M-50 steel, also known as HSS, is a remarkable superalloy that is recognized for its outstanding wear tolerance, ductility, and impressive durability. This unique combination of properties makes it the go-to choice for applications that demand unparalleled durability and the ability to easily withstand high temperatures.

This extraordinary steel alloy finds extensive usage in critical aerospace components, including bearings and gears. Its remarkable ability to retain hardness and withstand extreme conditions makes it indispensable in the demanding aerospace industry. Whether it’s the rigors of high-speed rotation or the challenges of operating in extreme environments, M-50 steel continues to excel, delivering optimal performance and reliability.

With a proven track record of excellence, M-50 steel stands as an integral material in numerous industries worldwide. Its unrivaled qualities have made it a trusted and preferred option for those seeking top-tier performance and long-lasting reliability in their applications.

M50 Tool Steel Composition

M-50 tool steel is an alloy composed of several key elements that work in harmony to give it remarkable properties. At the core of this alloy is Iron, which forms the majority of its composition. However, what sets M-50 apart is the significant amount of Molybdenum it contains, approximately 4.25-5.75%. This infusion of Molybdenum contributes to M-50’s exceptional high-temperature hardness and toughness.

Furthermore, M-50 contains other elements in smaller quantities, but still has a decisive role in the formation of its properties. The presence of 3.5-4.5% Chromium and 4.0–5.0% Tungsten significantly improves wear resistance, ensuring that M-50 can withstand demanding conditions. Additionally, small percentages of Silicon, Manganese, and Vanadium further contribute to the alloy’s unique characteristics, such as impressive wear resistance, superior toughness, and excellent strength.

This combination of carefully selected elements transforms M-50 into a formidable tool steel, offering exceptional performance and longevity in a variety of applications. Whether it’s withstanding high temperatures, resisting wear and tear, or delivering unmatched strength, M-50 tool steel is a reliable and versatile choice.[1]

Properties

Mechanical

M-50 grade steel is famous for its outstanding material qualities, making it highly suitable for a wide range of demanding applications.When properly hardened and tempered, it can achieve an exceptional hardness of 62-65 HRC. This exceptional hardness enables this steel to retain its strength even under extreme conditions, as it can withstand temperatures up to 600°C without losing strength. Its outstanding hot hardness ensures that it remains resilient and reliable in high-temperature environments.

One of the key strengths of M-50 steel lies in its remarkable tensile strength, which reaches approximately 2600 MPa. This indicates its exceptional ability to resist breaking under tension, providing durability and reliability for demanding applications. Furthermore, a higher yield point of approximately 2200 MPa allows it to endure significant deformation before failure, making it highly resilient and long-lasting.

In addition to its exceptional strength, M-50 steel also exhibits good toughness. At room temperature, it demonstrates a Charpy impact value of 16 J, indicating its ability to absorb energy and resist fracture. This toughness ensures that M-50 steel can withstand sudden impacts and shocks, making it a reliable choice for applications where durability is paramount.

Moreover, M-50 steel possesses a low modulus of elasticity, which contributes to its high resistance to deformation under stress. This means that it can maintain its shape and structural integrity even under heavy loads and intense pressure, making it ideal for applications that require stability and reliability.

The excellent technical characteristics of M-50 steel, combined with its superior resistance to abrasion, have made it widely used in demanding industrial environments. Its capacity to endure severe conditions, retain strength and resist deformation makes it the best choice for industries where reliability and performance are critical.

Thermal

M-50 steel possesses exceptional thermal properties that greatly contribute to its outstanding functionality in high-heat environments. With its high thermal conductivity, M-50 steel effectively dissipates heat, ensuring optimal performance in high-speed applications where heat build-up can lead to failure.

Additionally, its relatively low coefficient of thermal expansion allows M-50 steel to maintain its dimensions and structural integrity, even when exposed to temperature fluctuations. Furthermore, the alloy’s remarkable high-temperature hardness showcases its remarkable ability to sustain performance under extreme heat conditions. This unrivaled thermal stability, combined with its impressive hardness and toughness, positions M-50 steel as the ideal choice for parts operating in demanding high-temperature conditions. By choosing M-50 steel, engineers can rely on its exceptional thermal properties to enhance performance and durability in critical applications.

Physical

M-50 steel is widely recognized for its distinctive and exceptional physical properties, making it highly suitable for applications that require unparalleled resilience against wear and tear. Its dense and uniform structure contributes to its impressive wear resistance, ensuring long-lasting performance in demanding conditions.

With a relatively high density of approximately 8.11 g/cm3, M-50 steel owes its robustness to the presence of heavy elements like molybdenum, tungsten, and chromium in its composition. This unique combination of elements not only enhances its density but also reinforces its exceptional hardness, rendering it impervious to penetration and deformation.

In addition to its remarkable density and hardness, M-50 steel boasts a high melting point ranging between 1427°C and 1538°C, showcasing its exceptional capability to withstand high-temperature environments. This makes it an ideal choice for applications that involve exposure to extreme heat conditions.

Furthermore, M-50 steel exhibits excellent magnetic properties, consistently displaying a strong response to magnetic fields. This makes it particularly advantageous in applications where magnetic properties are desired.

Overall, the broad range of physical properties exhibited by M-50 steel makes it an incredibly versatile material in various industrial applications, ensuring optimal performance and longevity in demanding environments.[3]

Benefits of M-50

The benefits of M-50 steel stem from its unique combination of mechanical, thermal, and physical properties, making it a clear and highly versatile choice for various high-demand applications.

This ensures not only durability but also longevity, leading to significant cost efficiency in the long run.Moreover, the high thermal conductivity of M-50 steel allows for efficient heat dissipation, minimizing the risk of heat-induced failures. This, in turn, enhances the life span of components and further reduces maintenance costs.

In addition to its remarkable thermal properties, M-50 steel exhibits a low modulus of elasticity and impressive tensile and yield strength. These characteristics enable it to withstand deformation and deliver consistently high performance under stressful conditions.

Furthermore, the high density and uniform structure of M-50 steel contribute to its superior wear resistance, rendering it highly resistant to penetration and deformation. As a result, components made from M-50 steel experience an extended lifespan, ensuring optimal performance even in demanding environments.

Lastly, the strong magnetic response of M-50 steel makes it ideal for applications that require responsiveness to magnetic fields. This adds an extra dimension to its versatility and widens its range of potential uses.

Overall, the exceptional benefits of M-50 steel make it an appealing and sought-after choice for a wide range of industrial applications. Its popularity and consistent demand in the market are a testament to its outstanding performance and reliability.[4]

M50 Tool Steel Uses

Due to its robust properties and exceptional characteristics, M-50 steel finds a wide range of applications across various industries. In the aerospace industry, this exceptional material is frequently utilized in the manufacturing of high-performance bearings, gears, and other critical components that demand unparalleled resistance to extreme conditions. The ability of M-50 steel to retain hardness and strength at high temperatures, combined with its superior wear resistance, makes it the perfect choice for jet engine components that operate in demanding environments. Furthermore, in the automotive industry, M-50 steel is extensively employed in the production of piston rings, crankshafts, and other high-stress parts, ensuring optimal performance and durability. Similarly, within the power generation sector, this remarkable steel is chosen for its capability to withstand high temperatures and pressures, making it ideal for use in turbines and other vital components. Beyond these applications, the magnetic properties of M-50 steel make it highly valuable in electronic applications where responsiveness to magnetic fields is paramount. The versatility, durability, and high performance of M-50 steel underscore its immense value in a multitude of demanding industrial applications, making it an indispensable material in various industries.[2]

Corrosion Resistance

M50 steel exhibits commendable corrosion resistance, primarily due to the presence of chromium in its composition. The chromium content enables the formation of a passive layer of chromium oxide on the surface of the steel when exposed to oxygen. This layer acts as a protective barrier, effectively shielding the steel from corrosive elements. As a result, M-50 steel is less susceptible to rust and degradation in various environments, including those with high humidity or exposure to certain chemicals.

However, it is important to note that while M-50 steel demonstrates good corrosion resistance, it may not perform as exceptionally as stainless steel or other specifically corrosion-resistant alloys in highly corrosive environments. In such conditions, additional precautions and surface treatments may be necessary to enhance the steel’s corrosion resistance and ensure its durability and longevity.

Regular maintenance practices, such as cleaning and appropriate surface treatments, can further enhance the steel’s resistance to corrosion. By implementing these measures, M-50 steel can maintain its excellent performance and withstand the challenges posed by a wide range of applications.[5]

Heat Resistance

M-50 steel is renowned for its exceptional heat resistance, which can be primarily attributed to its remarkably high melting point and remarkable ability to maintain its hardness even in the most demanding high-temperature environments. This remarkable heat resistance is a direct result of the alloy’s precise composition, which includes key elements such as molybdenum, tungsten, and chromium. These elements synergistically contribute to the steel’s innate resistance to thermal degradation, making it an ideal choice for applications that involve exposure to intense heat.

In addition to its outstanding thermal stability, M-50 steel also possesses remarkable structural integrity and resistance to deformation when exposed to extreme temperatures. This characteristic is of utmost importance in critical applications such as jet engines, automotive parts, and power generation components, where materials must withstand prolonged exposure to heat-intensive conditions. The ability of M-50 steel to maintain its structural integrity even under such extreme temperatures is a testament to its exceptional heat resistance.

However, it is vital to acknowledge that while M-50 steel’s heat resistance is substantial, prolonged exposure to extremely high temperatures may gradually affect its performance over time. To mitigate this potential drawback and ensure the long-term functionality of the material, regular inspections and necessary maintenance measures are crucial. By implementing these measures, the performance of M-50 steel can be preserved and its remarkable heat resistance can continue to deliver exceptional results in various demanding applications.[1]

Heat Treatment

M-50 steel, a high-performance alloy, exhibits favorable responses to precise heat treatment processes. By subjecting the steel to carefully controlled heating and cooling, its physical and chemical properties can be altered to achieve desired characteristics. Heat treatment enhances the steel’s hardness, mechanical strength, and ductility, making it ideal for demanding applications.

The typical heat treatment process for M-50 steel begins with an initial hardening phase. During this phase, the steel is heated to temperatures between 1025°C and 1205°C, followed by a rapid quenching process using air or oil. This rapid cooling results in the formation of a hard structure, albeit with some brittleness.

To address the brittleness and achieve a balanced microstructure, a tempering phase is introduced. The steel is heated to a lower temperature, typically between 540°C and 650°C. This allows for stress relief and the formation of a balanced microstructure, imparting improved toughness and ductility to the steel while maintaining its hardness.

It is important to note that the specific parameters of the heat treatment process can be adjusted to meet the requirements of different applications. This flexibility allows for the customization of the steel’s properties to suit specific needs.

However, it is crucial to emphasize that heat treatment should always be carried out by trained professionals under controlled conditions. This ensures that unwanted alterations or damage to the material are prevented, guaranteeing the integrity and performance of the M-50 steel.[1],[2]

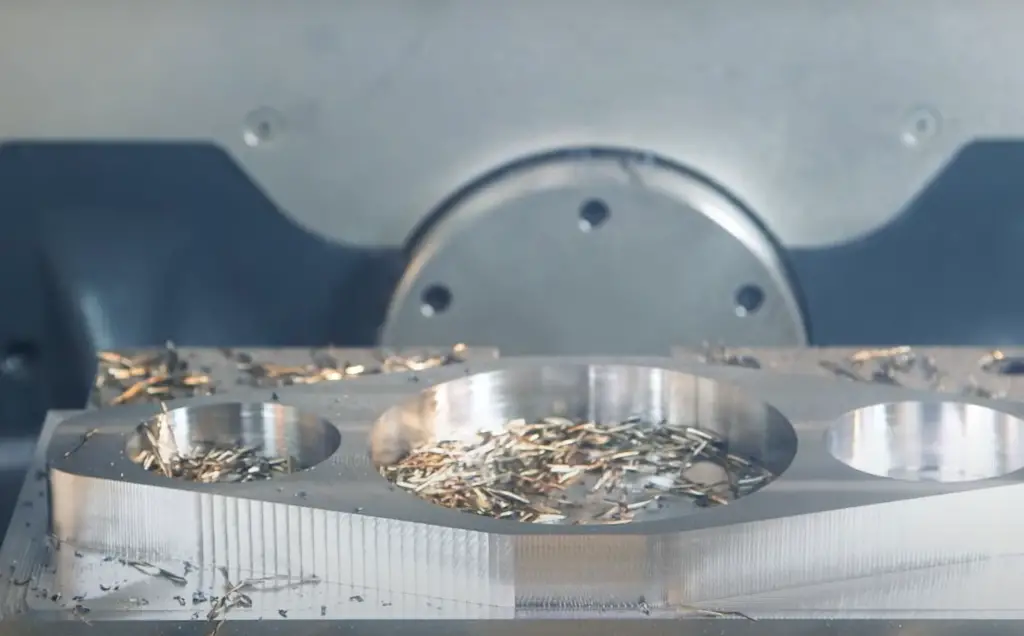

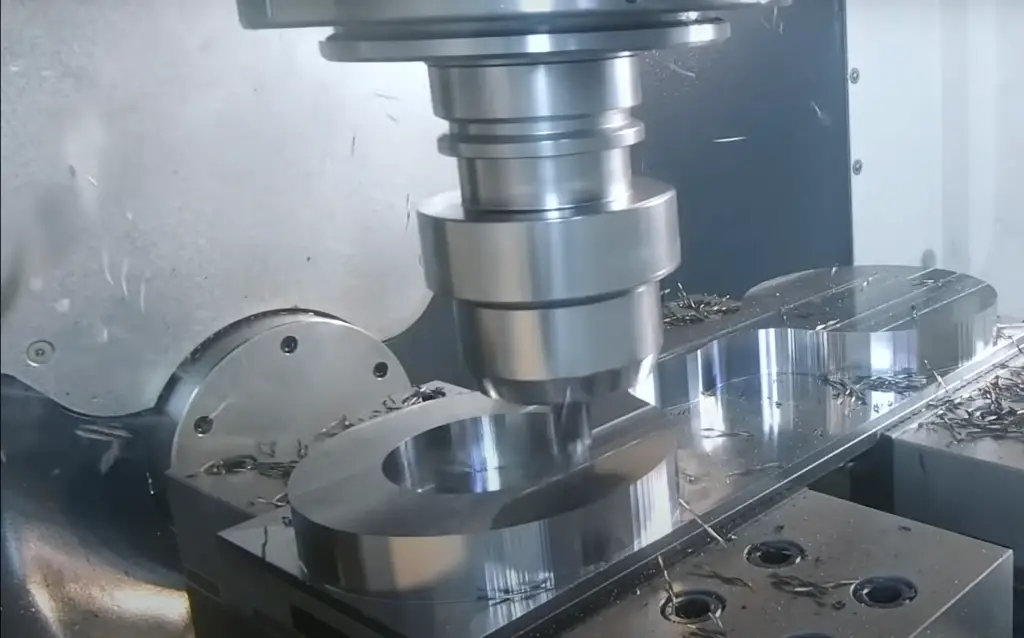

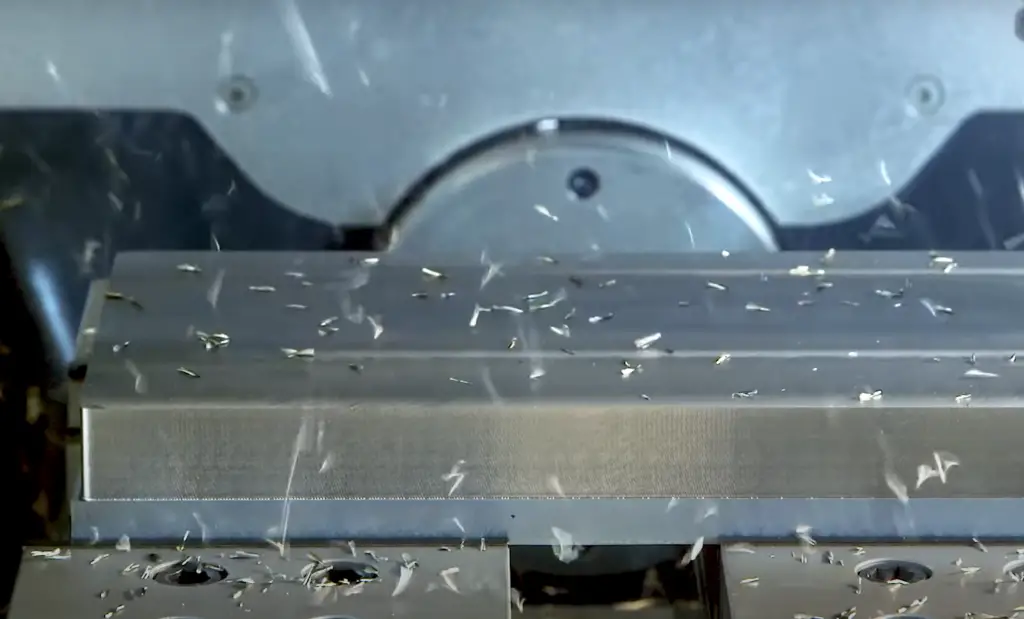

Machining

Machining M-50 steel can be a somewhat challenging task due to its high hardness and strength. Standard high-speed steel (HSS) tools may wear out quickly when used for machining this alloy. Therefore, it is typically to utilize carbide-tipped or other hard-wearing tooling to ensure longer tool life and efficiency. To manage the generation of excessive heat during the machining process, coolant is often employed, which not only helps in maintaining the tool’s longevity but also preserves the desirable properties of the steel.

Despite these inherent challenges, M-50 steel can be effectively machined to achieve a high degree of precision, making it exceptionally suitable for the production of complex parts and components. Various techniques such as milling, turning, drilling, and grinding can be employed to shape the steel according to specific requirements. However, it is crucial to exercise caution and employ appropriate feeds and speeds to prevent tool breakage and ensure a superior quality finish.

Finally, it is noteworthy to mention that after the machining process, M-50 steel parts often undergo further heat treatment. This additional step helps relieve any stresses induced during machining and optimizes the mechanical properties of the components for their intended end-use applications. By carefully considering these aspects, manufacturers can achieve remarkable results when working with M-50 steel.[6]

Welding

Wing M-50 steel can be a complex process, primarily due to its exceptional hardenability and strength, which make it a highly desirable material for various applications. To ensure a successful weld, it is generally recommended to preheat the steel before welding. This preheating process helps reduce the risk of cracking and ensures a more robust and reliable weld joint.

When it comes to welding M-50 steel, it is crucial to use consumables that closely match the composition and properties of this specific alloy. This ensures that the weld retains its strength and integrity, resulting in a high-quality weld that meets the required specifications.

Several popular welding methods are commonly employed for welding M-50 steel, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW). Each method offers its own advantages and considerations, allowing welders to choose the most suitable technique based on the specific requirements of the project.

Furthermore, post-weld heat treatment is often performed on welds made with M-50 steel. This additional step, such as stress relieving or tempering, helps reduce residual stresses and enhances the toughness of the weld. By carefully controlling the heat treatment process, welders can improve the overall performance and longevity of the welded structure.

Lastly, it is important to highlight that welding M-50 steel should always be conducted by trained professionals. Improper handling or insufficient knowledge of the material’s characteristics can lead to structural weaknesses or unintended alterations in its properties. Therefore, it is crucial to rely on skilled welders who have the expertise and experience to ensure the integrity and safety of the welded components.

Typical applications

M50 steel, renowned for its robust physical and mechanical properties, finds extensive use in a broad spectrum of demanding applications. With its exceptional hardness and strength, it stands as an exceptional material for manufacturing parts that endure substantial wear, such as ball and roller bearings commonly found in high-speed, high-load applications like aircraft engines and high-speed turbines.

Moreover, the impressive heat resistance of this alloy makes it particularly suitable for hot environments, such as aerospace turbine blades, where materials must reliably function at elevated temperatures. In the automotive industry, M-50 steel plays a pivotal role in the production of various components that require superior wear resistance and strength.

Furthermore, owing to its corrosion resistance, M-50 steel emerges as an ideal choice for applications where durability and longevity are of utmost importance. Despite its relatively challenging machinability and welding requirements, M-50 remains a popular choice across multiple industries due to its balanced combination of exceptional characteristics. Its versatility and reliability make it an invaluable asset in meeting the demanding needs of modern engineering.[2]

FAQ

What is M50 steel per AMS 6491?

AMS 6491 is a standard specification set by the SAE Aerospace Material Specification system for high-speed steels, including the renowned M-50 steel. This specification plays a crucial role in defining the chemical and mechanical requirements that M-50 steel must meet to earn the prestigious classification under AMS 6491.

Specifically engineered for high-performance applications, AMS 6491 M-50 steel has become a favored choice in the aerospace industry. Its exceptional combination of hardness, strength, and heat resistance make it an invaluable asset in critical components such as aircraft bearings and other high-stress parts.

What sets the M-50 steel under this specification apart is not only its similar composition to the general M-50 steel, but also the stringent quality control and testing it undergoes as mandated by the AMS standards. This meticulous process ensures the reliability and performance of the M-50 steel, providing peace of mind to engineers, manufacturers, and end-users alike.

It is important to note that the handling and processing of M-50 steel per AMS 6491 should always be entrusted to professionals. This guarantees that the finished product adheres to the specification’s high standards, resulting in optimal performance and safety in aerospace applications.

What does M steel mean?

“M” in M steel typically stands for “Molybdenum,” which is one of the key alloying elements used in the formulation of these types of steel. The addition of molybdenum improves the steel’s hardenability, strength, and heat resistance, making it suitable for high-performance applications.

The number that follows the M, such as the 50 in M-50 steel, usually denotes a series or grade within the M steel category. Each grade has a distinct composition and offers unique properties, enabling it to serve various applications across different industries. For example, M-50 steel is a high-speed, high-alloy steel known for its exceptional wear resistance and toughness, making it ideal for demanding applications like bearings and cutting tools.

In essence, M steel is a broad category of high-speed, high-alloy steels characterized by their remarkable hardness, strength, and heat resistance properties. These steels are carefully engineered to deliver superior performance in specific applications, ensuring optimal reliability and longevity in challenging environments.

What are the 4 classifications of steel?

Steel is an incredibly versatile material that comes in various types, each with their own unique properties. These types can be broadly grouped into four primary classifications, each with their own specific characteristics and applications:

- Carbon Steel: This is the most commonly used type of steel, known for its iron and carbon composition. Depending on the carbon content, carbon steel can be further subdivided into low, medium, and high carbon steel. The carbon content influences the steel’s strength, hardness, and durability.

- Alloy Steel: This type of steel is created by adding different elements such as nickel, chromium, and molybdenum to carbon steel. These additional elements enhance the properties of alloy steel, including increased strength, hardness, and resistance to wear and corrosion. The specific combination of alloying elements can be tailored to meet the requirements of specific applications.

- Stainless Steel: Stainless steel is recognized for its excellent corrosion resistance, making it suitable for various environments. It contains a significant amount of chromium, which forms a protective layer on the surface of the steel, preventing rust and corrosion. Additional elements like nickel, molybdenum, and nitrogen may also be added to improve specific properties such as increased strength or enhanced resistance to pitting and crevice corrosion.

- Tool Steel: This type of steel is specifically designed for the production of tools, where hardness, abrasion resistance, and the ability to withstand high temperatures are crucial. Tool steel can be either high-quality carbon steel or alloy steel, depending on the specific requirements. It is widely used in the manufacturing of cutting tools, molds, and dies.

Within each classification, there are numerous grades and subtypes of steel, offering a wide range of options for various applications across industries. Whether it’s construction, automotive, aerospace, or manufacturing, steel provides a versatile and reliable solution for virtually every need.

Which is better, M2 or M4 steel?

Choosing between M2 and M4 steel often depends on the application’s specific requirements as both types have distinctive attributes. M2 steel, also known as ‘High-Speed Steel,’ is a tungsten-molybdenum tool steel. It is renowned for its excellent hardness, wear resistance, and toughness, making it suitable for a wide range of applications, including metal cutting tools and drills.

On the other hand, M4 steel, also a member of the high-speed steel family, has higher levels of molybdenum and vanadium. This composition leads to remarkable hardness and superior wear resistance, especially when exposed to high temperatures. This makes M4 steel an excellent choice for applications that require superior hot hardness, like high-performance tooling and cutting tools that operate in high-heat environments.

While M4 steel’s enhanced hot hardness and wear resistance might make it seem superior, it is also more challenging to machine and grind compared to M2 steel. Therefore, the better choice between M2 and M4 steel ultimately depends on balancing the specific demands of the application with the material’s properties and ease of processing.

When it comes to the specific requirements of an application, it’s important to consider factors such as the type of cutting or drilling involved, the operating temperature, and the desired durability. M2 steel’s excellent hardness and toughness make it a versatile option for various cutting tools and drills. Its wear resistance ensures longevity and efficiency, even under demanding conditions.

On the other hand, M4 steel’s higher levels of molybdenum and vanadium offer superior hardness and wear resistance, especially in high-temperature environments. This makes it a prime choice for applications that require exceptional hot hardness and durability.

However, it’s worth noting that while M4 steel offers enhanced properties, it also presents challenges in terms of machining and grinding. It requires specialized techniques and tools to work with effectively. In contrast, M2 steel is relatively easier to machine and grind.

Ultimately, the decision between M2 and M4 steel boils down to finding the right balance between the specific demands of the application and the material’s properties and ease of processing. By carefully considering these factors, one can choose the most suitable steel type that will deliver optimal performance and longevity.

What is M7 tool steel?

M tool steel, a type of Molybdenum high-speed tool steel, belongs to the category of steels classified by the American Iron and Steel Institute (AISI). Renowned for its exceptional balance of wear resistance and toughness, M7 tool steel finds widespread use in applications that demand high-speed and high-volume machining. It serves as a reliable choice in the manufacturing of essential tools like drill bits, end mills, and reamers.

When it comes to its composition, M7 tool steel contains moderate levels of carbon, tungsten, and molybdenum, which collectively contribute to its remarkable ability to maintain high hardness even at elevated temperatures. This characteristic makes it highly suitable for usage in industries that require superior performance under demanding conditions, such as the automotive and aerospace sectors.

Moreover, M7 tool steel boasts excellent machinability and can be hardened to exceptional levels, further enhancing its suitability for various high-demand applications.

In summary, M7 tool steel stands out as a reliable and versatile material choice, providing the necessary durability, toughness, and machinability required in demanding machining applications across a range of industries.

Useful Video: 50mm mild steel cutting by 15000w laser cutting machine

Conclusion

In conclusion, M-50 steel, as defined by the AMS 6491 specifications, stands out due to its exceptional hardness, strength, and heat resistance, making it the material of choice for high-stress parts in the aerospace industry. Its production involves meticulous quality control measures to ensure compliance with the stringent AMS standards, making it highly reliable for critical applications where precision and performance are paramount.

Furthermore, M-50 steel falls within the broader category of high-speed, high-alloy steels, offering a diverse range of steel solutions for various industries. Alongside M-50, other similar materials such as M2, M4, or M7 also provide excellent performance attributes and are chosen based on the specific requirements of the application.

When selecting the appropriate steel material, engineers consider multiple factors, including the desired performance characteristics, ease of processing, and compatibility with existing manufacturing techniques. By carefully balancing these factors, engineers can optimize the material selection process to meet the unique needs of each application, ensuring the highest level of performance, reliability, and efficiency.

References:

- https://blog.thepipingmart.com/grades/m50-tool-steel-composition-uses-and-properties/

- https://www.suppliersonline.com/propertypages/m50.asp

- https://www.otaisteel.com/products/high-speed-steel/aisi-m50-high-speed-steel/

- https://www.sullivansteelservice.com/home/our-steel/m50/

- https://www.sciencedirect.com/science/article/abs/pii/0168583X9195701E

- https://www.techsteel.net/alloy/steel/m-50