It can be quite daunting to cut tungsten for the first time. There are a lot of factors to consider, and it’s easy to make a mistake if you’re not familiar with the process. This comprehensive guide will walk you through the entire process step-by-step. It will discuss the tools you need, the best way to cut tungsten, and what to do if things go wrong. By following this advice, you’ll be able to cut tungsten like a pro in no time!

What is Tungsten used for?

Tungsten is used for a wide range of applications, from industrial and engineering uses to consumer products. It has a high melting point and is extremely strong and durable, making it an ideal material for manufacturing tools and components that need to withstand extreme temperatures or corrosive environments.

In addition, tungsten has become an increasingly popular material in jewelry because of its durability and affordability. It is also used in computer chips as a heat conductor, due to its low thermal expansion rate. Finally, tungsten can be alloyed with other metals or elements to create specialized materials with unique properties that are used in a variety of industries. Alloys made from tungsten are commonly found in aerospace, defense, and medical applications, as well as in electronics.

Tungsten alloys are often used in place of high-strength steel to reduce weight or increase strength. They can also be used to create radiation shielding, as well as energy absorption materials and components. Tungsten carbide is a very hard and durable substance that is used to make cutting tools, drill bits, and wear-resistant coatings. It is also used for jewelry, including rings and watches, due to its strength and scratch resistance. In addition, tungsten is often alloyed with other metals such as nickel or cobalt to create high-strength magnets. These magnets can be used in a variety of applications, including power generation and automotive components.

Overall, tungsten is an incredibly versatile material with unique properties that make it ideal for many different industries and applications. Its impressive strength, heat resistance, and affordability make it a popular choice for many industrial and consumer products. With its wide range of uses, tungsten is an invaluable resource that will continue to be relied on for years to come [1].

Can Tungsten Rings Be Cut off In Case of Emergency?

Tungsten rings can be cut off in case of emergency. This is because tungsten is a very hard metal that requires special tools and expertise to work with. The best way to remove a tungsten ring in an emergency is to use a ring saw or diamond-tipped tool. If these methods are not available, then a hacksaw or Dremel tool can be used to cut the band. It is important to note that cutting off a tungsten ring may cause damage to the ring and its engravings. Therefore, it is advisable to have an experienced jeweler handle the removal of the ring.

Also, depending on the severity of the emergency, it may be wise to seek medical attention first before attempting to remove the ring. Additionally, if possible, contact an emergency locksmith service that specializes in removing finger jewelry. They have special tools designed for this purpose and can usually get the job done quickly and safely.

In conclusion, tungsten rings can be cut off in case of emergency, though it is important to note that this may cause damage to the ring and its engravings. It is therefore recommended that an experienced jeweler or emergency locksmith be contacted for safe and effective removal [2].

3 tips to correctly sharpen tungsten electrodes

Step 1: Cutting tungsten to length

Tungsten electrodes should be cut to the desired length for use in welding. This helps reduce spatter and provides a better arc transfer. It is important to have clean, straight cuts when cutting tungsten electrodes so that they fit properly into the torch collet or holder.

Step 2: Tungsten electrode sharpening (beveling and grinding)

After cutting tungsten electrodes to length, they should be sharpened by beveling and grinding the points. Beveling ensures that the arc is focused at the tip of the electrode and provides a consistent arc transfer.

Use an angle grinder with a dedicated tungsten grinding wheel to sharpen the electrode without changing its diameter or melting the tungsten.

Step 3: Tungsten electrode tip grounding

After the tungsten is cut and beveled, it should be grounded to ensure a good electrical connection between the electrode and the welding machine. This involves touching the tip of the tungsten electrodes with a piece of clean steel or copper to ground them. Make sure there is no contamination on either the electrode or grounding surface, as this could cause poor arc transfer.

Following these steps will help ensure that your tungsten electrodes are correctly sharpened and ready for use in welding or cutting. Sharpening tungsten electrodes correctly is an important part of the welding process, as it helps to ensure a good arc transfer and better weld quality.

Cutting tungsten step by step

- Begin by marking the tungsten piece with a sharpie or other permanent marker to identify where you will be cutting it.

- Secure the tungsten in a vise so that you have easy access to it and can safely cut without putting yourself at risk for injury.

- Put on safety glasses and gloves to protect yourself from sparks and debris.

- Insert a tungsten carbide tip cutting wheel into the angle grinder that is designed for use with tungsten. Make sure it has been installed correctly and securely.

- Set the speed on the grinder to its highest setting, which will be around 10,000 RPM.

- Turn on the angle grinder and slowly begin to make contact with the tungsten piece, applying minimal pressure. Let the speed of the grinder do all of the work.

- Cut along your marked line, taking care to keep a steady hand and to not overheat the metal by cutting too quickly.

- Once you have reached the end of your line, turn off the grinder and remove the cutting wheel.

- Use a file to smooth any rough edges that were left behind after cutting and to ensure a clean cut.

- Remove the tungsten piece from the vise and inspect it to ensure that the cut was clean and precise.

- Dispose of any debris and lubricants properly, according to the manufacturer’s instructions.

- Store the tungsten piece in a safe place away from heat or humidity until it is ready for use.

By following these steps carefully, you can safely and accurately cut a tungsten piece.

With patience and precision, you can achieve professional results with any project that requires cutting tungsten.Safe tips for cutting Tungsten Carbide

Tungsten carbide is an incredibly strong material used in a variety of industrial and commercial applications. However, without proper care and safety precautions, cutting it can be extremely hazardous. Below are some tips to help ensure the safe handling and cutting of tungsten carbide:

- Always wear protective gear when working with tungsten carbide, including gloves, goggles, and a face shield.

- Make sure to use sharp cutting tools when working with tungsten carbide in order to avoid any slipping of the tool from the material being cut.

- Use coolants or lubricants when cutting tungsten carbide as this will help reduce friction and heat.

- Use a vise or clamps to secure the material being cut in order to avoid slipping and potential injury.

- Make sure all cutting tools are properly maintained and inspected before use to ensure sharpness and good condition.

- Properly ventilate any area where tungsten carbide is being cut in order to reduce any potential inhalation of harmful particles.

- Never force the cutting tool when working with tungsten carbide as this can cause binding and potentially break the tool or create a hazardous situation.

- Take frequent breaks while cutting to avoid fatigue and ensure that all safety precautions are followed correctly.

- Dispose of any debris and materials properly to prevent any potential hazards.

- Always keep an up-to-date first aid kit nearby when cutting tungsten carbide to ensure that prompt medical attention can be provided if needed.

How to maintain Tungsten products?

Maintaining Tungsten products is key to ensuring that they remain in top condition and keep performing optimally. Here are some tips for properly caring for your Tungsten products:

- Clean regularly – Regularly wipe down the surface of any Tungsten product with a soft cloth to remove dust, dirt, or other debris.

- Store properly – If you aren’t using a Tungsten product, store it in a cool, dry place away from direct sunlight. This will help keep the material from warping or becoming damaged over time.

- Use mild soap and water – For deeper cleaning, use a gentle detergent and warm water to wipe down the surface of your Tungsten product. Avoid harsh cleaners or abrasives, as these can wear away at the material over time.

- Take care when handling – Always use gloves when carrying or handling a Tungsten product to avoid any potential damage from contact with sharp objects like jewelry or keys.

- Inspect for signs of damage – Regularly inspect your Tungsten product for any signs of damage, such as cracks or chips. If you notice any, contact a professional to make sure the product can be repaired without further risk of damage.

By following these simple tips and taking care of your Tungsten products, you can help ensure they stay in top condition and continue to provide years of reliable service.

They can help answer any additional questions you may have and give you the best advice on how to properly care for your Tungsten products.FAQ

Can an angle grinder cut tungsten?

No, an angle grinder is not designed to cut tungsten. Tungsten is a very hard metal and requires special tools for cutting it, such as a diamond blade or carbide-tipped saw blade. Attempting to use an angle grinder to cut tungsten will damage the blade and could lead to dangerous flying debris. If you need to cut tungsten, it is best to use specialized tools that are designed for the task.

Can an angle grinder cut steel?

Yes, an angle grinder can be used to cut through steel. The grinding wheel should be made of a material that is suitable for cutting steel such as aluminum oxide or zirconia. It is important to use the correct safety equipment and to take proper precautions when using an angle grinder, as the sparks generated by cutting steel can be hazardous. Additionally, you should make sure that you select a grinding wheel with enough power for your particular job.

How do you cut and grind tungsten?

The best way to cut and grind tungsten is with specialized tools designed specifically for the job. You can use a diamond blade or carbide-tipped saw blade for cutting, and an angle grinder equipped with a grinding wheel made from special materials such as aluminum oxide or zirconia for grinding.

Safety gear such as eye protection, dust masks, and gloves should be worn when working with tungsten. Additionally, it is important to take proper precautions when cutting or grinding tungsten, as the sparks generated by these activities can be hazardous.

What safety equipment do I need for using an angle grinder?

When using an angle grinder, you should always wear the proper safety gear. This includes eye protection, dust masks, hearing protection, and gloves. Additionally, you should make sure that you select a grinding wheel with enough power for your particular job and that it is made of a material suitable for cutting steel. It is also important to take proper precautions when using an angle grinder as the sparks generated by cutting steel can be hazardous.

Can you cut tungsten in half?

Yes, it is possible to cut tungsten in half. The best way to do so is with a diamond blade or carbide-tipped saw blade as these are specifically designed for cutting hard metals such as tungsten. Safety gear such as eye protection, dust masks, and gloves should be worn when working with tungsten.

What is used to cut tungsten carbide?

Tungsten carbide can be cut with specialized tools such as a diamond blade or carbide-tipped saw blade. Additionally, an angle grinder equipped with a grinding wheel made from special materials such as aluminum oxide or zirconia can also be used for cutting tungsten carbide. Don’t forget about safety gear such as eye protection, dust masks, and gloves when using any tools to cut tungsten carbide.

What can destroy tungsten?

Tungsten is a very hard metal that is difficult to destroy. Some acids such as hydrochloric acid can be used to dissolve tungsten, but this should only be done in a laboratory setting with proper safety precautions. Generally speaking, the best way to get rid of tungsten is by recycling it.

Is tungsten toxic to the touch?

No, tungsten is not toxic to the touch. This material is generally considered to be non-toxic and safe to handle. Moreover, wearing safety gear such as gloves and dust masks is recommended when working with tungsten to protect yourself from any flying debris or sparks generated by cutting or grinding the material. It is important to note that some forms of tungsten, such as tungsten carbide, may contain trace amounts of toxic metals such as cobalt. Therefore, it is best to research the particular type of tungsten you are working with before handling it.

What is tungsten’s weakness?

Tungsten’s primary weakness is its brittleness. This material is very hard and has a high melting point, but it can still be brittle when subjected to extreme temperatures or shocks.

Additionally, tungsten can corrode in certain types of acidic environments and may react with other metals such as beryllium and aluminum. Therefore, it is important to consider the environment in which tungsten will be used when selecting it for a particular job.

Can tungsten stop a bullet?

No, tungsten is not strong enough to stop a bullet. This material is very hard and resistant to wear, but it is not strong enough to resist the impact of a high-velocity bullet. Several other materials such as titanium or boron carbide can be used for this purpose.

What type of saw blade should be used for cutting tungsten?

The best type of saw blade to use for cutting tungsten is a diamond blade or carbide-tipped saw blade. These blades are specifically designed for tough materials such as tungsten and will provide the best results when cutting this material.

What is tungsten weak against?

Tungsten is weak against extreme temperatures and shocks, as these can cause the material to become brittle. Additionally, tungsten is vulnerable to corrosion in acidic environments and may react with certain other metals such as beryllium or aluminum. Therefore, it is important to consider the environment in which tungsten will be used before selecting it for a particular job.

Which country is rich in tungsten?

China is the leading producer of tungsten in the world. The country has a large supply of the material and accounts for approximately 85% of global production. Other countries that are known to produce tungsten include Russia, Canada, and the United States.

Can tungsten be recycled?

Yes, tungsten can be recycled. This is the best way to cope with tungsten waste, as it can be reused in various applications and save energy and resources compared to producing new material from scratch. Additionally, recycling tungsten can help reduce the environmental impact of mining for this material.

What tools are used to shape tungsten?

Tools such as saws, drills, grinders, and lathes are commonly used to shape tungsten.

It is important to take safety precautions when using these tools, such as wearing protective gear like dust masks and gloves. Additionally, it is recommended to use diamond or carbide-tipped blades when cutting tungsten since they are specifically designed for tough materials.

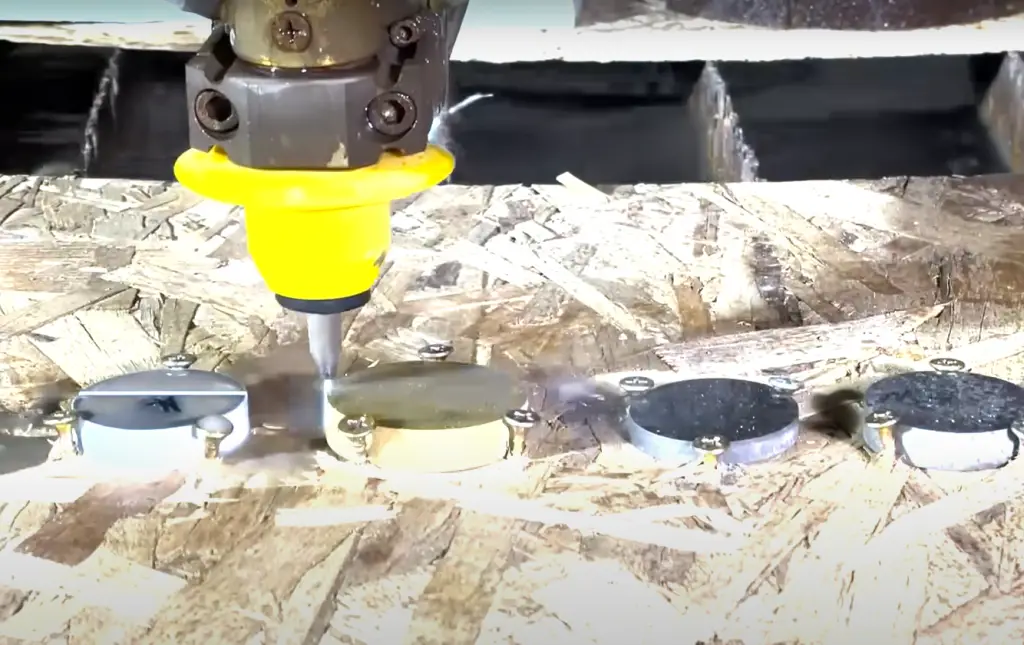

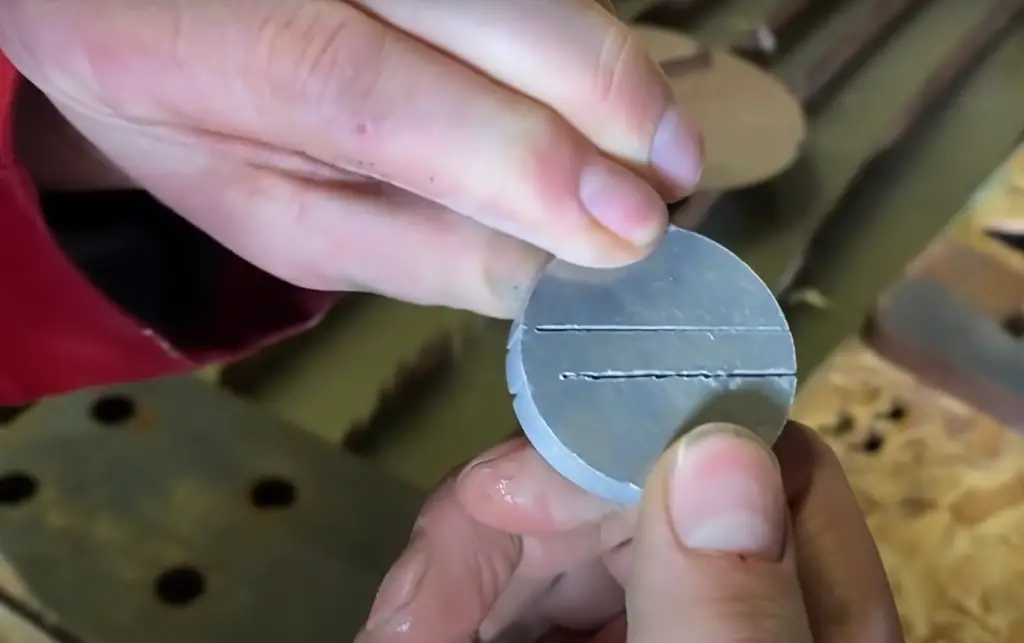

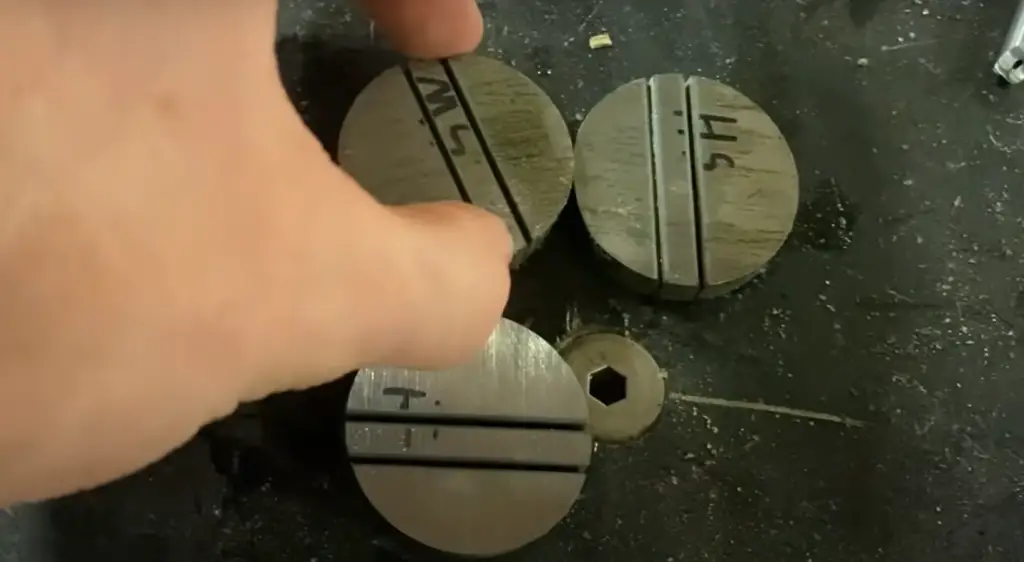

Useful Video: How Strong Is Tungsten? Waterjet Cutting Test

Conclusion

Cutting tungsten is a challenging process that requires specialized tools and techniques. If done correctly, however, it can be a rewarding experience with beautiful results. By understanding the properties of tungsten and using the right cutting tools, you can achieve an accurate, clean cut without any damage to your workpiece. With some practice and patience, you can master the art of tungsten cutting and create stunning pieces of jewelry or other works of art. With the right tools and techniques, you can confidently cut tungsten with great results every time. In conclusion, tungsten is a durable material that requires specialized tools and techniques to cut it properly.

References:

- https://www.rsc.org/periodic-table/element/74/tungsten

- https://www.larsonjewelers.com/can-tungsten-rings-be-cutoff#