Ferrous vs. Non-Ferrous Metals: What’s the Difference?

If you are involved in metal fabrication or use metals regularly, it is imperative to understand the distinction between ferrous and non-ferrous metals. Magnets are instantly drawn to ferrous metals due to their iron content, whereas non-ferrous metals that lack iron remain unaffected by magnetism. In this post, we’ll delve deep into the distinctions between these two metals. Keep reading to learn more!

Properties Of Ferrous Metals

Ferrous metals are commonly composed of iron and a small amount of carbon. They are known for their magnetic properties, strength, malleability, ductility, and corrosion resistance.

Ferrous metals have the ability to withstand extreme temperatures making them useful in a variety of industries such as automotive manufacturing where they can be used to construct parts that need to hold up under high-heat conditions.

Ferrous metals are also highly recyclable and can be melted down into other forms like sheet metal or castings. Apart from iron, ferrous metals are steel (which contains more carbon than pure iron), stainless steel, wrought iron and cast iron. [1]

Examples And Uses Of Ferrous Metals

Widely available and diverse in uses, ferrous metals are some of the most widely used substances on Earth. They are typically cheaper than non-ferrous metals and contain iron, which gives them their magnetic properties. Some of the most common examples of ferrous metals include:

- Steel: Steel is an alloy made up mostly of iron and a small percentage of carbon. It’s very strong and malleable, so it can be easily formed into various shapes. It’s often used in construction, automotive manufacturing, machine parts, tools and consumer products.

- Cast Iron: Cast iron is another alloy primarily composed of iron with up to 3% carbon. It’s known for its strength and ability to withstand high heat. Cast iron is used in manufacturing cookware, machine parts, pipes and auto parts.

- Stainless Steel: Composed of iron and minimum 10.5% chromium, stainless steel is a strong, resilient metal alloy that stands out for its corrosion-resistant properties. It’s resistant to corrosion and staining, making it a popular choice for items that come into contact with water, like sinks and bathtubs. It’s also used in kitchen appliances, medical equipment, automotive parts and architectural designs.

Properties Of Non-Ferrous Metals

Non-ferrous metals can be distinguished from ferrous metals through the lack of iron found in their composition. Non-ferrous metals are essential for numerous engineering applications, such as construction, automotive and aerospace.

Non-ferrous metals boast unique characteristics that make them perfect for particular uses, making them invaluable across a plethora of industries.A characteristic that makes non-ferrous metals stand out is their remarkable corrosion resistance. In contrast to ferrous metals that can corrode when exposed to water and oxygen, non-ferrous metals are inimitably resistant because of their absence of iron. Thanks to their robustness, these products are suitable for a multitude of environments that may be exposed to salt water or high levels of pollution. This makes them ideal for use on boats and in other industrial settings.

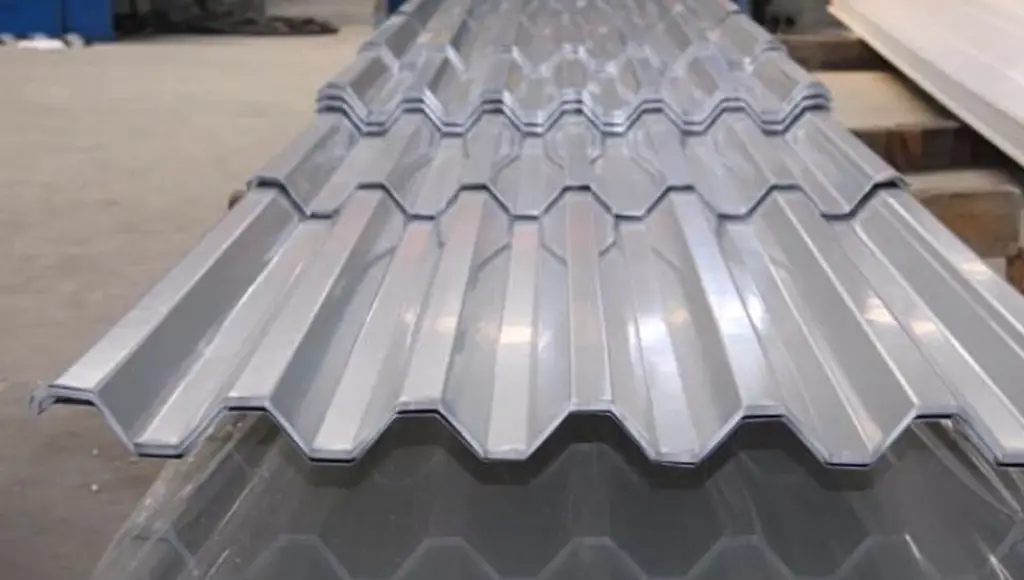

Non-ferrous metals are much lighter than ferrous metals, and can offer improved strength in relation to their weight – a crucial advantage for several uses. When considering machining, welding and forming, non-ferrous metals possess distinct properties that set them apart from other materials. Different non-ferrous metals require different techniques and processes in order to be shaped or cut properly. [2]

Examples And Uses Of Non-Ferrous Metals

Non-ferrous metals play a vital role in the production of many products and structures, serving as essential components. From automobile parts to medical equipment, the possibilities are endless when it comes to the utilization of their wide range of products. Metals other than iron, such as copper, aluminum, zinc, lead and nickel alloys are known as non ferrous metals.

Copper is widely used in electrical wiring, plumbing systems, roofing and even as decorative accents on buildings. It is also an important component in coins and medals. Aluminum has many applications including structural components for aerospace vehicles and boats. It’s also popularly used to produce cans, window frames and doors.

Zinc can be found in die casting alloys to make items such as locksets or gears for automobiles. Lead is often used in the production of batteries and radiation shielding. Nickel alloys are used to create jet engines, gas turbines, nuclear reactors and medical devices.

From coins to cookware, non-ferrous metals are a vital part of many everyday items such as jewelry and kitchen tools. Non-ferrous metals are commonly chosen for their attractive qualities due to their excellent corrosion resistance. Non-ferrous metals are incredibly versatile, serving a variety of purposes in both the industrial and everyday realms. [3]

Ferrous And Non-Ferrous Metals Comparison

Resistance To Rust & Corrosion

Due to their high iron content, ferrous metals are vastly more prone to rust and corrosion compared with other materials. In contrast, non-ferrous metals such as aluminum and copper don’t contain iron and virtually never corrode.

Strength & Durability

When it comes to enduring strength and toughness, ferrous metals remain unrivaled when compared to non-ferrous materials.

Because of their weight, ferrous metals are not ideal for tasks that require lightness.Cost

Cost-wise, non-ferrous metals are typically more expensive than ferrous varieties.

Ferrous metals are more common in the environment, making them easier to locate, extract and refine – which is why they are so widely used.

Magnetic Properties

Because of their elevated iron content, ferrous metals are naturally magnetic. On the other hand, non-ferrous materials like aluminum or brass have no such attractive properties whatsoever. Due to their lack of magnetism, these products are perfect for many situations where a magnetic field is not desired.[4]

Weight

Composed of additional iron than non-ferrous materials, ferrous metals are naturally denser and thereby heftier. With this in mind, these materials are not ideal for applications that require lightweight components.

Non-Ferrous & Ferrous Metal Recycling

Recycling metals can be a great way to reduce waste and preserve the environment.

Ferrous and non-ferrous metals are distinct varieties of metal materials, each exhibiting unique characteristics that lend themselves to specific recycling missions.

Ferrous metals contain iron and are magnetic in nature. Ferrous metal is much simpler to distinguish, locate, and separate from other substances during the recycling process due to this. With ferrous metals being relatively easy to recycle in comparison to non-ferrous, they usually carry a lower value on the commodities market as well. Everyday ferrous scrap items may include steel cans, home appliances, cars and buses, old railway tracks and demolition rubble. [5]

FAQs

What are the 4 ferrous metals?

Iron, steel, stainless steel, and alloy steel are the four ferrous metals that have become synonymous with strength and durability. Iron is an element found in nature that has a red-gray hue and is very strong and ductile. A manipulated blend of iron, carbon and other elements, steel is a versatile alloy that can be tailored to possess unique characteristics. Stainless steel contains chromium which helps it resist corrosion and oxidation better than other ferrous metals. Alloy steels contain compounds such as magnesium, nickel or titanium which help make them more heat resistant than other types of metal alloys.

What characteristics distinguish ferrous from non-ferrous metals?

Ferrous metals have superior densities compared to non-ferrous metals, thus they are considerably heavier in mass per unit volume than the latter. Ferrous metals are also more magnetic than non-ferrous metals. Moreover, ferrous metals tend to have a higher melting point than non-ferrous metals and interaction with water produces iron oxide (rust).

What are the main uses of ferrous metals?

Ferrous metals are used in a wide variety of applications due to their strength and durability. Common uses include construction projects (e.g., structural steel), industrial machinery, transportation equipment (e.g., cars), metalworking tools, and even electronic devices (e.g., phones). In addition, certain types of ferrous alloys can be used for medical implants such as hip replacements and artificial joints due to their biocompatibility and corrosion resistance properties.

Is ferrous stronger than non-ferrous?

Ferrous metals are usually more robust than non-ferrous ones, because they have a higher density and can be cold-worked to greater degrees. However, the strength of a specific metal alloy depends on its composition as well as how it is treated during manufacturing. Therefore, certain types of non-ferrous alloys can possess similar or even greater strength than ferrous alloys depending on their properties.

Are there any environmental benefits to using ferrous metals over non-ferrous?

Without a doubt, the use of ferrous metals in certain applications can have positive environmental impacts due to its far higher recyclability than non-ferrous materials. Steel is one of the most recycled materials in the world and can have up to 100% recycling potential when correctly processed.

By utilizing this method of production, we can reduce the amount of resources extracted from nature and help decrease energy consumption along with greenhouse gas emissions. Additionally, certain types of ferrous alloys can be used to help capture and store carbon dioxide in industrial processes.

Are there any limitations to using ferrous metals?

One major limitation is that some types of ferrous metals are susceptible to corrosion when exposed to moisture or other environmental conditions. Therefore, additional measures such as protective coatings may need to be applied to help prevent corrosion or extend the lifespan of a product. Additionally, because ferrous metals possess a higher density than non-ferrous metals, they require more energy during transportation due to their greater weight compared to non-ferrous materials. As such, extra care needs to be taken when shipping and storing ferrous metals.

Are there any health risks associated with using ferrous metals?

In general, the use of ferrous metal in everyday applications does not typically pose a health risk for humans. However, exposure to certain types of particles from welding or machining operations can cause respiratory irritation or eye/skin irritation depending on the type of operation being performed. Therefore, it is important that proper safety protocols are followed and protective gear is used if working with ferrous materials.

What are examples of non-ferrous metals?

Examples of non-ferrous metals include aluminum, copper, lead, nickel, tin, titanium and zinc. Aluminum is the most abundant metal on earth and is often used in construction due to its light weight and corrosion resistance. Copper has a higher electrical conductivity than any other metal except silver and is widely used in alloys for marine applications like boat fittings. Lead is malleable and easily extruded into many products such as cable sheathing, ammunition and roofing materials. Nickel is one of the strongest metals known to man with excellent ductility which makes it ideal for use in coins or specialty parts. Tin is often alloyed with other non-ferrous metals because of its low melting point making it easy to work with under heat. Titanium is a lightweight metal used for aircraft parts due to its strength and resistance to corrosion. Zinc is often found as a protective coating on steel and iron components because of its ability to form an oxide layer that prevents rust from forming. All of these non-ferrous metals have different uses based on their unique properties, making them essential for numerous industries such as construction, aerospace, automotive and marine.

What is the difference between ferrous and alloys?

Ferrous metals are those that contain iron, while alloys are combinations of two or more metals. Alloys can be ferrous or non-ferrous and the combination of different metals gives them unique properties. For example, steel is an alloy of iron and carbon which makes it much stronger than either metal alone. Non-ferrous alloys such as bronze (copper and tin) have higher electrical conductivity and corrosion resistance than pure copper or tin. Each alloy has specific properties that make it ideal for different applications, from coins to aircraft parts.

Is gold a ferrous metal?

No, gold is not a ferrous metal. It is classified as a non-ferrous metal because it does not contain any iron. Gold is often alloyed with base metals such as copper or silver to create stronger and more durable products such as jewelry. Gold’s properties include excellent electrical conductivity which makes it useful in the electronics industry and its corrosion resistance makes it an ideal material for coins, watches and other jewelry pieces.

Is aluminum a ferrous metal?

No, aluminum is not a ferrous metal. It is classified as a non-ferrous metal because it does not contain any iron. Aluminum is the most abundant metal on earth and has many uses due to its lightweight and corrosion resistance, making it an ideal material for construction and aerospace applications. Its electrical conductivity is also higher than that of copper or iron, making it useful for electrical components such as wires and connectors.

What is a significant disadvantage of ferrous metals?

One of the major disadvantages of ferrous metals is their susceptibility to rusting. Iron and steel are particularly prone to corrosion, which can cause them to weaken over time. This makes them less suitable for outdoor applications or products that will be exposed to moisture or water on a regular basis. Non-ferrous metals, such as aluminum and copper, are more resistant to corrosion, making them better suited for these types of uses.

Can non-ferrous metals corrode?

Yes, non-ferrous metals can still corrode in certain environments. While they are generally more resistant to corrosion than ferrous metals, prolonged exposure to air or water can result in oxidation and the formation of rust or corrosion on the surface. To protect against this, non-ferrous metals are often coated with a protective layer or treated with a corrosion inhibitor. Proper care and maintenance can extend the life of these products significantly.

Useful Video: The Difference Between Ferrous and Non-Ferrous Metals | Metal Supermarkets

Conclusion

When it comes to metal, the difference between ferrous and non-ferrous metals is clear. Ferrous metals are magnetic and contain iron, while non-ferrous metals do not contain any iron and are not magnetic. Understanding the difference between these two types of metal can help you make an informed decision when deciding which type of metal you need for your project or application. Non-ferrous metals tend to be more expensive than ferrous metals due to their higher cost of production, but they also offer superior corrosion resistance and so may be worth the extra expense in some applications. On the other hand, ferrous metals have their own advantages such as lower cost and greater strength.

Ultimately the choice between ferrous and non-ferrous metal will depend on the specific needs of your project or application. Knowing the difference between these two types of metal will help you make a better informed decision about which type of metal to use for your particular needs.

References:

- https://www.twi-global.com/technical-knowledge/faqs/ferrous-vs-non-ferrous-metals

- https://www.metalsupermarkets.com/the-difference-between-ferrous-and-non-ferrous-metal/

- https://civiltoday.com/civil-engineering-materials/steel/216-difference-between-ferrous-and-nonferrous-metals

- https://questtech.ca/blog/difference-between-ferrous-and-non-ferrous-metals/

- https://www.slrecyclingltd.co.uk/what-is-the-difference-between-ferrous-non-ferrous-metals/