When it comes to fixing metal surfaces such as aluminum, Bondo is the go-to adhesive for many DIY projects around the home. While Bondo does an excellent job when used on steel and other metals, have you ever wondered if this powerful adhesive will stick to aluminum? This blog post takes a deep dive into the answer as we explore whether or not Bondo can be used to fix any problems on aluminum items! We’ll also provide some helpful tips so you know how best to use Bondo in your repair work. Keep reading to find out if it’s possible to make any repairs using Bondo on metallic aluminum car body parts, household repairs, etc!

What Are Aluminum Properties?

Aluminum is a lightweight, malleable metal with excellent corrosion resistance and high electrical conductivity. It has an abundance of qualities that make it an attractive choice for many applications, such as:

- Lightweight – the material is one-third the weight of steel or copper, making it ideal for use in aircraft structural components and other lightweight engineering projects.

- Malleability – its ductility allows it to be formed into shapes or sheet stock. This makes aluminum easy to work with when creating intricate designs or complex curved parts.

- Corrosion Resistance – the protective oxide layer on aluminum helps protect against water and salt damage, making it suitable for outdoor structures like bridges and towers.

- Electrical Conductivity – aluminum has high electrical conductivity, making it an excellent choice for components in the electrical and electronic industries.

- Recyclability – the material is infinitely recyclable, which means less scrap material ends up in landfills. This makes it a popular choice for manufacturers who are looking to reduce their carbon footprint.

It is extremely affordable and readily available compared to other metals like titanium or steel. It can be formed into almost any shape imaginable, making it ideal for complex parts like aircraft fuselages and custom shapes used in automotive manufacturing.

The combination of its lightweight structure, malleability, corrosion resistance, and electrical conductivity make aluminum one of the most versatile metals on the market today. [1]

With these qualities in mind, aluminum remains a top choice for industrial manufacturers looking for reliable and cost-effective solutions.

What Exactly Is Bondo?

Bondo is a brand of automotive body filler, also known as a glazing putty or auto body repair putty. It is specifically designed to fill in small dents and scratches on car bodywork, and can be used for many other minor automotive repairs.

When applied correctly, it provides an undetectable repair with excellent adhesion to metal, fiberglass, wood, concrete, brick and more.Product provides superior rust protection when top-coated with primer or paint. When mixed properly according to the instructions on the package label, Bondo will harden within minutes so you can quickly move on to the next step of your repair.

Bondo provides a durable, long-lasting and virtually invisible repair that can save you time and money. It is available at most auto parts stores or online retailers, so it’s an excellent choice for do-it-yourselfers looking to complete minor body repairs on their own. [2]

When used correctly, Bondo offers a cost effective solution for restoring your vehicle’s original appearance – quickly, easily and affordably. Get your car back in shape with Bondo today.

Is Aluminum Repairable?

The answer to this question depends on the type and severity of damage. Generally speaking, aluminum can be easily repaired with a range of techniques including welding, cold patching, and epoxy repair.

It is possible to weld aluminum using special equipment that is designed for this purpose. Cold patching involves cutting out the damaged section of the aluminum component and replacing it with a new piece of metal. Epoxy repair requires bonding two pieces together using an adhesive which can be applied by hand or with a sprayer.

In all cases, it is important to use aluminum-appropriate materials when repairing aluminum components in order to ensure that the repair holds up over time. Additionally, professional repair services should always be consulted when attempting any kind of aluminum repairs as they have the necessary skills and equipment to ensure a successful repair. [3]

The item can be repaired successfully with the Bondo. This two-part polyester body filler can be used to patch holes or cracks in aluminum surfaces. It is also possible to use Bondo with other materials such as fiberglass, wood, and metal if the repair needs to go beyond just the aluminum surface.

However, it is always important to consult a professional when starting repairs as they will be able to advise on the best course of action for your specific situation. Additionally, regular maintenance should also be implemented in order to reduce the likelihood that aluminum components will become damaged in the first place.

What Is The Best Way To Repair Aluminum That Has Been Damaged?

The best way to repair aluminum that has been damaged is to use a brazing rod, which is an alloy of aluminum and copper that can be melted down and used as filler material. This can be applied to the area with heat, such as from a propane torch or blowlamp. It is important to ensure that the metal surfaces are clean before applying the brazing rod, as any oil or dirt on them will prevent it from adhering properly. Once cooled and hardened, it should be sanded and polished for a smooth finish.

If necessary, some automotive filler can also be used in order to further smooth out any imperfections in the repair job. Additionally, if aesthetics matter, a matching paint color can then be applied to the repaired area.

In some cases, replacing the damaged aluminum part may be the better option depending on its condition and importance. If it is an important structural component of a machine or vehicle, then it should not be repaired as that could compromise its integrity and performance. Therefore, if you are unsure about how to properly repair your damaged aluminum piece, it may be best to consult a professional for assistance. Specialists will be able to assess the damage and choose the best remedies to fix the problem. [4]

What’s So Different About Aluminum Body Filler?

Aluminum body filler is a unique form of auto body repair that uses aluminum to fill in and cover up minor dents, scratches and other damage on the exterior of cars, trucks, and other vehicles. It’s very different from traditional body filler because of its lightweight nature. Aluminum is much lighter than steel or fiberglass, which makes it significantly quicker and easier to apply than traditional body repairs. Additionally, aluminum is heat resistant which makes it ideal for use in extreme temperatures like those found during a hot summer day.

Unlike many traditional body fillers, aluminum body filler can be applied without sanding or priming prior to application. This allows for quick repairs when time is at a premium or when an emergency situation arises. This ease of application also allows anyone with even a moderate level of automotive repair experience to make repairs quickly and easily.

Aluminum body filler is also more durable than traditional body fillers, making it ideal for use in high-stress areas like around vehicle door frames or on bumpers. Additionally, aluminum’s superior heat resistance ensures that it will not warp or crack under exposure to extreme temperatures. The combination of its lightweight nature and strength makes aluminum an ideal material for body repair needs. [5]

Finally, aluminum body filler provides a much more natural appearance when used properly. It blends seamlessly into the exterior of your car, truck, or other vehicle so you don’t have to worry about unsightly patches or spots. By using aluminum body filler, you can maintain the original appearance of your vehicle and keep it looking new for years to come.

So if you’re in need of minor repairs or touch-ups on your car or truck, consider using aluminum body filler as a fast and efficient way to restore the exterior of your vehicle.

Simple Steps on How To Bondo Aluminum

With the proper preparation and application, you can create a strong bond between two aluminum surfaces for an improved appearance. Follow these simple steps to successfully bondo surfaces:

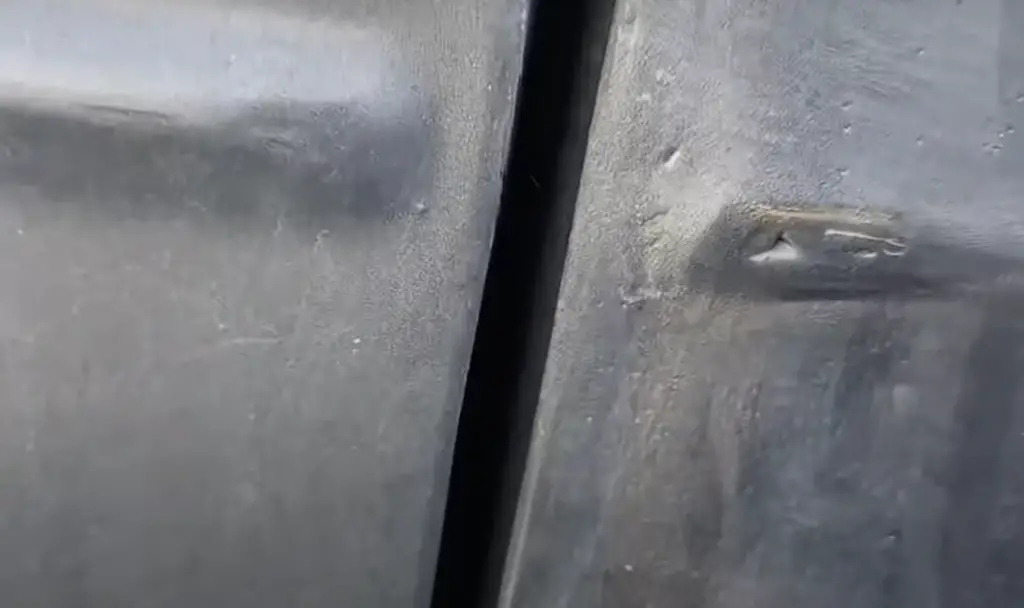

- Clean aluminum surface with a wire brush or degreaser to ensure that there is no dirt, grease, or other debris present.

- Prepare the area by applying a coat of self-etching primer to the aluminum surface and allowing it to dry completely according to manufacturer’s instructions. This will help improve adhesion between the Primer and Aluminum surfaces when applying Bondo.

- Mix Bondo with hardener in a clean container using a wooden stir stick and following manufacturer’s directions on how much hardener should be added.

- Apply Bondo mixture onto the aluminum surface using a putty knife, spread evenly over desired area making sure that all edges are covered.

- Allow Bondo to cure according to manufacturer’s instructions, usually 20-30 minutes.

- Once cured, use a sandpaper and/ or file to smooth out the surface of the Bondo until it is flush with the aluminum surface making sure that any imperfections or air pockets are eliminated.

- Apply a coat of self-etching primer over the bonded area once finished sanding, followed by your desired paint color for further protection and aesthetics.

- Allow Bondo and primer to dry completely before applying additional coats if needed. [6]

- Enjoy your newly bonded aluminum surface!

Does Bondo Cause Aluminum Corrosion?

Bondo is a popular brand of auto body filler used to repair dents and other damage to vehicle bodies. Bondo contains polyester resin, which may cause corrosion on aluminum surfaces when applied incorrectly. To reduce the risk of aluminum corrosion, it is important to clean the surface thoroughly before applying Bondo, use a metal-reinforced version of Bondo specifically designed for aluminum repairs, and paint over the repair as soon as possible after application.

Additionally, it is essential to select an appropriate primer prior to painting in order to ensure optimal adhesion between the primer and the aluminum surface. With proper preparation and care, you can minimize or even avoid potential corrosion caused by using Bondo on aluminum surfaces. [7]

Does Bondo Stick To Aluminum?

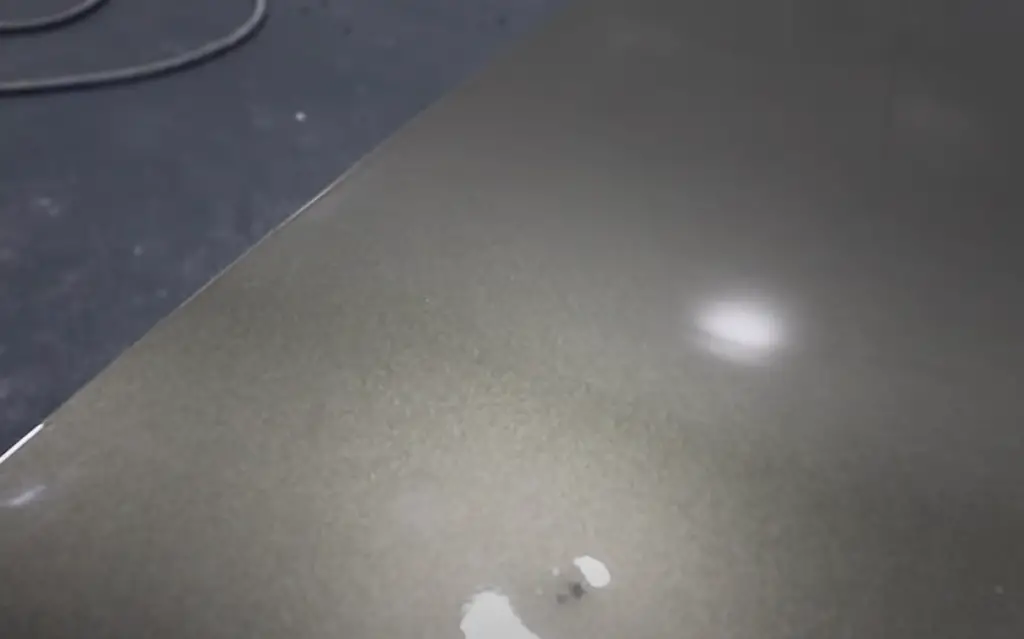

If you are looking for an easy way to repair dents, holes or scratches on aluminum surfaces, Bondo is an ideal choice. With the proper preparation and application techniques, you can create lasting repairs that stand up against wear and tear with ease.

Bondo is a polyester body filler that adheres to many surfaces including metal, fiberglass and concrete. It has a strong bond on aluminum and other metals when applied correctly, making it an ideal choice for repairing dents and holes in aluminum vehicle bodies.

After application, allow it to dry fully before sanding down any excess product.When using Bondo on aluminum make sure to use the appropriate hardener as well. This will help strengthen the bond between the aluminum and the Bondo.

Will Bondo Stick To Painted Aluminum?

Bondo can be used on painted aluminum surfaces, however, it is important to note that if you are dealing with an old paint job that has seen its share of wear and tear over time, it may not stick as well as it does to a new surface. Additionally, if the surface is rough or pitted, then it may also cause difficulty in properly adhering the Bondo to the surface. In this case, sanding down any irregularities and using a primer before applying the Bondo will help ensure proper bonding and a better finish. [8]

It is also important to note that different types of paint require different preparation prior to application for optimal results. For example, enamel paints require more thorough abrasion than latex or acrylic ones. Additionally, if you are dealing with a painted aluminum surface, it is essential to use an epoxy primer before application. This will create a better seal with the aluminum and ensure proper adhesion.

Is It Worth Bondo Aluminum or Taking It to an Expert?

If you’re looking to repair a dented or damaged aluminum piece, there are two techniques used: Bondo and taking it to an expert. Both methods have their own advantages and disadvantages, so it’s worth considering both before deciding which is best for your project.

Using Bondo can be a good solution if the damage isn’t too severe. This technique involves using a special compound that hardens when exposed to air, creating a strong bond between the metal surfaces. The process is fairly simple and can be completed in just a few minutes with basic tools. However, this method does not provide a permanent fix and may require reapplication after several months of use in order to maintain a tight seal. Additionally, it can be a bit of a messy process, as the compound needs to be mixed and applied with care.

Taking the piece to an expert is another option if the damage is more extensive or there are other problems that need to be addressed. An experienced technician will have the tools and expertise necessary to properly repair any dents or scratches in aluminum pieces. They may also use specialized techniques such as welding or chemical bonding in order to create a stronger bond between the pieces. Although this method may take more time and money, it ensures a much more secure connection than simply using Bondo.

When deciding which technique is right for your project, consider both Bondo and taking it to an expert. Depending on your needs, one option might be better than the other.

FAQs

Does Bondo stick to metal?

Yes, Bondo sticks to metal surfaces when it is applied correctly. It is important that the surface be clean and free of rust or dirt before application and in order for the product to properly adhere. Additionally, it is best to use primer on the surface to ensure a secure bond between the metal and Bondo.

How do you remove Bondo from aluminum?

Removing Bondo from aluminum surfaces can be accomplished by first sanding the area with a medium grit sandpaper. After that, use a razor blade to scrape away any remaining material. Then, use steel wool and mineral spirits or an appropriate solvent to remove any residue left behind. Be sure to rinse off all traces of the solvent before proceeding with your project. When finished, use an aluminum polish to restore the original shine and finish of the surface.

When should you not use Bondo?

It should not be used as a structural repair material. It is not designed to withstand heavy loads or support large amounts of weight, so it should not be used for any repairs that require strength and durability.

Additionally, Bondo does not adhere well to certain materials such as stainless steel, brass, and chrome; therefore, it is best avoided for these types of surfaces. Finally, Bondo is meant for automotive repair only and its use on other items may cause damage or poor results.

Is Bondo for Aluminum always a good solution?

No, it is not always a good solution. Bondo is a type of automotive body filler that is meant to repair damaged metal panels on cars and other vehicles. It can be used to fill in dents, scratches, or other cosmetic damage on most types of metals. However, it is not always suitable for aluminum because it does not adhere well enough to the metal which could result in poor repairs and additional damage down the line. So doing research and consulting experts in the automotive repair field are recommended before attempting to fix any damages on your own.

Useful Video: Bonding Fiberglass to Aluminum

Conclusion

All things considered, repair of aluminum parts doesn’t have to be a daunting task anymore – Bondo is an excellent and affordable solution that can help mechanics quickly and safely restore machines or bodies. Moreover, you don’t even need to be a professional as Bondo can easily be used by any individual looking for minor repairs that will make a big difference. If you are considering using Bondo as your primary repair tool, make sure to talk with a mechanic or another knowledgeable person to ensure safe usage and avoid potential injury. With some knowledge and preparation, you can get the job done right every time. So what are you waiting for? Get repairing!

References:

- https://collegedunia.com/exams/aluminum-chemistry-articleid-6288

- http://www.secondchancegarage.com/public/555.cfm

- https://www.mackinsab.com/blog/aluminum-auto-body-repair-guide/

- https://blog.thepipingmart.com/metals/how-to-repair-cast-aluminum-without-aluminium/

- https://everydayshowcar.com/all-metal-body-filler/

- https://www.cherishyourcar.com/can-you-bondo-aluminum/

- https://justdownsize.com/can-you-bondo-aluminum-siding/

- https://everydayshowcar.com/bondo-over-paint/