In the world of metals and their various applications, the difference between Polished and Stainless Steel can often cause confusion. Despite appearances, these two materials have distinctive properties that set them apart.

Polished steel, also known as mirror-coated steel, undergoes a thorough polishing process to achieve a smooth and reflective surface. This makes it extremely aesthetically pleasing and is widely used in decorative applications such as architecture, interior design and jewelry. The buffing process not only improves visual appeal, but also helps reduce susceptibility to corrosion.

Stainless steel, on the other hand, is a versatile alloy that contains a minimum of 10.5% Chromium, that creates a layer of protection on the outside known as a passive layer. This passive layer acts as a defense against corrosion, making stainless steel very resistant to rust and stains. It is widely used in industries such as construction, automotive, food processing and medical equipment due to its excellent durability and hygienic properties.

Brushed Stainless Steel

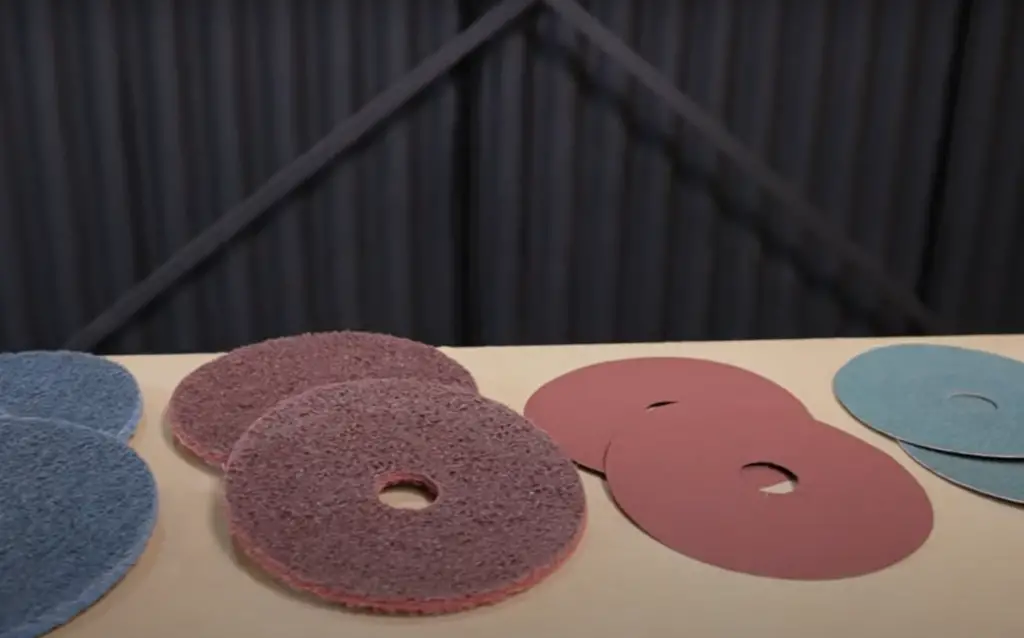

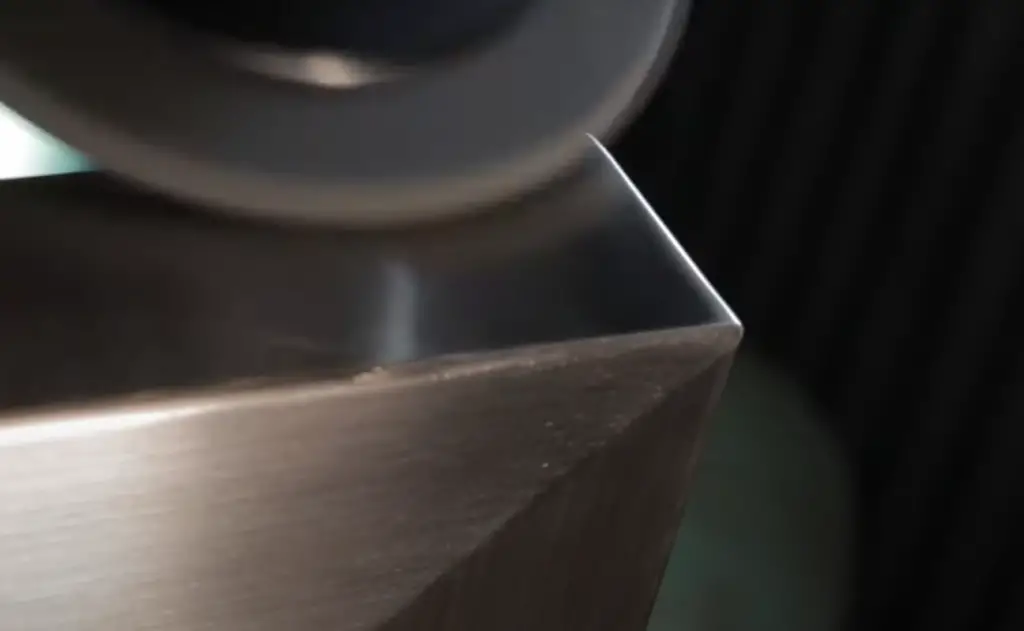

Let’s start with Brushed Stainless Steel, a popular choice in both home and industry. At first glance, the name is self-explanatory – it’s stainless steel that has been polished to achieve a fine satin finish. This meticulous process involves the use of abrasive materials to create parallel lines on the surface, resulting in a visually appealing texture that adds depth and volume to the material.

Brushing not only improves the aesthetic appeal of stainless steel, but also has practical benefits. The brushed finish effectively masks fingerprints and stains, making it an excellent choice for high-traffic areas and items that require frequent use. Whether it’s household appliances, kitchenware or interior design elements, polished stainless steel retains its original appearance with minimal effort.

In addition to its attractive appearance and easy cleaning, ground stainless steel retains all the main advantages of its base material. It is very resistant to corrosion, which ensures durability and strength even in difficult conditions. Its non-reactive nature makes it a safe choice for kitchen surfaces, and its exceptional strength and heat resistance make it suitable for a wide range of applications.

Thus, Brushed Stainless Steel combines style, functionality and durability. It has a visually pleasing glossy surface that is resistant to fingerprints and stains, and provides the corrosion resistance, ease of maintenance and long service life that stainless steel is known for. Whether you are looking to update your kitchen or add a touch of sophistication to your interior design, this steel is a practical and cost-effective choice that will stand the test of time.[1],[2]

Uses of Brushed Stainless Steel

Well-known for its versatile properties, Brushed Stainless Steel is widely used in a variety of applications. In the culinary industry, it is the preferred choice for cookware, kitchen utensils and sinks due to its exceptional heat and corrosion resistance. In architecture and construction, it is used for cladding, roofing and interior design elements such as countertops and backsplashes due to its extreme durability and modern look. In particular, its resistance to dirt and fingerprints makes it highly sought after in the manufacture of household appliances such as refrigerators, ovens and dishwashers. In addition, Ground Stainless steel provides a shiny yet durable surface for automotive grilles, trim and accessories, contributing to the sophisticated aesthetics of automobiles. In addition, the jewelry industry uses it to create stylish and affordable pieces that captivate with their unique appeal and durability.

Polished Stainless Steel

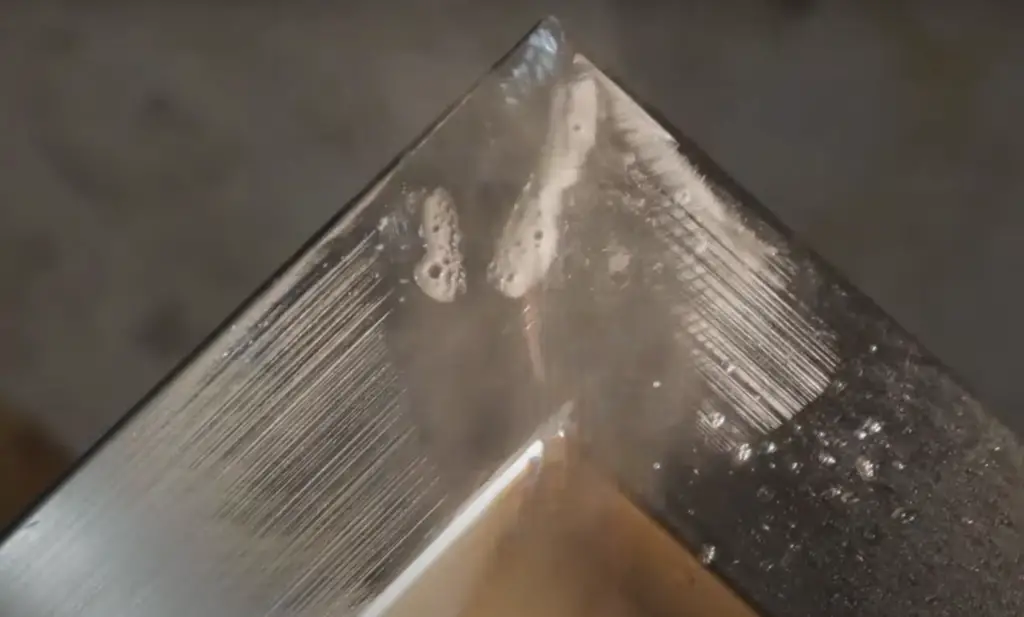

Polished Stainless steel is truly a remarkable variant that flawlessly combines aesthetics and function. The meticulous polishing process gives this steel an impeccable mirror-like finish, elevating it to an exceptional choice for decorative elements. Not only does it possess the same remarkable corrosion resistance, durability, and easy maintenance as its brushed counterpart, but the high-gloss finish of polished stainless steel adds an exquisite touch of elegance and sophistication to any application.

It is no wonder that this luxurious material is often favored for architectural features, including grand entrances and striking facades. Additionally, it finds its place in the world of luxury automotive trim, enhancing the allure of high-performance vehicles. In the realm of culinary creations, it graces high-end kitchen appliances, elevating the cooking experience to new culinary heights. And let’s not forget its use in the creation of stunning jewelry pieces that radiate opulence and beauty.

Consequently, to preserve its gleaming appearance, it may require regular cleaning and maintenance.[1],[2]Uses of Polished Stainless Steel

Polished Stainless steel boasts a broad spectrum of applications, demonstrating its versatility and visual appeal. On a larger scale, it is often utilized in the construction industry, where its high-gloss finish is capitalized on for decorative architectural features, such as building facades, interior wall panels, and elevator doors. Its strength and corrosion resistance make it suitable for structural components as well. Within the automotive industry, polished stainless steel is a preferred choice for luxury car trims and detailing, contributing a sleek and sophisticated aesthetic to the vehicle’s overall design.

In the realm of interior design and kitchen appliances, Polished Stainless steel’s mirror-like finish lends a contemporary, high-end look to items such as refrigerators, ovens, and dishwashers. It is also a popular choice for smaller appliances like toasters, kettles, and coffee makers. Additionally, it’s frequently used in the manufacturing of kitchen utensils and cutlery, not only for its aesthetic appeal but also for its easy maintenance and durability.

The jewelry industry also embraces polished stainless steel, using it to create fashion-forward pieces like necklaces, bracelets, and rings. This is largely due to the material’s gleaming finish, durability, and affordability. In the realm of watchmaking, polished stainless steel is often used in high-end watches for its luxurious sheen and resistance to wear and tear. However, as mentioned earlier, the downside to this material is its tendency to attract fingerprints and smudges, necessitating regular cleaning to maintain its luster.

Difference Between Brushed and Polished Stainless Steel

When it comes to choosing between Brushed and Polished Stainless steel, there are key differences to consider. Brushed stainless steel undergoes a finishing process that leaves a fine grain effect on the surface. This results in a dull, matte look that effectively hides scratches and fingerprints, making it an excellent choice for heavy-use items or areas with high visibility. It retains the superior durability and corrosion-resistance of stainless steel, while also boasting a contemporary, understated aesthetic.

Polished stainless steel, in contrast, is buffed until it acquires a glossy, mirror-like finish. While it shares the same resilience and corrosion resistance as its brushed counterpart, polished stainless steel is often chosen for its luxurious appearance. This high-shine finish adds a touch of elegance and sophistication, perfect for decorative applications or luxury items. However, this glossy surface tends to show fingerprints, smudges, and scratches more readily, which means it may require more frequent cleaning or careful handling. [2],[3]

Appearance

When it comes to the appearance of these two types of stainless steel, each boasts a unique aesthetic appeal. Brushed Stainless steel has a subtle sheen, offering a matte look that is modern and understated. The fine grain effect on its surface, a result of the brushing process, adds texture and depth, which can blend seamlessly into a variety of design schemes. This brushed finish not only provides a contemporary feel but also creates a sense of warmth and authenticity in any space.

On the other hand, Polished Stainless steel features a high-gloss, mirror-like finish that is striking and luxurious. This shiny surface can add an element of elegance and sophistication to any setting, whether it’s a modern kitchen appliance, a stylish piece of jewelry, or an architectural feature. The polished finish reflects light beautifully, creating a captivating visual effect that draws attention and enhances the overall aesthetics. However, it is important to note that this Polished look does require more upkeep to maintain its luster, due to its tendency to show fingerprints and smudges more readily. Despite this, the stunning appearance of polished stainless steel is well worth the extra effort in cleaning and maintenance.

Maintenance

Maintaining the luster of both Brushed and Polished Stainless steel requires different approaches due to their unique finishes.

Brushed Stainless steel, with its matte appearance, is known for its ability to hide fingerprints and smudges, making it easier to maintain. For everyday cleaning, a simple wipe with a damp cloth should suffice. However, for tougher stains, a mild detergent can be used. This combination of cleaning methods ensures that your Brushed Stainless steel surfaces remain free of blemishes and maintain their sleek, modern look.

On the other hand, Polished Stainless steel, with its mirror-like finish, tends to show fingerprints and smudges more easily. Regular cleaning is necessary to maintain its gleaming appearance.

This helps to avoid scratching the surface and ensures that the Polished finish stays intact. As an alternative, a homemade solution of warm water and mild detergent can also be used.When cleaning Polished Stainless steel, it is important to remember to wipe in the direction of the Polish lines for best results. This helps to maintain the consistency of the finish and minimize the visibility of any cleaning marks. Additionally, it is advisable to avoid using abrasive cleaners or tools that could potentially scratch the surface and compromise its pristine look.

By following these detailed cleaning instructions, you can effectively maintain both brushed and Polished Stainless steel surfaces, keeping them looking their best for years to come.

Cost

When it comes to cost, both Brushed and Polished Stainless steel tend to be priced similarly. This is because the difference in their finishes does not significantly alter the fundamental value of the steel itself. However, it’s important to note that the expense may vary depending on the specific application, quantity required, and any additional processing or finishing operations involved.

For bulk orders or larger projects, it’s recommended to reach out to suppliers for specific quotes. They can provide more accurate pricing based on your unique requirements. It’s worth noting that while the initial cost might be a consideration, the longevity and durability of Stainless steel often make it a cost-effective choice in the long run. Its resistance to corrosion and wear ensures that it will maintain its quality and appearance over time, reducing the need for frequent replacements.

Furthermore, the versatility of stainless steel makes it suitable for various applications. From architectural and construction projects to kitchenware and automotive components, its strength and aesthetic appeal make it a popular choice across industries. Whether you’re looking for a sleek and modern finish or a more rustic and textured look, Stainless steel can be customized to meet your specific design preferences.

In conclusion, while cost is an important factor to consider, it’s essential to evaluate the overall value and benefits that Stainless steel offers. By taking into account factors such as longevity, durability, and customization options, you can make an informed decision that aligns with your needs and budget.

Durability

Both Brushed and Polished Stainless steel are renowned for their exceptional durability, owed much to the base properties of Stainless steel itself. The material’s inherent strength, coupled with its remarkable corrosion resistance, make it an excellent choice for applications that demand longevity and reliability.

When it comes to Brushed Stainless steel, its unique surface texture, created by a subtle grain effect, not only adds visual appeal but also serves a practical purpose. This distinctive texture tends to conceal minor scratches and wear, contributing to an enduringly pristine appearance over time. It’s a testament to Brushed Stainless steel’s ability to maintain its allure and performance, even in the face of everyday use and wear.

On the other hand, Polished Stainless steel, while also exhibiting remarkable durability, may show scratches and signs of wear more readily due to its glossy finish. However, with regular care and maintenance, this Polished finish can retain its high-gloss, luxurious appearance for many years, adding a touch of elegance to any application or setting.

Regardless of the chosen finish, Stainless steel’s robustness and endurance make it a preferred choice for both functional and aesthetic applications across various industries. Whether it’s for architectural design, kitchen appliances, or industrial equipment, Stainless steel continues to be a trusted and reliable material that stands the test of time.

Use

The use of both Brushed and Polished Stainless steel is widespread across various sectors, thanks to their unique characteristics and versatility.

Think of kitchen appliances, sinks, or construction materials that require a robust yet aesthetically pleasing solution. Its understated, modern aesthetic also makes it a popular choice in interior design and architectural applications, adding a touch of sophistication to any space.

In contrast, Polished Stainless steel is commonly employed in more decorative or luxurious settings, owing to its glossy, mirror-like finish. This type of stainless steel is often used in jewelry, high-end watches, and ornate architectural features, where its lustrous appearance enhances the overall elegance of the piece. However, it is worth noting that the use of Polished Stainless steel comes with the caveat of requiring more frequent cleaning and careful handling to maintain its pristine look.

Ultimately, the decision between Brushed and Polished Stainless steel will rely on the specific application, the desired aesthetic, and one’s willingness to commit to any necessary maintenance. By understanding the unique attributes of each type and considering the particular requirements of the project, one can make an informed choice that perfectly suits their needs.

Other factors

Beyond aesthetics, durability, maintenance, and cost, other factors could influence your decision between Brushed and Polished Stainless steel. One such factor is the environment in which the material will be used. For instance, in humid or coastal areas, Brushed Stainless steel might be a better choice due to its resistance to salt, which can cause corrosion. For indoor applications requiring a sleek and modern appearance, Polished Stainless steel might be the preferred choice.

Another factor to consider is the lighting of the space. Polished Stainless steel, with its mirror-like finish, can reflect light superbly and add brightness to a room. Conversely, Brushed Stainless steel, with its matte finish, absorbs more light, providing a softer effect that can help create a warm and cozy ambiance.

Lastly, personal preference always plays a significant role. Some people may simply prefer the understated elegance of Brushed Stainless steel, while others might be drawn to the shiny, luxurious look of Polished Stainless steel. Always consider your personal design aesthetics when choosing between these two finishes.

FAQ

Is Polished steel the same as Stainless steel?

It’s common to confuse Polished steel with Stainless steel, but they are not the same. Polished steel is a broad term that refers to any type of steel that has undergone a polishing process to achieve a shiny, smooth surface. This can include various types of steel, not necessarily Stainless steel. The polishing process helps to enhance the steel’s aesthetic appeal and can also provide some level of protection against rust and other forms of corrosion.

Stainless steel, on the other hand, is a specific type of steel alloy that contains at least 10.5% Chromium, which gives it exceptional resistance to rust and corrosion compared to other types of steel. Stainless steel can be finished in a variety of ways, including brushing or polishing. Therefore, Polished Stainless steel refers to Stainless steel that has been polished to a high-gloss finish. It’s important to note that while all Polished Stainless steel is Polished steel, not all Polished steel is Stainless steel.

Is Polished Stainless steel better?

The question of whether Polished Stainless steel is “better” depends heavily on the context and the specific requirements of the application at hand. Polished Stainless steel, with its high-gloss, mirror-like finish, offers a luxurious aesthetic that’s particularly appealing in decorative or high-end applications such as jewelry, watches, or architectural features. It’s also highly reflective, which can be advantageous in adding brightness and a sense of space in interior settings. Furthermore, its smooth surface can be easier to clean, although it may require more frequent cleaning due to its tendency to show fingerprints and smudges.

However, Polished Stainless steel may show scratches and wear more readily than its brushed counterpart, which could be a disadvantage in high-traffic areas or applications that demand high durability and resistance to wear. Also, the maintenance requirements might be higher for Polished Stainless steel, given that it needs regular cleaning and careful handling to maintain its bright, glossy appearance.

Which is better: Stainless steel or steel?

The question of whether Stainless steel is better than Steel is not a straightforward one, as it largely depends on the specific application and requirements. Standard steel, characterized by its durability and strength, is an ideal choice for applications where these factors are critical, such as in construction and manufacturing.

On the other hand, Stainless steel, enriched with Chromium, offers superior resistance to rust and corrosion, making it a popular choice in environments susceptible to these elements like kitchens, medical facilities, or coastal areas. Additionally, it has a pleasing aesthetic appeal, which coupled with its longevity, makes it a favorite in the design and luxury goods industry.

Therefore, neither is inherently better than the other. The decision between Steel and Stainless steel should be guided by factors such as the environment, the functional requirements, the desired aesthetic, and the available budget.

Does polished stainless steel rust?

Polished Stainless steel is renowned for its superior resistance to rust and corrosion, a property attributed to its Chromium content of at least 10.5%. The Chromium reacts with oxygen in the air to form a thin, invisible layer of Chromium oxide. This layer is self-healing and will re-form if the steel is scratched, providing a protective barrier against rust. However, it’s important to note that while highly resistant, it is not completely immune, especially when exposed to harsh conditions such as high salinity or acidic environments. Therefore, although Polished Stainless steel has a high resistance to rust, appropriate care and maintenance are necessary to maintain its aesthetic appeal and longevity.

What are the 4 classifications of steel?

Steel, a versatile and durable material, can be classified into four main categories based on its chemical composition and properties:

- Carbon Steel: This is the most commonly used form of steel, making up about 90% of all steel production. It is classified further into three groups: Low-Carbon, Medium-Carbon, and High-Carbon, based on the amount of carbon content. Lower Carbon content makes the steel more malleable, while higher carbon content results in a harder, stronger steel.

- Alloy Steel: This type of steel is made by adding other elements to Carbon steel. The added elements, such as manganese, nickel, and chromium, can significantly alter the steel’s properties, such as increasing its strength or making it more resistant to corrosion.

- Stainless Steel: A type of alloy steel that contains at least 10.5% Chromium, resulting in a material that is highly resistant to corrosion. Other elements may be added to enhance specific properties, such as nitrogen for strength or nickel for improved toughness.

- Tool Steel: This is a type of carbon or alloy steel that’s designed for tool manufacturing due to its high hardness levels and abrasion resistance. It can withstand conditions that would cause other types of steel to deform, melt, or wear out.

Why is Stainless steel more expensive than Steel?

Stainless steel tends to be more expensive than standard Steel due to several reasons. Firstly, the production process of Stainless steel is more complex and requires additional steps compared to that of regular Steel. It involves the addition of alloying elements, notably chromium, which themselves are costly. Secondly, the raw materials used in Stainless steel, such as nickel and molybdenum, are more expensive than the primarily iron-based composition of standard Steel. Additionally, stainless steel has superior properties such as high corrosion resistance and an attractive aesthetic appeal, which further justify its higher price point. However, while the upfront costs are higher, the longevity and low maintenance needs of Stainless steel can make it a cost-effective choice in the long run for certain applications.

Which type of steel is strongest?

The strength of steel varies depending on its type and composition, but High-Carbon steel is generally regarded as the strongest. High-Carbon steels contain between 0.61% and 1.50% Carbon, making them exceptionally strong and durable.

They have a high tensile strength and are able to withstand significant stress without deformation or failure. However, this strength comes at a cost: High-Carbon steels are less ductile and more difficult to work with than their Lower-Carbon counterparts. In addition, they may be less resistant to corrosion unless treated appropriately. It’s important to remember that the “strongest” steel might not always be the most appropriate for a given application, as other factors such as corrosion resistance, ductility, and cost also come into play.

Is Polished Stainless steel real?

Yes, Polished Stainless steel is indeed real. It refers to stainless steel that has been physically polished to give it a highly reflective, mirror-like finish. This finish not only enhances the steel’s aesthetic appeal, but also makes the surface smoother and less susceptible to bacterial growth, a key consideration in hygienic environments such as kitchens and hospitals. However, it’s important to note that Polished Stainless steel requires regular maintenance to keep its shiny appearance, as it can easily show fingerprints and smudges.

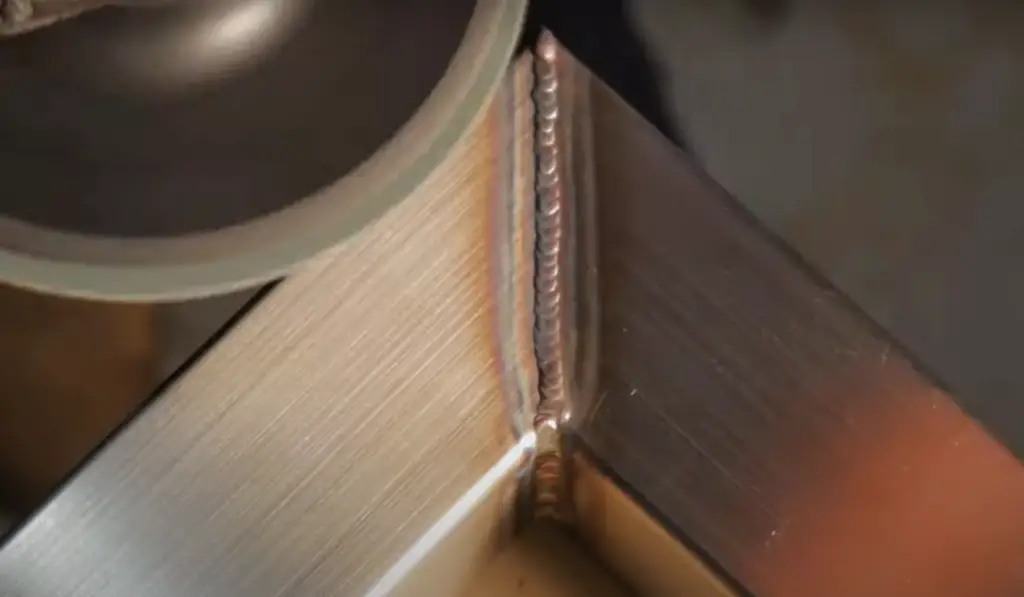

Useful Video: Miter Polishing Square Tube – Stainless Steel [With Basic Equipment]

Conclusion

In conclusion, both Polished steel and Stainless steel have their unique sets of properties and advantages that make them suitable for various applications. Stainless steel, with its corrosion resistance and elegant appearance, is ideal for environments demanding hygiene and aesthetics, such as kitchens, hospitals, and the luxury goods industry. However, its initial cost is higher, which can be a consideration for budget-conscious projects. On the other hand, Regular steel, known for its strength and durability, is widely used in construction and manufacturing sectors where these traits are paramount. Ultimately, the choice between the two should be guided by the specific requirements of the project, including factors such as the environment, functional needs, desired aesthetics, and budget.

References:

- https://www.geeksforgeeks.org/difference-between-brushed-and-polished-stainless-steel/

- https://blog.thepipingmart.com/metals/is-brushed-stainless-steel-better-than-stainless-steel/

- https://econtablelegs.com/the-difference-between-polished-and-brushed-stainless-steel/