If you are looking for a comprehensive guide on how to melt tungsten, you have come to the right place. This blog post will discuss all of the different ways that you can melt tungsten, as well as provide some tips on how to get the best results. It will also talk about the different types of equipment that you can use to melt tungsten, and what factors you need to consider when choosing a method.

5 Interesting Facts About Tungsten

- Tungsten is one of the densest elements on earth, with a density more than twice that of lead and about 1.7 times that of gold.

- Tungsten has the highest melting point (3410°C) among all metals, making it ideal for applications involving extreme temperatures or pressures, such as jet engines and electric light bulbs.

- Tungsten is extremely strong and hard but can be brittle if not alloyed properly – it’s often combined with other metals like nickel or cobalt to create an alloy that is perfect for specific uses.

- Tungsten has been used in jewelry and decorative items since ancient times – it was sometimes referred to as wolfram, a term derived from the German word for tungsten.

- Tungsten plays a crucial role in many modern-day technologies, including semiconductor manufacturing and consumer electronics. It is also used to make cutting tools and wear-resistant coatings for industrial machinery.

- The unique properties of tungsten make it an incredibly versatile material that can be used in a wide range of applications. Whether you’re looking for jewelry or parts for an engine, tungsten could be a perfect choice [1]!

Why Melt Tungsten?

Tungsten has several properties that make it an ideal material for melting. Tungsten is extremely heat-resistant, with a melting point of around 3422 °C (6192 °F). It also has a very high density which makes it difficult to melt and offers superior thermal conductivity, allowing it to quickly transfer heat away from the source. Lastly, tungsten is highly resistant to corrosion and oxidation, meaning it can be used in various industrial applications without fear of degradation. These properties combined make tungsten an excellent choice when seeking to melt materials such as steel or other metals.

Not only does tungsten offer higher temperatures than other common metals like iron or copper, but its resistance to corrosion and oxidation also makes it a more dependable choice in many industries.

It is also often used in the production of tungsten carbide tools, which are prized for their strength and durability.In conclusion, tungsten has several desirable properties that make it an ideal material for melting operations. Its exceptional heat resistance, high density, thermal conductivity, and resistance to oxidation and corrosion make it a highly sought-after choice for many industrial applications. With its advantageous characteristics, tungsten is sure to remain a go-to option when seeking to melt materials quickly and efficiently.

Equipment Needed for Melting Tungsten

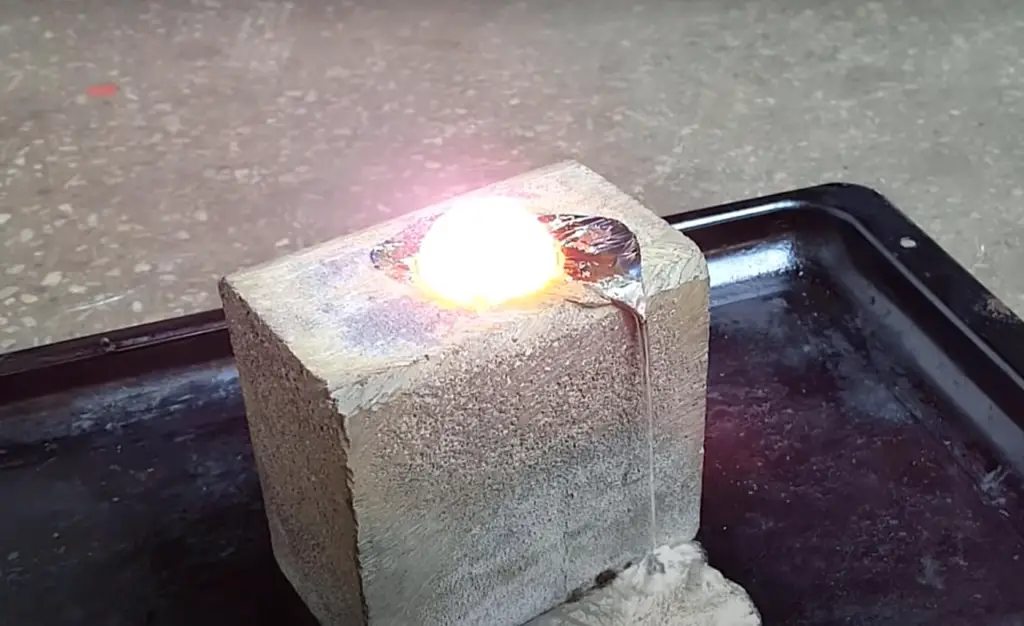

Tungsten is a dense, high melting point metal. This makes it ideal for applications such as furnace components and parts for high-temperature machines. Melting tungsten requires special equipment to safely achieve its required temperatures and process the molten material.

The most important piece of equipment for melting tungsten is an induction furnace. These furnaces use electromagnetic fields generated by coils of copper wire wound around an iron core to create heat in the tungsten without direct contact with the flame or heating element.

Along with a powerful induction furnace, other specialized pieces of equipment are necessary for safe and efficient melting and processing of tungsten. These include vacuum pumps, thermocouples, crucibles, water-cooled tongs, and quenching tanks.

Above all else, safety should be the top priority when melting tungsten. Be sure to take the appropriate precautions when working with this high-temperature material. Wear protective clothing such as heavy-duty gloves and a face shield; use proper ventilation; keep flammable materials away from the furnace; and always have a fire extinguisher nearby in case of accidents or emergencies. Following these simple rules will help ensure a successful molten tungsten project [2].

How to Melt Tungsten?

Prepare your work area

Before beginning the process of melting tungsten, it is important to make sure you are working in a safe and organized area. It is essential to have your safety gear such as goggles, work gloves, and fire retardant clothing on hand.

Additionally, ensure that all flammable materials and liquids are removed from your work area.

Put on your safety equipment

Before you start the process of melting tungsten, it is important to put on your safety equipment. This includes goggles, work gloves, and fire-retardant clothing. Be sure that all of these items are securely in place before beginning the process. Additionally, ensure that there is adequate ventilation in the area.

Gather materials

You will need a few materials for melting tungsten such as tungsten rods or pellets, a crucible (a ceramic container used for holding molten material), and an induction furnace or torch. You may also choose to use an argon or nitrogen atmosphere during melting; however, this step can be dangerous so it should only be done by experienced professionals.

Set up your furnace

Tungsten melts at a very high temperature of 3422 degrees Celsius (6192° Fahrenheit). To reach this temperature, you will need an industrial-grade furnace capable of reaching these extreme temperatures. Make sure to follow all the manufacturer’s instructions when installing or operating your furnace.

Insert tungsten into the furnace

Once you’ve reached the right temperature, you can insert the tungsten into the furnace.

Depending on the size and shape of your tungsten, you may need to break it into smaller pieces to fit in your furnace.Melt Your Tungsten

Once your tungsten is securely inside the furnace, all you have to do is wait for it to melt down. This will usually take a few minutes depending on the amount and size of material you’re working with. Once it’s fully melted, be sure to turn off your furnace and allow it to cool before attempting to remove the molten metal from the furnace.

Dispose of Your Tungsten

Once your tungsten has cooled, you can remove it from the furnace and place it in a designated area or container for safe disposal. Make sure to take all necessary safety precautions when handling molten metal to prevent any potential accidents or injuries.

Molten tungsten is an extremely hot and dangerous material, so make sure to work with caution and practice proper safety procedures throughout the entire process. With the right tools and know-how, anyone can successfully melt tungsten at home [3].

Safety Considerations When Melting Tungsten

When melting tungsten, certain safety considerations must be taken into account. First and foremost, it is important to wear protective clothing such as a face shield, gloves, and certified heat-resistant clothing when working with tungsten and its heated components. Additionally, any flammable substances should be kept out of the work area; sparks or flying debris can easily ignite combustible materials. A fire extinguisher should also be kept nearby in case of an emergency.

Furthermore, due to the high temperatures required for melting tungsten (3200°F or higher), extreme caution must be taken to avoid direct contact with the molten metal or accidental splashing which can cause serious burns or even blindness. It is also important to be aware of the toxicity of tungsten and any fumes emitted from its melting process. To ensure safety, proper ventilation should be maintained in the area to ensure that all vapors or airborne particles are quickly dispersed.

Lastly, it is important to not leave molten tungsten unattended as this can lead to potential hazards or accidents. Following these few but essential guidelines will help keep your workspace safe when melting tungsten.

FAQ

Is tungsten easy to melt?

Yes, tungsten is relatively easy to melt. It has a melting point of 3410°C (6170°F). This is slightly lower than some other metals like iron, which melt at 1535°C (2795°F). The fact that tungsten has such a high melting point means it can be used in applications where high temperatures are needed, such as jet engines and rocket nozzles. Tungsten alloys are also used for electrical contacts because they don’t corrode easily. Additionally, tungsten can be melted using an electric current or through the use of a furnace, depending on the purpose it will be used for.

What does it take to melt tungsten?

Tungsten can be melted using either an electric current or a furnace. When melting tungsten with an electric current, it must be passed through the metal to generate enough heat to cause the atoms to move around and form new bonds. This process is known as arc-melting. On the other hand, when melting tungsten in a furnace, temperatures of up to 3410°C (6170°F) may be required. It is important to note that tungsten should never be melted in an oxygen environment because it can react violently with oxygen at high temperatures, leading to explosions and fires. Additionally, all safety precautions should always be taken when working with molten tungsten.

What are some applications of tungsten?

Tungsten is used in a variety of applications due to its unique properties. Tungsten is highly resistant to corrosion and high temperatures, making it ideal for use in industries such as aerospace and defense.

It is also often used in electrical contacts, lightbulb filaments, drill bits, and welding electrodes. Additionally, tungsten alloys are often used in jewelry because they are durable and don’t corrode easily. Finally, tungsten compounds are sometimes used for medical radiotherapy treatments due to their ability to absorb radiation.

What other metals have a higher melting point than tungsten?

Some metals have a higher melting point than tungsten, including molybdenum (2617°C/4743°F), tantalum (3017°C/5431°F), and rhenium (3180°C/5756°F). Additionally, some alloys of these metals have higher melting points than tungsten. For instance, molybdenum-rhenium alloy has a melting point of 3460°C (6250°F), which is slightly higher than that of pure tungsten. These metals are often used in high-temperature applications such as jet engines and nuclear reactors where temperatures exceed the capabilities of tungsten.

What safety precautions should be taken when working with molten tungsten?

When working with molten tungsten, it is important to take safety precautions to avoid accidents and injuries. Protective clothing, such as goggles, gloves, and long-sleeved shirts should be worn at all times when working with molten tungsten. Additionally, it is important to ensure that the area is well-ventilated and free of flammable materials to prevent any fires or explosions. Finally, it is also important to never melt tungsten in an oxygen environment because it can react violently with oxygen at high temperatures.

Can a furnace melt tungsten?

Yes, a furnace can be used to melt tungsten. However, it is important to note that temperatures of up to 3410°C (6170°F) may be required to achieve this. Additionally, all safety precautions should always be taken when working with molten tungsten. It is also important to never melt tungsten in an oxygen environment because it can react violently with oxygen at high temperatures, leading to explosions and fires.

What’s the hardest thing to melt?

The hardest thing to melt is a metal called osmium. It has the highest melting point of any metal, at around 3045°C (5513°F). Additionally, due to its high density and chemical reactivity, it is also difficult to handle in its molten state. As such, it is not widely used in applications that require melting. Instead, other metals such as molybdenum and tungsten are generally preferred for their greater versatility and easier handling in molten states.

Useful Video: Sublimating Tungsten with Hydrogen and Oxygen

Conclusion

Melting a tungsten wire using a current is an interesting yet simple experiment to conduct. Not only does it demonstrate the principles of electric current and resistance, but it also gives students tangible proof that electricity can produce heat. With the help of the right materials, equipment, and safety measures, this experiment can be conducted safely in any classroom or lab environment. As students gain knowledge about electrical currents and their effects on matter, they will develop an appreciation for the power of electricity in their everyday lives.

References:

- https://monroeengineering.com/blog/5-fun-facts-about-tungsten/

- https://blog.thepipingmart.com/metals/how-to-melt-tungsten-at-home

- http://www.ctia.com.cn/TungstenNews/2012/112705.html