As technology and materials today continue to evolve, so do the safety standards surrounding them. When it comes to aluminum wiring, people commonly wonder if this type of electrical insulation is a safe solution when constructing or renovating a building. In order to provide you with an easy-to-understand answer, this blog post will help break down what you need to know about aluminum wiring and its suitability for use in various applications. From discussing potential risks associated with using aluminum wiring instead of copper, understanding how to mitigate those risks through proper installation practices, and identifying who should be involved in the decision process – this article has something for everyone!

Why Is Aluminum Used For Wiring?

Aluminum wiring has become a popular choice for electrical wiring due to its low cost and relatively good conductivity. It is often used in homes, buildings, and other structures where electrical systems are necessary. Aluminum’s malleability makes it less prone to breaking or cracking compared to copper wiring, which can be brittle when exposed to the high temperatures of electricity running through it. This makes aluminum an attractive option for those looking for a reliable yet inexpensive way to wire their property. Additionally, aluminum wiring does not corrode easily and requires minimal maintenance over time.

However, it is important to note that there are potential safety risks associated with using aluminum wiring in comparison to copper that must be considered before making any decisions. While some believe that aluminum wiring is safe, there have been various reports of potential fire hazards linked to the use of this material. In order for electrical systems using aluminum wiring to be safe, they must be installed and maintained properly in accordance with local building codes and regulations. Additionally, it may be necessary to install additional safety measures such as circuit breakers and arc-fault circuit interrupters (AFCIs) to prevent any catastrophic incidents from occurring. [1]

Ultimately, when deciding whether or not aluminum wiring is right for your property, it is important to weigh both the pros and cons of using this material carefully. While it can provide a cost effective solution for many homeowners and businesses, it is important to ensure that all safety precautions are taken in order to prevent any potential risks or disasters. With this in mind, it is always best practice to consult with a professional electrician when planning any wiring projects in order to ensure that your system is up-to-date and meets all applicable building codes and regulations.

By taking these precautions into consideration, you can ensure that your electrical systems are safe and reliable for years to come!

What Are The Downsides Of Aluminum Wiring?

Unfortunately, aluminum wiring does not come without its drawbacks. While it is an affordable option and can provide reliable service for many years if properly installed and maintained, there are some potential risks associated with using aluminum wiring in your home or business.

One of the main concerns about using aluminum wiring is that it can oxidize when exposed to air, leading to a buildup of metal oxide on the wire’s surface. This build-up of oxidation can lead to increased resistance along the wire’s length, which increases the risk of overheating and potentially causing fires due to high temperatures. Another issue with aluminum wiring is that it has a higher expansion rate than copper wiring, meaning it can loosen up over time and create voids or improper connections which can lead to dangerous shorts. [2]

Finally, aluminum wiring is more susceptible to damage since it is softer and more malleable than copper, so extra care must be taken when installing and managing the wiring system. Additionally, due to its softness, aluminum wiring is more likely to be corroded by things like acidic vapors, air pollution and other environmental elements that are common in many homes and businesses.

It’s important to consider these potential risks before deciding if aluminum wiring is right for your situation. If you decide it’s the best choice for you, make sure you hire a professional electrician who has experience with installing and maintaining aluminum wiring systems. This will help ensure that the job is done correctly and minimize the chances of any fires or other issues.

Ultimately, if done right aluminum wiring can be a safe and cost-effective option for your electrical system. Just make sure you understand the potential risks associated with it before making your decision.

Where Can Aluminum Wire Be Safely Used In Your Home?

Aluminum wiring is safe to use in most applications for your home. However, it should not be used in high-heat producing appliances and fixtures such as dryers, water heaters, or furnaces. Additionally, aluminum wiring may cause some problems when connected to certain electrical outlets or devices that are designed for copper wiring only.

When using aluminum wire, make sure it is of the highest quality and certified by a reputable laboratory. Installations should follow the manufacturer’s instructions for any device being wired with aluminum, and all connections must be properly secured and protected from corrosion. In addition, regular maintenance should be performed to inspect for any loose or corroded connections and replace them if necessary.

With proper installation and maintenance, aluminum wiring can be used safely in many applications around your home. As always, it is best to seek the advice of a qualified electrician if you are unsure about any aspect of your wiring job.

It should also be noted that there have been reports of problems with aluminum wire connections due to improper installation and maintenance. If you suspect that an installation or repair job was not done correctly, it is important to get it checked out as soon as possible by a professional electrician for safety reasons. Aluminum wiring may not be for everyone, but if properly installed and maintained, it can provide a safe source of electricity for your home.

How To Determine If The House Has Aluminum Wiring?

If you are not sure if the house has aluminum wiring, there are a few steps that you can take to check. First, look at the outlets and switches in the home. If they have “Al/Cu” or “Aluminium/Copper” stamped on them, then aluminum wiring is present. Secondly, look for gray colored wires in the electrical panel. If these are present as well, it is likely that some of the wiring in your home is made out of aluminum. Lastly, you can have an electrician come into your home and inspect all of the wiring with specialized equipment to determine definitively if any aluminum wiring exists.

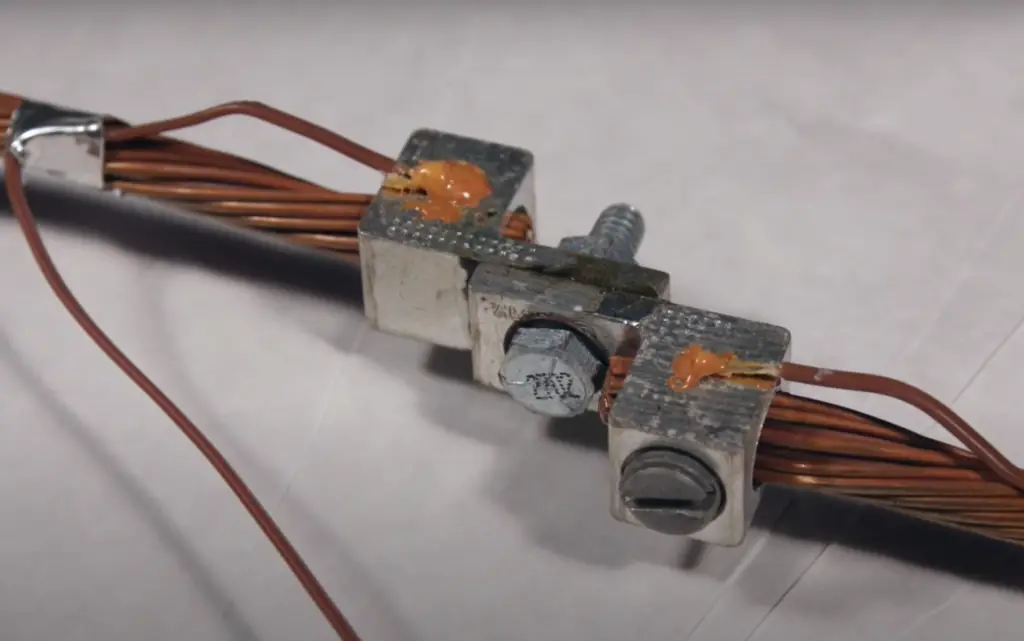

If you determine that aluminum wiring is present, it may be wise to consult an experienced electrician or professional for further advice and assistance.It is also essential to note that some homes may have mixed wiring, containing both copper and aluminum wires. In these cases, special care must be taken when connecting the two types of wires together as they expand differently when electrical current flows through them. If not done properly, this can result in serious fire hazards.

It is recommended to hire a certified electrician to handle any repairs or replacements in these cases to ensure proper installation and safety regulations are followed. [3]

What To Do If The House Has Aluminum Wiring?

If your home or building is wired with aluminum, it is important to make sure the wiring does not pose any safety risks. The best approach is to have a qualified electrician inspect and test the wiring for any signs of overheating or corrosion.

In some cases, aluminum wiring may need to be replaced with copper wiring. This process requires specialized tools and knowledge, so it should only be performed by a trained professional who has experience working with both types of wire. Depending on the extent of damage found during an inspection, repairs may need to be made as well.

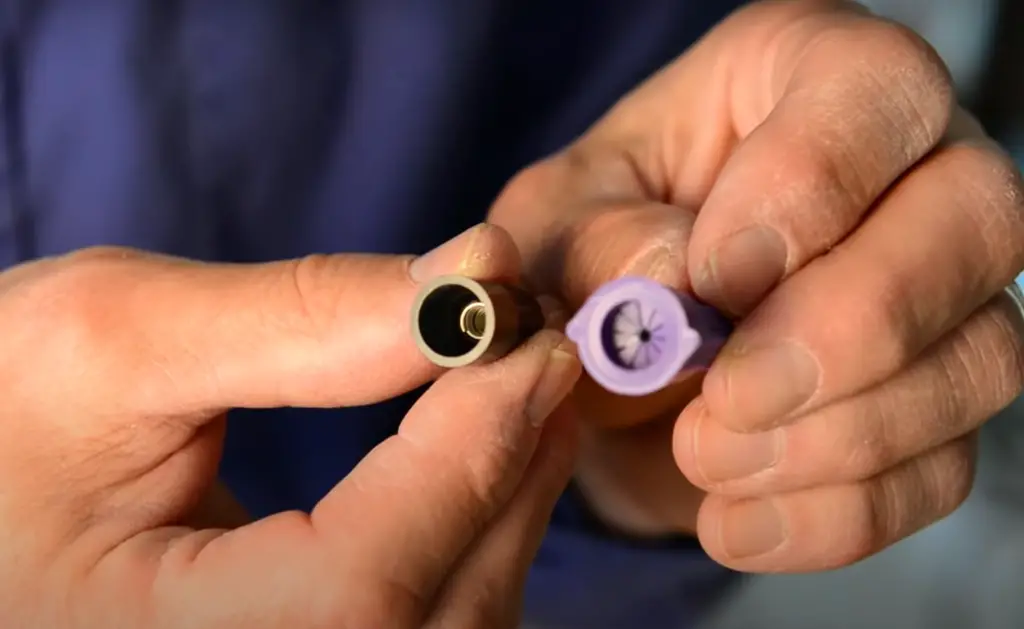

Another option for dealing with aluminum wiring is to install special connectors, such as COPALUM connectors. These are designed to create a secure connection between the aluminum wire and the device it is connected to, reducing the risk of overheating or sparking.

No matter what approach you take, it is always important to remember that proper maintenance and safe electrical practices are the key to avoiding accidents caused by faulty wiring. Be sure to check your home often for any signs of wear or damage, and contact an electrician immediately if any problems are suspected. By taking these steps, you can help ensure that your family remains safe and protected from potential dangers associated with aluminum wiring.

How To Identify Aluminum Wiring?

Aluminum wiring is not always easy to identify as it looks almost identical to copper wire. One way to tell the difference is by look and feel; aluminum wiring feels slightly softer than copper.

Another way to identify aluminum wiring is by the color of the insulation. Aluminum wiring will usually be an off-white/gray color, while copper typically has a reddish coloring.

A third option is to look for markings on the wire itself; some electrical wires have this information printed on them or marked with a small sticker near each end of the wire.

Additionally, if you suspect that your home has aluminum wiring, an electrician can come in and inspect your home’s electrical system. This professional will be able to accurately identify the type of wiring in your home and provide recommendations for safe use.

What Home Inspectors Look For?

When inspecting a home, a qualified home inspector will look for evidence of aluminum wiring by checking the breaker panel and other visible wiring connections. If they suspect that the wiring is aluminum, they may use an electronic testing device to confirm their suspicions.

Home inspectors also check for potential problems with existing aluminum wiring such as loose wire connections and improper splices. They will also make note of any damage to the insulation on aluminum wires, which can be a fire hazard if left unchecked. [4]

How To Maintain Aluminum Wiring?

Maintaining aluminum wiring is essential for ensuring its safety. It is important to take a few precautionary steps and properly maintain aluminum wiring in order to prevent any potential risks of fire due to arcing or overheating. Here are some tips for safely maintaining your aluminum wiring:

- Inspect regularly – Regularly inspect the wiring connections for signs of corrosion, discoloration or looseness. If you see any of these signs, it may be time to replace the connection with a newer copper-rated connector.

- Repair loose connections – Loose connections can cause arcing, an electrical current that heats up materials and can lead to fires. Make sure all screws are tight, and if necessary use an approved wire connector to replace the connections.

- Have a qualified electrician inspect your wiring – It is always best to have a qualified professional inspect and repair your aluminum wiring system. They can check for signs of wear, corrosion or arcing. If any problems are detected, they can take the necessary steps to make sure everything is up to code and safe for use.

By following these tips, you can ensure that your aluminum wiring is safe and reliable for years to come. Remember, safety always comes first when it comes to electrical work, so never hesitate to consult an expert if you have any concerns about maintaining your aluminum wiring system. [5]

FAQ

How risky is aluminum wiring?

Aluminum wiring is not necessarily risky, though it can increase the chance of fire or electric shock.

It should only be installed with special connectors and other precautions to ensure safety.

What is the difference between aluminum and copper wiring?

The main difference between aluminum and copper wiring is that aluminum has a lower conductivity than copper, meaning it takes more current to transfer power.

Additionally, typically special connectors are required for use with aluminum wiring.Is there any way to tell if I have aluminum wiring?

Typically, you can tell if your home has aluminum wiring if the wires are marked “AL”. Additionally, you may be able to tell by looking at the color of the insulation; older aluminum wires had a gray plastic sheathing while newer ones have white or black.

Can I replace aluminum wiring with copper?

Yes, in some cases it is possible to replace aluminum wiring with copper. However, for safety reasons, this should only be done with the help of a professional electrician.

How long can aluminum wiring last?

Aluminum wiring is known to last between 40 and 45 years, provided that it was installed correctly with the right materials. It is important to inspect aluminum wiring regularly as it may degrade faster than other types of wiring due to corrosion. Corrosion can be caused by water, oxygen, or other contaminants in the atmosphere.

This corrosion can lead to arcing and overheating which can cause a fire hazard. If any signs of damage are found, it should be replaced immediately by an electrician certified in aluminum wiring repair. Ultimately, proper maintenance of aluminum wiring will ensure its longevity for many years to come.

Is it OK to use aluminum wire instead of copper?

There may be situations where aluminum wiring is the only option available. In such cases, it is important to make sure that all of the requirements for using aluminum are met. This includes using suitable supporting devices and switchgear designed specifically for use with aluminum wiring. It is also important to ensure that any connections are properly made and properly maintained. Furthermore, if you choose to use aluminum wiring for any reason, it should always be installed by a certified electrician who has experience in working with this material. Overall, while aluminum wiring can be used as an alternative to copper, it requires more special care than other materials and should only be used when necessary.

Useful Video: Is aluminum wiring safe

Conclusion

The verdict on aluminum wiring safety is mixed. While experts agree that risks associated with aluminum wiring can be managed, there are still concerns about the long-term risk associated with aluminum wiring due to its tendency to corrode and expand more than copper wiring. In addition, the higher electrical resistance of aluminum can cause overheating in certain cases if it isn’t installed correctly.

For homeowners who will never need to alter or add onto their home’s existing electric system, an aluminum wired house may be perfectly safe. However, for those looking to make changes or additions to their home’s existing electric system, a full rewiring with copper wires may be the safest option. Ultimately, homeowners should consult a qualified electrician before making any decisions about aluminum wiring safety.

By carefully assessing the situation and taking the necessary precautions, homeowners can safely manage potential risks associated with aluminum wiring and use their home’s electrical system for years to come.

References:

- https://esasafe.com/home-renovation-buying-and-selling/aluminum-wiring/

- https://www.angi.com/articles/aluminum-wiring-safe.htm

- https://www.familyhandyman.com/article/aluminum-wiring-can-be-hazardous-heres-what-to-do-about-it/

- https://www.wirechiefelectric.com/aluminum-wiring-in-homes-answers-to-common-questions

- https://cosmiccomfort.com/is-aluminum-wiring-safe/