Duplex stainless steel is a remarkable type of steel known as a “duplex” because it ingeniously combines the exceptional qualities of austenitic and ferritic grade of steel. This unique combination results in a material that not only has extraordinary strength, but also exhibits excellent corrosion resistance, making it a perfect match for a broad spectrum of uses. From the harsh conditions of the petroleum sector to the rigors of chemical processing, it demonstrates exceptional performance. Its outstanding properties have made it a top pick where extreme strength and unparalleled corrosion resistance are of paramount importance. With its versatile composition and exceptional properties, this material continues to play a crucial role in a variety of industries, providing optimum performance and durability in demanding environments.

What Is Duplex Stainless Steel?

Duplex stainless steel is a special type of stainless steel with a unique texture consisting of grains of both aluminized and enamelled steel. This two-phase structure, aptly called “duplex,” is achieved through a precise combination of alloying elements, including chromium, nickel, molybdenum and nitrogen. These elements work synergistically to create a material with exceptional properties.

With its distinctive composition, it not only has double the toughness of conventional AISI or FSI grades, but also demonstrates superior stability against corrosion, especially stress strain cracking. This makes it an optimal selection for a diverse range of manufacturing industries, including petrochemical, desalination, pulp and paper, and offshore.

The versatility and durability of duplex steel make it indispensable in harsh environments where reliability and durability are of paramount importance. Its unparalleled combination of robustness, stress resistance and performance has strengthened its position as the material of choice for demanding engineering applications.[1],[2]

How is Duplex Steel Made?

The production of duplex stainless steel involves a complex and precise process known as alloying. In this process, the primary components – iron, carbon, chromium, nickel, molybdenum, and nitrogen – are carefully selected and melted together in a high-temperature furnace. This marks the beginning of the alloying process, where the composition of these ingredients is meticulously controlled to achieve the desired proportions of ferritic and austenitic phases in the resulting steel.

Once the molten mixture is ready, it is cast into the form of semi-finished slabs, blooms, or billets, which serve as the foundation for the final product. These semi-finished products undergo further heating and mechanical working through a series of rolling or forging processes. This intricate shaping and manipulation of the steel ensure that it acquires the necessary strength and structural integrity.

To further enhance the physical and structural qualities of steel, the final product undergoes a critical thermal modification process. This involves exposing the material to controlled cycles of warming and chilling, which changes its microstructure at the molecular level. The heat treatment is carefully calibrated to achieve the perfect balance among the various austenitic and pherrite phases, ultimately resulting in the characteristic duplex structure that gives this type of steel its outstanding robustness and resistance to rust.

By combining the different stages of alloying, shaping, and heat treatment, the production of duplex stainless steel becomes a meticulous and intricate endeavor. The attention to detail throughout the entire process ensures that the final product exhibits superior properties, making it an ideal choice for various applications in industries such as architecture, automotive, and marine engineering.[3]

Principle of Duplex Stainless Steels

The underlying principle of duplex stainless steels lies in their unique two-phase microstructure, which is a 50/50 mix of austenitic and ferritic grains. This distinctive microstructure provides a remarkable combination of properties that render it highly desirable in a variety of applications.

The austenitic phase, renowned for its superior workability and resistance to erosion, especially in chloride-containing atmospheres, provides exceptional durability and reliability. The ferrite phase, on the other hand, contributes to excellent tensile strength and stability against pressure corrosion failure, ensuring the structural integrity of the material.

By combining both of these phases, duplex stainless steels achieve higher strength levels than either alloy or ferritic grade stainless steel while maintaining excellent anti-corrosion properties. Additionally, the addition of nitrogen during the alloying process further enhances the steel’s strength and corrosion resistance, making it even more versatile and reliable.

The principle behind duplex stainless steels is to strike the optimal balance between the beneficial properties of the austenitic and ferritic phases. This delicate balance is carefully controlled during the manufacturing process to ensure the intended properties are achieved, resulting in a material with superior performance characteristics and an extended range of applications.[3]

A Brief History Of Duplex Stainless Steel

Dup stainless steel, a remarkable material, has a fascinating history that dates back to the 1920s. In those early years, scientists embarked on a journey of experimentation, exploring different alloy combinations to achieve the desired balance of properties. Although their initial attempts showed promise, the resulting material lacked consistency.

It wasn’t until the 1970s when significant breakthroughs in the production of duplex stainless steel took place. A Swedish company called Avesta, which later became part of Outokumpu, played a pivotal role in this revolution. Avesta became the pioneering force behind the first commercial production of duplex stainless steel, forever changing the landscape of stainless steel manufacturing.

At first, early grades of duplex stainless steel faced limitations due to poor weldability, which restricted their use primarily to cast forms for valve bodies. However, a turning point arrived in the 1980s. Improved refining methods, including the innovative use of argon oxygen decarburization (AOD), paved the way for second-generation duplex steels. These new alloys boasted enhanced weldability and superior corrosion resistance, making them an ideal choice for industries requiring high-strength, durable, and corrosion-resistant materials.

Today, the journey of duplex stainless steel continues, with advancements being made to further enhance its properties and expand its utilization across a wide array of industries worldwide. As we look ahead, the future of duplex stainless steel shines brightly, promising even greater possibilities and applications in the years to come.[1]

Benefits Of Duplex Stainless Steel

Improved Strength

One of the most significant advantages of duplex stainless steel is its exceptional strength. Compared to traditional austenitic or ferritic stainless steels, duplex stainless steel stands out with its two-phase microstructure — a combination of austenitic and ferritic grains. This unique construction not only enhances its strength but also imparts improved resistance to corrosion and stress cracking. As a result, duplex stainless steel is highly sought after for applications in high-pressure environments, heavy load-bearing structures, and demanding industrial settings.

Furthermore, the doubled strength of duplex stainless steel allows for the use of thinner sections, reducing weight and material costs without compromising structural integrity. This aspect makes it an attractive choice in industries such as construction, chemical processing, and offshore installations, where both performance and cost-effectiveness are critical factors.

In summary, the exceptional strength, corrosion resistance, and cost-effectiveness of duplex stainless steel make it a versatile material that finds extensive use across various industries and environments, proving its value in demanding applications.

High Toughness And Ductility

Another noteworthy feature of duplex stainless steel is its high toughness and ductility. These properties refer to the material’s ability to deform without fracturing, which is particularly valuable in industries with rigorous mechanical demands or under unpredictable impact loads.

The balanced microstructure of the duplex stainless steel, with its mix of austenitic and ferritic phases, contributes to this high toughness and ductility. While the ferritic phase provides the material with strength, the austenitic phase lends it excellent ductility. This combination allows duplex stainless steels to resist a wide range of damaging forces, including those from thermal expansion, mechanical stress, impact, and environmental corrosion.

Its ability to withstand extreme conditions and maintain its integrity makes it a reliable choice for critical infrastructure projects. Additionally, the versatility of duplex stainless steel allows for cost-effective solutions in various industries, providing durability and longevity to the structures and equipment it is used in.

In summary, the unique combination of high toughness, ductility, and corrosion resistance make duplex stainless steel an ideal choice for demanding applications that require reliability and longevity. Its exceptional properties ensure the safety and performance of critical structures and equipment, making it a preferred material across industries.

High Corrosion Resistance

One of the most outstanding features of duplex stainless steel is its exceptional resistance to corrosion. The unique blend of ferritic and austenitic phases in its microstructure offers high resistance to a wide range of corrosive environments, including those with elevated temperatures and highly concentrated chloride levels. This means that duplex stainless steel can withstand the corrosive effects of sea water, acidic chemicals, and high-salinity environments with remarkable resilience, maintaining its structural integrity and performance over time.

The corrosion resistance of duplex stainless steel is further enhanced by the presence of nitrogen and molybdenum in its alloy composition. These essential elements contribute to its resistance against pitting and crevice corrosion, which are common forms of localized corrosion. Additionally, duplex stainless steel surpasses conventional austenitic stainless steels in its resistance to stress corrosion cracking, making it an ideal material for high-stress applications or those with fluctuating temperature conditions.

Due to its high corrosion resistance, duplex stainless steel is widely used in various industries. It is particularly favored in the oil and gas industry, chemical processing, desalination plants, and marine applications. These industries often expose materials to harsh and aggressive environments, where the durability and longevity of duplex stainless steel are highly valued.

Cost Effectiveness

Duplex stainless steel’s cost-effectiveness isn’t merely subjective—it’s demonstrably realized in both initial procurement and throughout the lifecycle of the equipment or structure where it is used. This steel’s high strength-to-weight ratio reduces the amount of material needed for a project, resulting in lower upfront costs. Furthermore, its exceptional resistance to corrosion and overall durability means that it requires less maintenance over time, reducing long-term expenses related to repair or replacement. Additionally, with its superior resistance to a range of corrosions, investments in protective measures or coatings are minimized, leading to further savings.

Moreover, the versatility of duplex stainless steel makes it an ideal choice for a wide range of applications, from marine environments to chemical processing plants. Its unique combination of strength, toughness, and corrosion resistance ensures reliable performance even in the harshest conditions. Whether it’s used for offshore oil rigs or wastewater treatment facilities, duplex stainless steel offers unparalleled reliability and longevity.

Furthermore, the sustainability aspect of duplex stainless steel cannot be overlooked. With its long lifespan and ability to be recycled, it minimizes the environmental impact associated with frequent replacements or disposal of inferior materials. This makes it a responsible choice for industries striving to reduce their carbon footprint and promote a circular economy.

In summary, duplex stainless steel offers an economical and sustainable solution without compromising quality or performance, particularly in industries where high-strength, corrosion-resistant materials are a necessity. Its numerous benefits, including reduced material requirements, lower maintenance costs, minimized investment in protective measures, and extended replacement cycles, make it a compelling choice for a wide range of applications.[1],[2]

Best Uses For Duplex Stainless Steel

Duplex stainless steel is highly versatile and finds application in a myriad of industries, thanks to its exceptional properties. In the oil and gas industry, it is extensively utilized in pipelines and various equipment due to its remarkable strength and unparalleled resistance to corrosion, especially in extreme temperature and high-pressure conditions. The marine industry greatly favors duplex stainless steel for shipbuilding and offshore facilities, benefiting from its unmatched resistance to sea water and chloride-induced corrosion.

In the construction industry, duplex stainless steel stands out as an excellent choice for structural and architectural applications. Its impressive combination of high strength, toughness, and ductility makes it ideal for constructing bridges, buildings, and reinforcement bars. Desalination plants rely on duplex stainless steel for its exceptional resistance to corrosion in highly saline environments.

Moreover, the chemical processing industry highly values duplex stainless steel for its resilience against corrosive agents such as sulfuric and hydrochloric acids. In the food and beverage industry, duplex stainless steel’s hygiene properties and resistance to organic acids and compounds make it a preferred choice.

In essence, duplex stainless steel shines as a top contender wherever there is a need for a robust, durable, and corrosion-resistant material. Its wide range of applications and outstanding performance make it an indispensable asset across various industries.[3],[4]

FAQ

What Is The Difference Between Duplex Stainless Steel And Stainless Steel?

Despite similarity in their names, duplex stainless steel and regular stainless steel differ significantly in their compositions and properties. To begin with, conventional stainless steel, often austenitic, is composed primarily of iron, chromium, and nickel. It is renowned for its excellent corrosion resistance and ductility but can be prone to stress corrosion cracking.

On the other hand, duplex stainless steel is a fusion of austenitic and ferritic stainless steels. This blend results in a metal that combines the best features of both types, achieving twice the strength of regular stainless steel, high toughness, and superior resistance to corrosion. Duplex stainless steel also excels in resistance to stress corrosion cracking, a common problem with austenitic stainless steels.

Furthermore, its high strength-to-weight ratio leads to cost savings, as less material is required for the same applications, leading to lower procurement and maintenance costs. Additionally, the unique microstructure of duplex stainless steel provides enhanced resistance to pitting and crevice corrosion, making it suitable for even more challenging environments.

In summary, while both materials possess qualities that make them useful in various industries, duplex stainless steel stands out for its superior strength, resistance to a wider range of corrosions, and cost-effectiveness, making it an ideal choice for applications in demanding and corrosive environments. Its unique composition and properties make it a reliable and durable option for industries such as oil and gas, chemical processing, and marine applications.

What Is Meant By Duplex Stainless Steel?

Duplex stainless steel refers to a remarkable type of stainless steel that combines the advantageous properties of two distinct steel types – ferritic and austenitic. The term ‘duplex’ originates from the fact that these exceptional steel alloys possess a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel. This unique blend of features provides duplex stainless steel with an exceptionally balanced combination of mechanical strength and corrosion resistance, making it highly desirable in various demanding industries.

The composition of duplex stainless steel typically includes high levels of chromium, nickel, and often molybdenum, which significantly enhance the steel’s ability to resist pitting and crevice corrosion. Moreover, the high nitrogen content further improves its resistance to corrosion while promoting structural strength. This outstanding resistance to both general and localized corrosion makes duplex stainless steel an excellent choice for applications in harsh environments.

One of the most remarkable aspects of duplex stainless steel is its high yield strength, which can be double that of regular stainless steel types. This exceptional potency, combined with its excellent corrosion resistance, makes duplex stainless steel highly sought after in critical industries such as oil and gas, marine, and chemical processing. Its ability to withstand extreme conditions and maintain structural integrity makes it an ideal choice for applications where strength, durability, and corrosion resistance are paramount.

What Is The Difference Between Duplex And 316 Stainless Steel?

316 Stainless Steel, a form of austenitic stainless steel, is highly regarded for its exceptional corrosion resistance. It is composed of iron, chromium, nickel, and molybdenum, with the latter being a key component that significantly enhances its resistance against chloride ion pitting. This makes it an ideal choice for applications in saline or extreme environments where chloride corrosion is a concern. Notably, 316 Stainless Steel is often referred to as Marine Grade Stainless Steel due to its superior resistance to chloride corrosion compared to other stainless steel grades.

On the other hand, Duplex Stainless Steel offers a unique combination of austenitic and ferritic stainless steels. Its structure consists of equal proportions of ferrite and austenite, resulting in a metal with exceptional strength and corrosion resistance. This hybrid composition allows Duplex Stainless Steel to inherit the best properties of both types, making it a preferred choice in various industries.

In terms of performance, Duplex Stainless Steel often surpasses 316 Stainless Steel in strength and resistance to stress corrosion cracking and crevice corrosion, particularly in chloride-rich environments. This makes it highly suitable for heavy-duty applications not only in marine environments but also in the oil and gas, chemical processing, and construction industries.

While 316 Stainless Steel remains a popular option for many marine applications, the superior strength and excellent corrosion resistance of Duplex Stainless Steel make it a more economical and durable choice for demanding environments. Its versatility and reliability have positioned it as a preferred material for critical applications where both strength and corrosion resistance are paramount.

What Type Of Stainless Steel Is Duplex?

Duplex stainless steel, a type of stainless steel that falls under the category of ferritic-austenitic stainless steels, is renowned for its exceptional properties. The term “duplex” refers to its unique dual-phase microstructure, which comprises roughly equal proportions of ferritic and austenitic grains. This two-phase composition gives rise to a metal that combines the best attributes of both ferritic and austenitic stainless steel, including superior strength and outstanding resistance to corrosion.

This carefully balanced composition enhances its resistance to various forms of corrosion, such as pitting, crevice corrosion, and stress corrosion cracking. Additionally, the higher chromium and molybdenum content in duplex stainless steel imparts excellent heat resistance, surpassing that of its austenitic counterparts.Within the realm of duplex stainless steel, there exist several grades, each with its own unique characteristics. These include lean duplex, standard duplex, super duplex, and hyper duplex. Each grade offers varying levels of corrosion resistance, strength, and cost-effectiveness, making them suitable for a wide range of demanding applications across diverse industries.

With its exceptional properties and versatile range of grades, duplex stainless steel stands as a formidable choice for applications that require both strength and corrosion resistance, providing a reliable solution for numerous industrial needs.

Why Is Duplex Steel Called Duplex?

The “duplex” in duplex stainless steel is derived from the Latin word “duplex”, meaning “double” or “twofold”. This name is fitting as duplex stainless steel consists of a two-phase microstructure made up of approximately equal proportions of ferritic and austenitic stainless steel grades. These two distinct phases, existing simultaneously, give duplex stainless steel its characteristic properties, making it a versatile material for various applications.

The balance of these phases allows the alloy to maintain the robustness and magnetic properties of ferritic steel. At the same time, it gains the ductility, toughness, and welding capability of austenitic steel. This unique combination of attributes makes duplex stainless steel highly desirable in industries where both strength and corrosion resistance are crucial.

By having a dual nature, duplex stainless steel offers the best of both worlds – the strength and durability of ferritic steel, along with the corrosion resistance and formability of austenitic steel. Its exceptional mechanical properties and resistance to stress corrosion cracking make it suitable for demanding environments such as offshore oil and gas platforms, chemical processing plants, and marine applications.

In conclusion, the “duplex” term aptly reflects the two-fold nature of this remarkable steel, which combines the superior attributes of both ferritic and austenitic stainless steel types to deliver exceptional performance in a wide range of challenging conditions.

What Is The Difference Between Duplex And Austenitic Stainless Steel?

Austenitic stainless steel, the most widely used subtype, is renowned for its exceptional resistance to corrosion and excellent formability. It is composed primarily of iron, 18% chromium, and 8% nickel, giving it the distinctive property of being non-magnetic. In addition to its non-magnetic nature, austenitic stainless steel also exhibits superior toughness, even at cryogenic temperatures. This makes it highly versatile and suitable for a broad range of applications, from kitchen utensils to chemical equipment and nuclear vessels.

On the other hand, Duplex stainless steel, as described earlier, is a hybrid of austenitic and ferritic stainless steel, combining the beneficial properties of both. It is characterized by its high yield strength, which can be double that of regular austenitic stainless steel. This enhanced strength makes it an ideal choice for heavy-duty applications in demanding environments. Furthermore, duplex stainless steel offers enhanced resistance to stress corrosion cracking, pitting, and crevice corrosion, making it extremely durable and reliable in corrosive environments.

The unique dual-phase structure of duplex stainless steel, consisting of roughly equal proportions of ferrite and austenite, contributes to its superior strength and corrosion resistance. This allows it to withstand harsh conditions and maintain its performance over extended periods.

In conclusion, while both austenitic and duplex stainless steels offer excellent corrosion resistance, the latter provides higher strength and better resistance to certain types of corrosive environments. This makes duplex stainless steel the preferred choice for heavy-duty applications where strength and durability are paramount.

What Is The Advantage Of Duplex Stainless Steel?

Duplex stainless steel holds several advantages over other types of stainless steel, making it a highly favored and versatile choice for various industrial applications. Firstly, its exceptional resistance to corrosion, particularly stress corrosion cracking, pitting, and crevice corrosion, can be attributed to its high chromium and molybdenum content. This remarkable corrosion resistance makes duplex stainless steel an ideal material for use in even the most severe and demanding environments where other stainless steel types might fail to perform.

Secondly, duplex stainless steel exhibits not only superior corrosion resistance but also an impressive strength that is nearly double that of austenitic stainless steel.

Furthermore, this enhanced strength doesn’t come at the expense of ductility, ensuring a perfect balance between sturdiness and flexibility in various applications.Another notable advantage of duplex stainless steel is its exceptional resistance to heat and oxidation, making it highly suitable for applications that require high temperature processing. Whether it’s in the chemical, petrochemical, or oil and gas industries, duplex stainless steel can withstand and perform excellently in harsh and demanding conditions.

Lastly, despite its superior properties and performance, duplex stainless steel offers a cost-effective solution compared to other types of stainless steel. This is due to its lower nickel and molybdenum content, making it more accessible and affordable without compromising on quality, durability, and performance.

In summary, duplex stainless steel stands out as a reliable and versatile material choice, providing excellent corrosion resistance, superior strength, high-temperature resistance, and cost-effectiveness. Its unique combination of properties makes it an indispensable solution for a wide range of industrial applications where reliability, performance, and longevity are paramount.

What Grade Is Duplex Steel?

Duplex stainless steel is available in various grades, each offering unique properties that make them suitable for specific applications. Let’s dive into more detail about these grades:

- Lean Duplex: This grade falls within the lower range of duplex steel, featuring lower alloying content. It provides a cost-effective solution while still offering improved strength and corrosion resistance compared to standard austenitic stainless steel. Lean duplex finds common applications in construction and structural projects.

- 2205 Duplex: Also known as standard duplex, this grade strikes a balance between austenitic and ferritic properties. It exhibits higher corrosion resistance and twice the strength of standard austenitic stainless steel. Widely used in chemical processing, oil and gas, and marine applications, 2205 duplex is a reliable choice.

- Super Duplex: Taking it a step further, this grade offers even greater strength and corrosion resistance than 2205 duplex. Its higher alloying content, particularly chromium and nickel, contributes to enhanced performance. Super duplex is ideal for demanding environments such as desalination plants, chemical plants, and offshore platforms.

- Hyper Duplex: As the pinnacle of duplex stainless steel, hyper duplex stands out with superior corrosion resistance and strength. This grade is specifically designed for the most severe applications, including high-pressure and high-temperature environments, where extreme performance is required.

Each of these grades has its unique chemical composition, ensuring a balance of strength, corrosion resistance, and cost-effectiveness. With their versatile characteristics, they find applications across diverse industries that demand high-performance materials.

Does Duplex Steel Rust?

Duplex stainless steel, renowned for its high chromium and molybdenum content, exhibits exceptional resistance to corrosion, including the dreaded rust. The presence of chromium prompts a chemical reaction with oxygen, forming an imperceptible yet robust layer of chromium oxide on the steel’s surface. This invisible shield acts as a barrier, preventing direct contact between the iron within the steel and the oxygen in the air, effectively thwarting the formation of iron oxide, commonly known as rust.

However, it is imperative to note that while duplex stainless steel boasts remarkable rust resistance, it is not impervious to the phenomenon. In environments characterized by elevated levels of salinity, humidity, or acidity, or in instances where the protective chromium oxide layer is compromised or worn away, duplex stainless steel may still succumb to rust. Therefore, while duplex steel generally outperforms other steel variants in terms of rust resistance, it warrants appropriate maintenance and protection measures to ensure its longevity and optimum performance.

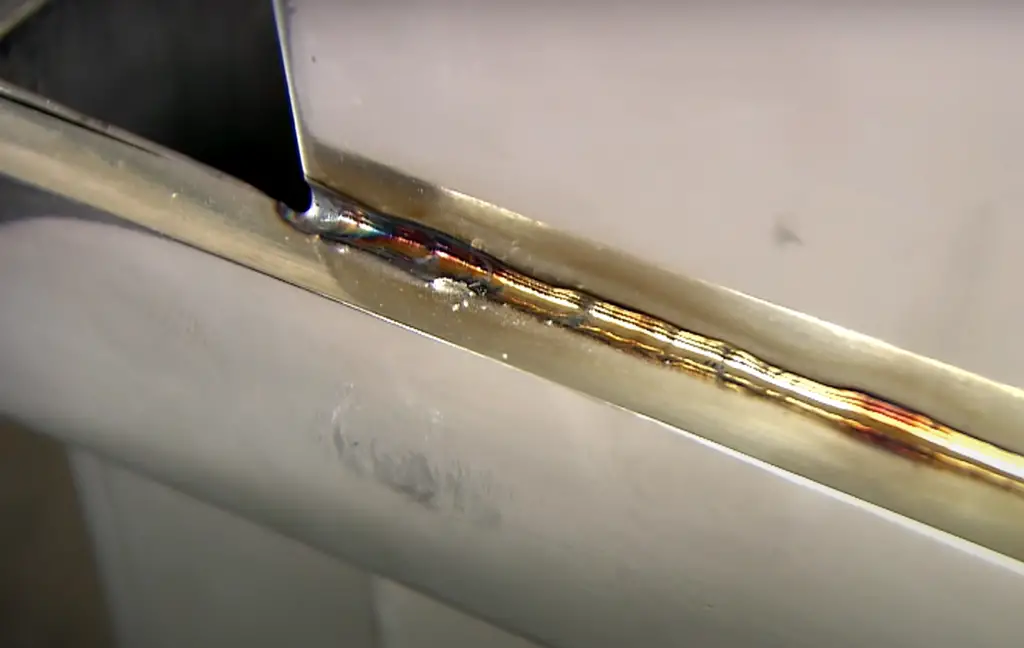

Useful Video: What is Duplex Stainless Steel? #DSS- Types, Welding, Properties #DSS Vs SDSS #Whizz Engineers

Conclusion

In summary, Duplex stainless steel is a remarkable material that distinguishes itself in the realm of metallic materials. Its unique combination of strength, corrosion resistance, and cost-effectiveness makes it highly sought after in various industries. The different grades of Duplex stainless steel, ranging from Lean Duplex to Hyper Duplex, cater to a wide range of industrial applications, each tailored to meet specific requirements.

One of the standout features of Duplex stainless steel is its exceptional rust resistance, which can be attributed to its high chromium and molybdenum content. However, it is still crucial to take proper care to maintain and protect this material to ensure its longevity.

From construction to chemical processing, and from marine to extreme high-temperature applications, Duplex stainless steel has proven to be the material of choice. Its exceptional performance, coupled with its economic efficiency, makes it a reliable option for various industries. Whether it’s durability in challenging environments or cost-effectiveness in large-scale projects, Duplex stainless steel continues to exceed expectations and deliver outstanding results.

References:

- https://www.unifiedalloys.com/blog/what-is-duplex-stainless

- https://www.imoa.info/molybdenum-uses/molybdenum-grade-stainless-steels/duplex-stainless-steel.php

- https://bssa.org.uk/bssa_articles/2-duplex-stainless-steels-a-simplified-guide-2/

- https://www.metalsupermarkets.com/what-is-duplex-steel/