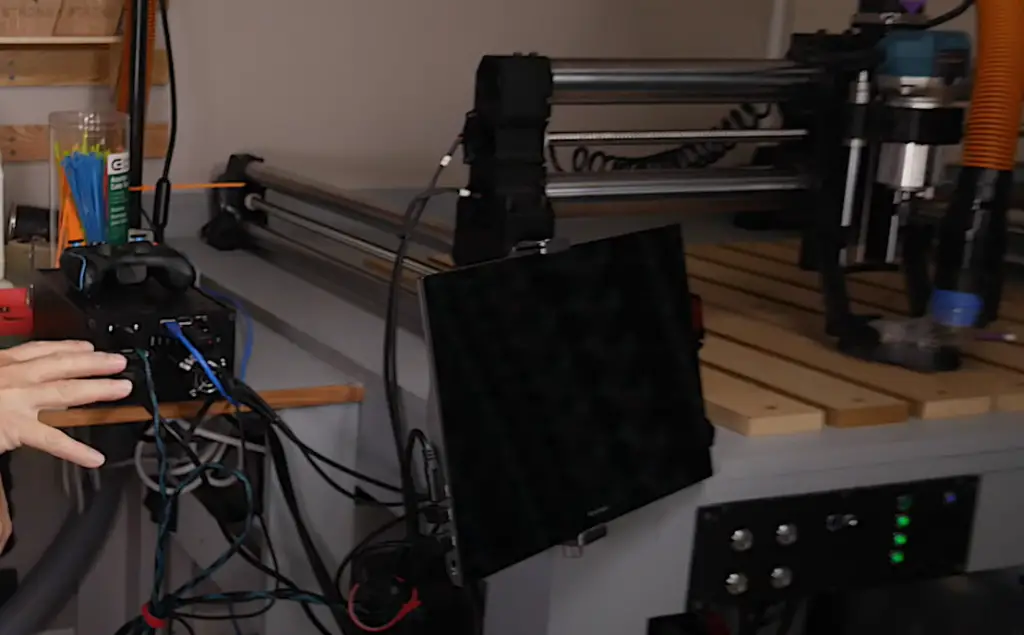

Hobbyist Machines

For hobbyists, there are many lower-cost CNC machines available. These machines can cost anywhere from a few hundred to a few thousand dollars depending on the type you choose and its features.

Entry Level CNC Machines

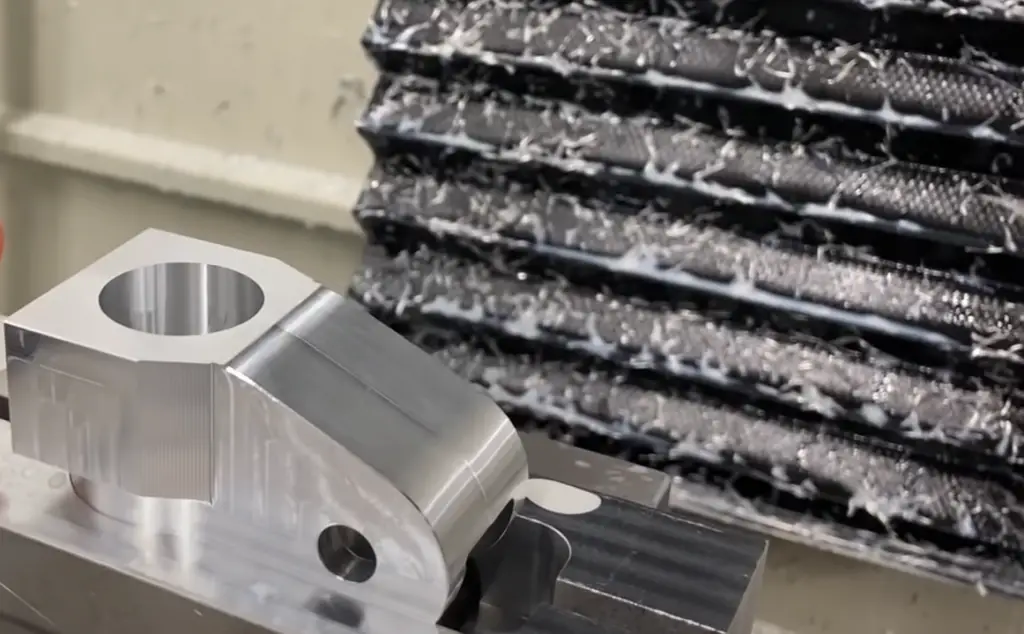

If you are just starting out, there are many entry level CNC machines available. These machines will get the job done but they won’t have as many features or be as precise as more expensive models.

There are many things to consider when you want to buy a CNC machine. The type, size, speed, accuracy, and power requirements are all important factors in determining the price of the machine.

You should also consider the brand before making your purchase. Knowing how much a CNC machine costs is an important part of any successful manufacturing operation.

Production Machines

If you want to make a lot of parts quickly and accurately, then you need a production machine.

No matter what type of CNC machine you choose, it is important to do your research and find one that fits your budget and meets your needs. With the right machine, you can take your manufacturing operation to the next level.

Unexpected Costs of CNC Machines

As you plan your budget for a CNC machine, don’t forget to include costs that may not be expected. These can include:

- Shipping cost

- Installation fees

- Maintenance and repair fees

- Training/consultation fees

- Software upgrades

- Tooling and supplies

Make sure to include these costs when you budget for a CNC machine. This will help make sure that you don’t have any bad surprises after you buy the machine. [2]

Warranty and Maintenance Costs

The warranty and maintenance costs of a CNC machine will also affect the total cost. Many manufacturers offer extended warranties, which can cover any damages or repairs that may be necessary over time. It is important to factor in these costs as well when deciding how much a CNC machine will cost you in the long run.

CNC machines can cost a lot or a little depending on what kind it is and how big and powerful it is.

With the right machine, you can improve your manufacturing operation.Buying Used CNC Equipment

Buying a used CNC machine is a good way to save money. You can find used machines at auctions, online, or from local dealers. Inspect the machine before you buy it.

Be sure to know about any extra costs for things like maintenance and repairs. Doing this will help you get a good quality machine at a fair price. [2]

FAQ

Is a CNC machine worth it?

Yes, a CNC machine can be worth it depending on what you need it for. If you’re looking to streamline your manufacturing process and create accurate parts quickly, then a CNC machine is definitely worth the investment.

How much does it cost to run a CNC machine?

The cost of running a CNC machine will vary depending on the type and size of the machine.

Generally speaking, a CNC machine will cost a few hundred dollars per hour to run, including electricity and labour costs.

How long does it take to learn to use a CNC machine?

Learning how to use a CNC machine can take a short time or a long time. It all depends on how complicated the machine is and if you have used similar machines before.

If you are a professional CNC programmer, you will be able to learn more quickly than someone who has never used one of these machines before. If you only need to use the machine for one specific job, it will probably take less time to learn how to use it correctly.

How much does it cost for CNC cutting?

The cost of CNC cutting will vary depending on the type of material you are cutting and the complexity of the job. On average, CNC cutting can cost anywhere from $0.50 to $2.00 per minute, depending on the materials used and how many parts are being cut.

How much is an entry level CNC machine?

An entry level CNC machine can cost anywhere from $5,000 to $50,000. The price will depend on the size and capabilities of the machine. An entry level machine will be able to cut basic shapes and perform simple operations, but won’t have as many features as a higher-end model.

How much money can you make with a CNC machine?

The amount of money you can make with a CNC machine will depend on what type of work you are doing and how good you are at using it. If you are making custom parts or creating products to sell, then you could make a lot of money from a CNC machine.

But, if you are only using it for simple tasks like cutting basic shapes, then the amount of money you make will probably be less.

What are 3 disadvantages of a CNC machine?

- High Initial Cost – CNC machines are usually more expensive than manual machines and require a larger initial investment.

- Maintenance Costs – CNC machines require regular maintenance to stay in top running condition which can add up over time.

- Programming Knowledge – If you don’t know how to program the machine, you will need to hire someone who does or learn how to program it yourself.

This can add up in training costs and time spent learning the programming language.

Why is CNC expensive?

CNC machines cost a lot of money because they are complicated machines with many different parts. They also require special software and someone who knows how to program the machine, which costs even more money.

The materials used to make a CNC machine are also more expensive than the materials used for a manual machine. All of these factors add up, making CNC machines very expensive, but sometimes manufacturers need to buy them anyway.

When should I buy a CNC machine?

You should buy a CNC machine if you need to produce accurate parts quickly and efficiently. You should also make sure that the types of materials you will be cutting and the complexity of your operations require a CNC machine for best results. If so, then it is probably worth investing in one of these machines.

What are the benefits of using a CNC machine?

CNC machines are good because they can help save time and money. They also usually make parts that are more accurate than if a person made them by hand.

In addition, CNC machines can make parts with shapes and designs that would be difficult or impossible to make using manual methods.

What types of materials can a CNC machine cut?

A CNC machine can cut almost any type of material including wood, metal, plastics, and composites. The exact types of materials that the machine can cut will depend on the type of cutting tool used. Higher end machines may also be able to cut different materials with the same tool.

What are some safety tips for using a CNC machine?

It is important to be safe when using any kind of machine, especially a CNC machine. Some safety tips include wearing protective clothing, making sure all parts of the machine are working well, and following instructions carefully.

You should never reach into the cutting area of the machine while it is running because you could get hurt. It is also a good idea to have someone else nearby when using the machine for safety reasons.

Which CNC machine should I buy?

The kind of CNC machine you should buy depends on how much money you have, what you will be cutting, and how complex the operations are. It is important to look at different models and find one that fits your needs.

Make sure you read reviews and look at specs before making a purchase. You may also want to ask a professional for advice if you are unsure.

How long does it take to learn how to use a CNC machine?

It can take a long time to learn how to use a CNC machine. This depends on your experience and how hard the machine is to use. Be sure to read the instructions and practice often. If you have trouble, get help from someone who knows how or take a class.

Why is it important to have someone who knows how to use a CNC machine?

It can be helpful to have someone who knows how to use a CNC machine. This person can help you with programming, fixing problems, and operating the machine safely. Having an expert around can also help you save time and money in the future.

CNC machines are a good investment for any manufacturing business that needs to produce accurate parts quickly and efficiently. Although they can be expensive, if you follow the tips in this article you should be able to find one that fits your needs and budget.

Does the price of a CNC machine include tooling?

No, the price of the CNC machine does not include any tools. You will need to buy these separately, depending on what you are cutting and how difficult it is. Make sure you have enough money to buy the tools when considering buying a CNC machine.

How can I get the most out of my CNC machine?

To get the most out of your CNC machine, be sure to read the instructions and follow them carefully. Make sure you use quality tools when cutting materials, and keep all parts of the machine clean and properly lubricated.

It is also important to practise using the machine regularly and make sure you keep up with maintenance.

Do I need training to use a CNC machine?

It is a good idea to get some kind of training before using a CNC machine, especially if you are new to this type of technology. You can find classes or tutorials online which can help teach you the basics.

Having someone who knows how to operate the machine nearby can also be helpful in case you have any questions.

Can I use a CNC machine for prototyping?

Yes, CNC machines can be used for making models of products. This allows you to create accurate parts quickly and make adjustments as needed before committing to a full production run.

It is important to find the right software and tools to do this though, so it may be worth investing in some additional training or resources.

Do CNC machines need to be calibrated regularly?

Yes, you should calibrate CNC machines regularly. This is usually done with a specialized tool and it can help keep the machine running smoothly and accurately. Make sure to follow the manufacturer’s instructions for calibrating your machine.

CNC machines can provide a great advantage for any manufacturing business, but it is important to make sure you have the right one for your needs. Make sure you research different models and get advice from an expert if needed.

Which kinds of materials can a CNC machine cut?

CNC machines are capable of cutting almost any type of material, including wood, plastic, metal and more. The kind of tooling used will vary depending on the material you are working with. Make sure to use quality tools that are suitable for the job at hand.

What are some things to consider when buying a CNC machine?

When buying a CNC machine, it is important to think about how much power and precision you need. You should also look at the software used by the machine and make sure it can do what you want.

Compare prices between different models and look for extra features that might be helpful. Also, don’t forget that you will need to buy tools separately.

Is it worth buying a used CNC machine?

In some cases, it can be worth buying a used CNC machine. This can save you money and if the machine is in good condition it should still be able to do its job.

However, make sure to research any used machine before you buy it and get advice from an expert if necessary. It is important to make sure that you are getting a good deal and not buying something with major problems.

Are CNC machines difficult to maintain?

CNC machines need regular maintenance to keep them running well. This means checking and changing fluids, inspecting parts for wear, and cleaning the machine on a regular basis. It can take some time to do this, but it will help your machine run better if you do it right.

CNC machines help businesses make products quickly and well. To get the best machine, look at different models and compare their features. You will also need to buy tools for the machine. Remember to keep the machine clean and in good working order so it lasts a long time.

Do CNC machines require special skills to use?

Yes, CNC machines require some knowledge and skill to operate properly. It is a good idea to take a class or tutorial on using the machine before getting started. You can also get advice from an expert if you are unsure of anything.

With some practice and proper care, you should be able to get the most out of your CNC machine.

Useful Video: The REAL cost of a CNC machine

Conclusion

The price of a CNC machine changes based on what kind of part it will make. If the machine can make lots of different things and needs to make complex parts, then it will be more expensive. But if the machine is only for one specific thing, like a small computer-controlled router that can go on your desk, then it will be less expensive.

It is important to know what you want from a CNC machine before you buy one. This way, you can easily find the machine that meets your needs. You should also research different brands and compare prices before making your final decision.

Last but not least, if you have any questions feel free to reach out to us with any inquiries or concerns you might have. We’d love to help ensure that you make the right investment for your business’s success.

References:

- https://mellowpine.com/cnc/how-much-do-cnc-machines-cost/

- https://makeitfrommetal.com/how-much-does-a-cnc-machine-cost/