Aluminum welding can be a tricky process, but with the right tools and techniques, you can create strong, reliable bonds. Whether for repairs or construction projects, bonding aluminum to aluminum is an effective way of joining two pieces together. But it’s important to understand the best methods for creating a strong bond that will last through numerous uses. Read on to find out more about how to bond aluminum to aluminum.

Can you bond aluminum to aluminum?

Yes, you can bond aluminum to aluminum using a few different methods.

The best and most reliable method is welding, but you can also use epoxy adhesives or soldering. All these techniques require specialized tools and knowledge to achieve strong, lasting bonds between two pieces of aluminum [1].

Why is choosing the right bonding method crucial?

When bonding aluminum to aluminum, you should choose the right method. Each bonding option will produce different results and yield varying degrees of strength and durability. You need to research each type of adhesive or welding technique before beginning the project so that you can make sure you are using the best possible method for your needs.

Understanding Aluminum

The following are the main characteristics to be aware of when working with aluminum:

Properties of aluminum and its suitability for bonding

Aluminum is a light, malleable metal that has excellent corrosion resistance and thermal conductivity. It is also easy to shape and form into desired shapes, making it an ideal material for many projects. Its low cost makes it a popular choice in engineering and construction applications. In terms of bonding, aluminum is well-suited because it can be easily melted and worked with [2].

Different types of aluminum alloys and their characteristics

Aluminum alloys are created by combining different metals to form a material with specific properties. Each alloy will have its characteristics, such as strength, corrosion resistance, electrical conductivity, and thermal conductivity. You should understand the properties of different alloys before selecting one for your bonding project. Commonly used aluminum alloys are 6061, 5052, and 7075. Each has the characteristics that make it suitable for different types of applications.

Preparation for Bonding

When bonding aluminum to aluminum, it is important to prepare properly by taking the following steps:

Step #1. Preparation for Bonding – Cleaning the aluminum surfaces thoroughly

Before bonding aluminum to aluminum, clean both pieces thoroughly.

This will remove dirt, debris, or oil that may interfere with the bond and prevent a strong bond from forming. Use a lint-free cloth dampened with rubbing alcohol to wipe down the surfaces and remove dirt or debris.

Step #2. Identifying surface imperfections and addressing them

Aluminum is a relatively soft metal. So, it can easily be scratched or dented during handling. Inspect both pieces of aluminum for imperfections that may interfere with the bond, such as scratches, gouges, or dents. If there are imperfections present, they should be addressed before attempting to bond the two pieces of aluminum together. It may include filing down rough edges or filling in gaps with a filler material.

Step #3. Choosing the right adhesive or bonding method

When it comes to bonding aluminum to aluminum, several methods can be used. The most common methods are welding, epoxy adhesives, and soldering. Each method has its advantages and drawbacks. So, you should research each option before selecting the best one for your project [3].

What are the methods of aluminum bonding?

The following are some of the most popular methods for bonding aluminum to aluminum:

Mechanical Bonding Techniques

When it comes to bonding aluminum to aluminum, you can use the following mechanical bonding techniques:

Riveting and Rivet Bonding

Riveting is a technique that involves pressing two pieces of aluminum together with a strong, durable fastener known as a rivet. This method can create strong bonds between the two aluminum pieces and can be used for both repairs and construction projects. For an even stronger bond, rivet bonding can be used, which involves filling the space between the two aluminum pieces with an epoxy adhesive before inserting the rivet.

Screw Fastening and Threaded Inserts

Another mechanical bonding technique for joining aluminum to aluminum is screw fastening and threaded inserts. This method involves using a threaded insert, which is inserted into a hole in one piece of aluminum. A screw is then used to secure the two pieces together. This method creates strong bonds that can withstand heavy use and vibration without coming loose.

Chemical bonding techniques

Chemical bonding techniques involve using adhesives and/or solvents to join two pieces of aluminum:

Using Adhesives Specifically Designed for Aluminum

When bonding aluminum to aluminum, you can use adhesives specifically designed for this purpose.

These adhesives are designed to be used on aluminum surfaces and come in a variety of different types, such as epoxy adhesives, polyurethane adhesives, acrylic adhesives, and silicone-based adhesives. When using these adhesives, you must read the instructions carefully and follow them for the best results.

Epoxy Bonding and its Effectiveness

Epoxy bonding is one of the most effective methods of bonding aluminum to aluminum. Epoxy is a two-part adhesive that is mixed before applying it to the surfaces. Once cured, epoxy forms an extremely strong bond between two pieces of metal that can withstand wear and tear as well as extreme temperatures. Ensure all surfaces are clean and dry before applying the epoxy for the best results [4].

Metallurgical bonding techniques

Metallurgical bonding techniques involve altering the surfaces of two pieces of aluminum to improve their bond:

Metallurgical bonding techniques involve using heat to create a bond between two pieces of metal. Two popular metallurgical bonding techniques for joining aluminum are welding and friction stir welding.

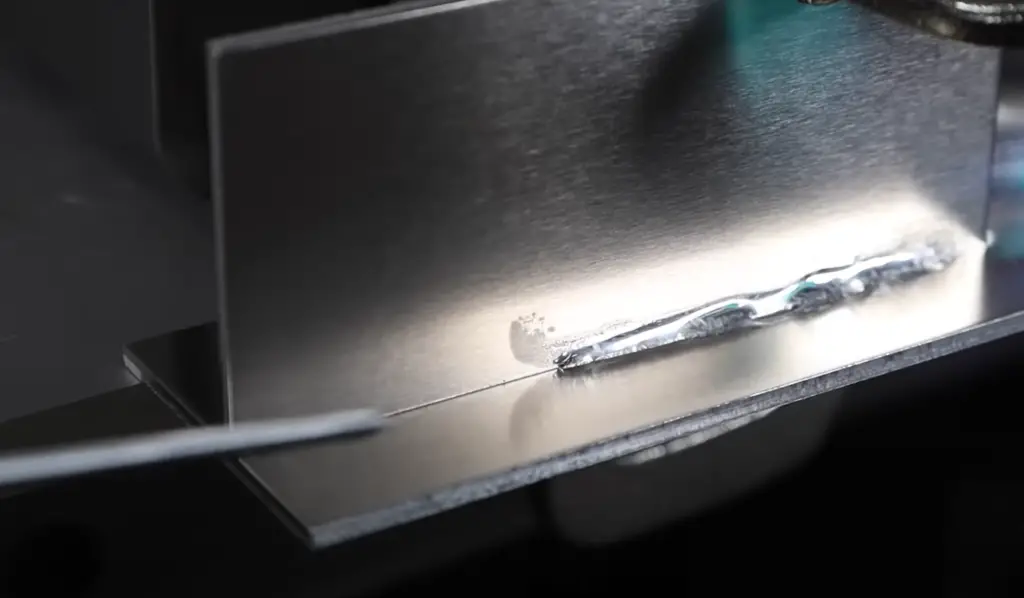

Welding Aluminum to Achieve a Strong Bond

The most common metallurgical bonding technique for joining aluminum is welding. This process involves applying an electric arc or gas flame to the two pieces of aluminum that you wish to join together, which creates a strong bond when cooled. Welding requires specialized equipment and should only be performed by experienced welders, as it can be dangerous if not done properly.

Friction Stir Welding and Its Advantages

Friction stir welding (FSW) is another metallurgical bonding technique used for joining aluminum. This method involves using a rotating tool to generate friction between the two pieces of aluminum, which melts and stirs the metals together to form a strong bond when cooled. FSW is highly effective for joining thin-gauge aluminum and is also easy to use and requires less specialized equipment than traditional welding methods.

FSW creates minimal heat distortion in the materials being bonded, making it ideal for projects where precision is important [5].

How to choose the right way to bond aluminum together?

When it comes to bonding two pieces of aluminum, several methods can be used, each with its advantages and disadvantages. Before selecting a bonding method for your project, consider the following factors:

- Strength Requirements: The strength of the bond is an important factor to consider when looking for the right bonding method for your aluminum pieces. If you need a strong bond that will withstand heavy use or vibration, then mechanical methods like riveting or screw fastening are usually best. On the other hand, if you just need a general-purpose bond, then adhesives may be enough.

- Heat Resistance: If heat resistance is an important factor in your application, then welding and friction stir welding may be better options than adhesives or mechanical fasteners. Both these techniques create bonds that can withstand extreme temperatures without coming apart.

- Durability: The durability of the bond is also an important consideration when selecting a bonding method for your aluminum pieces. Adhesives tend to be less durable than mechanical fasteners, but they are often easier and quicker to use.

- Cost: Assess the cost of each bonding method before making a decision. Mechanical methods may require specialized equipment or tools, which can increase costs significantly. On the other hand, adhesives may be cheaper in the short term but may need to be replaced more often as the bond weakens over time.

Step-by-Step Guide for Bonding Aluminum to Aluminum

Bonding aluminum to aluminum is a great way to create strong and durable connections between two pieces of metal. Several different methods can be used, each with its advantages and disadvantages. This guide will walk you through the steps needed to bond aluminum using mechanical, chemical, or metallurgical bonding techniques [6].

Step 1. Preparing the surfaces for bonding

Regardless of the method chosen for bonding aluminum to aluminum, ensure the surfaces are adequately prepared before applying adhesive, fastener, or other material. Start by cleaning both surfaces thoroughly to remove dirt and grease. Then lightly scuff or sand the surface area where the bond will be made to ensure good adhesion. If needed, use a commercial aluminum cleaner or etching solution to further enhance the adhesion of the bond.

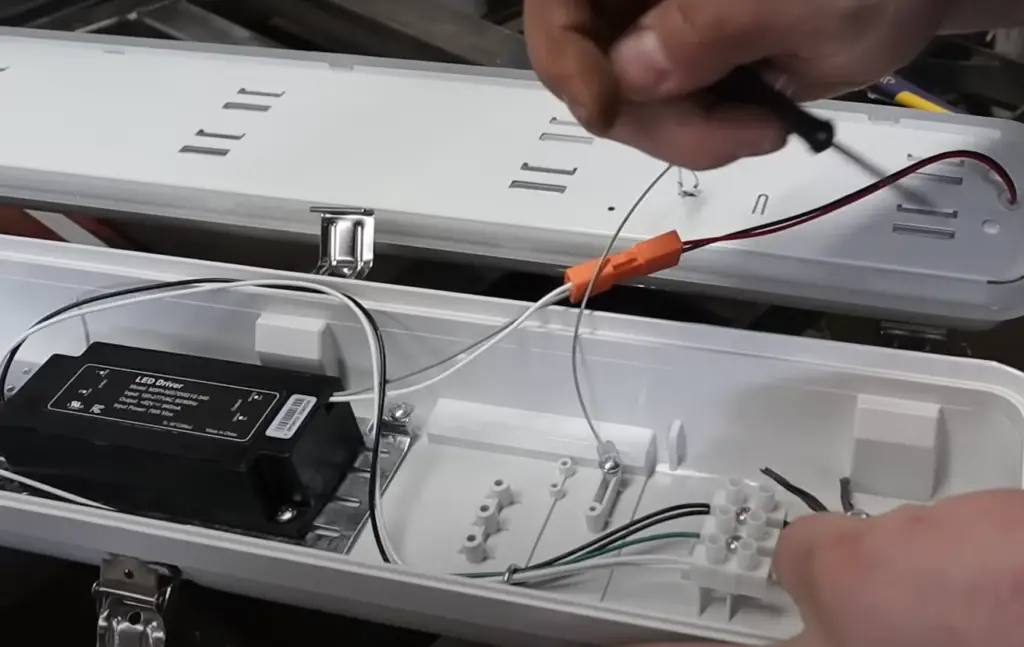

Step 2. Applying The Chosen Bonding Method

Once the surfaces have been prepared, it’s time to apply your chosen bonding method. For mechanical methods like riveting or screw fastening, make sure all holes are properly drilled and that specialized tools are available before starting.

Carefully press each surface together until they form a uniform bond.Step 3. Proper Curing and Curing Time

Different bonding methods require different curing times before the bond is considered fully cured. For adhesives, always follow the waiting times indicated in the manufacturer’s instructions. For mechanical and metallurgical bonding techniques, allow sufficient cooling time before testing or using the connection.

Make sure to properly inspect all bonds for strength and durability before using them in the application. Once you’ve followed these steps, your aluminum pieces should be securely bonded together. If done correctly, this bond can last for many years with minimal maintenance.

How to Choose the Right Method for Your Aluminum Bonding Project

When it comes to bonding aluminum, there are several options available, each with its advantages and disadvantages. Here is a list of the most popular ones:

- Consider the strength requirements of the bond – if a strong bond is needed that can withstand vibration or heavy use, consider mechanical methods such as riveting or screw fastening.

- Consider the heat resistance of the bond – for projects requiring extreme temperatures, welding, and friction stir welding are often better options than adhesives or mechanical fasteners.

- Evaluate the durability of your chosen bonding method – while adhesives may be quicker and easier to apply, they tend to be less durable than mechanical fasteners.

- Consider the cost involved with each bonding method – certain techniques may require specialized tools or equipment which can increase costs significantly.

- Ensure both surfaces are adequately prepared before applying the bonding method – cleaning and lightly scuffing or sanding the surfaces will ensure good adhesion.

- Always follow the manufacturer’s instructions when using adhesives – mix and apply a thin layer of adhesive according to the instructions for best results.

- Allow sufficient cooling time before testing or using mechanical and metallurgical bonds – this will ensure that the bond has fully cured and is ready for use.

- Inspect all bonds for strength and durability before using them in application – if done correctly, your aluminum pieces should be securely bonded together.

- When welding, make sure to use proper safety gear, including gloves, goggles, and breathing masks to protect yourself from splatter and fumes.

- Consider using a professional when tackling complicated bonding projects – having an experienced hand to guide you through the process can help ensure that your project is done correctly and safely.

Aluminum Bonding Tips and Considerations

Bonding aluminum requires careful consideration of several factors, from the load-bearing capacity to the temperature of the bonding process. This guide outlines a few tips and considerations to keep in mind when bonding aluminum pieces together.

Understanding the load-bearing capacity of the bond

Before beginning an aluminum bonding project, you should learn the load-bearing capacity of the bond. This will inform the type of bonding method used and help to ensure that the bond is strong and secure enough to withstand intended loads or pressures. Mechanical methods like riveting or screw fastening are usually the best option for projects requiring strong and secure bonds that can withstand heavy loads.

Temperature considerations for the bonding process

The temperature of the aluminum during the bonding process should also be considered as it can affect the strength and durability of the bond.

Adhesives tend to work better in warmer temperatures, while mechanical and metallurgical processes may require cooling times before being tested or used. If you’re welding, make sure to use proper safety gear, including gloves, goggles, and breathing masks to protect yourself from splatter and fumes [7].

Longevity and maintenance of the bond

Regardless of which method is chosen for bonding aluminum, always consider the longevity of the bond and necessary maintenance. Adhesives can be less durable than mechanical fasteners, so it may be worth considering this when choosing a bonding method. Properly inspecting all bonds for strength and durability before using them in the application is also key to ensuring they stand the test of time.

FAQs

What metal bonds to aluminum?

Aluminum can be bonded to other metals like steel, copper, and brass using mechanical fastening methods such as riveting or screw fastening. Adhesive bonding techniques such as epoxy also work well with aluminum.

What is the best glue to bond aluminum to aluminum?

The best glue to bond aluminum to aluminum is an epoxy adhesive designed specifically for metal surfaces. This type of glue forms a strong and durable bond that is resistant to vibration, heat, and other environmental factors. Make sure to follow the manufacturer’s instructions for proper mixing and application [8].

What is the strongest epoxy for aluminum?

The strongest epoxy for aluminum is a two-part, structural acrylic adhesive designed specifically for metal surfaces. This type of epoxy provides an incredibly strong and durable bond with minimal maintenance. It is resistant to vibration, shock, and extreme temperatures, making it ideal for projects that require an extra-strong bond.

How do you prepare aluminum for epoxy?

To prepare aluminum for epoxy, it is important to clean the surface and lightly scuff or sand it to create a better surface for adhesion. A primer can also be used to improve the adhesion of the epoxy if desired. Once the surface is prepped, apply a thin layer of epoxy according to the product instructions and allow it to fully cure before testing.

What should you not use on aluminum?

Certain chemicals should not be used on aluminum, including hydrofluoric acid and trichloroethylene. These chemicals can corrode and damage aluminum, leading to structural weakening. It is best to use products specifically designed for aluminum as they are formulated with the metal in mind.

Useful Video: Stick Aluminum Together Without a Welder.

Conclusion

Bonding aluminum pieces can be an intricate and complicated process. With the right tools and supplies, everything is possible. Choose the right bonding method for your project, evaluate the durability of your chosen method, and consider all costs and temperature factors that may arise. By following the tips outlined in this guide, you can ensure your aluminum pieces are bonded securely and safely.

References:

- https://www.clickmetal.co.uk/blog/post/how-to-join-aluminium-without-welding/

- https://www.azom.com/article.aspx?ArticleID=4192

- https://forgeway.com/how-to-choose-an-adhesive/

- https://www.coppsindustries.com/epoxy-resources/epoxy-a-complete-guide/

- https://www.sbb.ca/blog/sbb-now-offers-friction-stir-welding-fsw/

- https://waterwelders.com/how-to-bond-aluminum-without-welding/

- https://s-bond.com/solutions-and-service/aluminum-bonding/

- https://forgeway.com/best-glue-for-bonding-aluminium/