When it comes to durability, not all metals are the same. Each metal has a unique set of properties that make it more suitable for specific applications. For example, Stainless Steel is known for its corrosion resistance, making it an ideal material for kitchen appliances and medical equipment. Titanium, on the other hand, is extremely strong yet lightweight, making it a popular choice in the aerospace and automotive industries.

Whether you work in the construction industry, manufacturing, or are just a curious person who wants to dive deeper into the materials that shape our world, you’ve undoubtedly wondered: which metal is the strongest in terms of durability? In this comprehensive guide, we’ll dive into the fascinating realm of metals, exploring their characteristics, strengths, and weaknesses. Together, we’ll discover the true champions of durability and gain a deeper understanding of the incredible diversity of metals that surround us.

Types of Metal Strengths

When evaluating the strength of metals, we typically look at four main types of strength: tensile strength, which measures resistance to stretching; compressive strength, which measures resistance to crushing or squeezing; yield strength and impact strength, which measures the ability to withstand sudden jolts or shocks.

These different types of strength provide a complete picture of the overall mechanical properties of a metal and its suitability for various applications.[1]

Tile Strength

This important property measures a metal’s ability to resist being pulled apart or stretched under tension. It is quantified as the maximum amount of tensile stress that a material can withstand before failure. Metals with high tensile strength are particularly suitable for demanding applications such as cables, wires, and structural beams, where they need to withstand significant forces without breaking or deforming. This characteristic ensures the reliability and durability of these materials in various industries and engineering fields.

Compressive strength

Unlike tensile strength, compressive strength refers to a material’s ability to resist forces that attempt to squeeze or crush it. It is the maximum load per unit area that the metal can bear under crushing force, making it a crucial property in industries where metals are subjected to high compression, such as structural engineering. Understanding the compressive strength of a material helps engineers determine its suitability for various applications, ensuring the durability and safety of structures under heavy loads. By evaluating this characteristic, engineers can make informed decisions regarding material selection, design, and construction, ultimately contributing to the overall integrity and longevity of the built environment.

Yield strength

Yield strength is a crucial property to consider when evaluating metals. It quantifies the maximum amount of stress that a metal can withstand before it undergoes permanent deformation. This measurement is typically expressed in pounds per square inch (PSI). Metals with high yield strength are particularly well-suited for components that experience continuous loading, such as structural beams, as they can withstand significant forces without compromising their structural integrity. By selecting metals with optimal yield strength, engineers can ensure the durability and reliability of their designs, even under demanding conditions.

Impact strength

Also known as toughness, which is a fundamental property, it is a measure of a metal’s ability to absorb energy and undergo plastic deformation without breaking or tearing apart. It plays a crucial role in the characteristics of metals used in the production of various items that are subjected to severe impacts or loads, such as automotive components and protective equipment. The ability of the metal to withstand and tolerate such challenging conditions is critical to ensuring the durability and stability of these products, which ultimately increases their overall quality and reliability.

An in-depth understanding of these different types of strength can help in determining the most suitable and durable metal for a particular application. Each application, with its unique requirements, may require specific strength properties, making it crucial to consider various factors such as Tensile Strength, Compressive Strength, Yield Strength and Impact Strength. By carefully analyzing these properties, an informed decision can be made to ensure optimal performance and durability of the selected metal.

Alloys Vs. Natural Metals

Before we delve into this topic, it is important to distinguish between natural metals and alloys. Natural metals, as the name implies, are those elements that exist in nature in pure metallic form or can be easily extracted from ores. Examples of natural metals would be Gold, Silver, Copper, and Iron.

Each natural metal has unique properties that lead to its distinctive characteristics. For example, Gold is known for its ductility and corrosion resistance, while Copper is highly electrical conductive. These properties make natural metals suitable for a variety of applications.

Alloys, on the other hand, are a combination of two or more metals or a metal with another element. Alloys are created to improve the properties of the base metal, making it more suitable for specific applications. Let’s take Steel, for example, which combines an alloy of Iron and Carbon. Steel exhibits greater strength and durability than its base metal, Iron. Similarly, Titanium alloys are often mixed with Vanadium or Aluminum to increase their strength, making them well suited for high-stress applications.

When talking about the strongest metals, it is important to consider not only natural metals but also their alloy counterparts. The improved properties of alloys can often tip the scales in their favor, especially in terms of toughness and longevity. However, it is worth noting that the processing and combination of metals to produce alloys usually involves an additional level of complexity and cost.

By better understanding the differences between natural metals and alloys, we can appreciate the unique qualities and possible applications of each. This knowledge allows us to make informed decisions when selecting materials for different applications, taking into account factors such as strength, durability and cost-effectiveness.[2]

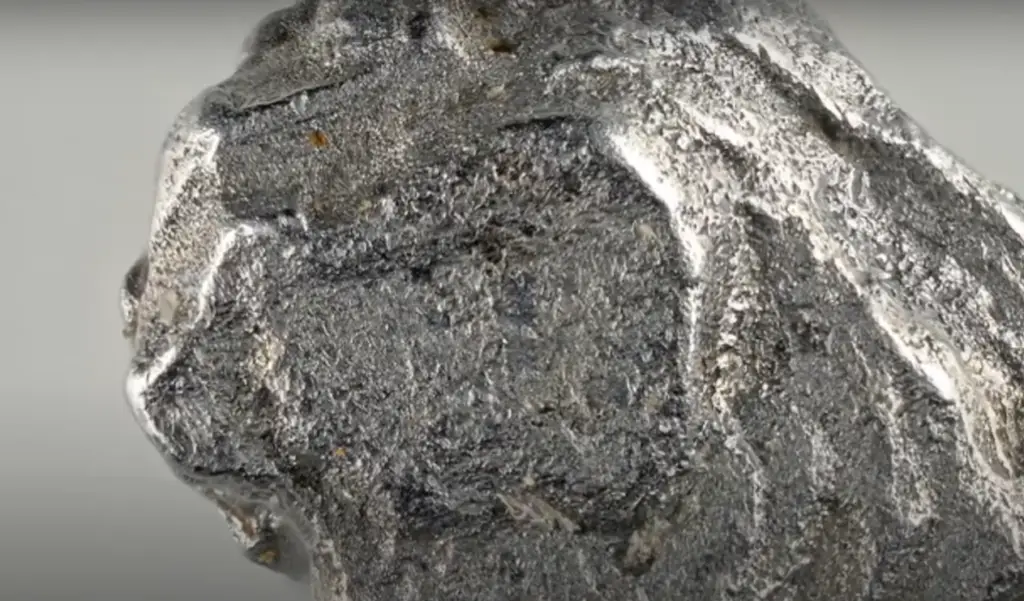

The Most Durable Metal: Titanium

When it comes to the most durable metal, Titanium takes the crown. Renowned for its remarkable strength-to-weight ratio,

From crucial aircraft components and life-saving surgical implants to reliable everyday tools and exquisite jewelry, Titanium’s versatility knows no bounds.However, durability is not solely determined by strength alone. While Titanium’s strength is undeniable, what truly sets it apart is its unparalleled resistance to corrosion. Its surface forms a passive and protective oxide layer that renders it virtually impervious to the harmful effects of water and air. This unique characteristic grants Titanium an extended service life, even in the harshest environmental conditions. With Titanium, you can trust that durability is not just a feature but a defining quality.

Despite its superb properties, it’s important to note that Titanium is not perfect for every application. While it offers exceptional durability, strength, and corrosion resistance, there are certain considerations to keep in mind. One of the main factors to consider is the cost. Titanium tends to be significantly more expensive than most other metals, which can make it an impractical choice for projects where budget is a key consideration.

However, for applications where durability, strength, and corrosion resistance are paramount, Titanium remains a top contender. Its exceptional properties make it ideal for industries such as aerospace, automotive, medical, and marine. The high strength-to-weight ratio of Titanium ensures that structures can be built with reduced weight, without compromising on strength.

When selecting a metal for a specific application, it’s essential to consider the specific demands of that application and balance these against factors like cost, availability, and workability. In some cases, an alloy may be a more practical and cost-effective choice. Alloying Titanium with other metals can enhance its properties and tailor it to meet the specific requirements of a project.

But when it comes to sheer durability, Titanium is hard to beat. Its outstanding resistance to corrosion and extreme temperatures makes it suitable for challenging environments where other metals may deteriorate. Whether it’s for critical components in aircraft engines, medical implants, or offshore structures, Titanium proves its worth time and again.

To ensure you’re getting the most durable metal for your project, it is highly recommended to consult a professional metals expert. They can provide valuable guidance on the best solution for your specific needs. A metals expert can help you identify and source the right material for your application and provide insights on processing, installation, and maintenance. With their expertise, you can be confident that your project will benefit from the highest quality metal, tailored precisely to your requirements.[3]

A List of the Strongest Metals

Known for its exceptional durability, Titanium is indeed a superior metal. However, when considering alternatives for your project, it is worth exploring other metals that offer superior strength and corrosion resistance. Whether due to financial constraints or limited availability, Titanium may not always be the ideal choice. With that in mind, here are some additional metals worth considering, each with their own unique set of properties and benefits: Stainless Steel, Aluminum Alloys, Nickel Alloys, and High Strength Steels. By considering these alternatives, you will be able to make an informed decision that meets the requirements of your project.

Stainless Steel

Stainless steel, an alloy composed of Iron, Chromium, and other elements, possesses exceptional corrosion resistance and strength, making it an ideal choice for various applications. This versatile material is widely employed in construction projects, thanks to its remarkable durability and relatively affordable price point. Its resistance to rust and ability to withstand harsh environments contribute to its long-lasting performance, making it a popular choice among architects, engineers, and manufacturers alike.

Nickel Alloys

Nickel alloys, such as Inconel and Hastelloy, are renowned for their exceptional resistance to corrosion and wear. These remarkable alloys are specifically engineered to withstand the harshest conditions, making them ideal for use in extreme environments like highly corrosive chemical processing plants and demanding marine applications where durability and reliability are paramount. With their superior properties, these Nickel alloys offer unparalleled protection and longevity, ensuring optimal performance and safety in the most challenging operational settings.

Aluminum Alloys

Aluminum alloys like 7075 are renowned for their exceptional strength and remarkable strength-to-weight ratios, surpassing the capabilities of pure Aluminum. This makes them an excellent choice for a wide range of applications, including critical aircraft components that require both durability and lightness, automotive parts that demand optimal performance, and military equipment that necessitates robustness in the face of challenging conditions. The utilization of these high-performance alloys in such industries highlights their invaluable contribution to advancing technology and enhancing overall performance.

When selecting the right metal for your application, it is very important to carefully consider various factors. First of all, evaluate the strength requirements of your project and make sure that the selected metal can withstand the anticipated loads and stresses. In addition, take into account the Environmental requirements to which the material will be exposed, such as temperature, humidity, corrosion, and chemical attack.

Cost and availability are also important factors. Evaluate the budgetary constraints and availability of different metal options to find the most suitable one for your project. In addition, take into account any unique needs or specifications your project may have, such as weight, conductivity, or compatibility with other materials.

Once you’ve selected the right metal, it’s critical to implement a comprehensive maintenance plan to ensure its long-term durability and reliable performance.

Regular inspections should be carried out to detect any signs of wear, corrosion, or damage at an early stage. This will allow for timely repair or replacement to prevent further deterioration.Proper storage of the metal when not in use is also vital. Keep it in a dry and clean environment, away from moisture, chemicals, and other potentially harmful substances. This helps to prevent corrosion and maintains the metal’s integrity over time.

By implementing these measures and following a proactive maintenance approach, you can ensure that your metal components remain durable and perform reliably throughout their lifespan. With proper care, your project will continue to operate smoothly and efficiently for years to come.

FAQ

What is the most durable metal in the world?

When it comes to the absolute toughest and most durable metal in the world, the title goes to Tungsten. This extraordinary metal has the highest tensile strength and melting point of all metals, and it maintains its strength at high temperatures better than any other known element. It’s significantly denser and harder than steel and titanium, making it extremely wear-resistant. Like Titanium, it also exhibits a high level of corrosion resistance. However, its extreme hardness and high melting point also make it notoriously difficult to work with, and it’s often used in small amounts to harden steel and other alloys. Despite these challenges, when maximum durability is needed in high-temperature applications, Tungsten is often the metal of choice.

Which metal is stronger than Steel?

When it comes to a metal that is stronger than Steel, one standout contender is Chromium. Chromium is an extremely hard metal with a high tensile strength, surpassing that of steel. It is often used in small amounts to harden and strengthen other metals, including steel, forming what is known as high-strength, low-alloy steel. Chromium also provides impressive resistance to tarnish and corrosion, and is used in applications that require superior durability and resistance to wear. However, it’s important to note that Chromium is typically more expensive and less readily available than steel, which may limit its practicality in certain applications. So while Chromium does display superior strength characteristics compared to steel, these benefits must be balanced against its cost and availability.

What metal is unbreakable?

No metal is truly “unbreakable”, as every material has its limits under certain conditions. However, one of the toughest and most resilient metals known to man is Tungsten. As mentioned earlier, Tungsten has the highest tensile strength of all metals and can withstand incredibly high temperatures, which contributes to its reputation as an exceptionally strong and durable material. Even so, under extreme conditions or forces, it can still be damaged or broken. Therefore, while Tungsten comes close to being “unbreakable”, it’s important to understand that no material is completely indestructible.

What is stronger than Titanium?

While Titanium is renowned for its superior strength-to-weight ratio and corrosion resistance, there is a metal that surpasses its strength: Tungsten. As previously mentioned, Tungsten possesses the highest tensile strength of all metals. Its extraordinary durability and ability to withstand high temperatures make it more robust than Titanium.

However, its hardness also makes it challenging to work with, and it is typically used in smaller quantities to fortify other metals. Despite these factors, when exceptional strength is required, Tungsten often outshines Titanium. It’s important to note, however, that Tungsten’s exceptional strength comes with a higher price tag and it’s not as readily available as Titanium.

Is Vibranium real?

Vibranium, a metal known to many through the Marvel comic universe, particularly the “Black Panther” and “Avengers” series, is unfortunately not real. It is a fictional metal with amazing abilities such as absorbing, storing, and releasing large amounts of kinetic energy. While it would certainly be exciting if such a metal existed, no known metal in our world possesses these properties. This doesn’t diminish the fact that we have many incredible metals with their own unique characteristics and strengths, as we’ve discussed throughout this piece. From Tungsten to Chromium to Steel, there are plenty of real-world examples.

What’s the weakest metal?

In terms of pure metals, Lithium is considered the weakest. It’s extremely soft and can be cut with a standard kitchen knife. Lithium is the least dense metal and has the lowest melting point of all the pure metals. This light, soft metal is used in many industries, from the manufacture of batteries to pharmaceuticals, despite its relative weakness. It’s important to note, however, that the term “weakest” can be subjective depending on the specific metric being considered – for example, tensile strength, hardness, or resistance to heat or corrosion.

What is the 2nd strongest metal?

After Tungsten, the second strongest metal in terms of tensile strength is Chromium. Known for its high hardness, Chromium exhibits excellent resistance to corrosion and wear, hence it’s often used to harden other metals like steel. This results in high-strength, low-alloy steel that is both robust and durable.

However, similar to Tungsten, Chromium’s superior strength is accompanied by higher costs and limited availability. Thus, while it stands second in rank, its practical use for everyday applications may be restricted due to these factors.

What is the lightest metal but strongest?

Despite its low density, Titanium is an extraordinarily strong and lightweight metal. It has the highest strength-to-weight ratio of any metal, making it both incredibly durable and remarkably light.

However, like many high-performance materials, it is more expensive than common metals like steel. Yet, for applications where strength, weight, and corrosion resistance are critical, Titanium often stands as the superior choice.Useful Video:Top 10 Strongest Metals On Earth || Top 10 Eveything

Conclusion

In conclusion, the choice of metal for any given application is a careful balancing act that considers strength, durability, weight, corrosion resistance, cost, and availability. While Tungsten and Chromium are recognized for their superior strength, they are often more costly and less readily available than other metals like Steel and Titanium. On the other hand, Titanium, famous for its strength-to-weight ratio and corrosion resistance, is a go-to choice for industries where these properties are paramount, despite its higher cost. Even the softest metal, Lithium, despite its relative weakness, finds its niche in numerous applications due to its low density and unique characteristics. Therefore, it is essential to understand the specific needs of your project and select a metal that provides the best balance of the properties required. From the marvels of real-world metals to the fantasies of Vibranium, the world of metals is truly a testament to the diverse materials nature has to offer.

References:

- https://www.wasatchsteel.com/metal-strength-types-and-strongest-metals/

- https://gemsbylyc.com/blogs/metals-are-crystals-too/metals-vs-alloys

- https://tampasteel.com/what-are-the-strongest-metals/