Choose the Best Blade for Cutting Aluminum

Customer’s Choice: the Best Rated Blades for Cutting Aluminum

80 users answered this survey. Please help us improve this review!

There is a lot of debate surrounding the best blades for cutting aluminum. In this comprehensive article, we will take a look at some of the top blades on the market and provide you with our expert opinion on which one reigns supreme. We’ll also provide you with some tips on how to get the most out of your blade when cutting aluminum. So whether you’re a professional contractor or just someone who likes to do DIY projects around the house, read on for all the information you need to make an informed purchase!

Concord Blades ACB0825T030HP 8-1/4″ 30 Teeth TCT Non-Ferrous Metal Saw Blade

The Concord Blades ACB0825T030HP 8-1/4″ 30 Teeth TCT Non-Ferrous Metal Saw Blade is an ultra sharp and hard titanium carbide blade that is ideal for cutting through non ferrous metals such as aluminum, brass, copper, bronze and more, as well as plastics, Plexiglas, PVC, Acrylics & fiberglass.

The Concord Blades ACB0825T030HP 8-1/4″ 30 Teeth TCT Non-Ferrous Metal Saw Blade is an ultra sharp and hard titanium carbide blade that is ideal for cutting through non ferrous metals such as aluminum, brass, copper, bronze and more, as well as plastics, Plexiglas, PVC, Acrylics & fiberglass.

Oshlun SBNF-072560 7-1/4-Inch 60 Tooth TCG Saw Blade with 5/8-Inch Arbor (Diamond Knockout) for Aluminum and Non Ferrous Metals

Looking for a top-quality circular saw blade? Check out the Oshlun SBNF-072560 7-1/4-Inch. This professional-grade blade is made from C-1 carbide and features a negative hook angle and triple chip tooth grind for unbeatable performance.

Looking for a top-quality circular saw blade? Check out the Oshlun SBNF-072560 7-1/4-Inch. This professional-grade blade is made from C-1 carbide and features a negative hook angle and triple chip tooth grind for unbeatable performance.

Diablo D1080N Non-Ferrous Metal & Plastic Cutting Saw Blade

The Diablo D1080N Non-Ferrous Metal & Plastic Cutting Saw Blade is the perfect choice for those who want to make quick, clean cuts through a variety of materials. The laser cut stabilizer vents trap noise and vibration, keeping the blade cool and reducing blade warp.

The Diablo D1080N Non-Ferrous Metal & Plastic Cutting Saw Blade is the perfect choice for those who want to make quick, clean cuts through a variety of materials. The laser cut stabilizer vents trap noise and vibration, keeping the blade cool and reducing blade warp.

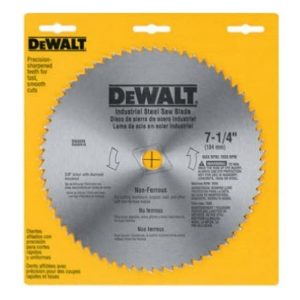

DEWALT 7-1/4″ Circular Saw Blade, Metal Cutting, 5/8-Inch and Diamond Knockout Arbor, 68-Tooth (DW3329)

Looking for a blade that will give you precise, smooth cuts and long-lasting performance? Then check out the EWALT 7-1/4″ Circular Saw Blade. The precision sharpened teeth are perfect for fast, smooth cuts, while the blade coating prevents rust and reduces friction. Plus, the thicker body provides increased durability in heavy-duty applications.

Looking for a blade that will give you precise, smooth cuts and long-lasting performance? Then check out the EWALT 7-1/4″ Circular Saw Blade. The precision sharpened teeth are perfect for fast, smooth cuts, while the blade coating prevents rust and reduces friction. Plus, the thicker body provides increased durability in heavy-duty applications.

MASTEC 10-Inch 100T Carbide Tooth TCG for Aluminum Saw Blade with 5/8-Inch Arbor

Looking for an aluminum saw blade that won’t leave behind a jagged, messy edge? Then check out our MASTEC 10-Inch 100T Carbide Tooth TCG Aluminum Saw Blade! This top-of-the-line blade features triple chip teeth that are ideal for cutting through aluminum, Plexiglass, plastic, and other non-ferrous metals.

Looking for an aluminum saw blade that won’t leave behind a jagged, messy edge? Then check out our MASTEC 10-Inch 100T Carbide Tooth TCG Aluminum Saw Blade! This top-of-the-line blade features triple chip teeth that are ideal for cutting through aluminum, Plexiglass, plastic, and other non-ferrous metals.

Buyer’s Guide

What is a circular saw blade?

A circular saw blade is a cutting tool that can be attached to a power drill or other power tool in order to cut through various materials. The blades are usually made out of metal, but there are also diamond-tipped and carbide-tipped options available. Circular saw blades come in a variety of sizes and with different numbers of teeth, which will affect their performance when cutting through different materials.[2]

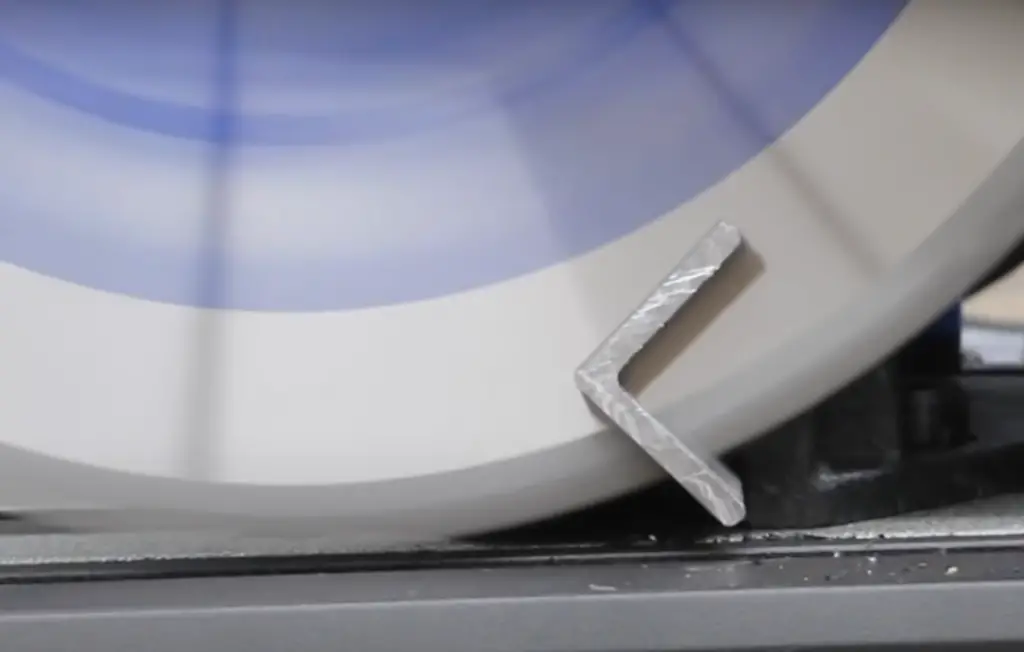

How to choose the perfect blade for cutting aluminum.

Types of blades

Choosing the perfect blade for cutting aluminum can be tough. With all of the different types and brands of blades on the market, it’s hard to know which one is right for your project.

There are two main types of blades for cutting aluminum: expanded and unexpanded. Expanded blades have teeth that are spread out, while non-expanded blades have teeth that are closer together. Both types of blades can be used for cutting aluminum, but expanded blades are better suited for thicker materials, while non-expanded blades are better for thinner materials.

When choosing a blade for cutting aluminum, you’ll also need to decide on the size and shape of the blade.

The four-inch blades are better for smaller projects, while the seven-inch blades are better for larger projects. The most common shapes are round and square. Round blades are better for cutting curved surfaces, while square blades are better for cutting flat surfaces.[2]Once you’ve decided on the type, size, and shape of blade you need, it’s time to choose a brand. There are many different brands of blades on the market, but not all of them are created equal. Some brands are better than others, and it’s important to do your research before making a purchase. We’ve done the legwork for you and compiled a list of the best blades for cutting aluminum, as well as some tips.

Blade diameter and arbor size

When it comes to cutting aluminum, the diameter of your blade is important. A too-small diameter will cause excessive friction and heat, potentially leading to blade breakage. Conversely, a too-large diameter can make it difficult to control your cuts. As a general rule of thumb, you should use a blade with a diameter that is about 80% of the thickness of the aluminum you are cutting.

For example, if you are cutting ½” thick aluminum, a ¼” diameter blade would be ideal. If you don’t have a blade with the perfect diameter for your project, it’s better to err on the side of a larger diameter. It’s always easier to control a larger blade than a smaller one. [3]

The other important measurement to consider is the arbor size. The arbor is the hole in the center of the blade that attaches it to the saw. Most blades for cutting aluminum have a standard arbor size of but there are some that have a larger size. If you are unsure what size arbor your saw takes, it’s best to consult the owner’s manual or the manufacturer of your saw.

Using a blade with the wrong arbor size can be dangerous and may damage your saw.

Material

There are a few things to consider when purchasing your blades for cutting aluminum. The most important factor is the material of the blade. You want to make sure that the blade is made of high-quality materials that will be able to withstand repeated use. There are a few different types of materials that can be used for blades, but the most common is carbon steel.

However, it is also the most expensive option. If you are on a budget, stainless steel is a good alternative. It is not as durable as carbon steel, but it is still strong enough to get the job done.Size

The next thing to consider is the size of the blade. You want to make sure that the blade is large enough to handle the aluminum that you will be cutting. If you are only going to be cutting small pieces of aluminum, a smaller blade will suffice. However, if you plan on cutting larger pieces, you will need a larger blade. The size of the blade will also affect the price. Larger blades are more expensive than smaller ones.

Safety

Safety should always be your number one priority when working with any kind of power tool. Be sure to wear the proper eye and ear protection, and follow all manufacturer guidelines for your specific saw or blade.

There are a few things to keep in mind when choosing the best blade for cutting aluminum. First, you need to consider the thickness of the material you’ll be cutting. If you’re only going to be working with thin sheets of aluminum, then a standard wood-cutting blade will suffice. However, if you’re planning on cutting thicker pieces of aluminum, you’ll need a blade that’s specifically designed for metal.

Another thing to consider is the type of saw you’ll be using. If you have a standard table saw, then you can use just about any type of blade. However, if you’re using a miter saw or chop saw, you’ll need to make sure you get a blade that’s designed for that particular tool.

Finally, you need to decide what type of finish you want on your cut aluminum. If you’re looking for a clean, precise cut, then you’ll want to get a blade with carbide teeth. However, if you’re just looking to make a quick cut and don’t care about the finish, then a standard steel blade will work just fine.

Kerf

The width of the blade is important when you are making a cut. If the blade is too wide, it will take longer to make the cut. If the blade is too narrow, it may not be able to handle the load and may break. The ideal width of the blade depends on the thickness of the aluminum and the depth of the cut .

To determine the ideal width of the blade, you need to know the kerf. The kerf is the width of the cut that the blade makes. It is important to have a consistent kerf so that your cuts are accurate.

The most common widths for expanded metal blades are .032″, .045″, and .0625″.

For most applications, the .045″ blade is the best choice. It is wide enough to make clean cuts in aluminum while still being able to handle a heavy load.

If you are cutting thick aluminum, you may need to use a wider blade. The .0625″ blade is the widest that is commonly available.

Tip: You can use a smaller blade if you are only making light cuts. For example, if you are cutting sheet metal, you can use a .032″ blade. [1]

Tooth count

The number of teeth per inch (TPI) will determine the smoothness of the cut. The higher the TPI, the finer the cuts.

For example, a 24-tooth blade is great for general purpose cutting while a 80-tooth blade produces extremely fine and precise cuts

(but also creates more friction and heat).

You’ll want to use a lower TPI blade (15-20 teeth per inch) when cutting thicker aluminum sheets (> 0.06 inches or 14 gauge).

For thinner aluminum (< 0.04 inches or 20 gauge), you can go with a higher TPIblade (40-80 teeth per inch).[2]

Tooth shape and arrangement

The blades you use to cut aluminum should have teeth that are fine and sharp. The teeth should also be arranged in such a way that they form a “V” shape. This will help to ensure that the blade can make clean cuts through the aluminum without leaving any jagged edges.

In addition, the teeth on the blades should be spaced out evenly. This will help to prevent the blade from getting stuck in the aluminum and will also make it easier for you to control the blade as you are cutting.

Finally, make sure that the blades you use have a good quality blade guide. This will help to keep the blade from wobbling as you are cutting and will also help to extend the life of the blade.

Gullet

The gullet is the space between the teeth of a saw blade. It’s important because it determines how much material the blade can remove with each tooth. A large gullet can quickly remove a lot of material, but it also produces more heat and can cause the blade to bind in the cut. A small gullet removes less material, but it produces less heat and is less likely to bind.

There are two common gullet shapes: U-shaped and V-shaped. U-shaped gullets are more common on blades for cutting wood, while V-shaped gullets are more common on blades for cutting metal.

Hook Angle

The hook angle is the angle between the face of the tooth and the back of the blade. A smaller hook angle will result in a cleaner cut, while a larger hook angle will be more aggressive.

There are two types of blades that you can use to cut aluminum: standard or expanded. Standard blades have a set number of teeth, while expanded blades have variable teeth spacing.

Expanded blades are ideal for cutting aluminum because they provide a cleaner cut and don’t require as much power to operate.

Which types of blades do you use to cut aluminum?

There are three types of blades that can be used to cut aluminum:

- Tungsten carbide-tipped (TCT) blades

- High speed steel (HSS) blades

- Diamond blades

Each type of blade has its own advantages and disadvantages that make it more or less suitable for different tasks.

Tungsten carbide-tipped (TCT) blades are the most common type of blade used for cutting aluminum. They’re inexpensive and can be used with both hand-held and table saws. TCT blades are also the only type of blade that can be used to cut aluminum with a miter saw.

The main disadvantage of TCT blades is that they wear down quickly when cutting aluminum. This means that you’ll have to replace them more often than you would if you were using a different type of blade.

High speed steel (HSS) blades are more expensive than TCT blades, but they last much longer. HSS blades can be used with both hand-held and table saws, but they’re not suitable for use with miter saws.

The main disadvantage of HSS blades is that they can’t be used to cut aluminum with a miter saw.

Diamond blades are the most expensive type of blade, but they’re also the longest lasting. Diamond blades can be used with both hand-held and table saws, but they’re not suitable for use with miter saws.

The main disadvantage of diamond blades is that they can’t be used to cut aluminum with a miter saw.

However, if you’re on a budget and only need to use your saw occasionally, then TCT blades are a good option. And if you’re looking for the longest lasting blade possible, then diamond is the way to go.[1]

Why is the blade diameter critical?

The blade diameter is critical because it determines how much material can be cut with each stroke of the saw. A larger diameter blade will allow you to make more cuts before needing to replace the blade.

When choosing a blade diameter, keep in mind that a smaller diameter will provide more control while cutting. If you are new to using an expanded metal saw, it is best to start with a smaller blade diameter. You can always move up to a larger diameter blade if you find that you need more cutting power.

The most common diameters for expanded metal blades are four inches and six inches. Four-inch blades are typically used for light-duty cutting, while six-inch blades are better suited for heavy-duty cutting.[3]

Comparison of Indicators for Choosing Blades for Cutting Aluminum

When it comes to cutting aluminum, selecting the right blade is crucial for achieving accurate and efficient results. Different blades offer varying levels of performance based on several indicators. This table presents a comparison of various indicators to consider when choosing blades for cutting aluminum.

| Indicator | Carbide Tipped Blade | High-Speed Steel Blade | Abrasive Blade | Diamond Blade |

|---|---|---|---|---|

| Durability | High | Moderate | Low | High |

| Cutting Speed | High | Moderate | Moderate | High |

| Heat Resistance | High | Moderate | Low | High |

| Smoothness of Cut | High | Moderate | Low | High |

| Cost | High | Moderate | Low | High |

Explanation:

- Durability: Carbide tipped blades and diamond blades offer high durability, while high-speed steel blades and abrasive blades have moderate to low durability.

- Cutting Speed: Carbide tipped blades and diamond blades provide high cutting speed, while high-speed steel blades and abrasive blades have moderate cutting speed.

- Heat Resistance: Carbide tipped blades and diamond blades offer high heat resistance, while high-speed steel blades have moderate heat resistance, and abrasive blades have low heat resistance.

- Smoothness of Cut: Carbide tipped blades and diamond blades deliver a high level of smoothness in the cut, while high-speed steel blades provide a moderate level, and abrasive blades produce relatively low smoothness.

- Cost: Carbide tipped blades and diamond blades tend to be more expensive, high-speed steel blades have a moderate cost, and abrasive blades are relatively low-cost options.

Consider these indicators when choosing a blade for cutting aluminum to ensure you make an informed decision based on your specific requirements, such as the desired finish, speed, and budget constraints.

FAQ

Can a hacksaw cut aluminum?

Yes, a hacksaw can cut through aluminum. However, you will need to use a blade that is specifically designed for cutting metal. These blades are usually made of high-carbon steel or tungsten carbide. You will also need to take care not to overheat the metal while you are cutting it.

If you are cutting aluminum that is thicker than about ¼ inch, you may want to use a bandsaw instead of a hacksaw. Band saws can make straighter cuts and don’t overheat the metal as easily.[9]

Can you cut aluminum with a carbide saw blade?

Yes, you can cut aluminum with a carbide saw blade. In fact, carbide is one of the best materials for cutting aluminum. Carbide blades are able to withstand the high temperatures that are generated when cutting aluminum. This makes them ideal for use in power saws and other power tools.[10]

How do I know that a blade needs to be replaced?

One of the most telltale signs that a blade needs to be replaced is when it starts to produce sparks. If you see sparks, it means that the blade is no longer sharp enough to make clean cuts. Additionally, if the blade starts to bind or feels like it’s getting stuck in the material, it also needs to be replaced.

Another way to tell if a blade is dull is by the quality of the cut. If you see jagged or rough edges, it’s time for a new blade. When in doubt, err on the side of caution and replace the blade. It’s always better to be safe than sorry![11]

How to take care of the circular saw blade?

After each use, it is important to clean the circular saw blade to remove any built-up debris. Abrasive materials like aluminum can cause the blade to dull quickly, so it is important to keep it clean and sharp.

To clean the blade, first unplug the saw and remove the battery (if applicable). Use a brush to remove any large particles of debris from the teeth. Next, use a cloth to wipe down the blade, being careful not to touch the teeth. Finally, use a toothpick or other sharp object to clean out any small particles that may be lodged in the teeth.

Once the blade is clean, it is important to store it properly to prevent damage. If possible, store the blade in its original packaging. If not, wrap the blade in a soft cloth and place it in a safe location away from children and pets.

With proper care, your circular saw blade will last for many years.[12]

What are the types of circular saw blades?

There are three main types of circular saw blades: metal-cutting, wood-cutting, and multi-purpose. As the name implies, metal-cutting blades are designed specifically for cutting through metals such as aluminum or steel. Wood-cutting blades, on the other hand, are made for cutting through softer materials like lumber or plywood.[2]

What are the things to consider in buying a circular saw blade for cutting aluminum?

When looking for the best circular saw blade for cutting aluminum, there are several factors you need to take into account. The most important thing is the material of the blade. You want a blade that is made specifically for cutting aluminum. There are two types of blades that can be used for this: carbide-tipped and high-speed steel.

Carbide-tipped blades are more expensive but they last longer and can handle more heat. They are also better at cutting through thick aluminum. High-speed steel blades are less expensive but they dull faster and can’t handle as much heat. If you’re only going to be doing occasional cuts, a high-speed steel blade will probably suffice.

How important is the number of teeth?

The number of teeth is one of the most important things to consider when choosing a blade for cutting aluminum. The more teeth a blade has, the smoother the cut will be. However, more teeth also mean that the blade will wear out faster. For most applications, a 24-tooth blade is a good choice.[3]

What are the materials used in saw blades?

The most common materials used in making saw blades are carbon steel and high-speed steel. Carbon steel is less expensive than high-speed steel, but it is not as durable. High-speed steel is more expensive, but it holds its edge longer and can be used to cut tougher materials.[1]

Can a wood blade cut aluminum?

The answer is yes, but it’s not ideal. Wood blades can dull quickly when cutting aluminum, and they’re also more likely to cause the material to tear. If you do need to use a wood blade, make sure it’s sharp and that you’re using a slow speed setting on your saw. [10]

What is a kickback?

When cutting aluminum, it’s important to be aware of the potential for kickback. Kickback occurs when the material being cut binds on the blade, causing the blade to stop suddenly. This can cause the saw to jerk backwards, potentially injuring the operator. To avoid kickback, use a sharp blade and make sure that the material is properly supported.

What type of blade is best for cutting aluminum?

When cutting aluminum, it is recommended to use a carbide-tipped blade specifically designed for non-ferrous metals. These blades have a high tooth count and specialized geometry to provide clean and precise cuts on aluminum materials.

What are the advantages of using a carbide-tipped blade for cutting aluminum?

Carbide-tipped blades offer several advantages for cutting aluminum. They have a longer lifespan compared to other types of blades, provide clean and smooth cuts, and reduce the chances of material buildup or binding during the cutting process. Additionally, they are less likely to produce excessive heat, which can damage the aluminum material.

How many teeth should a blade have for cutting aluminum?

For cutting aluminum, it is recommended to use a blade with a high tooth count, typically around 80 to 100 teeth or more. The higher tooth count allows for finer and smoother cuts, minimizing the risk of chipping or tearing the aluminum material.

Can a diamond blade be used to cut aluminum?

Diamond blades are not recommended for cutting aluminum. They are designed for cutting hard materials like concrete, stone, or tile. Using a diamond blade on aluminum can cause excessive heat buildup and potentially damage the blade or the material being cut. It is best to use a carbide-tipped blade specifically designed for non-ferrous metals like aluminum.

What safety precautions should I take when cutting aluminum with a blade?

When cutting aluminum, it is important to wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and hearing protection. Make sure the workpiece is securely clamped to prevent movement during cutting. Additionally, avoid applying excessive force or pushing the blade too hard, as it can cause binding or kickback. Always follow the manufacturer’s guidelines and safety instructions for the specific blade and cutting tool you are using.

Can I use a circular saw to cut aluminum?

Yes, a circular saw can be used to cut aluminum. However, it is important to use a carbide-tipped blade specifically designed for cutting non-ferrous metals like aluminum. Ensure that the circular saw is properly adjusted and set to the appropriate cutting speed for aluminum materials.

What are some common problems when cutting aluminum, and how can they be avoided?

Common problems when cutting aluminum include chipping, burrs, and rough edges. To avoid these issues, use a high-quality carbide-tipped blade with a high tooth count. Take your time when cutting, applying steady and even pressure to achieve a smooth and clean cut. Clamping the workpiece securely and using appropriate cutting lubricants can also help minimize these problems.

Can a miter saw be used for cutting aluminum?

Yes, a miter saw can be used for cutting aluminum. Make sure to use a carbide-tipped blade specifically designed for non-ferrous metals and set the miter saw to the appropriate cutting speed. Follow safety precautions and manufacturer guidelines for both the miter saw and the blade.

How should I handle the cut aluminum pieces after cutting?

After cutting aluminum, use caution when handling the cut pieces, as the edges may be sharp. It is advisable to wear protective gloves to avoid cuts or injuries. Additionally, carefully inspect the cut edges for any burrs or sharp points that may need to be smoothed or deburred before further handling or use.

What are some signs that a blade is not suitable for cutting aluminum?

If you notice excessive heat buildup, rough or jagged cuts, frequent blade binding, or premature dulling of the blade, it may indicate that the blade is not suitable for cutting aluminum. Consider switching to a carbide-tipped blade designed specifically for non-ferrous metals for optimal results.

Useful Video: Best Metal Cutting Circular Saw Blades

Conclusion

So, what is the best blade for cutting aluminum?

Well, it really depends on the application. For general purpose use, a good quality all-purpose blade will do just fine. However, if you’re looking for something more specialized, then one of the other options might be a better choice.

In any case, we hope that this article has been helpful in guiding you towards the best blade for your needs. Happy shopping!

References:

- https://toolsngoods.com/best-circular-saw-blades-for-cutting-aluminum/

- https://www.thebesthometools.com/best-circular-saw-blade-for-cutting-aluminum-review

- https://repairart.net/best-circular-saw-blade-for-cutting-aluminum

- https://www.amazon.com/dp/B00LFCMI34

- https://www.amazon.com/dp/B0012YKRYW

- https://www.amazon.com/dp/B00008WQ38

- https://www.amazon.com/dp/B00004RH4L

- https://www.amazon.com/dp/B07DQJCQW3

- http://www.secondchancegarage.com/public/320.cfm

- https://home.howstuffworks.com/what-type-of-circular-saw-blade-do-i-need-to-cut-metal.htm.

- https://www.toolboxtoday.com/sharpen-replace-saw-blade/

- https://www.thespruce.com/cleaning-saw-blades-1398304