Choose the Best Paint for Aluminum

Customer’s Choice: the Best Rated Paints for Aluminum

459 users answered this survey. Please help us improve this review!

Aluminum objects are very common in everyday life. But over time, they lose their appearance, and you may need to renovate and paint them. Most people who want to paint this metal believe that it is quite simple and easy to do. But it is not enough to put the brush in a jar of paint, smear it on the metal and wait for it to dry. Actually, everything is much more complicated than it seems. The process of metal painting requires not only skills and abilities but also knowledge about the composition and types of paints and the properties of the aluminum surface.

Painting aluminum can become a real challenge, especially if you are going to do it at home. The difficulty of working with such a material is due to its oxidation upon contact with air. Aluminum has excellent corrosion resistance as it forms a special film when interacting with air. It prevents moisture and rust. At the same time, this layer prevents the penetration of paint into the metal. Therefore, it is extremely important to follow the instructions for painting aluminum surfaces, otherwise, your efforts will be practically useless, and the color will not last long.

In this article, we will review the 5 best aluminum paints and discuss the most common methods of this metal painting.

All-in-one spray paint – the best means for DIY repair

This spray paint is designed for a number of surfaces like metal, plastic, tile, wood, and others. It works fine on the specified surfaces without any prior preparation and provides high-class adhesion even without preliminary sanding.

This spray paint is designed for a number of surfaces like metal, plastic, tile, wood, and others. It works fine on the specified surfaces without any prior preparation and provides high-class adhesion even without preliminary sanding.The current product comes in matte silver shade but the manufacturer also offers other colors of paints to choose from. It is advisable to wear a protective mask and gloves when working with this paint. The paint will work best in a warm environment and not too high humidity.

Pros

- Smooth coverage;

- Rust protection;

- Waterproof;

- Matte finishing;

- Quick dry.

Cons

- The nozzle easily gets clogged providing uneven coverage.

The paint is a great solution for DIY projects both indoors and outdoors. You can restore many things at home with this silver metal spray. Users say they applied it even for aquarium tanks and flower pots with a superb result. One spray bottle will allow you to cover 25-30 square feet. The full drying will need 48 hours, and the finish is very durable. Aluminum and other metal surfaces may need several coatings for the best outcome.

Black Finish for Metal – a must-have for gunsmiths.

This paint does a good job when you need to turn aluminum parts black or darken them. It is designed specifically for aluminum and will not bring good results on other alloys.

This paint does a good job when you need to turn aluminum parts black or darken them. It is designed specifically for aluminum and will not bring good results on other alloys.Its main role is to turn raw aluminum black, so avoid using the paint on the anodized surfaces. The final color is from gray to black depending on the surface color. But you may reapply the paint until you get the desired shade.

Pros

- Works at room temperatures;

- Quickly removes scratches;

- Easy to use;

- Instant result;

- Good for small touch-ups.

Cons

- Cannot be used for other alloys

If you need to perfect your gun appearance, this finish will be the right choice. The product is especially good for scratches and other touch-ups. You will have to prepare properly the surface you intend to finish and deoxidize it to get it clean from oils and protective films. Only then you can use the product. This paint will also be good for other small aluminum objects like nameplates, trophies, etc.

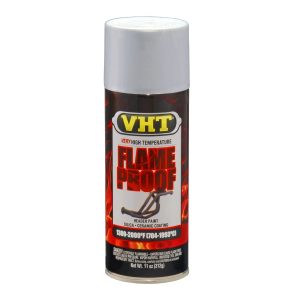

Flameproof Aluminum Coating – a great assistant for every motorist

This spray is a part of 3 step paint system – primer, color coating, and clear coating. It is designed for the auto industry, namely, for the parts that contact with extremely high temperatures.

This spray is a part of 3 step paint system – primer, color coating, and clear coating. It is designed for the auto industry, namely, for the parts that contact with extremely high temperatures.You can use it for brakes, engine parts, exhaust, and much more. The properly applied and cured paint will provide durable protection for your vehicle.

Pros

- Withstands very high temperatures;

- Flameproof;

- Ultimate protection;

- Durable coating;

- Matte finish.

Cons

- Complicated curing process.

You can use this paint for many purposes for your vehicle finishing – engine parts, exhaust, headers, brakes. Overall, it is specifically designed for all the parts that work in high temperatures. The only difficulty the user may experience is a bit of a complicated curing process that requires alternating periods of curing and heating. You will need to carefully follow the enclosed instructions to achieve the best results. Do not forget to clean and degrease the surface before treatment.

High Temperature Paint for Aluminum – the best treatment to heat exposed parts

This heat-resistant coating will help you prolong the life of many parts of your car and bike. It is easy to use as it comes as an aerosol spray.

This heat-resistant coating will help you prolong the life of many parts of your car and bike. It is easy to use as it comes as an aerosol spray.The manufacturer provides all instructions on application and curing. The paint can withstand extreme temperatures which makes it ideal to be used for all types of cars. The finished parts will not lose color for a long time.

Pros

- Temperature resistant;

- Water-resistant;

- Easy to apply;

- Durable color;

- Empty cans can be normally utilized.

Cons

- Paint leftovers must be disposed of responsibly.

When using this paint, the main idea is to prepare the surface properly before application and to follow the curing instructions precisely. Otherwise, you will not achieve the desired result. It is recommended to sandblast the surface and only then paint it. The paint will be dry to touch in 4 hours approximately, but the second coating can be applied in 24 hours only. The paint should be used only outdoors in a well-aired area. Do not work with it without protective clothing.

Metal ultra-cover – multi-purpose aluminum finish spray

This innovative product will work equally well on wood and metal, plastic, and ceramic. Actually, you will be able to apply it anywhere you like, it is good for anything inside or outside your home.

This innovative product will work equally well on wood and metal, plastic, and ceramic. Actually, you will be able to apply it anywhere you like, it is good for anything inside or outside your home.The paint comes in a spray bottle, and it is easy to cover even hard-to-reach places using it. It can be applied at any angle with a superb result.

Pros

- Double cover technology;

- Can be used indoors and outdoors;

- Good for many surfaces;

- Durable effect;

- Easy to apply;

- Shiny metal finish.

Cons

- The nozzle can get clogged.

This paint is fine for a number of purposes indoors and outdoors. It will work ideally on various surfaces, including aluminum. Double cover technology will make the whole process fast and efficient. The paint needs only 20 minutes to dry. These features make the product a perfect choice for DIY projects. It comes as a 2 bottle package that allows you to cover almost 50 square feet of the surface.

Buyer’s Guide

If you are going to paint aluminum at home, be prepared to devote enough effort and time to this job. If you do not do it correctly, the wrongly applied paint will be easily scratched or damaged. Moreover, it can simply come off after drying. First of all, learn everything about the technology you will need to follow for a good result. This way you will achieve strong adhesion and the painted surface will serve for a long time.

Aluminum is a metal with high chemical activity. The aluminum surfaces get quickly covered with a special oxide film when they are in the open air. That is why, the paint plays not only a decorative role, but also protects this metal. In general, you can use two methods for this job – you can plain aluminum with anodizing or apply a special primer to avoid this procedure. Let us have a look at these methods in detail.

How to anodize aluminum?

Now there are many ways to paint aluminum on your own, but a durable effect can be obtained with the help of special pretreatment of the surface. It is anodizing that allows you to avoid a temporary result. What is the purpose of this procedure? This process improves the appearance of a metal and does not allow it to react to the air influence. Anodizing makes the metal surface look greyish. But you can use any suitable paint to give the surface a different color.

- You will need baking soda and usual table salt. Then you have to make two highly-concentrated solutions. For this, dissolve substances separately in water and leave for thirty minutes. You may occasionally stir them, and these should be filtered finally.

- When you mix these two solutions, you will get the electrolyte. For the best results, take 9 parts of the soda concentrate and 1 part of the salt solution. Be sure to mix everything properly.

- An aluminum surface must be prepared for the procedure. Use sandpaper to process it, degrease it using a special substance or prepare a solution of washing liquid with hot water. Be careful not to leave fingerprints on the finished surface. The best method is to use gloves.

- Then you need to pour the electrolyte into a container and place an aluminum product there. The next step is to find a current source. You can use a device with a voltage of 12 volts and a current of 2 amperes. Connect the minus to the container, and the plus to the aluminum surface. You will need an hour and a half for this process. In the result the surface will get a greyish shade.

- After successful completion of the process, you can paint aluminum parts.

Using primer for aluminum painting

The above-described procedure can be avoided. If necessary, you can achieve good results without anodizing and use a primer that allows you to increase the quality of adhesion of paint and metal. You will need the following things for this task:

- kerosene, acetone and cleansers for degreasing;

- paints that can be used for metal;

- special primer;

- sandpaper;

- a tool for applying paint.

The whole procedure starts with surface cleaning with sandpaper to achieve better adhesion of the primer. The best option is a medium abrasive sandpaper. After this stage, use acetone – apply it with a cloth. It is important to do all this in protective gloves to protect your hands.

The next step is to apply the primer. The key point is to spread the primer evenly as quickly as possible. The result of the treatment largely depends on the speed of your performance. It is suggested to prepare the primer at the very beginning. But small drawbacks that may be found after application of the primer can be improved with sandpaper.

You will need to apply at least two layers to the surface. Before applying the next coating, the previous layer should be ideally dry.

Types of paints for aluminum

Most often aluminum surfaces are treated with the following paints:

- Acrylic paints. This option is very durable and does not react to moisture and sudden changes in temperature. But you will need a primer layer before using acrylic paint.

- Epoxy paint. It is made on the basis of special resins, thanks to which it is very strong.

- Aniline paint. This coating was originally created for textile production. It is optimal for aluminum products that have been preliminary anodized. But it can be low-resistant to moisture and sunlight.

Precautionary measures

After you have chosen the painting method, you should also learn safety measures to follow during this work. It only seems that this process is not complicated. Follow these instructions if you want to paint aluminum at home:

- It is necessary to prepare the area where you will be conducting the painting. It is advisable to clean it of dust, since its particles can spoil the result, settling on the painted surface.

- It is important to paint the part in good lighting. So all the flaws, irregularities and smudges will be visible.

- All the painting procedures should be carried out in well-ventilated areas, regardless of the composition of the paints.

- It is necessary to avoid drafts.

When working with paints containing toxic components, all work must be carried out in special protective clothing. Protective glasses will also help protect your eyes from splashing components and ready-made formulations. Hands must be protected with gloves.

FAQ

How do you permanently paint aluminum?

To permanently paint aluminum, you will need to clean it to remove any dirt that may prevent the paint from adhering properly. Then, use a primer specifically designed for metal surfaces before applying several light coats of an outdoor-grade spray paint. Let each coat dry before adding the next one, and finish with a clear top coat for extra protection. This should ensure that your paint job lasts!

What is the best paint for outside aluminum?

The best paint for outside aluminum depends on your preferences. The best types of paint to use on aluminum surfaces are latex or acrylic. Both types of paint provide a durable finish that can stand up to the elements. They also can be applied easily with sprayers or brushes. Additionally, they are resistant to fading and cracking in the sun’s UV rays. If you need an extra-durable finish, consider using an epoxy-based paint on your aluminum surfaces. This type of paint is more expensive, but it offers superior protection from corrosion and abrasion. Finally, make sure to properly prepare the aluminum surface before applying any type of paint for optimal results. Clean the area with a degreaser or sand it lightly if necessary, then apply a primer. With these tips in mind, you can get the perfect paint job for your outdoor aluminum surfaces!

How do you get paint to stick to raw aluminum?

The best way to get paint to stick to raw aluminum is by using a good primer. Primers are designed to create a surface that paint can easily adhere to, and it also helps protect the metal from corrosion. When priming raw aluminum, you’ll want to use an alkyd-based primer such as Rust-Oleum Automotive Primer. This primer can be applied directly to the metal surface and left to dry for a minimum of four hours. Once the primer has been applied, you can apply your paint of choice, such as an enamel paint designed specifically for metals. It’s important that each layer of paint is allowed to dry before applying the next one. Сhoose a paint specifically designed for metal surfaces; otherwise, the paint may not adhere properly to the aluminum surface.

How do you prepare aluminum for painting?

If you are looking to paint aluminum, there are a few steps you need to take in order to prepare it properly. First of all, make sure that the aluminum is free from dirt and grease. You can do this by scrubbing the surface with warm soapy water and then wiping it down with a clean cloth. Once the surface is clean, you should use a wire brush or sandpaper to scuff up the surface. This will help ensure that the primer and paint adhere better. After that is done, it’s time to apply a coat of rust-inhibiting metal primer. Be sure to follow the instructions on the can for the best results!

Good luck with your project – painting aluminum surfaces is definitely an art! Just take your time and make sure everything is properly prepped and you’ll have great looking results in no time.

Why does paint peel off aluminum?

Paint peels off aluminum because aluminum is a metal that expands and contracts with temperature changes. When temperatures are extreme, the metal expands or contracts more than the paint can handle, causing it to separate from the metal surface. Additionally, if the aluminum isn’t properly prepped before painting, any contaminants such as grease or oil on its surface can cause paint to not adhere correctly. This often leads to bubbling and eventual peeling of the paint. To prevent this problem it’s important to carefully prepare the surface by thoroughly cleaning it with soap and water before applying a primer coat.

Another major factor in why paint may peel off aluminum is because of using the wrong type of paint. Latex paints and oil-based paints have different chemical makeups, so it’s crucial to choose the right one for aluminum surfaces.

Finally, another key factor contributing to peeling paint is inadequate protection from sunlight and other harsh weather conditions. Exposing painted aluminum surfaces to direct sunlight or moisture can accelerate the breakdown of paint over time, leading to cracking and peeling. To prevent this problem, be sure to apply a topcoat that provides UV protection to your painted aluminum surface.

Should you sand aluminum before painting?

Yes, it is important to sand aluminum before painting. Sanding removes any imperfections or residues on the surface of the metal and creates a smooth, uniform surface that helps ensure better adhesion for the paint. Before you start sanding, make sure to clean the aluminum with soap and water. Start with a medium grit sandpaper, then finish up with a fine grit paper to give it a smoother finish. Once you’re done sanding, wipe down the piece of aluminum with a damp rag to remove any debris from the sanding process. This will help create a clean surface for your paint job!

How long does paint on aluminum last?

The durability of the paint on aluminum depends on several factors, such as the type of paint used, how well it was applied, and what kind of exposure it has to weather. Generally speaking, you can expect quality paint to last anywhere from 5 to 10 years on aluminum surfaces. However, this range may be shorter or longer depending on the specific elements in play. It’s also important to keep in mind that a fresh coat of paint can help extend the life of your aluminum surface and keep it looking its best for longer. If you’re concerned about how long your paint will last, consider investing in a high-quality product and taking steps to ensure proper application. This is an investment worth making — after all, no one wants their hard work and money to go to waste! Aluminum siding that is well-maintained and painted can last up to 40 years.

If you want your paint job to last for many years, it is important to maintain the aluminum surface by cleaning it regularly. This will help keep dirt, dust, and other debris from eating away at the paint layer. Additionally, try applying a clear sealant or coating once a year for extra protection against extreme weather conditions.

Will Rustoleum stick to aluminum?

Yes, Rustoleum can stick to aluminum. It is a common choice for painting aluminum surfaces because of its durability, versatility and easy application. When applying Rustoleum to aluminum, it is important to prepare the surface properly so that the paint will adhere correctly. This includes cleaning off any dirt or debris with soap and water, then sanding down any rough spots. Once the surface has been prepped and dried, you can apply a coat of Rustoleum primer followed by your desired top coat finish. With proper preparation, you can create a long-lasting finish on your aluminum surface with Rustoleum!

Can I paint over old paint on aluminum?

Generally, yes, you can paint over old paint on aluminum. However, for best results and ensure longevity of your paint job, it is important to properly prepare the surface before applying a new coat of paint.

Start by removing any loose or flaking paint from the aluminum surface with a wire brush or sandpaper. Then clean the area with detergent and water. Once the area is dry, use a primer specifically designed for metal surfaces before painting. This will help the new coat of paint adhere better and last longer. Finally, once you have finished prepping the surface, apply two to three coats of latex-based paints to achieve optimal coverage.

Take your time when preparing the aluminum surface as this process can determine the end result of your paint job.

Does vinegar help paint stick to aluminum?

Yes, vinegar can help paint adhere to aluminum surfaces. It is best to use white distilled vinegar for this purpose. Before you begin painting, mix one part of vinegar with four parts of water in a spray bottle and shake it until the mixture is blended well. Spray the solution onto the aluminum surface and allow it to sit for several minutes before wiping it off with a clean cloth. This will create an acidic layer on the surface that helps paint stick better than if you were to just start painting without pre-treating the surface. Make sure you let your painted project dry thoroughly before using or displaying it for maximum adhesion.

Can you put acrylic paint on aluminum?

Yes, you can put acrylic paint on aluminum. All you need to do is prepare the surface of the aluminum by sanding it down and then applying a primer to it. This will help the paint stick better and give you a longer-lasting finish. Once the primer has dried, you can then apply the acrylic paint in several thin coats, allowing each coat to dry before applying the next one. When finished, make sure to seal your work with a clear lacquer or varnish for extra protection and durability.

Can you use enamel paint on aluminum?

Yes, you can use enamel paint on aluminum. It offers a durable finish that is resistant to scratches and chips. Before applying the paint, it’s important to thoroughly clean and degrease the surface with soap and water or a degreasing solvent. After this step, make sure to sand the surface lightly with fine-grit sandpaper in order to give the paint something to adhere to. Once cleaned and prepped, apply two coats of enamel paint for the best results. Allow each coat of paint for at least 24 hours before adding another layer. And voila – your aluminum project should now be protected from corrosion and wear!

Is painting aluminum hard?

Painting aluminum can be a tricky task, but with the right supplies and techniques, it is certainly doable. To paint aluminum you’ll need to use an oil-based primer specially designed for metals, followed by a coat of water or latex based paint for color. Be sure to prepare the surface properly before painting and use multiple coats of each material for a durable finish. It’s also important to choose outdoor rated paints as regular interior paints may not last long when exposed to weather elements. With the right materials and some patience, painting aluminum can be an easy DIY project!

Is it better to powder coat or paint aluminum?

It really depends on the situation. If you want a long-term finish that won’t fade or chip over time, powder coating is usually the better choice. The powder coating process involves applying an electrostatically charged dry powder to the aluminum surface and then curing it in an oven. This creates a hard, durable finish that resists damage from weather, corrosion, and wear and tear much better than paint. Plus, it offers a wider range of color options than traditional painting.

On the other hand, if you need something more affordable with less of a lead time for installation, painting might be your best bet. The painting also gives more flexibility in terms of color customizations – plus there are many formulas available that are specifically designed for aluminum surfaces.

If you need a long-term, durable finish that won’t chip or fade, powder coating is probably the way to go. But if you want something more affordable and easier to install, painting might be the better choice. Ultimately, it’s up to you!

Is oil based paint good for aluminum?

Oil-based paints and primers will corrode aluminum siding, so you must use a different type of paint. Acrylic latex paints are the best choice for painting aluminum, as they form a strong bond with the surface and won’t break down or flake off over time. Make sure to use a primer before applying any paint, as this will help ensure that you get a good finish. When painting aluminum siding, always remember to use long strokes in order to ensure even coverage. This will also extend the life of your paint job and keep your siding looking great!

Is epoxy paint good for aluminum?

Yes, epoxy paint is a great choice for painting aluminum. But the key is to make sure you’ve prepped the surface carefully first, to get it back to ‘like-new’. It provides good adhesion and protection against corrosion, making it an ideal choice for outdoor applications. Epoxy paint also offers excellent color retention and durability. Plus, it’s relatively easy to apply and can be used on a variety of surfaces including wood, concrete, and metal. If you’re looking for a high-quality finish that will last a long time, then epoxy paint is definitely worth considering.

Useful Video: Painting Aluminum, Spray Can Primers Compared

Summary

The choice of any method, adherence to recommendations, technology, sequence of actions, will allow you to get a high-quality painted part, protected from oxidative processes. It is important to choose high-quality materials, paints, degreasing solutions to achieve the positive results. From this article, you can see that painting aluminum can be done even at home if you approach it responsibly.