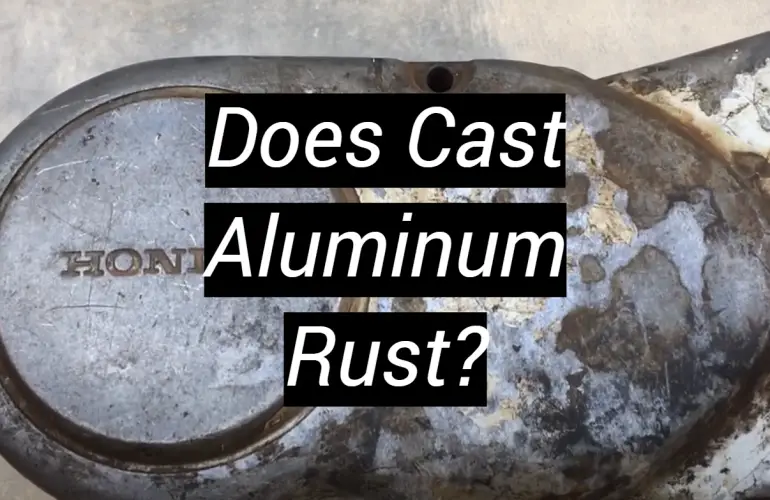

Does Cast Aluminum Rust?

If you’re like most people, you probably think of aluminum as a metal that doesn’t rust. After all, it’s used in a lot of products that are designed to resist corrosion, such as gutters and downspouts. However, the fact is that cast aluminum does rust, although not in the same way as other metals. In this blog post, we’ll take a closer look at how cast aluminum develops corrosion and what you can do to prevent it.

What is Rust?

Rust is a type of corrosion that occurs when metals are exposed to oxygen and moisture. This process causes the metal to corrode, resulting in the formation of an oxide layer on its surface. The most common form of rust is iron oxide, which appears as a reddish-brown flaky material that can weaken and damage metal structures over time. Rust can affect any type of metal including aluminum, however, it affects aluminum differently than other metals due to its protective oxide layer.

When discussing cast aluminum rust, we must first understand how this corrosion process works with different types of metals. Aluminum has a unique ability to form an oxide layer on its surface when it comes into contact with air or moisture. This oxide layer acts as a barrier, protecting the underlying metal from further corrosion. Thus, while other metals may corrode when exposed to oxygen and moisture, aluminum is much more resistant to rusting.

The formation of this protective oxide layer makes cast aluminum one of the best materials for outdoor applications as it is extremely durable and resistant to corrosion. It does not require any additional protection such as coatings or sealants in order to remain rust-free. In addition, it is lightweight yet strong which makes it an ideal metal for use in construction projects. [1]

Does Cast Aluminum Rust?

The short answer is no, cast aluminum does not rust. This is because aluminum has a protective oxide layer that prevents it from corroding when exposed to air or water. However, this doesn’t mean that it can never be affected by corrosion. Cast aluminum can still succumb to corrosion if exposed to acidic or alkaline solutions for prolonged periods of time. Additionally, the protective oxide layer can be damaged by harsh chemicals and abrasives, which will then leave the metal vulnerable to corrosion.

Galvanic corrosion occurs when two different metals are in contact with one another (in this case, the cast aluminum and another metal), creating an electrolyte which allows for electrical current to flow between them. This results in a chemical reaction which can cause corrosion on both metals. Pitting corrosion is caused by a concentration of an acidic or alkaline solution in one area, resulting in localized damage to the metal surface.In order to protect cast aluminum from any type of corrosion, it is important to keep it clean and dry at all times, and avoid contact with any corrosive substances (such as strong acids or bases). Additionally, regular cleaning with soap and water can help maintain the protective oxide layer that prevents rusting. To protect against any potential damage, this material must be rinsed off immediately if it comes in contact with water or other corrosive substances.

Overall, cast aluminum does not rust in the traditional sense – however, it is still susceptible to other types of corrosion if exposed to certain conditions or substances. Therefore, proper maintenance and care is important in order to keep it looking its best and ensure that it lasts for many years to come. [2]

Aluminum Oxides in Nature

Due to its excellent corrosion resistance, cast aluminum does not typically rust. Cast aluminum has a stable layer of aluminum oxide that forms when the metal is exposed to oxygen in the air. This thin film prevents further oxidation from taking place and makes it difficult for moisture or other oxidizing agents to penetrate the surface.

Aluminum oxides are also found naturally in nature and can be seen as an orange-yellowish powder called bauxite.

The natural formation of this protective layer on cast aluminum helps keep it safe from corrosion damage caused by water, salt spray, and other environmental elements. The aluminum oxide layer also helps prevent warping or cracking due to heat, which is one of the main reasons why cast aluminum items are so strong and durable.

In order to maintain the protective layer of aluminum oxide on cast aluminum items, it’s important to properly clean them after use. This will help ensure that any dirt or residue does not build up on the surface which could lead to corrosion over time. With regular cleaning and maintenance, cast aluminum should remain rust-free for many years!

How to Protect Aluminum from Corrosion?

Aluminum is naturally corrosion-resistant due to its protective oxide layer, however this layer can become compromised over time. To help protect aluminum and extend its life, it’s important to take the proper precautions. Some of these include:

- Cleaning – Regular cleaning with a mild detergent and water helps remove dirt and other contaminants that can lead to corrosion. Rinse away all soap residue after cleaning to prevent damage from the detergents used.

- Coating – Painting or powder coating aluminum helps create an additional barrier between the metal and potential corrosive elements like salt in harsh environments. Be sure to use a paint formulated for outdoor use if you live in an area with salty air or coastal air.

- Anodizing – Anodization is a process that forms an oxide layer on the surface of aluminum and can provide additional protection from corrosion. The anodic coating results in a thicker, more durable oxide layer than the natural one created by oxygen exposure alone. This makes it useful for harsh environments like industrial or marine settings.

- Avoiding Exposure to Corrosive Agents – Whenever possible, try to avoid exposing aluminum to agents such as chlorine, salt, acids and alkalis which can cause corrosion over time. If exposed, it’s important to rinse away all residue with clean water after contact has been made with these elements.

With proper care and maintenance, cast aluminum will last for many years. By following the recommendations above, you can help ensure your aluminum is well-protected and resists corrosion for years to come! [3]

Benefits of Cast Aluminum Patio Furniture

Cast aluminum patio furniture offers a variety of benefits. Not only does it not rust, but it is also lightweight and easy to move around. It is resistant to weathering and scratches and can last for decades with minimal upkeep.

Additionally, cast aluminum resists warping or cracking thanks to its strong construction and durable materials. Furthermore, cast aluminum is attractive and comes in many styles, shapes, sizes, and colors.

Finally, it’s great for outdoor entertaining as it won’t heat up in the sun like other metals do. Overall, cast aluminum patio furniture provides beauty, durability, and convenience all in one package! [4]

Disadvantages of Cast Aluminum Patio Furniture

Cast aluminum patio furniture is a popular choice due to its corrosion-resistance and durability, but there are also a few disadvantages to consider. Despite cast aluminum’s resistance to rust, it can still be affected by environmental conditions such as coastal air, high temperatures, and frequent exposure to water. Over time these factors can cause the surface of the metal to degrade, leading to discoloration and pitting.

Additionally, aluminum does not have the same strength as steel so cast aluminum structures may not be able to withstand winds or heavy loads like other metal furnishings. Furthermore, cast aluminum furniture usually has a more costly price tag than similar pieces made from other materials.

In conclusion, while cast aluminum patio furniture is an excellent option for many homeowners looking for durable outdoor furniture, it is important to take into account the potential drawbacks of this material before making a purchase.

Cast Aluminum Vs Aluminum Alloys

When it comes to aluminum, there is a difference between cast aluminum and aluminum alloys. Cast aluminum is made by pouring molten liquid metal into a mold, while aluminum alloys are created when metals such as magnesium, copper and zinc are added to pure aluminum.

While both types of aluminum can be susceptible to corrosion in certain conditions, the presence of alloying elements makes aluminum alloys more resistant to rust in many cases than cast aluminum. In order for cast aluminum to remain rust-free, protective coatings must often be applied or regular maintenance performed on the surface.

It’s important to consider your specific needs and climate when making a selection, as the right aluminum material may depend on where it will be used and how high an environment’s humidity levels are. [5]Cast Aluminum Vs Cast Iron

When comparing cast aluminum and cast iron, it’s important to keep in mind that both materials are used for a variety of applications. Cast aluminum is lightweight, has excellent thermal properties, and can be finished with a hard-anodizing process that allows it to resist corrosion better than many other metals.

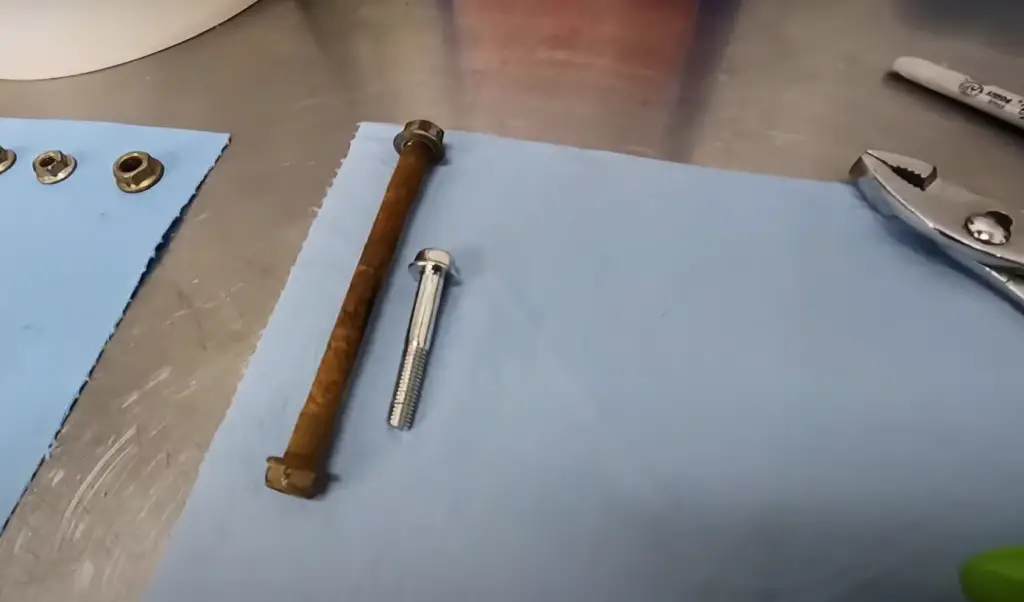

On the other hand, cast iron is heavier and more brittle than aluminum but its high melting point makes it ideal for applications where heat resistance is needed. A key difference between these two materials is their propensity to rust.

Aluminum does not typically rust because it forms an oxide layer on the surface when exposed to oxygen which prevents further corrosion. However, cast iron will rust easily because the carbon content enables oxidation when exposed to moisture or air. Although it is possible to paint or coat cast iron surfaces, this doesn’t prevent rusting and must be applied regularly to maintain its protective properties over time. In conclusion, the differences between aluminum and cast iron come down to their malleability, weight, corrosion resistance, and heat resistance.

Ultimately, both metals can be used for a variety of applications but aluminum has better rust-resistance which makes it preferable in certain situations.

FAQ

Does cast aluminum last?

Cast aluminum is known for its durability and longevity, making it a popular choice for outdoor projects. Cast aluminum does not rust or corrode as other metals do due to its high resistance to atmospheric oxidation. It also has a low coefficient of thermal expansion and can withstand extreme temperatures without warping or cracking. This makes it an ideal material for constructing long-lasting pieces that will stand up to the elements. In addition, cast aluminum does not require painting or other regular maintenance to stay looking great over time, saving you both time and money in upkeep costs. With proper care, cast aluminum can last for many years before needing repair or replacement.

How do I clean cast aluminum?

Cleaning cast aluminum is fairly simple and requires only basic cleaning supplies. Start by wiping the surface down with a damp cloth to remove any dust or debris that has accumulated. For tougher spots, use a mild detergent and warm water and scrub the area gently with a soft brush or sponge. Rinse off the soap and let it air dry. If you have an aluminum polish, you can use that to give the cast aluminum a glossy finish. No matter which method you choose, be sure to avoid using abrasive cleaners or scouring pads as they may damage the coating on your cast aluminum piece.

Are there any special considerations when working with cast aluminum?

Yes! It is important to note that some types of cast aluminum are more prone to heat warping than others, so it is best to consult a professional before beginning any project that involves cutting, welding, or other high-temperature operations. Additionally, cast aluminum should never be exposed to direct flame as it can cause permanent damage. Lastly, due to its high conductivity, cast aluminum can become very hot when exposed to direct sunlight – so use caution when working with the material outdoors in warm weather.

What is the difference between aluminum and cast aluminum?

Aluminum is a lightweight, corrosion-resistant metal that has been used for centuries in many different applications. Cast aluminum is a form of aluminum alloy which is created by pouring molten aluminum into a mold to create a desired shape or size. This process results in the formation of an extremely strong and durable material that is perfect for use in a variety of industries. It also provides superior rust resistance over regular aluminum due to its increased density. Cast aluminum can be anodized or enameled to provide further protection against corrosion and wear, extending the life of any product crafted from it.

Useful Video: Does Aluminium rust in water?

Conclusion

Ultimately, cast aluminum does not rust. Even though it is exposed to oxygen, moisture, and other elements in the environment that can lead to corrosion, its structure prevents it from forming rust or corroding. The presence of chromium in a casting makes it even more resistant to rusting. Cast aluminum is an excellent material choice for outdoor applications because of its long-lasting properties and corrosion resistance. It requires minimal maintenance over time and retains its strength and integrity when exposed to different weather conditions. With all these benefits, cast aluminum is an ideal solution for many applications where durability is important.

References:

- https://porchandpatio.net/cast-aluminum-patio-furniture-ct/

- https://sonomabackyard.com/does-cast-aluminum-rust/

- https://www.reliance-foundry.com/blog/does-aluminum-rust-or-corrode

- https://todayspatio.com/why-cast-aluminum-furniture-may-be-right-for-you/

- https://www.build.com/cast-aluminum-patio-furniture/a22118