Metal extrusion is a versatile and widely adopted manufacturing process used to shape metal materials with precision. By exerting pressure and forcing metal through a specifically designed die, objects with a defined, cross-sectional profile are created. This process, applicable to various metals such as Aluminium, Copper, Steel, and Titanium, plays a pivotal role in the production of an extensive range of items. From basic pipes and tubes to intricate automotive and aerospace components, metal extrusion empowers industries to craft complex and finely engineered products that meet the demands of modern technology.

Characteristics of metal extrusion

The metal extrusion process possesses several distinct characteristics that set it apart from other manufacturing methods. First and foremost, it enables the creation of intricate and elaborate shapes with an exceptional surface finish, contributing to the final product’s aesthetic appeal and functional qualities. This meticulous attention to detail ensures that the end result not only meets but exceeds expectations.

Moreover, extrusion proves to be highly efficient and economical for mass production due to its continuous nature. By minimizing the need for excessive labor and reducing production time, extrusion offers a cost-effective solution without compromising on quality. This efficiency translates into significant savings for manufacturers and enables them to meet increasing market demands promptly.

Furthermore, the extrusion process imparts exceptional strength to the resulting products. By aligning the grain structure of the metal along the extrusion direction, it enhances the overall structural integrity. This structural superiority ensures that the manufactured products can withstand rigorous use and adverse conditions, providing long-lasting durability and reliability.

Lastly, the versatility of extrusion is another notable advantage. With the ability to handle different alloys and metals, it caters to diverse industry needs. Whether it’s Aluminum, Steel, or other materials, extrusion adapts seamlessly, offering a wide range of options for manufacturers to choose from. This flexibility enables them to create products tailored to specific requirements, ensuring optimal performance and customer satisfaction.

In summary, the metal extrusion process combines intricate shaping capabilities, cost-effectiveness, exceptional strength, and versatility to provide a comprehensive solution for various manufacturing needs. Its ability to create complex shapes with superior surface finish, coupled with its efficiency and adaptability, makes extrusion a preferred choice in numerous industries.[1]

Types of the metal extrusion process

Direct Extrusion

Directusion, also known as forward extrusion, is widely recognized as the most extensively utilized method in the metal extrusion process. This technique commences with the placement of a solid block of metal, called a billet, into a robust container. The billet is then subjected to high pressure exerted by a ram or screw, which effectively propels the material through the opening of a die. As a result of this applied force, the billet undergoes deformation and flows to conform to the cross-sectional profile of the die. Consequently, a lengthy piece of metal, mirroring the shape of the die, is formed and can subsequently be cut into desired lengths. It is worth noting that direct extrusion involves substantial friction between the billet and the container’s walls, which may lead to increased wear on the equipment. Nevertheless, this method remains a popular choice due to its inherent simplicity, cost-effectiveness, and remarkable capability to produce intricate shapes with utmost precision.

Indirect Extrusion

Indirect extrusion, also known as backward extrusion, is an alternative method employed in the metal extrusion process. In this technique, the die is positioned at the end of the ram instead of the container. This unique configuration allows the billet to remain stationary while the ram, equipped with the die, pushes into it. As a result, the metal flows in a backward direction and forms through the fixed die, ultimately creating the desired profile.

One of the primary advantages of indirect extrusion is the reduction in friction between the billet and the container. By minimizing friction, the force required for extrusion is significantly reduced. This reduction not only increases the lifespan of the equipment but also enables the processing of more complex or delicate shapes. Moreover, the reduced friction allows for better control over the extrusion process, ensuring higher precision and quality in the final product.

However, it is important to note that the setup for indirect extrusion can be more intricate compared to direct extrusion. It may require additional resources and careful calibration to achieve optimal results. Despite the considerations of complexity and resource usage, indirect extrusion is often chosen when the benefits of reduced friction and force outweigh the potential challenges. Its ability to enhance the extrusion process and produce superior profiles makes it a compelling choice for various applications in the metalworking industry.

Hydrostatic Extrusion

Hydrostatic extrusion is a highly effective variant of the metal extrusion process that involves the ingenious use of fluid pressure to facilitate the extrusion. In this remarkable process, the billet, which is the material to be extruded, is completely enveloped and immersed in a pressurized liquid medium, typically oil, carefully enclosed within a sturdy container. The magic happens when a ram, operating with precision, applies pressure to the fluid, which in turn evenly transfers the force onto the billet, causing it to gracefully flow through the meticulously designed die.

One of the primary advantages of hydrostatic extrusion lies in its ability to place the metal under hydrostatic pressure, resulting in a substantial reduction in the material’s inherent strength while significantly enhancing its desirable ductility. This remarkable characteristic enables the extrusion of harder and more challenging materials, as well as the creation of intricate and complex shapes that were once considered unattainable. Moreover, the presence of the fluid medium in this unique process plays a crucial role in mitigating friction between the billet and the container, thereby minimizing wear and tear on the equipment and ensuring a smoother extrusion experience.

Despite its undeniable advantages, it is important to note that hydrostatic extrusion demands specialized equipment and incurs higher operational costs compared to conventional direct and indirect extrusion methods. Consequently, it is less commonly utilized in industrial applications. Nonetheless, when it comes to the extrusion of difficult-to-work materials or the achievement of superior surface finishes, hydrostatic extrusion shines as an irreplaceable tool in the vast realm of the manufacturing industry, making it an indispensable technique for manufacturers seeking unparalleled precision and versatility.

Lateral or Vertical Extrusion

Lateral or vertical extrusion, as the name suggests, deviates from the conventional horizontal extrusion methods by employing a vertical direction for the extrusion process. This type of extrusion is typically used for producing long, narrow profiles such as rods or tubes. In the lateral extrusion process, the die is placed laterally relative to the billet. The billet is then forced through the die in a sideways motion, resulting in a product that extends perpendicularly from the original billet.

Vertical extrusion, on the other hand, involves the upward or downward movement of the die or billet. The choice between upward and downward extrusion depends on factors such as the specific characteristics of the metal, the desired product, and the manufacturing setup.

Downward extrusion, on the other hand, is advantageous for materials that are more ductile, allowing for better control over the extrusion process.

Both lateral and vertical extrusion processes offer unique advantages, including reduced footprint, improved straightness of the extruded profiles, and enhanced grain structure due to the vertical flow of the material. These processes are commonly used in industries such as aerospace and construction, where the production of long, straight, and narrow profiles is often required. The ability to precisely control the extrusion direction and the resulting grain structure allows for the creation of high-quality components that meet the stringent requirements of these industries.

Hot extrusion

Hot extrusion is a highly precise metal extrusion process where the billet is heated to a temperature above its recrystallization point.

By carefully heating the billet, it becomes easier to force it through the die, enabling the creation of intricate and complex shapes.The hot extrusion process begins with the preheating of the billet, ensuring it reaches the optimal temperature for extrusion. Once heated, the billet is loaded into the container and carefully positioned. With a combination of force and precision, the heated billet is pressed through the die using a ram or a hydraulic press. The force exerted causes the heated metal to flow and take on the desired cross-sectional profile, resulting in a precisely shaped product.

One of the significant advantages of hot extrusion is its ability to form complex shapes with high precision. The deformation of the material during the extrusion process leads to improved mechanical properties, making it an ideal choice for manufacturing components with enhanced strength and durability. Furthermore, the absence of residual stresses in the final product ensures a more stable and reliable end result.

However, it is crucial to manage the hot extrusion process carefully due to the high temperatures involved. The elevated temperatures can lead to rapid oxidation of the metal surface, potentially causing surface degradation. To overcome this challenge, protective atmospheres or special coatings may be utilized to prevent oxidation and maintain the integrity of the final product.

Despite these considerations, hot extrusion remains an integral part of various manufacturing industries, including automotive, aerospace, and construction. Its versatility and capacity to produce high-quality products make it a preferred choice for creating components and parts with intricate designs and superior mechanical properties.

Cold Extrusion

Cold extrusion is an extrusion process that offers numerous advantages in various industries. This process involves deforming a metal billet at or around room temperature, eliminating the need for preheating and thereby reducing energy consumption. Unlike hot extrusion, cold extrusion preserves the original mechanical and physical properties of the metal, ensuring it retains its strength and hardness.

The process itself begins by placing the metal billet in a container, followed by using a ram or hydraulic press to force the metal through a die, shaping it into the desired profile. Cold extrusion results in higher strength and hardness due to strain hardening, along with improved surface finish and tighter tolerances. It also minimizes oxidation, eliminating the need for protective atmospheres or coatings.

However, it is important to note that cold extrusion does require more force to deform the metal, making it less suitable for metals with low ductility or for creating complex shapes. Despite these limitations, cold extrusion has found extensive use in industries such as automotive and consumer goods, where strength, precision, and cost-effectiveness are of utmost importance.

By leveraging the advantages of cold extrusion, manufacturers can achieve enhanced product quality, reduce energy consumption, and optimize production processes for greater efficiency and cost-effectiveness.

Impact Extrusion

Impact extrusion is a specialized form of metal extrusion that employs a high-speed, high-pressure process to shape metal with precision. In this fascinating technique, a metal slug, typically heated just below its recrystallization temperature, is carefully positioned within a die. A punch then swiftly strikes the slug, compelling it to flow and conform effortlessly to the contours of the die. As a result, the slug material elegantly flows upward and gracefully envelopes the punch, forming a seamless and symmetrical part.

This remarkable method is particularly well-suited for the production of hollow components that exhibit remarkable symmetry around the axis of revolution. Notably, impact extrusion boasts a multitude of advantages, including exceptional production speed, flawless surface finish, and judicious material usage with minimal to no wastage. Nonetheless, it is worth mentioning that the process necessitates a considerable amount of force and is generally limited to the malleability of softer metals such as Aluminum, Tin, or Lead.

Given its impressive capabilities, impact extrusion finds wide-ranging applications in the manufacturing of diverse components, including containers, cylinders, tubes, and other similar parts. Its ability to create intricate and precisely shaped hollow components sets it apart as a highly valued technique in the metalworking industry.[2]

Extrusion Defects

Despite the efficiency and effectiveness of the various extrusion processes, they are not without their potential pitfalls. Certain common defects may occur during the extrusion process, affecting the quality of the final product. These defects include:

- Surface Cracking: High temperatures and excessive friction can cause cracks on the surface of the extruded product. This is a common issue in hot extrusion and can be mitigated by proper lubrication and careful control of the extrusion speed.

- Internal Cracking: Also known as center burst, it occurs when the center of the product develops cracks due to uneven flow of material. Adjusting the die design and ensuring uniform heating of the billet can help prevent this defect.

- Piping: This defect involves the formation of a hollow section at the back end of the extruded product. Piping can be reduced by using a suitable backing plate or dummy block.

- Inclusions: These are impurities in the metal that cause inconsistencies in the finished product. Using high-quality billets and maintaining a clean extrusion environment can help avoid inclusions.

- Seam Defects: These occur when the material folds over itself during extrusion, forming a line or seam. They can be prevented by proper design of the container and die, and by controlling the bullet’s temperature and the extrusion speed.

Understanding these potential defects and their causes is crucial in maintaining the quality of extruded products and ensuring the effectiveness of the extrusion process.[4]

Metal Extrusion Process

Preparation of feed metal

The preparation of the feed metal, or billet, is a critical initial step in the metal extrusion process. This stage involves carefully heating the billet for hot or impact extrusion, or leaving it at room temperature for cold extrusion, to ensure optimal working conditions. The billet, typically cylindrical in shape, is meticulously selected to match the extrusion press and the desired final product. Prior to extrusion, the billet undergoes a thorough cleaning process, removing any surface impurities that could potentially compromise the quality of the final extruded product. This meticulous cleaning can be accomplished through a combination of mechanical and chemical processes, ensuring a pristine surface finish.

If the billet requires heating, it is carefully placed in a precisely controlled furnace, ensuring a uniform temperature distribution throughout its entire volume. This uniform heating facilitates consistent deformation and allows for precise shaping of the metal. The temperature at which the billet is heated depends on the specific metal being used and the type of extrusion process to be employed, ensuring optimal conditions for successful extrusion. The meticulous preparation of the billet is of utmost importance, as it directly influences the overall success of the extrusion process, the quality of the final product, and the efficiency of the entire operation.

Preparation for extrusion

The preparation for extrusion involves critical steps to ensure the success of the entire operation. The die, a tool with a specifically designed hole profile, needs to be carefully chosen or designed based on the desired final product. The properly prepared billet is then placed into the extrusion press, with the die at one end. The alignment of the billet and die must be precise to prevent any defects during the extrusion process. Lubrication is typically applied to the billet to reduce friction and facilitate its flow through the die. The hydraulic press or ram is then prepared to apply the necessary force to deform the billet and push it through the die. The preparation process also involves setting up the appropriate cooling or heat treatment processes for the extruded product as it emerges from the die. This pre-extrusion preparation, encompassing both the billet and the extrusion machinery, is a significant determinant of the quality and efficiency of the overall metal extrusion process.

Metal extrusion

Metal extrusion, a well-established manufacturing process, involves shaping materials by directing them through a specially designed opening in a die. As the material passes through, it emerges on the other side as an elongated piece with precisely the desired cross-sectional profile. This versatile technique can be employed with different metals, including Aluminum, Copper, Steel, and Titanium, among others.

There are three primary forms of metal extrusion: hot extrusion, cold extrusion, and warm extrusion. Each form operates at different temperatures and is suitable for specific types of metals. The choice depends on factors such as the metal’s properties, desired characteristics of the final product, cost considerations, and efficiency parameters.

The applications of metal extrusion are vast and varied. This invaluable method finds application in the manufacturing of a wide range of products, ranging from simple bars and tubes to highly intricate profiles used in architectural, automotive, and electrical industries.

Metal extrusion offers remarkable versatility and efficiency, enabling the production of intricate and complex shapes with precision. With its ability to transform raw materials into high-quality finished products, metal extrusion continues to play a pivotal role in modern manufacturing processes.

Heat treatment and post-processing

Following the extrusion process, the extruded product often undergoes a series of post-processing steps to enhance its properties and achieve the desired final characteristics. One critical post-extrusion operation is heat treatment. This process involves heating the extruded metal part to a specific temperature and then cooling it at a controlled rate. Heat treatment can be used to alter the part’s hardness, strength, ductility, toughness, and stress resistance. The specific heat treatment process will vary depending on the type of metal used and the desired mechanical properties of the final product.

Post-processing operations may also include surface finishing techniques to improve the appearance, surface quality, and corrosion resistance of the extruded part. These techniques can involve mechanical processes like grinding, polishing, and sanding or chemical processes like acid cleaning, anodizing, or coating. The choice of surface finishing technique will depend on the extruded part’s intended use, the desired aesthetic, and specific industry standards or requirements. Other post-processing steps could include cutting the extruded part to the desired length, bending or forming it into a specific shape, or assembling it with other components to create a finished product. These post-extrusion processes play a vital role in ensuring the extruded parts meet the exacting standards of modern manufacturing applications.[3]

Extrusion Equipment

Direct extrusion

The equipment required for direct extrusion is integral to the success of the process. Central to this setup is the hydraulic press, responsible for the application of the necessary force that propels the billet towards the die. This force causes the billet to deform and take the shape of the die opening, resulting in the extruded product.

The container in direct extrusion serves a significant role, holding the billet as it is pushed by the hydraulic press towards the die. This container must be constructed from materials that can comfortably endure the extreme pressures and high temperatures involved in the extrusion process.

Supporting equipment, such as heating furnaces, cooling tables, and various post-processing machinery, also play key roles in ensuring the successful execution of direct extrusion. Regular inspection and maintenance of all equipment are vital for maintaining the efficiency, quality, and safety of the direct extrusion process.

Indirect extrusion

The equipment used in indirect extrusion is essential to ensuring the process runs smoothly and efficiently. The most important pieces of this equipment include the hydraulic, the container, and the die. Much like in direct extrusion, the hydraulic press is responsible for applying the necessary force to initiate the deformation of the billet. Yet, unlike direct extrusion, the direction of the force is reversed, pushing the die towards the billet instead of vice versa.

The container in indirect extrusion plays a crucial role as it holds the billet stationary as the die moves. This piece of equipment must be constructed from robust materials capable of withstanding the high pressures and temperatures associated with the process.

Additional auxiliary equipment may include heating furnaces, cooling tables, and post-processing machinery. As with all extrusion processes, regular inspection and maintenance of the equipment are essential to ensuring the efficiency, quality, and safety of the indirect extrusion process.

Hydrostatic extrusion

Hydrostatic extrusion is a distinct type of metal extrusion where the billet is completely surrounded by a pressurized liquid, typically oil, enclosed within the container. This setup requires specialized equipment to create and maintain this pressurized environment.

Supporting equipment such as pressure generators, heating elements for maintaining the liquid in a suitable state, cooling tables for solidifying the extruded product, and various post-processing machinery, also play pivotal roles in the hydrostatic extrusion process. As always, regular inspection and maintenance of all equipment are crucial for upholding the efficiency, quality, and safety of the hydrostatic extrusion process.

Impact extrusion

Impact extrusion, also known as cold extrusion, is a unique form of metal extrusion where the billet is placed in a die and struck with a swift, forceful blow, causing the metal to flow in the direction opposite the impact.

At the heart of impact extrusion is the punch or ram, which delivers the quick, high-force impact necessary to reshape the billet. This component is typically made from high-strength materials like tool steel or carbide, which can withstand the significant forces without deforming.

Supporting equipment in impact extrusion includes precise loading mechanisms that accurately position the billet, ensuring optimal extrusion. Additionally, ejecting systems are employed to efficiently remove the extruded part from the die. Just like in any extrusion process, consistent inspection and maintenance of all equipment are crucial to uphold the efficiency, quality, and safety of the impact extrusion process. By prioritizing these measures, manufacturers can achieve exceptional results and maximize the benefits of impact extrusion.

Lateral extrusion

Lateral extrusion is a unique form of metal extrusion where the billet is forced sideways, out through openings in the die wall, forming complex cross-sectional profiles. This process requires specialized equipment designed to exert lateral forces on the billet.

The primary piece of equipment in lateral extrusion is the hydraulic press. This press must be capable of applying force in a lateral direction, in contrast to the traditional forward or rearward forces seen in most extrusion processes. The press is typically constructed from high-durability materials like tool steel or carbide that can withstand the significant pressures and temperatures encountered during extrusion.

The die in lateral extrusion must be intricately designed with openings along its sides to allow the billet to be extruded laterally. This die must be fabricated from materials able to endure the high pressures associated with the extrusion process.

Supporting equipment in lateral extrusion may include heating furnaces, cooling tables, and post-processing machinery, all critical to the successful execution of lateral extrusion. As with all extrusion processes, regular inspection and maintenance of all equipment are essential to maintain the efficiency, quality, and safety of the lateral extrusion process.

Common Defects

Despite the precision and robustness of metal extrusion processes, defects can still occur. These defects can be attributed to various factors ranging from material quality to equipment malfunctions.

One of the most common defects in extrusion is surface cracking, which can be caused by excessive friction between the billet and the container or from a too-rapid cooling process after extrusion. This type of defect is often observed when the extrusion speed is high or the billet temperature is not properly controlled. By carefully monitoring the extrusion parameters and ensuring optimal lubrication and cooling, the occurrence of surface cracking can be minimized.

Internal cracking is another typical defect, occurring when the billet’s centerline experiences intense stress during extrusion. This defect is often associated with direct and hydrostatic extrusion processes, where the pressure exerted on the billet is particularly high. To mitigate internal cracking, it is important to carefully control the extrusion speed and temperature, as well as the billet’s microstructure and mechanical properties.

Distortion of the extruded profile is a defect often seen in lateral extrusion or when complex cross-sectional profiles are involved. This can be caused by uneven flow of the metal during the extrusion process, leading to variations in the dimensions and shape of the extruded product. To minimize distortion, optimizing the die design, ensuring uniform material flow, and maintaining proper die temperature are crucial.

Inclusions, or foreign particles within the billet, can also lead to defects. These inclusions can disrupt the smooth flow of the metal, leading to surface defects or internal inconsistencies in the extruded product. It is essential to implement effective quality control measures, including thorough inspection and cleaning of the billet, to prevent the presence of inclusions and ensure the production of high-quality extruded products.

In all cases, it is crucial to identify and correct the underlying causes of these defects to ensure the production of high-quality, reliable extruded products. Regular inspection, maintenance, and quality control measures are essential in preventing and mitigating these defects in metal extrusion processes. By continuously improving process parameters and implementing best practices, manufacturers can achieve consistent quality and optimize the performance of extruded products.[4],[5]

Surface cracking

Surface cracking is a common defect encountered in metal extrusion processes, often resulting from excessive friction between the billet and the container or from rapid cooling post-extrusion. These cracks appear on the exterior of the extruded product, compromising its aesthetic appeal and structural integrity. To prevent surface cracking and ensure high-quality extruded products, it’s crucial to optimize various extrusion process parameters, including the temperature, speed, and pressure.

One aspect to consider is the temperature.

Maintaining an optimal temperature range specific to the type of material being extruded plays a crucial role in minimizing thermal stresses and preventing cracks from forming on the surface.In addition to temperature control, the speed at which the extrusion process is carried out also affects the occurrence of surface cracks. Adjusting the extrusion speed to a level that allows sufficient time for the material to flow smoothly through the die can help prevent excessive stress build-up and minimize the likelihood of cracks forming on the surface.

Furthermore, the use of lubricants can greatly reduce friction between the billet and the container, thereby reducing the chances of surface cracking. Proper lubrication not only improves the flow of the material but also acts as a protective barrier, ensuring a smoother extrusion process and minimizing the formation of cracks.

Another important consideration is the cooling phase after extrusion. Rapid cooling can lead to thermal shock and uneven temperature gradients, which can contribute to surface cracking. Implementing controlled cooling methods, such as controlled air or water cooling, can help maintain an even temperature gradient throughout the extruded product, reducing the likelihood of cracks forming on the surface.

Regular inspection of both the extruded products and the machinery involved is also crucial in early detection and resolution of surface cracking defects. By closely monitoring the quality of the extruded products and identifying any signs of cracking at an early stage, appropriate corrective measures can be taken to address the issue promptly.

In conclusion, preventing surface cracking in metal extrusion processes requires a comprehensive approach. Optimizing process parameters, including temperature, speed, and pressure, along with the use of lubricants and controlled cooling methods, can significantly minimize the occurrence of surface cracks. Regular inspection and early detection of defects are also vital for maintaining high-quality extruded products.

Internal cracking

Internal cracking is a common defect that frequently occurs in metal extrusion processes. It arises when the billet’s center undergoes excessive stress during the extrusion operation. This particular type of defect is characterized by the presence of cracks within the body of the extruded product, which can pose significant risks to its mechanical properties and overall performance.

To prevent internal cracking, it is crucial to implement careful monitoring and adjustment of various extrusion parameters, such as temperature and pressure. Additionally, ensuring that the billet is uniformly heated before the extrusion process promotes a more even flow of the metal, thereby reducing internal stresses. Regular inspection of both the extruded products and the extrusion equipment is highly recommended as it aids in the early detection of potential issues, allowing for timely corrective actions to be taken. By paying attention to these details, manufacturers can effectively mitigate the occurrence of internal cracking and enhance the quality of their extruded products.

Piping

Piping is a specific defect that can occur in metal extrusion processes, usually towards the end of the billet. It is characterized by the formation of a cavity or pipe-like structure at the center of the extruded product, which significantly impacts its structural integrity and mechanical properties. This defect arises due to frictional forces that arise during extrusion, where the outer region of the billet moves forward while the center remains relatively stationary, creating a hollow region.

To prevent piping, several measures can be taken. One approach is to optimize the extrusion speed and pressure, ensuring that the material flows uniformly throughout the process. Additionally, using suitable lubricants can help reduce friction and minimize the chances of pipe formation. Another critical factor is ensuring uniform heating of the billet, as any temperature variations can contribute to the development of piping defects.

Maintaining a consistent inspection and quality control process is vital for early detection and prevention of piping defects in metal extrusion processes. By identifying any signs of piping at an early stage, corrective actions can be implemented promptly, reducing the potential impact on the final product’s quality and performance.

FAQ

What is metallic extrusion?

Metallic extrusion is a high-pressure manufacturing process used to create objects of a fixed, cross-sectional profile. A metal billet is heated to a specific temperature, making it pliable, and then forced through a die, which is a tool with the shape of the desired profile. The extrusion process can produce a variety of items, including rods, wires, pipes, and beams. It works with a wide array of metals, such as aluminum, copper, steel, and precious metals. The extrusion process is highly efficient, versatile, and capable of producing complex cross-sectional profiles with excellent precision and consistency.

Why is metal extrusion used?

Metal extrusion is a highly versatile and widely utilized manufacturing process that offers a multitude of advantages. It stands out as an efficient and cost-effective method for mass-producing uniform cross-sectional profiles, making it an ideal choice across various industries such as construction, automotive, and aerospace.

One of the key strengths of metal extrusion lies in its remarkable flexibility, enabling the creation of intricate and complex shapes and profiles that may otherwise be challenging or prohibitively expensive to achieve with alternative manufacturing techniques. This exceptional adaptability opens up endless possibilities for designers and engineers to bring their innovative ideas to life.

Moreover, metal extrusion boasts superior surface quality, often yielding smoother finishes compared to other manufacturing processes. This inherent feature significantly reduces the need for additional finishing operations, saving time and resources while ensuring a high standard of aesthetic appeal.

In addition to its technical advantages, metal extrusion aligns with the principles of sustainability and resource conservation. The process facilitates the reuse and recycling of any excess metal, minimizing waste and contributing to both cost efficiency and environmental responsibility.

What is metal extrusion manufacturing?

Metal extrusion manufacturing is an intricate method that falls under the broader domain of materials processing. It serves the purpose of transforming metals into objects with a precisely defined cross-sectional profile. The process commences by heating a metal billet to a temperature that renders it malleable. Subsequently, the metal is subjected to high pressure as it is forced through a die – a tool possessing a distinct, predetermined shape. The resulting metal that emerges from the other side mirrors the shape of the die, ultimately yielding a lengthy piece with a consistent cross-section throughout its length.

This technique predominantly finds application in the creation of various components such as pipes, wires, rods, and beams. What sets metal extrusion manufacturing apart is its commendable efficiency, accuracy, and ability to fabricate intricate shapes. Furthermore, it minimizes waste as any excess material can be recycled or reused, thereby bolstering its environmental sustainability. With its ability to produce complex shapes and its resource-conscious approach, metal extrusion manufacturing stands out as a versatile and eco-friendly process within the realm of materials processing.

What is the principle of extrusion?

The principle of extrusion revolves around the transformation of metals into definitive shapes by applying high pressure and heat. This process is widely used in manufacturing industries to create a wide range of products with precise specifications.

The process begins with the heating of a metal billet to a specific temperature until it becomes malleable or semi-liquid. This crucial step ensures that the metal can be easily shaped and formed. Once the billet reaches the desired temperature, it is ready for extrusion.

During extrusion, the heated billet is forced under high pressure through a die, which is a hardened tool with the desired cross-sectional profile. The die acts as a mold, shaping the metal as it passes through. As the billet is pressed against the die, it takes the shape of the die’s profile and emerges as a long piece with a uniform cross-section on the other side.

This process is governed by the principles of material deformation and flow. The application of heat and mechanical force changes the metal’s form, allowing it to flow and take the shape of the die. This controlled deformation ensures that the final product has the desired shape and size.

The extrusion process can be performed using various methods, including hot extrusion, cold extrusion, and warm extrusion. Each method has its own advantages and is suited for specific types of metals and products. Hot extrusion involves heating the billet to high temperatures, while cold extrusion is performed at room temperature. Warm extrusion, as the name suggests, is carried out at intermediate temperatures. These different methods offer flexibility in terms of the metals that can be extruded and the properties of the final product.

Overall, extrusion is a versatile and efficient manufacturing process that allows for the production of complex shapes with tight tolerances. It finds applications in various industries, including automotive, aerospace, construction, and more.

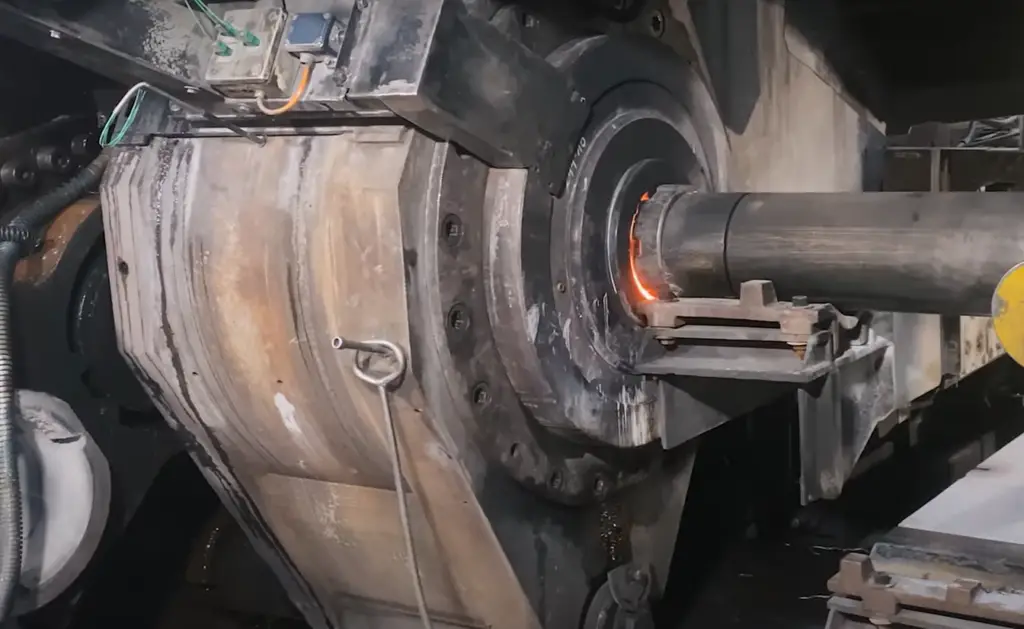

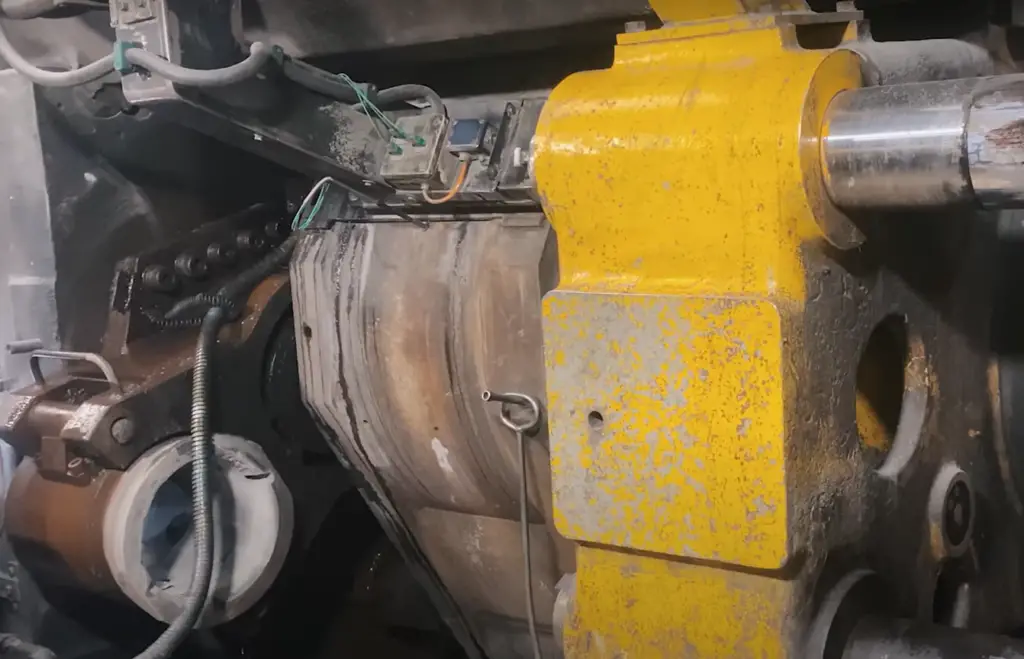

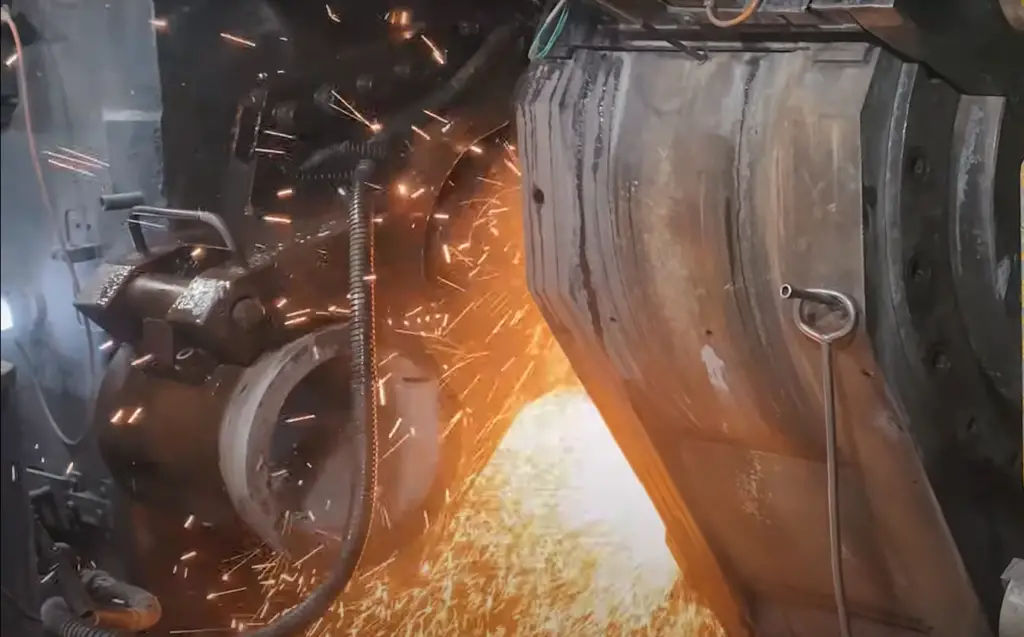

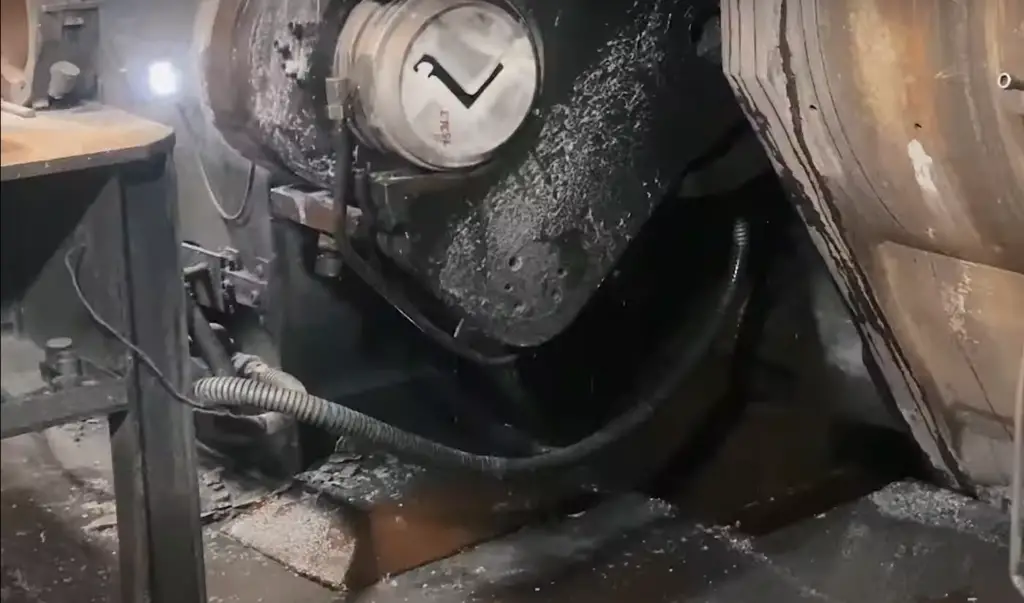

Useful Video: Hot Extrusion technology for special profiles in steel and stainless steel

Conclusion

Metal extrusion is a highly versatile and cost-effective manufacturing process that plays a vital role in a wide range of industries. With its remarkable ability to produce uniform and intricate cross-sectional profiles with exceptional precision, it has become an indispensable choice for fabricating various objects such as pipes, wires, rods, and beams.

To ensure the quality and integrity of the final product, it is crucial to anticipate and address common defects that may arise during extrusion, including surface cracking, internal cracking, and piping. By understanding the fundamental principles of extrusion and following best practices, manufacturers can optimize the process to achieve greater efficiency, accuracy, and sustainability.

Despite the potential challenges that may arise, the benefits of metal extrusion are undeniable. Not only does it enable material conservation, but it also offers the potential for mass production, making it an essential component in the landscape of modern manufacturing. Its versatility and cost-effectiveness make it an attractive option for industries seeking to enhance their production capabilities while maintaining high standards of quality and precision.

References:

- https://engineeringproductdesign.com/knowledge-base/metal-extrusion/

- https://fractory.com/metal-extrusion/

- https://paulmurphyplastics.com/2019/09/25/extrusion-process-working-types-application-advantages-and-disadvantages/

- https://mechanicalengineering.blog/defects-in-extruded-products/

- https://thelibraryofmanufacturing.com/extrusion_design.html