When it comes to materials for making jewelry, there are a lot of options out there. Two of the most popular choices are tungsten and tungsten carbide. But what’s the difference between them? And which one is better? This blog post will compare and contrast tungsten and tungsten carbide, so you can make an informed decision about which material is right for you!

What is Pure Tungsten?

Pure Tungsten, also known as tungsten carbide, is a dense refractory metal alloy composed of equal parts of tungsten and carbon. It is one of the hardest materials on the market and has a melting point of 6170°F (3400°C).

Because of its high density and remarkable strength-to-weight ratio, pure tungsten is often used for aerospace components where lighter-weight materials are preferred. This property makes pure tungsten ideal for bullets or projectiles that require maximum kinetic energy transfer when fired from a gun barrel.

Pure tungsten is also used in construction and manufacturing due to its extreme hardness and corrosion resistance. It is commonly used as armor plating on military vehicles, as a tooling material for machining precision parts, or as an alloying agent in steel production. It is also highly sought after in the medical industry, where pure tungsten’s high density makes it ideal for radiation shielding materials.

In addition to its industrial applications, pure tungsten can also be found in jewelry – such as rings or pendants – as well as electronic components like resistors and transistors. Tungsten’s properties give it a unique combination of strength and hardness that make it invaluable to many industries around the world.

Overall, pure tungsten is an incredibly strong and versatile material that has many uses and applications. Its strength, wear resistance, hardness, and corrosion resistance make it a highly sought-after material in a variety of settings. With its extreme properties and versatility, it’s no wonder that pure tungsten has become such a popular choice for industrial and commercial purposes.

How to Work with Pure Tungsten?

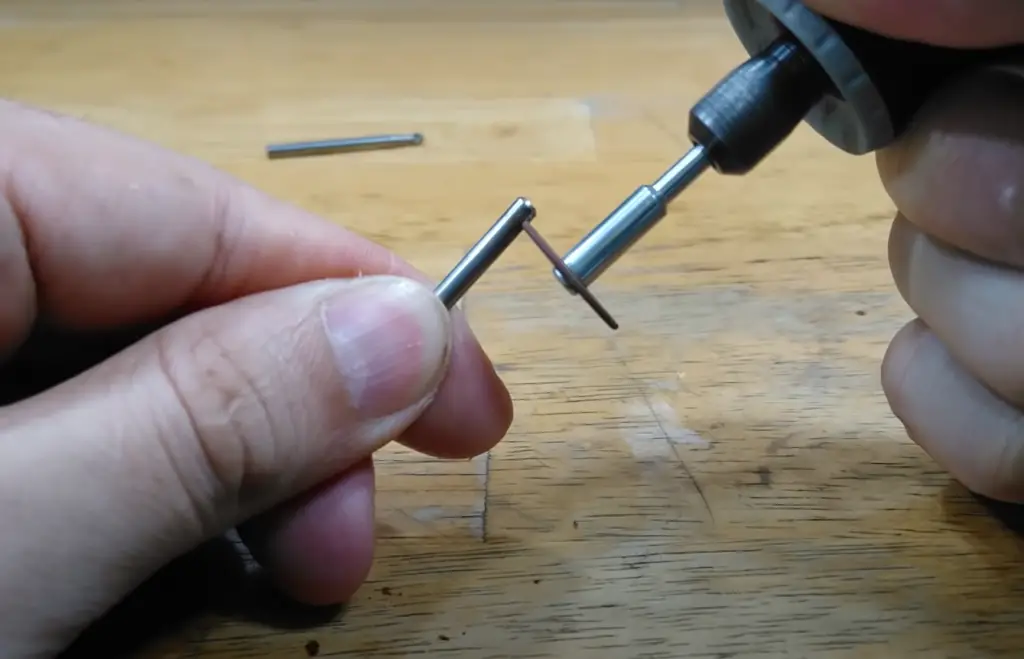

Working with pure tungsten can require specialized tools due to its dense nature. It is important to use the right protective equipment when handling or machining tungsten so as not to cause any damage or harm yourself in the process. In addition, you should always wear safety goggles and masks to protect your eyes and nose from debris.

When machining pure tungsten, it is important to remember that the material can get very hot during the process.

Additionally, high-speed steel tools with sharp edges tend to work better than carbide when cutting tungsten due to its hardness.Finally, before welding tungsten, it is best practice to preheat the material before actually welding it together. This will help prevent cracking or other damage during the process. Once preheated, you can then use a standard TIG welder with an argon gas shield for the best results.

What is Tungsten Carbide?

Tungsten carbide is a compound of tungsten and carbon.

Tungsten carbide has many applications due to its extreme hardness and durability. It is primarily used as an industrial material, but more recently has been used for jewelry and other decorative items.Tungsten carbide is made by combining tungsten metal powder with carbon at very high temperatures. This process creates a strong bond between the two elements that yields a tough material that can stand up to wear and tear from heavy use or extreme environments. Additionally, because it does not corrode easily, it often lasts much longer than steel or other materials.

Uses for Tungsten Carbide

Tungsten carbide is primarily used in industrial settings, where it is often combined with other metals to create a strong and durable alloy. It is particularly effective when used to make tools, such as saw blades, drill bits, and lathe cutters that must stand up to extreme conditions and hard materials. Additionally, tungsten carbide is often used in the production of dies, molds, bearings, valves, seals, and machine parts due to its strength and resistance to wear.

More recently tungsten carbide has also become popular in jewelry making thanks to its toughness and ability to hold a polished shine over time. Many rings are made with tungsten carbide and can be embellished with engravings or inlaid designs. It is also often used to make watches, pendants, and other pieces of jewelry.

Tungsten carbide has also been used for decorative purposes such as home accents or figurines. These items must be carefully crafted to ensure that the delicate material does not break during production or use [1].

Differences between Tungsten and Tungsten Carbide

Modulus of Elasticity

Tungsten has a modulus of elasticity of 15,400 ksi while tungsten carbide has a much higher modulus of elasticity at about 550,000-650,000 ksi. This makes tungsten carbide more resistant to deformation under loads and stresses than tungsten.

Hardness

Tungsten is relatively soft compared to other metals with a hardness of 6 on the Mohs scale while tungsten carbide is one of the hardest materials available with a hardness rating up to 9.5 on the Mohs scale making it even harder than diamond. The hardness (Rockwell A) of tungsten carbide is 88.5 while that of tungsten is only 43.

Melting Point

Tungsten has a melting point of 6,192°F (3,422°C) while tungsten carbide has a much higher melting point of up to 7,400°F (4,072°C). This makes it ideal for withstanding high temperatures and prevents it from losing its form or shape as easily as tungsten under high-temperature processes [2].

Weight

Tungsten is much heavier than tungsten carbide due to the difference in their densities which are 19.25 g/cm3 for Tungsten and 14-15 g/cm3 for tungsten carbide. This makes tungsten carbide more suitable for applications where weight is a factor, such as aerospace and automotive components.

Shear Modulus

Tungsten and tungsten carbide also have different shear modulus values, with tungsten having an elasticity of 7,500 ksi while tungsten carbide has a much higher value at 220,000 ksi. This makes it more resistant to shear forces than tungsten.[3]

Chemical Resistance

Tungsten has excellent corrosion resistance due to its dense surface layer which prevents oxidation and other chemical reactions from occurring.

Tungsten carbide is even more resistant to corrosion and chemicals due to its extremely hard surface which provides a strong barrier against such reactions.

Use and durability

Tungsten is used in various industries such as electronics, construction, automotive, and medical due to its good ductility, resistance to wear, and high melting point. Tungsten carbide has even more uses and applications due to its hardness, chemical resistance, and ability to withstand high temperatures making it ideal for use in tools, cutting blades, and abrasive materials. Its durability also means that it can be reused many times without losing its form or shape.

Cost

Tungsten is generally more expensive than tungsten carbide due to its higher density and cost of production. Tungsten carbide is more economical and can be used in a wide variety of applications where cost is a factor. On average, tungsten carbide tends to be around two-thirds cheaper than tungsten.

Best material for ring making: Tungsten vs. Tungsten Carbide

Rings made of tungsten and tungsten carbide are both attractive choices for wedding bands, engagement rings, and fashion jewelry. Both metals offer durability and a classic look that will last a lifetime. But which one should you choose?

Tungsten is a strong metal often used in industrial applications and is becoming increasingly popular as an affordable alternative to higher-priced metals such as gold or platinum. It’s more scratch resistant than titanium and can be polished to a bright shine without losing its luster. Tungsten also has the unique ability to resist heat up to 6,000 degrees Fahrenheit (3,200 Celsius).

Tungsten Carbide takes the already durable tungsten metal and mixes in other elements such as carbon, creating a material that is even harder and more scratch resistant. Tungsten carbide rings are 10 times harder than 18K gold, 5 times harder than tool steel, and 4 times harder than titanium. A properly made tungsten carbide ring will hold its shape and shine for years to come.

When it comes to price, tungsten is a bit less expensive than tungsten carbide but the difference isn’t enough to be a deciding factor when purchasing jewelry. As far as comfort goes, both metals have a smooth finish that won’t irritate your skin like some other types of metal jewelry can.

In summary, both tungsten and tungsten carbide rings are excellent choices for anyone looking for a lasting and beautiful piece of jewelry. Tungsten is an affordable option that is strong, heat-resistant, and scratch resistant. Tungsten carbide adds even more durability to an already hard metal but carries a slightly higher price tag. In the end, it really comes down to personal preference. Either way, you can be sure that your ring will last for many years of enjoyment and style [4]!

How to choose the right ring?

When shopping for a ring, there are several important factors to consider. First, determine the size and shape of the ring that you want. Consider whether you would prefer a traditional round or oval shape or if you’d like something more unusual such as a marquise or heart-shaped design. The metal type is also an important factor when selecting a ring; gold and silver are popular choices, but platinum and palladium are also options.

Additionally, consider any special features you may want on the ring such as diamonds or gemstones. Lastly, think about how much money you’re willing to spend on the purchase – this will help narrow your selection down to rings within your budget range. With these factors in mind, you’ll be able to find the perfect ring for you or your loved one [5].

FAQ

Which is better: tungsten or tungsten carbide for rings?

When it comes to rings, tungsten carbide is usually the better option. Tungsten carbide is extremely hard and scratch-resistant due to its extremely high melting point of over 6,000°F. This makes it ideal for creating a ring that will last a lifetime without becoming scratched or dulled. Additionally, tungsten carbide rings are hypoallergenic, so they won’t cause any reactions on your skin.

On the other hand, plain tungsten rings are not as strong and can be easily scratched or dented; they also may cause some skin irritation due to their low melting point of only 4,500°F. For these reasons, tungsten carbide is generally the preferred choice for rings.

What is the most durable type of metal for jewelry?

When it comes to durability, titanium is considered one of the most durable metals available for jewelry. It has a very high strength-to-weight ratio, meaning that it can withstand a lot of abuse without becoming damaged or deformed. Additionally, titanium is extremely corrosion-resistant and hypoallergenic, so it won’t cause any reactions on your skin. Other metals such as tungsten carbide and stainless steel are also very durable options for jewelry; however, they may not be as lightweight or corrosion-resistant as titanium. Therefore, if you’re looking for a piece of metal jewelry that will last a long time without showing wear, titanium is an excellent choice.

How do I care for my jewelry?

To ensure that your jewelry continues to look its best, there are some simple steps you can take to care for it properly. First and foremost, always store your jewelry in a cool dry place away from direct sunlight or moisture. Additionally, it’s important to keep any jewelry pieces separated so that they don’t get scratched. Finally, be sure to use a gentle cleaner such as warm water and a mild detergent when cleaning your jewelry; never use harsh chemicals or abrasive materials as these could damage the metal or stones. By taking the time to properly care for your jewelry pieces, you’ll be able to enjoy them for many years to come.

Are gold-plated jewelry pieces good quality?

Gold-plated jewelry can be a great way to get the look of real gold without spending as much money. However, it’s important to be aware that these pieces are not made with solid gold and therefore may not last as long or retain their value over time like a piece made of solid gold would.

Additionally, some gold-plated jewelry pieces may contain nickel which could cause skin irritation in some people. Therefore, if you’re looking for a high-quality piece of jewelry that will last for many years, then it’s best to opt for a piece made from solid gold or another precious metal such as sterling silver or platinum.

Is tungsten carbide better for ring making?

Tungsten carbide is one of the best materials for making rings due to its strength and scratch resistance. It has an extremely high melting point of over 6,000°F, which makes it ideal for creating a ring that will last a lifetime without becoming scratched or dulled. Additionally, tungsten carbide rings are hypoallergenic and therefore won’t cause any reactions on your skin. For these reasons, tungsten carbide is generally the preferred choice when it comes to making rings.

What is the strongest tungsten?

The strongest form of tungsten is tungsten carbide, which is a compound made up of equal parts carbon and tungsten atoms. This makes it extremely hard, with a melting point of over 6,000°F. It is also scratch-resistant and hypoallergenic, making it an ideal choice for jewelry such as rings that need to stand up to everyday wear and tear. Tungsten carbide is the strongest type of tungsten available on the market today.

Can tungsten carbide rust?

Tungsten carbide is highly corrosion-resistant and doesn’t easily rust or corrode. This makes it an ideal choice for jewelry such as rings, which may be exposed to harsh conditions daily. It can be explained by the fact that tungsten carbide is a compound of carbon and tungsten atoms, which are non-reactive and therefore don’t corrode easily. Therefore, if you’re looking for a piece of jewelry that will last for many years without showing signs of wear or discoloration, then tungsten carbide is an excellent choice.

Are stainless steel jewelry pieces good quality?

Stainless steel jewelry is one of the most popular choices when it comes to metal jewelry. It is an incredibly durable material with very high tensile strength, meaning that it won’t easily bend or break under pressure. Additionally, stainless steel is corrosion-resistant and hypoallergenic so it won’t cause any skin irritation. For these reasons, stainless steel is an excellent choice for high-quality jewelry pieces that will last for many years.

What is the strongest metal for jewelry?

The strongest metal for jewelry is titanium. It has an incredibly high strength-to-weight ratio, making it extremely strong while still being lightweight. Additionally, titanium is corrosion-resistant and hypoallergenic so it won’t cause any skin irritation. For these reasons, titanium is often used to create jewelry pieces that need to stand up to everyday wear and tear without showing signs of wear or discoloration.

How can I protect my jewelry?

One of the best ways to protect your jewelry is by storing it in a cool, dry place when not in use. Jewelry should also be kept away from direct sunlight or moisture as these elements can damage certain metals and stones over time. Additionally, you should keep your jewelry clean and use a soft cloth to polish it on occasion. Finally, if you’re storing multiple pieces together, make sure to wrap each item separately in acid-free tissue paper or store it in individual compartments of a jewelry box. By taking these precautions, you can help ensure that your jewelry remains in perfect condition for many years.

Is tungsten the same as carbide?

No, tungsten and carbide are different materials. Tungsten is a naturally occurring metal that is commonly found in jewelry such as rings and watches.

Carbide is a compound composed of equal parts carbon and tungsten atoms, which makes it extremely strong with an ultra-high melting point. Therefore, while they may be similar due to the presence of tungsten atoms, they are not the same material.

Is tungsten carbide good for knives?

Yes, tungsten carbide is often used to make knives due to its incredibly high strength-to-weight ratio and extreme durability. The material is also corrosion-resistant and hypoallergenic which makes it ideal for creating knives that will stand up to everyday use without rusting or corroding. Additionally, tungsten carbide is harder than stainless steel so it can maintain a sharper edge over time. For these reasons, tungsten carbide is an excellent choice when it comes to making knives.

What else can be made of tungsten carbide?

Tungsten carbide is used in a wide range of products and applications, from jewelry to industrial tools. Some examples include drill bits, saw blades, milling cutters, shearing blades, mining tools, and cutting tools. Additionally, tungsten carbide has been used to create wear-resistant coatings for tools and components that are subject to extreme wear or friction. As such, tungsten carbide is an incredibly durable and versatile material with many uses in the modern world.

Useful Video: THE SUPERIOR TUNGSTEN PROJECTILE | Tungsten Carbide vs Tungsten Alloy Armour Piercing Simulation

Conclusion

Tungsten carbide and tungsten alloys are versatile and have a range of valuable uses in industry. They are strong and durable, making them ideal for use in jewelry, tools, machinery, and other applications. Additionally, the unique properties of tungsten alloys make them well-suited for use in aerospace and defense technologies. Ultimately, tungsten carbide and its alloys remain an invaluable resource for many industrial needs. With their combination of strength, durability, heat resistance, and low coefficient of friction they offer numerous advantages over traditional metals or plastics. The versatility of these materials makes them suitable for a wide variety of applications across various industries.

References:

- https://www.jewelrynotes.com/tungsten-and-tungsten-carbide-what-you-should-know-about-them/

- https://www.thomasnet.com/articles/metals-metal-products/tungsten-vs-tungsten-carbide/

- https://www.jewelryshoppingguide.com/tungsten-vs-tungsten-carbide/

- https://www.stevengdesigns.com/blogs/news/the-difference-between-tungsten-and-tungsten-carbide

- https://www.brides.com/story/ring-shopping-before-the-proposal