If you need a durable and lightweight aluminum alloy, you might want to consider 5052 or 6061 aluminum as they are both excellent options. Can you explain the difference between these two alloys? What makes one better than the other? Continue reading to discover information regarding their makeup, distinctive traits, and suggested applications. This will aid you in making a knowledgeable choice when considering your alternatives. From automotive components to tooling needs or decorative accents, this blog post will help you sort out which type of aluminum is suitable for each requirement. Dive deeper into how 5052 vs. 6061 Aluminum differ and whether one should be used over the other in specific circumstances!

What Is 5052 Aluminum?

The alloy 5052 aluminum, which is commonly used, predominantly consists of magnesium as its alloying element. It has excellent durability and formability, rust-resistance, weldability and conductivity.

Its properties make it suitable for various commercial uses such as kitchenware, appliances, automotive parts, fuel tanks, sheet metal work, pressure vessels, and others. In general, 5052 aluminum is more resistant to corrosion than 6061 aluminum because it contains magnesium in its composition. Compared to 6061 aluminum, this material offers improved formability and machinability. However, 5052 aluminum does have a lower strength than 6061 aluminum which means that it is not suited for some applications where high strength is required such as aircraft or aerospace components. [1]

What Is 6061 Aluminum?

6061 aluminum is a popular grade of aluminum that is frequently utilized in both industrial and consumer environments. This material is a great option for projects involving fabrication such as structural supports, brackets, frames, etc., because it offers excellent weldability, formability, and machinability characteristics. The alloy has a high strength-to-weight ratio, good corrosion resistance, and can be anodized in various ways. 6061 aluminum is heat treatable to achieve higher mechanical properties in varied applications.

5052 vs. 6061 Aluminum: Differences in Performance

There are significant differences in performance between the two alloys. The 5052 aluminum is known for its strength as compared to 6061 aluminum. It is also appreciated for its capability to be forged or extruded, which makes it an ideal choice for customized applications. It’s also very corrosion-resistant and has high fatigue strength.

In addition, it offers excellent resistance to stress-related cracking when exposed to extreme temperatures.Both alloys can be used in marine applications due to their superior corrosion-resistance. However, since 5052 aluminum is stronger, it’s often seen as being better suited for saltwater environments than 6061 aluminum.

Furthermore, it’s worth noting that 5052 has a higher fatigue strength and better temperature resistance compared to the other material being discussed.

At the end of the day, it really comes down to what your application requires. Both alloys are excellent choices for certain applications, so be sure to do your research before making a decision.

In summary, 5052 aluminum is ideal for customized marine applications due to its superior strength and corrosion resistance when compared to 6061 aluminum. However, 6061 aluminum is softer and more workable due to its high levels of magnesium and silicon content, which makes it great for certain applications as well. In the end, you’ll need to evaluate your specific needs to decide which alloy is best for your application.

Pros and Cons of 5052 Aluminum

The biggest benefit of 5052 aluminum is that it can be easily formed into any desired shape. This makes the material a great choice for many fabrication projects, as it allows manufacturers to create complex parts with relative ease. Additionally, 5052 aluminum has excellent corrosion resistance and is highly resistant to saltwater damage, making it an ideal choice for marine applications. The material also has a relatively high strength-to-weight ratio and an impressive fatigue strength rating.

On the other hand, there are also some downsides to using 5052 aluminum. This material’s tensile and yield strengths are slightly lower than those of 6061 aluminum, which makes it unsuitable for heavy duty or high stress applications where strength is a priority. Additionally, 5052 aluminum is more expensive than other aluminum alloys and may not be the most cost-effective material for certain projects.

Overall, 5052 aluminum offers a great combination of strength, formability, and corrosion resistance that make it an excellent choice for many applications. However, it’s important to consider its slightly lower tensile and yield strengths when making a decision about which alloy to use. [2]

Pros and Cons of 6061 Aluminum

6061 Aluminum has many advantages when compared to 5052 aluminum. It is much more formable and weldable, making it great for applications requiring complex shapes and parts. It also offers higher strength, durability, and corrosion resistance than 5052 aluminum. 6061 aluminum also has good machinability making it easier to work with than other alloys. Furthermore, 6061 aluminum is an economical choice that can be used in a variety of applications from aircraft structures to bicycle frames.

However, there are some drawbacks to using 6061 aluminum over 5052 aluminum. The primary disadvantage is its lower corrosion resistance in certain environments or chemical exposures. Additionally, the alloy’s ability to resist fatigue cracking increases as the temperature decreases which can limit its performance in high-temperature applications. Lastly, 6061 aluminum does not work as much as 5052 aluminum making it unsuitable for certain applications requiring a higher hardness.

Overall, 6061 aluminum is an excellent all-purpose alloy that offers good strength and formability at an economical price. It can be used in a variety of industries including aerospace, automotive, and recreational activities such as mountain biking. Its machinability and corrosion resistance make it ideal for projects requiring intricate shapes or parts that must withstand harsh environmental conditions. However, its lower corrosion resistance in some situations coupled with its limited fatigue cracking capabilities may require the use of other alloys such as 5052 aluminum for certain applications. [3]

Maintenance Tips for 5052 Aluminum

5052 aluminum is a popular choice for many applications due to its high strength-to-weight ratio, corrosion resistance, and weldability. To keep your 5052 aluminum in excellent condition, there are some maintenance tips worth following:

- Cleaning: Regularly clean your 5052 aluminum with mild soap and water or an approved metal cleaner. This will help protect it from dirt buildup that can corrode the surface over time.

- Finish protection: Consider coating your 5052 aluminum with a clear lacquer or sealant to prevent further damage caused by oxidation. This will also make it easier to clean and maintain in the future!

- Corrosion prevention: Apply a protective oil or grease to the surface of your 5052 aluminum regularly. This will help prevent corrosion caused by moisture or other environmental factors, as well as provide a layer of protection against physical damage.

- Structural integrity: Inspect and maintain the structural integrity of your 5052 aluminum on a regular basis by checking for signs of wear and tear such as scratches, dents, or cracks. If any issues are discovered, take steps to repair them quickly before they spread further and cause more damage down the line.

By following these simple maintenance tips, you can ensure that your 5052 aluminum is in excellent condition for many years to come!

Maintenance Tips for 6061 Aluminum

6061 aluminum is a popular option for many types of metal projects because it is strong and lightweight. It can be machined, welded, formed, and anodized to create a variety of different products. However, if you are using 6061 aluminum in your project, there are some maintenance tips you should keep in mind.

First and foremost, it is important to clean the surface of any dirt or debris that could affect the quality of the finished product. This can be done with water and soap or other specialized cleaners depending on the type of application. Additionally, regular lubrication will help reduce friction during fabrication processes such as cutting, drilling, and tapping to ensure maximum efficiency. The use of protective coatings such as oils and waxes can also help protect the aluminum from corrosion, wear, and tear.

Another important maintenance tip for 6061 aluminum is to avoid contact with harsh chemicals. These chemicals can cause corrosion or discoloration of the metal surface over time. In addition, some chemical compounds may react with the aluminum and weaken its structure. It’s best to keep any chemical-based cleaning agents away from your projects when possible.

Lastly, it is important to monitor the temperature of your project when working with 6061 aluminum. Excessive heat can cause warping or deformity of the aluminum which will negatively affect its overall performance. To ensure optimal results, use a thermometer during fabrication processes to make sure that temperatures remain within the recommended range for 6061 aluminum.

Overall, following these maintenance tips will help extend the life of your project and ensure you get the best possible performance from your 6061 aluminum. With a little bit of care and attention, you can keep your projects looking and performing like new for years to come. [4]

Alternatives to 5052 and 6061 Aluminum

Although 5052 and 6061 aluminum are the most commonly used alloys, they are not the only options available. Some other alternatives include:

- 2024 Aluminum Alloy – This is an aluminum-copper alloy with a high strength-to-weight ratio. It is often used for aerospace components due to its ability to withstand extreme temperatures.

- 3003 Aluminum Alloy – This alloy offers excellent machinability, formability, and moderate strength. It is often used in food processing equipment and transportation applications.

- 7075 Aluminum Alloy – This is one of the strongest aluminum alloys available on the market today. It has good weldability but is somewhat difficult to machine and can be susceptible to stress corrosion cracking.

No matter which alloy you decide to use, make sure that it is the best fit for your application. Consider factors such as strength, malleability, and corrosion resistance before making a final decision. Additionally, always ensure that your aluminum supplier uses high-quality materials from reliable mills. This will help ensure that you get the most out of your purchase.

Applications of 5052 Aluminum

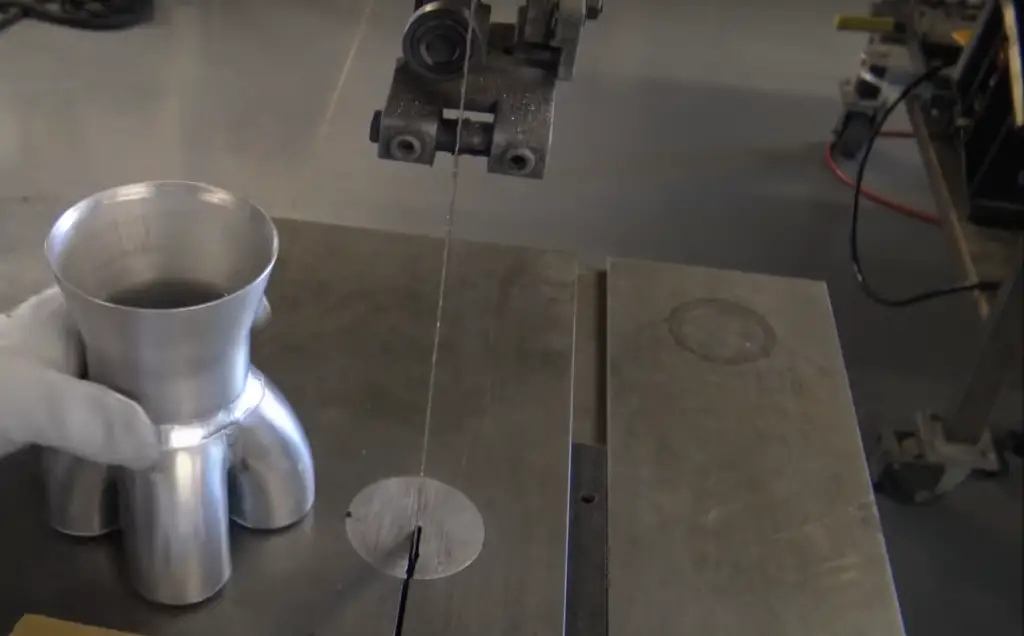

Due to its excellent corrosion resistance, 5052 aluminum is often the preferred alloy for highly corrosive environments such as marine applications. It is also used in structural components, sheet metal work, fuel tanks and much more. Some of the popular applications of this alloy include:

- Automotive Parts – Used in a variety of automotive components including engine parts, transmission components, exhaust system parts and other accessories.

- Marine Equipment – Ideal for boat hulls due to its high corrosion resistance. Also suitable for propeller shafts and other equipment exposed to saltwater or humid conditions.

- Tanks & Gas Cylinders – Often used for gas cylinders due to its excellent strength-to-weight ratio and ability to withstand extreme temperatures.

- Structural Components – Used in aircraft and transportation industries for structural components that require a high strength-to-weight ratio.

- Sheet Metal Work – Commonly used in sheet metal work due to its excellent formability, weldability and ductility. It is also resistant to corrosion making it a great choice for outdoor applications.

5052 aluminum is considered one of the most versatile alloys available, making it an ideal choice for a wide range of applications where strength and durability are required. [5]

Applications of 6061 Aluminum

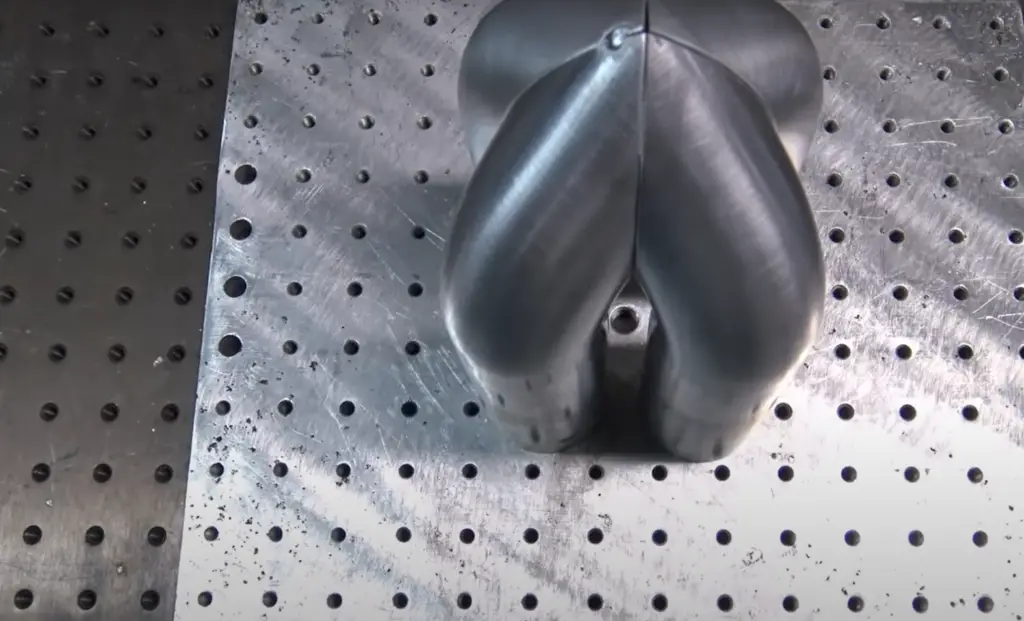

6061 aluminum is one of the most versatile and commonly used aluminum alloys. It has a wide range of applications, from automotive body panels to aerospace components, due to its good formability, weldability, machinability and high strength-to-weight ratio. The alloy can be extruded easily into complex shapes and it provides excellent corrosion resistance when exposed to salt water or other corrosive elements. It’s also an ideal material for many engineering applications such as machine parts, frames, brackets and couplings.

Additionally, 6061 aluminum is often chosen for uses in outdoor structures such as railings and fences because of its ability to resist weathering conditions like rain and snow without losing its durability or strength over time. Its light weight makes it an ideal choice for marine applications, such as boat components and engine covers. It is also popular in the automotive industry, where it is used to make suspension parts, wheels and car bodies. Finally, 6061 aluminum’s strength and durability have made it a favorite material for recreational vehicles like ATVs, snowmobiles and mountain bikes.

Overall, 6061 aluminum is a versatile alloy that can be used in a wide variety of applications due to its strength, lightweight and corrosion resistance properties. Its versatility means that it can be used in many different industries and for many different purposes. Whether you need an aerospace component or an RV part, there’s no doubt that 6061 aluminum has you covered!

Which Is Cheaper, 5052 or 6061?

The cost of both 5052 and 6061 aluminum varies based on the form in which you purchase it. Generally, 5052-H32 has a higher cost than 6061-T6 due to its greater strength and corrosion resistance. However, since the two types are commonly found in sheet form, they often have similar prices. For instance, when comparing 1/8” thick sheets, the price difference between 5052-H32 and 6061-T6 is usually small enough that it won’t be a major factor when selecting one alloy over the other. If pricing is your primary consideration for choosing an aluminum alloy, you may want to shop around for different suppliers until you find the best deal.

Additionally, if there’s a particular application or form of aluminum that you need, the cost could differ significantly between 5052 and 6061.

Ultimately, it’s important to take into account both the pricing and performance when choosing which alloy is best for your project.In summary, either 5052 or 6061 aluminum could be cheaper depending on the form and supplier that you select. In terms of performance characteristics such as strength and corrosion resistance, however, 5052 typically has an edge over 6061. Still, if price is your main concern then it’s recommended that you compare different suppliers to get the best deal. Ultimately, it’s important to weigh both price and performance when selecting a material for any application. [6]

Does 6061 Aluminum Rust?

6061 aluminum is made up of both magnesium and silicon, making it a heat-treatable alloy. It is also commonly referred to as an architectural alloy because of its strength and corrosion resistance. This combination makes it highly resistant to corrosion in most cases, however 6061 aluminum may still corrode if exposed to certain elements or conditions. The areas where 6061 aluminum may be more vulnerable to rust include untreated marine environments, acidic solutions such as vinegar, and high temperature exposure for extended periods of time. To protect against these potential risks, using protective coatings and proper maintenance can ensure that your 6061 aluminum will not corrode over time.

Additionally, regular inspection for signs of damage or deterioration should be done in order to take preventative measures before rust sets in. Applying a protective coating of wax or paint can also help to maintain the integrity of your 6061 aluminum and prevent it from rusting over time. Proper maintenance and regular inspection are essential for preventing corrosion and ensuring that your 6061 aluminum lasts for years to come. With proper care, you can keep your 6061 aluminum shining like new!

FAQ

Is 6061 aluminum better than 5052 for machining?

The answer depends on the desired end application. Generally, 5052 aluminum alloy is preferred for machining operations due to its superior malleability and ductility, making it easier to cut and form than 6061 aluminum alloy. However, 6061 aluminum provides increased strength and hardness over 5052 aluminum, making it ideal for more demanding applications such as structural components. Additionally, both alloys are weldable using various welding techniques. Therefore, it really comes down to what kind of use you intend for the final product when deciding which option is ideal for your project or needs. Ultimately, a combination of both 5052 and 6061 may be an even better solution depending on the specific requirements and design parameters of your project.

Is 6061 t4 better than 5052 H32?

It depends on your application. 5052 H32 is a higher strength alloy than 6061 T4 and is generally used in applications that require greater strength. It has excellent corrosion resistance, especially in marine environments. However, it is not as weldable or formable as 6061 T4. 6061 T4 is an alloy that offers good formability and weldability while maintaining moderate strength levels. It is the most commonly used aluminum alloy for structural applications such as automotive parts, machinery components, frames, and extruded shapes. As compared to 5052 H32, 6061 T4 provides better corrosion resistance but lower mechanical properties.

Is 5052 or 6061 cheaper?

The cost of both 5052 H32 and 6061 T4 is usually similar, though it will depend on the specific alloy used and the form in which they are purchased.

When purchasing raw material stock, thicker sections may also be cheaper due to decreased processing costs associated with manufacturing parts from them.Is 5052 stronger than 6061?

In general, 5052 H32 offers higher strength than 6061 T4. However, it is important to note that there are several different tempers available for each type of aluminum alloy. The temper designation indicates how much work has been done to the metal and can affect both its strength and ductility. 5052 H32 is a higher strength alloy than the standard temper of 6061 T4, but it is less formable. To compare two similar tempers, such as 6061 T6 vs. 5052 H32, the 5052 H32 would generally be stronger. Overall, both alloys have their own advantages and disadvantages depending on the application they are used for.

What are the advantages of 5052 Aluminium alloy?

5052 aluminum is a popular alloy for general sheet metal fabrication and architectural applications. It has excellent properties such as high strength, good formability, corrosion resistance, weldability, and surface finish. Due to these advantages, 5052 aluminum is often used in the automotive industry as well as many other industries where parts need to be strong and able to resist corrosion over time. The fact that it can be easily formed makes it a great material for intricate parts such as brackets, housings, tanks or covers. Additionally, its aesthetic properties make it suitable for decorative trim pieces and panels. Another advantage of 5052 aluminum alloy is that it has an exceptional fatigue life which makes it perfect for components subject to dynamic loading like pistons or shafts. Thanks to its combination of good formability and corrosion resistance, it is often used in marine applications like boats or yachts. As a result, many boat manufacturers use 5052 aluminum alloy for their hulls and decks.

Useful Video: 5052 VS 6061

Conclusion

When it comes to 5052 vs. 6061 aluminum, both alloys possess strength and corrosion resistance in addition to various other properties that make them suitable for numerous applications. However, each alloy offers different benefits depending on the application. 5052 is a softer alloy that can be easily cold worked and formed in tempers ranging from H22 to O, while 6061 has excellent weldability and machinability characteristics and higher strength than 5052 aluminum, making it more suitable for structural applications such as aerospace parts or automotive components. Ultimately, the choice between these two alloys depends upon the specific needs of the application at hand. With their many strengths, understanding the differences between 5052 vs. 6061 aluminum is essential when selecting an alloy for a particular application.

References:

- https://www.industrialmetalsupply.com/blog/6061-vs-5052-aluminum

- https://www.nemaenclosures.com/blog/5052-vs-6061-aluminum-property-strength-differences/

- https://www.thomasnet.com/articles/metals-metal-products/6061-aluminum-vs-5052-aluminum/

- https://metalscut4u.com/blog/post/5052-aluminum-vs-6061-aluminum.html

- https://blog.thepipingmart.com/metals/aluminium-6061-vs-5052-whats-the-difference/

- https://www.chalcoaluminum.com/blog/differences-5052-6061-aluminum/