Titanium is one of the strongest and most durable metals known to man. Because of its high strength-to-weight ratio, it is widely used in many different applications, including aerospace, medicine, and the automotive industry. But what happens when titanium is exposed to extreme heat? In this post, we’ll take a look at what temperature titanium melts and how this information can be used in various industries.

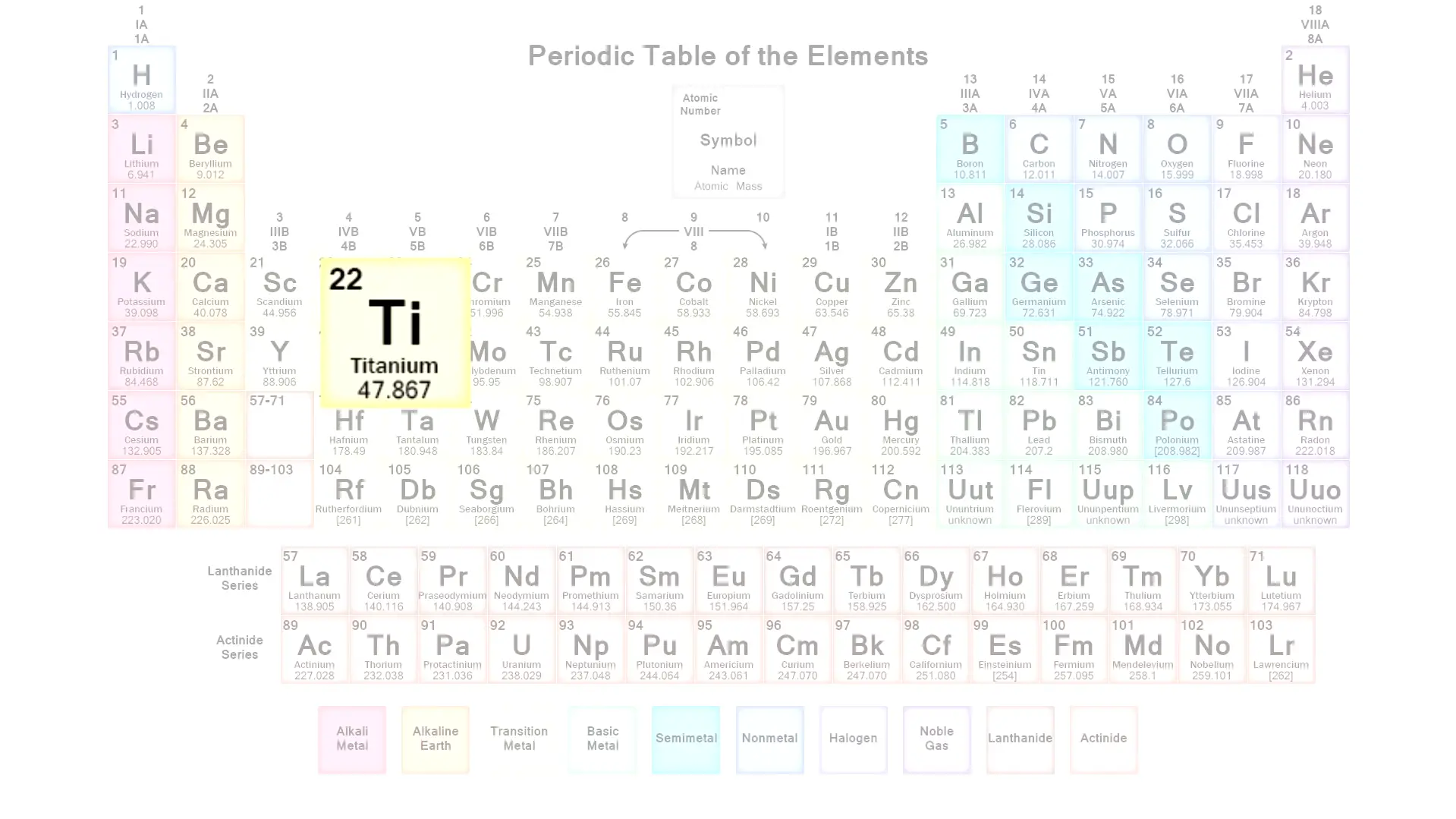

Titanium: What It Is

Titanium is a metal that has truly revolutionized the modern world. It is a naturally occurring element that is abundant in the Earth’s crust and is used in various applications from aviation, medicine, and even fashion. It is famous because of its durability, resistance to corrosion, and lightweight, which makes it easier to use in applications where weight is a concern. In this blog, we will explore the uses of titanium and why it has become the go-to material for modern technology.

Why is Titanium so Strong?

One of the most significant benefits of titanium is that it is really strong. Titanium has a tensile strength about twice that of aluminum, which makes it ideal for structural components in aircraft. The reason behind its strength lies in its atomic structure. Titanium is a transition metal, and its ability to form crystalline structures leads to higher strength and ductility.

Titanium’s Corrosion Resistance

Another benefit of titanium is its corrosion-resistance.Chemicals, saltwater, and even acids are unable to penetrate titanium’s oxide layer, as a result it is a great option for marine applications. Additionally, this layer also acts as a self-healing mechanism that repairs any damage to the surface and prevents further corrosion.

Medical Applications of Titanium

Titanium has found many applications in modern medicine. It is non-toxic and biocompatible. It is commonly used in dental implants, joint replacement surgeries, and spinal implants. Furthermore, titanium’s biological properties allow it to integrate with living tissues easily, which leads to faster healing times.

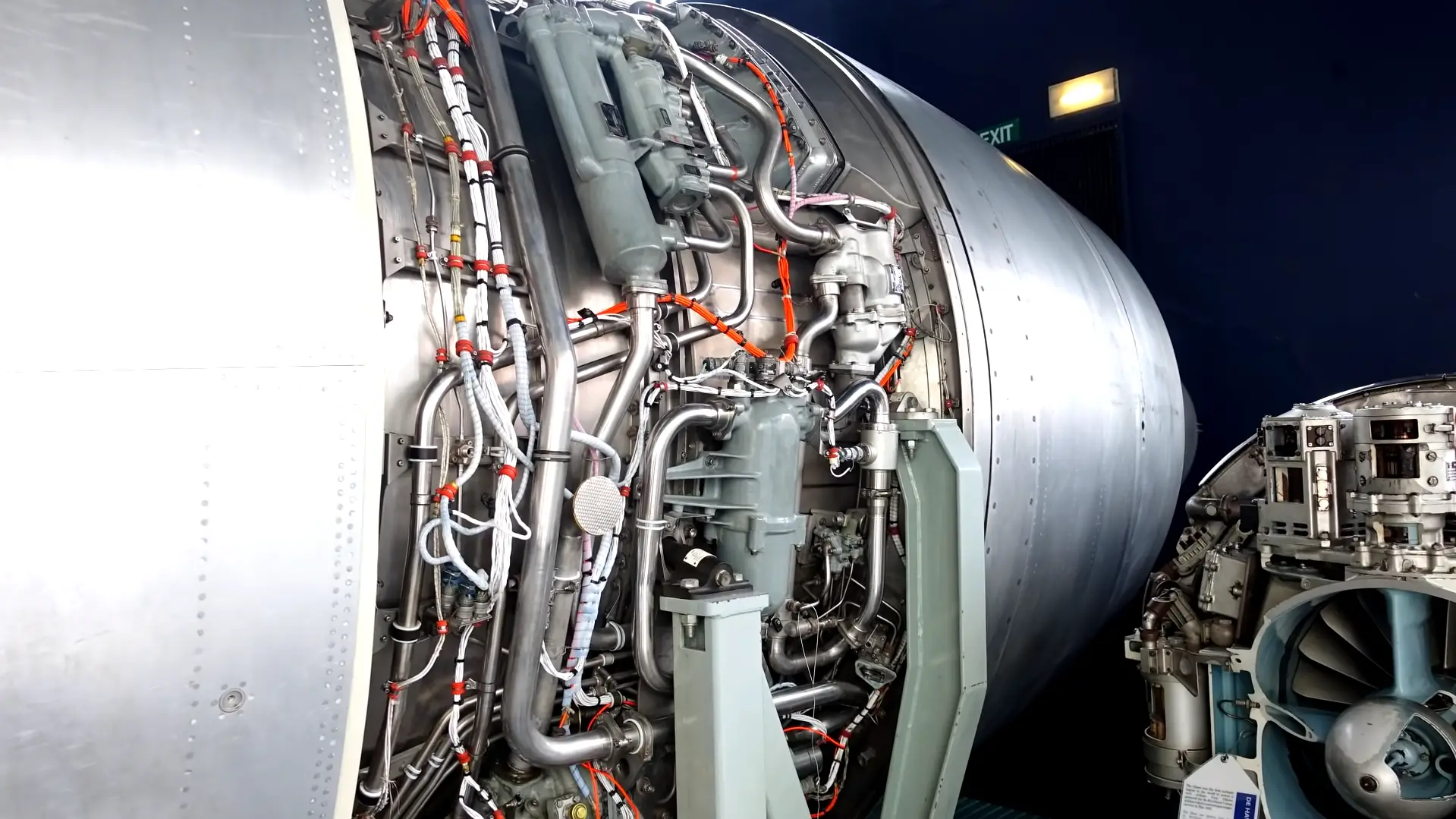

Aerospace Applications of Titanium

Aerospace is one of the largest applications of titanium. It is an essential material for constructing aircraft, rockets, and space shuttles. Titanium’s resistance to fatigue and high-temperature applications also makes it ideal for jet engine components.

Fashion Applications of Titanium

Titanium is lightweight, strong, and hypoallergenic, and these properties have made it a popular choice for jewelry. Additionally, its ability to take on different colors through anodizing has made it a unique and distinct material for watchcases, phone covers, and even eyeglasses.

Titanium is indeed a wonder material that has revolutionized a number of spheres in the modern world. The future of titanium is exciting, with ongoing research, innovations, and development in its applications. The possibilities are endless, and we can only wait and see how this wonder material continues to shape the modern world.

Characteristics of Titanium

Titanium has an incredible array of unique characteristics that make it the metal chosen for a range of different applications. Whether you are looking for a material that is incredibly strong, lightweight, and durable, able to withstand even the most extreme environments, titanium is the metal that can deliver. Now we will explore the key characteristics of titanium, and explain exactly why this amazing metal has been so popular for so many years.

One of the most defining characteristics of titanium is that it is an incredibly lightweight metal. In fact, it is around 40% lighter than steel, but still just as strong. This makes it ideal for use in applications where weight is a concern, such as aircraft manufacturing, where every pound counts. Titanium is an attractive material for use in consumer products, such as high-end bicycles, where users may be looking to shave off a few ounces without sacrificing strength or durability.

Titanium is also incredibly strong, durable and fatigue resistant. Its high tensile strength makes it capable of withstanding extreme amounts of pressure and weight, while its fatigue resistance means that it can withstand repeated stress and strain over time without becoming weakened or damaged.

Another impressive characteristic of titanium is its heat-resistance. Titanium can withstand temperatures of up to 600 degrees Celsius without losing its strength or other physical properties. This makes it an essential material for industries where extreme heat is a constant concern.

Finally, titanium is a highly biocompatible metal which means that it is compatible with living tissue and does not cause any adverse reactions or side effects. This makes it the perfect material for use in medical implants and other devices, where biocompatibility is essential. Titanium’s biocompatibility makes it ideal for use in dental implants, joint replacements, spinal fusions and other surgical procedures.

Titanium is an incredibly versatile and unique metal with an amazing array of characteristics that make it the material of choice for a wide range of different industries. From its lightweight nature to its impressive corrosion resistance, titanium is the ideal metal for everything from consumer products to highly specialized industrial and medical applications. So, whether you are looking to create the next generation of cutting-edge aerospace components, or simply need an ultra-strong and durable material for your next product, titanium is the metal that can deliver.

Titanium Melting Process

The first challenge in titanium melting is that it has a high melting point of 1,668°C, making it one of the toughest metals to melt. Hence, special furnaces are required that can generate temperatures as high as 1,800°C to 2,000°C to melt the titanium. Moreover, during melting, titanium is known to absorb gasses like nitrogen, hydrogen or oxygen that can impair the metal’s properties. Therefore, the furnace’s atmosphere is tightly controlled to prevent gas contamination by using vacuum, argon or helium environments. [1]

The second challenge is the microscopic presence of interstitial contaminants like oxygen, carbon, and nitrogen within the titanium metal’s atomic structure, which can lead to internal defects in the casting. Therefore, the titanium melting process demands preventative measures like reducing or removing interstitial elements and ensuring that the metal is entirely clean and pure.

The third challenge is related to the casting and shaping of the molten titanium. Because the titanium metal tends to react with most casting materials, it is often necessary to use ceramic molds, which can withstand high temperatures without reacting with the metal. Once cast, the titanium alloys are machined to precision by grinding, polishing and cutting to achieve the desired shape and dimensions.

Titanium is one of the most challenging metals to melt and shape. The titanium melting process demands specialized equipment and technologies, expert handling, and meticulous attention to detail. However, the end results are beneficial and well worth the costs and efforts involved. From medical implants to aerospace and defense applications, titanium alloys are invaluable in so many industries. It is indeed a fascinating metal with endless possibilities.

Melting Point of Titanium

To understand it, we must first define what it means. The melting point is the temperature at which a solid metal transitions into a liquid state. For titanium, this temperature is around 1,668 degrees Celsius or 3,034 degrees Fahrenheit. This temperature is relatively high in comparison to some other metals. The high melting point is one of the reasons why titanium is a valuable metal in many industries. [2]

Titanium has a strong and unique crystalline structure that requires a lot of energy to break down. Additionally, it has a high atomic weight which means that it has more protons, neutrons, and electrons in its atoms. More particles in the atoms mean more energy is needed to break them apart and transform the metal from a solid to a liquid. Lastly, titanium has strong metallic bonding that requires a large amount of energy input to melt.

Titanium is incredibly versatile. Its melting point makes it resistant to heat, which is why it’s commonly used in high-temperature applications. It also means that it can be melted down and reformed into various shapes, making it useful in manufacturing. With its numerous applications and versatility, titanium has proven to be one of the most useful and valuable metals in modern society.

The melting point of titanium is around 1,668 degrees Celsius or 3,034 degrees Fahrenheit, which is relatively high for metals. The properties of titanium, including its strong crystalline structure, high atomic weight, and metallic bonding, offer insight into why it has a high melting point. Understanding the fundamentals of titanium’s properties and its melting point is crucial in understanding its value and applications in modern society.

FAQ

Is titanium hard to melt?

The high melting point of titanium can be a challenge but is not impossible to work with. It can be melted using specialized equipment and techniques, such as electric arc furnaces and vacuum arc remelting furnaces. While it may be more challenging to work with than other metals, the end result is worth it.

How hot does titanium burn?

The burning temperature of titanium is a complex topic that depends on several factors such as purity level, environment, and alloy composition. While it’s rare for titanium to burn in normal conditions, it’s essential to understand its ignition point and take preventive measures when handling it in high-heat situations. By following proper safety protocols and handling procedures, we can continue to enjoy the benefits of this remarkable metal in various applications. [2]

How much heat can titanium handle?

It can handle temperatures up to 1,668 °C (3,034 °F) due to its high melting point. With its wide range of heat-resistant properties, it should come as no surprise that titanium is commonly used in different spheres from aerospace to medical implants. [3]

Is there anything stronger than titanium?

While titanium is known for being one of the strongest metals on Earth, there are several materials that are stronger. Graphene, tungsten, and carbon nanotubes are all incredibly strong and durable substances that have unique properties and applications. It’s important to remember that the strength of a material depends on how it’s used and what conditions it’s subjected to. Different materials have different strengths and weaknesses, so it’s important to choose the right material for the application. Whether it’s titanium, graphene, tungsten, or something else, it’s amazing to see the incredible strength of modern materials and how they’re changing the world around us.

What is Earth’s strongest metal?

Earth’s strongest metal is subjective to its application. While tungsten and chromium are incredibly durable, titanium is light and strong, and carbon steel is tough and shock-resistant. Despite these differences, they all have one thing in common: their strength and durability make them integral to various industries across the globe. Understanding the properties of different metals allows us to harness their power and drive innovation in countless industries.

Can titanium survive lava?

Titanium can survive lava, but not without a few bumps and bruises. Its high melting point and resistance to corrosion make it an excellent metal for use in volcanic environments. It can provide crucial data for volcanologists monitoring volcanic activity, and it’s used in volcano monitoring equipment around the world. With titanium and other metals, we can continue to explore the fascinating world of volcanoes and learn more about our planet and its geology.

Useful Video: Melting Point Of Different Metals

Conclusions

In conclusion, the melting point of titanium is a critical factor in many different industries. With a melting point of over 3,000 degrees Fahrenheit, titanium is one of the strongest and most durable metals on the planet. Its high melting point makes it an ideal material for high-temperature applications, such as jet engines and other high-performance machinery. When exposed to extreme heat, titanium will soften and become more malleable, making it easier to shape and form. However, great care must be taken when welding titanium, as it can be extremely sensitive to impurities and other factors that can weaken its strength. So, the next time you see titanium in action, take a moment to appreciate its incredible strength and durability, even in the face of extreme heat.

References:

- https://blog.thepipingmart.com/metals/melting-point-of-titanium/

- https://www.titaniumexposed.com/titanium-melting-point.html

- https://www.nuclear-power.com/titanium-melting-point-boiling-point/