Choose the Best Hole Saws for Metal

Customer’s Choice: the Best Rated Hole Saws for Metal

47 users answered this survey. Please help us improve this review!

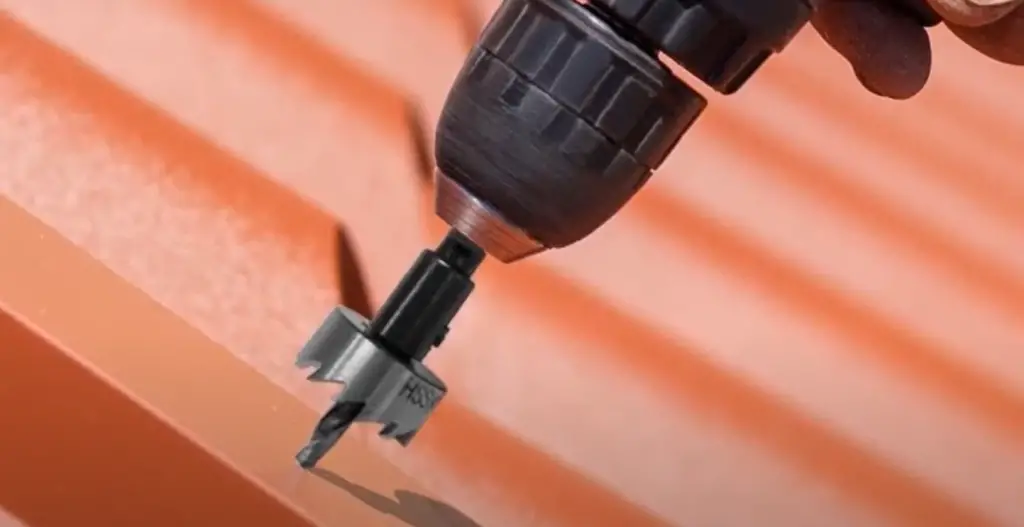

Hole saws are one of the most versatile tools in a homeowner’s or contractor’s toolbox. Hole saws are ideal for slicing through everything from wood to metal, and they can even be used on tile and concrete.

If you’re looking for a power tool that can make quick and easy work of cutting holes in metal, you need to check out this guide.

In this buying guide, we’ll tell you everything you need to know about metal hole saws so that you can choose the right one for your needs. We’ll cover the different types of hole saws available, as well as what to look for when making your purchase. So whether you’re a professional contractor or a DIY enthusiast, read on for all the information you need to buy the perfect hole saw for your next project.

Milwaukee 49-22-4185 All-Purpose Professional Hole Saw Kit

If you’re looking for an easy-to-use, durable hole saw kit that will give you 50% with life longer than that of the competition, look no further than the Milwaukee 49-22-4185 All Purpose Professional Ice Hardened Hole Saw Kit.

If you’re looking for an easy-to-use, durable hole saw kit that will give you 50% with life longer than that of the competition, look no further than the Milwaukee 49-22-4185 All Purpose Professional Ice Hardened Hole Saw Kit.

However, international standards for outlets and voltage differ, so this item may need a converter or an adapter for use at your destination.

The case is flimsy and won’t stand up to heavy use, but it won’t affect the overall performance of the product. It should be mentioned as well that this product is perfect for home use, but it’s not designed for commercial use.

But when in need for a cheap product, then this is the one for you!

DEWALT Hole Saw Kit D180002

Check out the DEWALT Hole Saw Kit, Standard Electrician’s Set. Made in the USA with global materials, this versatile set is designed for thick materials and offers outstanding drilling performance.

Check out the DEWALT Hole Saw Kit, Standard Electrician’s Set. Made in the USA with global materials, this versatile set is designed for thick materials and offers outstanding drilling performance.

However, there are a few downsides to this set. First, the mandrel is quite cumbersome to use, and it can be difficult to keep it stable while you’re drilling. Second, the drill bits are not round, so they don’t always cut through material evenly. And finally, the case isn’t very sturdy, so it doesn’t provide much protection for your investment. Overall, the DEWALT hole saw kit is a good choice for electricians who need an affordable and easy-to-use set.

Drillpro Hole Saw Kit HSS Drill Bit Hole Saw Set for Metal

This versatile and affordable set is perfect for anyone who needs to frequently cut through metal, wood, or other materials.

This versatile and affordable set is perfect for anyone who needs to frequently cut through metal, wood, or other materials.

The downside is that elements are heavy-duty, the hole saw is shallow and the sizes are given in millimeters, not in inches as some users may prefer.

Greenlee – Carbide Cttr, Quick Chge, 6Pc, Hole Making (660)

Greenlee 660 is a top-quality carbide cutter that can handle all your hole-making needs. It features a flange stop to prevent over-drilling and an ejector spring on all sizes above 3/4-inch to make removal of the slug easier.

Greenlee 660 is a top-quality carbide cutter that can handle all your hole-making needs. It features a flange stop to prevent over-drilling and an ejector spring on all sizes above 3/4-inch to make removal of the slug easier.

DEWALT Hole Saw Kit DWACM1802

Get the job done right with the DEWALT Metal Cutting Hole Saw Kit. The DEWALT 3-Piece Metal Cutting Hole Saw Kit is designed for long life in material cutting. With carbide teeth and an ejection spring for easy plug ejection, this hole saw set is perfect for a range of applications.

Get the job done right with the DEWALT Metal Cutting Hole Saw Kit. The DEWALT 3-Piece Metal Cutting Hole Saw Kit is designed for long life in material cutting. With carbide teeth and an ejection spring for easy plug ejection, this hole saw set is perfect for a range of applications.

Buyer’s guide

Characteristics to consider when choosing a right hole saw

Now that you know a bit about the different types of hole saws available, let’s talk about what to look for when making your purchase.

When you’re in the market for a new hole saw there are so many different types and styles available, that it can be tough to know which one is right for you.

To avoid mistakes there are several factors to consider. With all of these factors in mind, you will be ready to start shopping for your new hole saw.

Hole Saw Size and Width

The first thing to consider is size. There is a wide range of sizes available from small ones that can just take up space in your toolkit and large ones extending far beyond what most people would need for their projects. You also might want one with different accessories such as endcaps or carbide cutting tools depending on exactly how much time (and money)you’ve got available.

Hole saws come in a wide range of diameters, from small ones that are just a few inches in diameter to large ones that can be a foot wide.[2],[3]

The size of your saw blade will depend on what material you’re cutting. If it’s a thin metal like a sheet or aluminum siding, then a smaller hole saw might work for the job; but if thicker pieces are required such as steel pipe and stainless steel – go ahead and get yourself one that can cut through these types.

If you’re not sure what size hole saw to get, it’s always better to err on the side of caution and get a larger one. That way, you’ll be able to cut through thicker metal if you need to.

Hole saws are also available in a variety of widths:

- Narrow: between 14 and 18mm (0.55-0.71 inches)

- Medium: between 19 and 24mm (0.75-0.94 inches)

- Wide: between 25 and 30mm (0.98-11.81 inches)

The width of the hole saw will determine how big the hole is that it can cut.

If you’re not sure what size hole you need, it’s best to get a saw with a larger width.

Wider hole saws can cut through thicker metal, but they’re also more difficult to control. Again, the size you need will depend on the job you’re doing. If you’re cutting through thicker metal, you’ll need a wider hole saw so that it can handle the material.

Metal consideration

Think as well about the type of metal you’ll be cutting through. Some hole saws are designed for specific materials, like aluminum or stainless steel.

Others can cut through multiple types of metal.

Therefore, it’s important to check what type of metal your saw can cut before making your purchase.

Different types of metals will require different types of hole saws.

These are designed to cut through the metal without damaging it. The same goes for stainless steel and other materials.When using your hole saw for a specific application, it’s worth getting one that’s designed specifically for that task. It will make your life much easier in the long run. In case you don’t know which type of metal you’ll be working with, a good all-purpose hole saw can usually cut through most types of metals without any problems.

Cutting depth

Another important consideration is the cutting depth of the hole saw. This is the depth of the hole that the saw can cut through. Typically hole saws have a cutting depth between two and six inches. [4]

The cutting depth will be determined by the size of the hole saw. Smaller hole saws will have a shallow cutting depth, while larger ones can cut through thicker materials.

When choosing a hole saw, make sure to pick one with the right cutting depth for your project. You don’t want to get a hole saw that’s too small and can’t cut through the material you’re working with. On the other hand, you also don’t want one that’s too large and will take forever to cut through your material.

The best way to determine the perfect cutting depth is to think about the thickness of the metal you’ll be cutting. If it’s less than an inch thick, then a shallow cutting depth should suffice. But if you’re working with thicker metal, then you’ll need a hole saw with a deeper cutting depth.

Keep in mind that the cutting depth is different from the length of the drill bit. The drill bit is the part of the hole saw that does the drilling, and it can extend beyond the cutting depth.

Teeth

The number of teeth per inch, or TPI, is another important factor to consider when choosing a metal hole saw. The TPI is a measure of the number of teeth on the blade.

Generally speaking, the higher the TPI, the smoother and cleaner the cut will be. However, more teeth also mean that the hole saw will cut more slowly.

If you’re cutting through thin metal, you can get away with a hole saw that has fewer teeth. But if you’re cutting through thicker metal, you’ll need a hole saw with more teeth so that it can make a clean cut.

You should also keep in mind that hole saws with more teeth will require more power to use. So if you’re using an electric drill, make sure it has enough power to handle the TPI of the hole saw.

In general, most hole saws have several teeth between 3 and 14 [5]. For thin metal, a hole saw with around six teeth will suffice.

Speed

The speed is the number of times the blade rotates in one minute. T

But you can also find hole saws that run at higher or lower speeds. The speed you need will depend on the material you’re cutting.

If you’re cutting through thin metal, you can get away with a slower speed. But if you’re cutting through thicker metal, you’ll need a higher speed so that the hole saw can cut through the material.

Keep in mind that the higher the speed, the more power the hole saw will need. So if you’re using an electric drill, make sure it has enough power to handle the speed of the hole saw.

Power source

When it comes to the power source, you have a few different options. You can use an electric drill, a cordless drill, or a hole saw attachment for your power drill.

If you’re only going to be using the hole saw occasionally, an electric drill will be sufficient. But if you’re going to be using it frequently, a cordless drill will be worth the investment.

And if you already have a power drill, you can get a hole saw attachment that will allow you to use your existing tool.

If you’re using a power drill, you’ll need to make sure it has enough torque to handle the hole saw. Power drills typically have more torque than electric drills, so they can usually handle larger and more powerful hole saws. And if you’re using a cordless drill, make sure the battery is charged so that you don’t run out of power in the middle of your project.

In general, most hole saws require between two and four amps of power. But you can also find ones that require up to eight amps of power.

Make sure to check the power requirements of the hole saw before you buy it.

Durability

The durability of a hole saw is important to consider because you want it to last for a long time. The most durable hole saws are made from high-speed steel or carbon steel.

Carbon steel is less expensive but it’s not durable, but it will probably be fine if you’re planning to use the hole saw for occasional projects.

When it comes to using it continuously in a wet environment or storing it in a humid place, you might want to get a hole saw that’s made from stainless steel.

High-speed steel is a type of tool steel that can withstand high temperatures without losing its strength and is not susceptible to rusting.

Price

Hole saws for metal range in price from around $20 to over $100. [7]. It’s important to find one that’s within your budget. The price of a hole saw depends on other factors, such as the size, speed, power source, and durability.

The size of the hole saw will have the biggest impact on the price. The larger the hole saw, the more expensive it will be.

Speed is also a factor that affects the price. The higher the speed, the more expensive the hole saw will be.

If you want a hole saw that’s durable and can handle tough jobs, you’ll have to pay more for it.

Brand

The longevity of your hole saw is contingent on the brand you choose.

Some of the most popular brands are Bosch, Milwaukee, and Dewalt.

There are a lot of other brands out there on the market, but these are more trusted and backed by strong warranties, offer hole saws that are made from high-quality materials, and

Bosch is a German company that’s been making tools for over 125 years. They’re known for their quality and durability.

Milwaukee is an American company that’s been making tools since 1924. They’re known for their innovation and they offer a wide range of products.

Dewalt is an American company that’s owned by Stanley Black & Decker. They’re known for their quality, durability, and performance.

Do your research and read reviews before making your final decision. And don’t forget to factor in the price.

Arbors and pilot drill bits

To use a hole saw, you’ll need an arbor. An arbor is a tool that holds the hole saw in place.

You can get an arbor that’s specifically made for the hole saw or you can get an adjustable one.

The advantage of an adjustable arbor is that you can use it with different size hole saws. But they’re not as durable as the ones that are made specifically for the hole saw.

You’ll also need a pilot drill bit. The pilot drill bit is what goes in the center of the hole saw and helps to guide it as it cuts through the material.

Pilot drill bits come in different sizes and they’re usually made from high-speed steel.

Benefits of using hole saws

Hole saws offer numerous benefits for anyone looking to do some drilling, especially when compared to other power tools.

They’re great for making clean holes and are far less likely to wander off course.

For starters, they’re much easier and faster to use than traditional drill bits. Simply put the hole saw on the metal surface and start cutting! There’s no need for a lot of setup or prep work.

Hole saws are also very versatile. They come in such a wide range of sizes that you can find one that’s perfect for any job, big or small.

Finally, hole saws are relatively inexpensive and easy to find. You can get good quality ones for under $100. [1] So if you’re looking for an affordable power tool that can tackle a variety of jobs, a hole saw is a great option.

Construction of a hole saw

There are three main parts to a metal hole saw: the body, the teeth, and the pilot drill bit.

It’s usually made out of steel or another strong metal.The teeth are an element that does the cutting. They’re usually made out of carbide, which is a very strong and durable material. The number of teeth on a hole saw will determine how fast it can cut through metal. More teeth mean a faster cut, but it will also create more friction and heat.

The pilot drill bit is the part of the hole saw that does the drilling. It’s usually made out of high-speed steel and is located in the center of the saw.

The pilot drill bit is what helps the hole saw stay on course while it’s cutting through metal.

Types of Hole Saws

Now that we’ve gone over some of the benefits of hole saws, let’s take a look at the different types available.

There are two main types of hole saws: bi-metal and carbon steel. Bi-metal hole saws are made with a combination of high-speed steel (HSS) and cobalt. This makes them very durable and able to withstand heavy use. They’re also less likely to overheat, so you can use them for longer periods without having to take a break.

Carbon steel hole saws, on the other hand, are made with a single piece of carbon steel.

For occasional use, you can make your life easier with a carbon steel model that is more affordable than other types of blades and has less risk of dulling from abuse due to its hard nature versus soft ones made out of aluminum which will bend when cutting through materials too tough for them so keep this in mind if you plan on using it often as well!

The next thing defining the type of a saw is the shape of the hole you need. For example, do you need a round one or an oval one?

There are three kinds of saws based on the shape of a hole they make: round, oblong, and irregular. Round hole saws are the most common type and can be used for a variety of tasks such as drilling into wood, metal, plastic, and drywall. Oblong hole saws are ideal for making elongated holes for things like pipes and conduits. Finally, irregular hole saws are perfect for making odd-shaped holes like those needed for recessed lighting.

FAQ

How do the hole saws work?

Hole saws consist of a metal ring that has sharp teeth on the inside circumference. They work by cutting through the material using a rotating blade. The blade is attached to a shaft, which is connected to a power source. The power source can be an electric drill or a power drill.

The hole saw cuts through the material by spinning the blade around at high speeds. The faster the blade spins, the easier it will be to cut through the material.

The type of material you’re cutting will also dictate how fast the blade needs to spin. In general, softer materials like wood can be cut at lower speeds than harder materials like metal.

So if you’re cutting through metal, you’ll need to use a higher speed setting on the hole saw. And if you’re cutting through wood, you can use a lower-speed setting.

How to adjust the cutting depth?

There are two main ways to adjust the cutting depth of a hole saw. The first way is to use the adjustable cutting depth stop. This is a small knob that is located on the side of the hole saw. The second way to adjust the cutting depth is to use a drill press.

If you are using a hole saw with an adjustable cutting depth stop, you will need to loosen the knob before you can adjust the depth. Once the knob is loosened, you can turn the hole saw to the desired depth. To ensure that the hole saw is level, you can use a spirit level. Once the hole saw is at the desired depth, you can tighten the knob to secure it in place.

If you’re using a hole saw with a drill press, you will need to adjust the height of the drill press so that the hole saw is at the desired depth. You can use a ruler or tape measure to make sure that the hole saw is level. Once the hole saw is in place, you can start cutting through the metal.

What kind of drill do I need for a hole saw?

In general, most hole saws require between two and four amps of power. But you can also find ones that require up to eight amps of power.

If you think you’ll be using a hole saw frequently, it’s probably worth it to buy your electric drill. Check it has enough amperage to handle the hole saw. Another option is to rent or borrow an electric drill from someone.

That way, you’ll always have it on hand and you won’t have to worry about renting or borrowing one every time you need it.

You can also use a hand drill if you don’t have access to an electric drill. But it will be more difficult and take longer to cut the hole.

But if you’re using a large or powerful hole saw, it’s best to use a power drill because it will have more torque and be able to handle the larger and more powerful hole saws.

You can also use a cordless drill, but it’s usually best to use a corded one. That way, you won’t have to worry about the battery running out of power in the middle of a project.

Finally, make sure that the drill has a chuck that can accommodate the size of the hole saw’s arbor. If not, you won’t be able to use the hole saw with that particular drill.

Most drills come with a keyless chuck, which makes it easy to change out the bits. But if yours doesn’t have one, you can usually buy one separately.

What is the best hole saw for cutting steel?

There are a few different types of hole saws that can be used to cut steel.

The most common type is the high-speed steel (HSS) hole saw. [8]

Another type of hole saw that can be used to cut steel is the tungsten carbide-tipped (TCT) hole saw [9]. These have tips that are made from tungsten carbide, which is one of the hardest materials on earth.

This makes them ideal for cutting through tough materials like stainless steel. But they’re also more expensive than HSS hole saws.

If you’re not sure which type of hole saw to get, it’s usually best to ask someone at the store where you’re buying it. They should be able to help you choose the right one for your needs.

Or, if you know what kind of metal you’ll be cutting, you can usually find that information on the package. That way, you can make sure you’re getting the right type of hole saw for the job.

What is a hole saw kit?

A hole saw kit is a set of hole saws that includes a variety of sizes.

They’re great for people who need to make a lot of different size holes, or for people who want to be prepared for any situation.

Hole saw kits usually come with an arbor, which is the part of the hole saw that attaches it to the drill, and a case or storage container to keep everything organized in one place.

A hole saw kit is a great option for people who need to make a variety of different size holes.

If you only need one or two specific sizes, though, you might be better off buying them individually, depending on your needs.

Whatever your needs, there’s sure to be a hole saw that’s perfect for the job.

How Much Should I Spend on a hole saw kit for metal?

There’s no one answer to this question because it depends on a few different factors.

First, consider what you’ll be using the hole saw kit for. If you only need it for occasional projects around the house, you might not need to spend as much as someone who needs it for their job.

Second, think about the types of materials you’ll be cutting. If you’re only going to be cutting soft metals like aluminum, you might not need a very expensive or powerful hole saw kit.

But if you’re planning on cutting through tougher materials like stainless steel, you’ll need a more durable and expensive hole saw kit.

Finally, consider how often you’ll be using the hole saw kit. If you only need it for a one-time project, you might be able to get away with renting or borrowing one instead of buying your own.

In general, though, most people should expect to spend at least $100 on a good quality hole saw kit.

Of course, you can always spend more if you want higher quality or more powerful hole saw kits. But for most people, that’s not necessary.

No matter how much you spend, though, make sure you’re getting a hole saw durable kit that will last for years. Otherwise, you’ll end up having to replace it sooner than you’d like.

Where can I buy a hole saw?

You can buy hole saws at most hardware stores and home improvement stores. You can also find them online, although it’s often easier and cheaper to buy them in person. When you’re shopping for a hole saw, keep in mind the size of the holes you need to make, the type of materials you’ll be cutting, and how much you’re willing to spend.

The best online shops for metal hole saws are:

- Amazon

- eBay

- Alibaba

- Grainger

- MSC Industrial Direct.

How do I know if a hole saw is of high quality?

One way to tell if a hole saw is high quality is to look at the warranty. Most high-quality hole saws will come with a strong warranty that covers defects and damage. Another way to tell if a hole saw is high quality is to look at the reviews. People who have bought and used high-quality hole saws will usually leave positive reviews. Finally, you can ask someone at the store where you’re buying the hole saw. They should be able to help you select a high-quality hole saw for your requirements.

How can I use a hole saw to enlarge an existing hole?

If you need to enlarge an existing hole, you can use a hole saw. First, make sure that the drill bit is the same size as the inside diameter of the saw. Next, attach the saw to the drill and set it to spin in a clockwise direction. Finally, slowly guide the drill into the existing hole until it reaches the desired depth. Be sure to go slowly and apply gentle pressure to avoid breaking the saw or damaging the workpiece.

Can you sharpen hole saw teeth?

Yes, you can sharpen hole saw teeth. First, use a file to remove any burrs from the teeth. Next, use a sharpening stone to sharpen the teeth. Be sure to go slowly and evenly over all of the teeth. Finally, use a wire brush to clean off any debris from the saw.

Once you’ve sharpened the hole saw, it should be able to cut through material more easily. However, keep in mind that it will likely not be as effective as a new one.

If you find that your hole saw is getting dull frequently, it might be time to replace it.

Useful Video: Best Hole Saw Brand? DeWalt vs Milwaukee vs Irwin, Bosch, Lenox, Diablo, Bosch, MK Morse

Summing up

So, there you have it! Metalworking is an essential part if you want to get into any type of design, and Metal hole saws can be a great addition to your tool collection, much helpful to make your projects come together faster with less difficulty! With so many options available, it can be overwhelming to try to figure out which one is right for you. You can simplify this procedure and obtain the finest tool for your application if you have all of the information.

We hope that this guide has given you a better understanding of what to look for when shopping for a hole saw kit and that you feel confident in your purchase.

If you keep these things in mind, you’ll be able to narrow down your choices. Remember to consider the size of the hole you need to cut, the type of metal, and the price when making your purchase.

Did this article teach you something new?

Let us know in the comments below!

Thanks for reading! Happy shopping!

References:

- https://toolsdoctor.com/best-hole-saw-for-stainless-steel/

- https://www.wonkeedonkeetools.co.uk/holesaws/what-hole-saw-sizes-are-available

- https://shopdivergent.com/hole-cutter-for-duct-and-sheet-metal-2-to-12-inch/

- https://www.amazon.com/Spyder-600833-Diameter-Cutting-Depth/dp/B06ZZG7GQ

- https://www.wonkeedonkeetools.co.uk/holesaws/a-guide-to-hole-saw-teeth-and-tpi

- https://www.petersenproducts.com/Hole-Saw-Cutter-Speed-s/2168.htm

- https://www.amazon.com/sk=hole+saw+for+metal+cutting&crid=28XPBMV40639Q&sprefix=hole+saw+for+metal%2Caps%2C563&ref=nb_sb_ss_ts-doa-p_2_18

- https://www.unika.co.jp/en/products/holesaw/holesaw6.html

- http://www.tolsentools.com/product/tct-hole-saw/