Low-alloy steel is a versatile type of metal alloy which comprises fewer than 8% of mixed metal alloying agents in its composition. This category of steel is widely known for its outstanding material qualities, which include not only power, firmness and abrasion resistance, but also the capacity to endure extreme environments. With its enhanced resistance to corrosion and superior heat resistance, LS steel is a preferred choice in various industries such as auto, building and energy. Its exceptional structure and characteristics make it an excellent choice for demanding uses that require longevity and robustness. Whether it’s the manufacture of heavy machinery or the construction of high-rise buildings, alloy grade demonstrates superior performance, delivering long-lasting and efficient results.

What Does Low-alloy Steel Mean?

Low-alloy steel is a versatile family of steels characterized by a relatively low percentage (less than 8%) doping components in their structure. These steels encompass a wide range of materials that have been carefully crafted by adding specific features like Mn, Ni, Cr, Mo, V, Si and B. The addition of these elements gives steel unique physical and chemical qualities that allow it to exhibit outstanding toughness, stability and resistance to stress, rust and temperature.

What sets this alloy steel apart is the fascinating microstructural changes induced by the alloying elements. These changes have resulted in a refined and enhanced steel matrix, which makes it an excellent selection for demanding industries such as the automotive, construction, and oil and gas industries.Its superior performance in these sectors is attributed to its capability to endure harsh environments and provide long-lasting durability.

Thanks to its exceptional characteristics, LSS continues to be the material of choice for critical applications that require robustness, durability and productivity. Whether it’s building robust structures, designing high-performance automotive components, or operating in harsh environments, low-alloy steel stands as a reliable and versatile choice for industries worldwide.[1]

Explains Low-alloy Steel

Low-alloy steel, despite containing fewer than 8% of beneficial alloying components, demonstrates exceptional corrosion resistance. This remarkable property is primarily due to the special austenitizing materials that are part of its composition. These elements play a crucial role in inducing microstructural changes in steel, which ultimately increases its resistance to corrosion processes. The corrosion resistance of mild steel makes it a great option for use in industries that require exposure to harsh environmental conditions, such as the oil and gas industry.

Furthermore, the addition of small amounts of certain elements, such as copper, can further enhance the steel’s corrosion resistance, providing an extended lifespan for the material in highly corrosive environments. This additional layer of protection ensures that LS steel retains its functional integrity and performance even when exposed to continuous corrosive agents. In essence, the careful selection and composition of these alloying agents in the steel contribute to its exceptional strength and reliability, making it the best choice for industries where reliability and durability are of paramount importance.[1]

The Distinction Between Low Alloy Steel and Stainless Steel

Composition

When comparing the ingredients of low-alloy and stainless steel, there are clear differences that have a significant impact on their qualities and utilization.

Each of these elements plays a crucial role in determining the overall mechanical properties and resistance of the steel. For example, Mn enhances hardenability, Ni improves toughness, and Cr improves rust protection.Stainless steel, by contrast, is defined by a high degree of Cr component present in the steel, i.e. at 10.5%. It is precisely because of those values that make this type of steel exceptionally hard to corrode and stain. In addition to this element, it also includes other items including Ni, Mn, and N, which further enhance its properties. Nickel improves ductility and toughness, molybdenum increases stress resistance, and Nitrogen increases durability.

In summary, while mild steel and SS have some similar elements in their composition, they differ significantly. The specific mixture and concentration of these elements determine their respective strengths and performance characteristics. This variability offers great flexibility in choosing the appropriate material based on the specific application requirements, ensuring optimal performance and durability.

Properties

Despite sharing some common alloying elements, low alloy steel and stainless steel differ significantly in terms of their properties due to variations in composition.

Low alloy steel, which contains less than 8% alloying elements, is renowned for its superior strength, hardness, and resistance to corrosion and wear. These desirable properties are attributed to microstructural changes induced by elements such as Manganese, Nickel, Chromium, Molybdenum, Vanadium, Silicon, and Boron. The presence of these elements leads to the formation of specific phases and structures within the steel matrix, enhancing its mechanical and chemical characteristics. This makes low alloy steel an excellent choice for industries that demand exceptional strength and durability, including automotive, construction, and oil and gas sectors.

On the other hand, stainless steel, characterized by a minimum of 10.5% Chromium, stands out for its exceptional corrosion and stain resistance. The high chromium content in stainless steel forms a passive, self-repairing surface layer that prevents oxidation and corrosion, contributing to its remarkable stainless property. In addition to Chromium, elements like Nickel, Molybdenum, and Nitrogen further enhance the properties of stainless steel, making it even more resistant to corrosion and providing additional strength and toughness. These attributes make stainless steel a preferred choice for applications where corrosion resistance is vital, such as in the food and beverage industry, medical equipment, and architectural applications.

In essence, the selection between low alloy steel and stainless steel depends largely on the specific property requirements of the intended application. By understanding the distinctive characteristics of each type of steel, engineers and designers can make informed decisions to ensure optimal performance and longevity in their projects.

Uses

Low alloy steel, with its superior strength, hardness, and resistance to corrosion, is widely used in industries that highly value these characteristics. It finds extensive applications in the automotive industry, where it contributes to the manufacturing of car bodies, engines, and suspension systems, ensuring durability and safety on the road. In the construction industry, low alloy steel plays a vital role in building robust structures that can withstand various environmental conditions and structural loads. Moreover, the oil and gas industry relies on this versatile material for the construction of pipelines, ensuring the efficient and reliable transportation of resources.

In summary, both low alloy steel and stainless steel have their unique uses and advantages. The choice between the two depends on the specific demands of the application, considering factors such as strength, corrosion resistance, durability, and aesthetics.

Cost

When examining the cost difference between low alloy steel and stainless steel, several factors come into play. Generally, low alloy steel tends to be less expensive than stainless steel due to the lower quantity of alloying elements. This is because the production process for low alloy steel is less complex, requiring fewer steps and resources, which contributes to its lower cost.

Conversely, stainless steel, with its higher chromium content and other alloying elements, is typically more costly to produce. The additional processes, such as alloying and heat treatment, that are necessary to enhance the stainless property further add to the production expenses. These additional steps require precision and expertise, resulting in a higher cost for stainless steel compared to low alloy steel.

However, it is important to consider that the initial cost of the material is only one aspect of the total cost. Over the life of a product, stainless steel’s superior corrosion resistance and durability can lead to lower maintenance and replacement costs. This can potentially offset the higher initial material cost. Stainless steel’s ability to withstand harsh environments without rusting or corroding makes it a preferred choice in applications where longevity and reliability are crucial.

In conclusion, while it is true that the upfront cost of low alloy steel is typically less than that of stainless steel, it is essential to consider the total cost of ownership when deciding between the two materials for a specific application. Taking into account factors such as maintenance, replacement, and overall durability, stainless steel may prove to be a more cost-effective choice in the long run.

Maintenance

The maintenance needs of low alloy steel and stainless steel differ significantly due to their distinct compositions and properties. Low alloy steel, known for its durability and resistance to wear, may necessitate regular inspections and potential treatment to mitigate corrosion risks, particularly in environments with high humidity or corrosive elements. This could involve the application of protective coatings or periodic heat treatments to uphold its strength and longevity.

On the other hand, stainless steel, characterized by its high chromium content, forms a self-healing oxide layer that offers inherent corrosion resistance. This unique attribute greatly reduces the requirement for routine maintenance and preventive measures, making stainless steel an appealing choice for applications that prioritize low maintenance and long-term performance. Nevertheless, it is important to note that stainless steel is not entirely maintenance-free. In environments with elevated salinity or acidity levels, occasional cleaning or treatment may be necessary to prevent pitting corrosion.

In summary, while both materials have their respective maintenance needs, stainless steel generally demands less upkeep than low alloy steel, especially in corrosive environments. However, the specific maintenance requirements will depend on the environmental conditions and the specific application of the material, ensuring optimal performance and longevity.[2]

Low Alloy Steel Properties

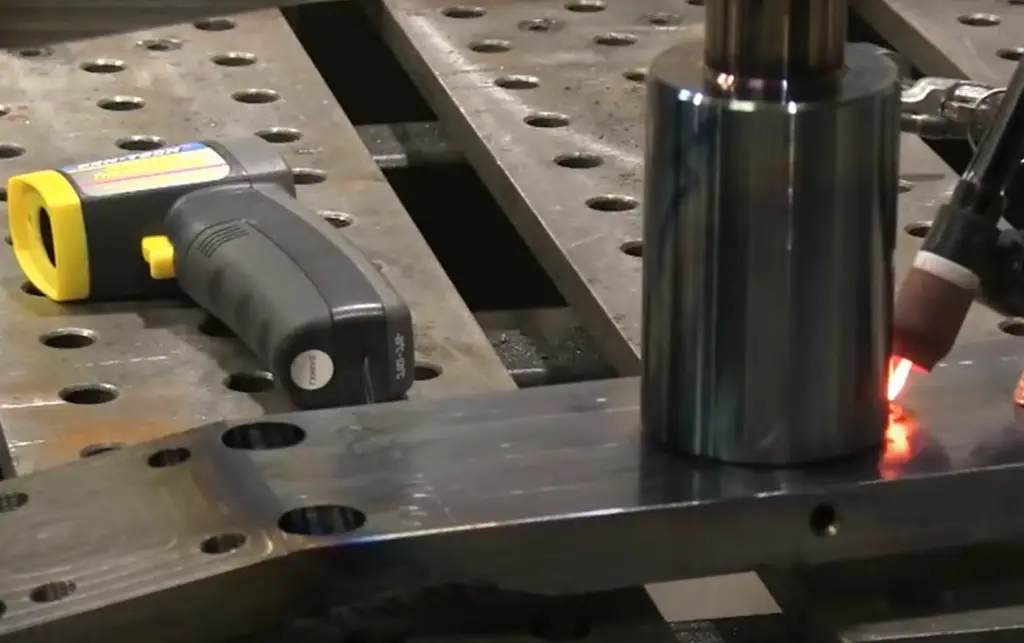

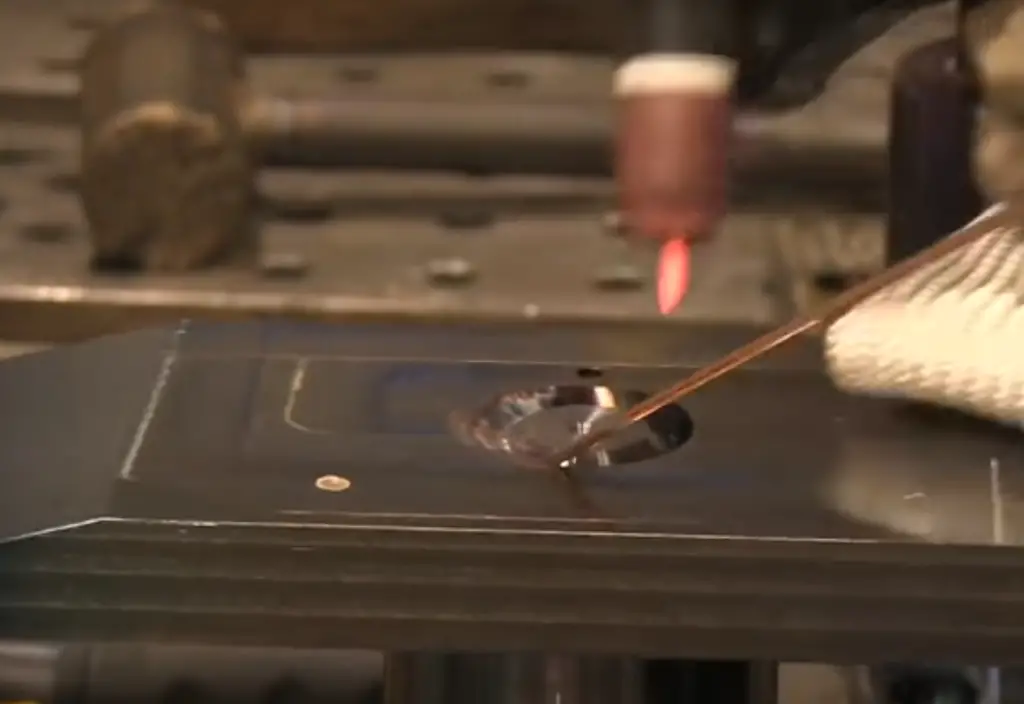

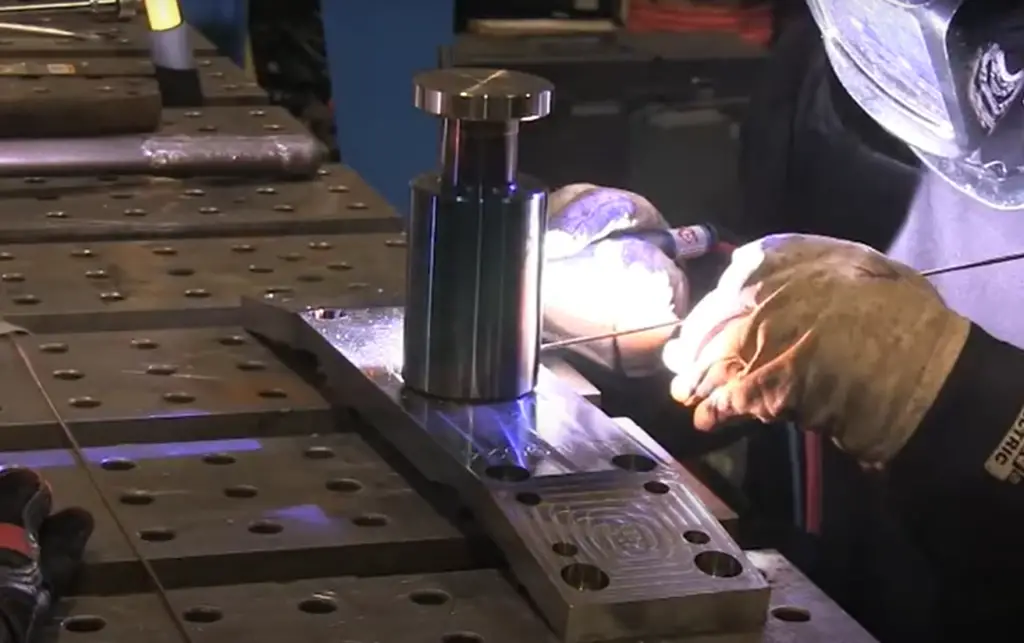

Welding Properties

The welding properties of low alloy steel and stainless steel vary significantly due to their different compositions. Low alloy steel, while it can be welded, preheating and a specific welding technique to maintain its structural integrity and prevent cracking. Furthermore, the weld area may need post-weld heat treatment to relieve stresses and improve the mechanical properties of the joint.

Stainless steel, particularly the austenitic types, is renowned for its excellent weldability. It generally does not require preheating and can be welded using various techniques, which adds flexibility to the welding process. However, it’s critical to select an appropriate filler material to avoid issues such as carbide precipitation, which may reduce corrosion resistance. Moreover, some grades of stainless steel may require post-weld heat treatment or cooling at a controlled rate to maintain their properties, ensuring optimal performance in specific applications.

In sum, while both low alloy steel and stainless steel can be welded, their welding procedures vary, and each comes with its own set of considerations. The choice between the two materials will depend on the welding capabilities, the required weld performance, and the specific requirements of the application. Taking these factors into account is crucial to achieving high-quality, durable welds in different scenarios.

Corrosion Resistance

Corrosion resistance is a crucial differentiating factor between low alloy steel and stainless steel, primarily attributed to their distinct chemical compositions. Low alloy steel, although possessing a certain level of resistance to atmospheric corrosion, is vulnerable to rust formation when exposed to moisture or corrosive environments. This susceptibility can be attributed to the absence of significant amounts of chromium in its composition, which is renowned for its exceptional oxidation resistance. Therefore, in applications where corrosion resistance is of utmost importance, low alloy steel may necessitate additional protective measures such as coatings or treatments to mitigate potential damage.

In contrast, stainless steel is widely acclaimed for its remarkable corrosion resistance, mainly due to its high chromium content. When exposed to oxygen, chromium forms a thin but robust oxide layer on the surface of the steel, creating a protective barrier against corrosive elements. An intriguing characteristic of this oxide layer is its self-healing nature, allowing it to reform if damaged, thereby ensuring the long-term durability of the steel even in harsh and corrosive environments.

Thus, while both low alloy steel and stainless steel offer a degree of corrosion resistance, stainless steel generally provides superior protection, making it the preferred choice for applications in harsh or corrosive environments. Nevertheless, the selection of the appropriate material should be based on a comprehensive understanding of the specific requirements of the application and the operating environment, taking into account factors such as chemical exposure, temperature, and the presence of other corrosive agents.[3]

The Impact

The choice between low alloy steel and stainless steel significantly impacts the performance, longevity, and overall cost of the final product. While low alloy steel might be more cost-effective initially, it is important to consider the potential for increased maintenance and replacement costs due to corrosion over time. On the other hand, stainless steel, with its excellent corrosion resistance, generally requires less maintenance, leading to potential long-term cost savings. However, it is worth noting that stainless steel does come with a higher upfront cost.

When considering the welding properties, it is crucial to understand that each material presents its own set of challenges and requirements. These factors can potentially affect the efficiency and cost of the manufacturing process. Additionally, in terms of corrosion resistance, stainless steel, with its self-healing oxide layer, is generally considered superior. This makes it more suitable for harsh or corrosive environments where low alloy steel may be more susceptible to degradation.

Therefore, the choice between low alloy steel and stainless steel will significantly depend on the specific requirements of the application and the operating environment. It emphasizes the need for a comprehensive understanding of the material properties and their implications to make an informed decision that ensures optimal performance, longevity, and cost-effectiveness.[4]

FAQ

What is Low Alloy Steel?

Low alloy steel is a fascinating type of steel that stands out for its limited concentration of alloying elements, typically less than 8%. Unlike stainless steel, which boasts substantial amounts of Chromium, low alloy steel primarily consists of Carbon, with smaller quantities of elements like Silicon, Manganese, Sulfur, and Phosphorus. These controlled amounts of alloying elements give low alloy steel its unique mechanical properties. Notably, it exhibits higher strength and hardness compared to carbon steel, while still maintaining good ductility and improved resistance to wear.

However, it’s important to note that low alloy steel does not possess the high corrosion resistance that stainless steel offers, mainly due to the absence of significant chromium content. While low alloy steel is an attractive choice for applications requiring high strength and durability, it may require additional protective measures in environments prone to corrosion.

In summary, low alloy steel’s distinctive composition and mechanical properties make it a versatile material in various industries. Its higher strength and hardness, along with good ductility and improved wear resistance, make it suitable for demanding applications. However, it’s essential to consider the potential need for additional corrosion protection in certain environments.

What is Low and High-Alloy Steel?

Both low and high-alloy steels are types of alloy steel, which are distinguished by the quantity and variety of alloying elements they contain. This type of steel, as mentioned earlier, has a relatively low concentration of alloying elements, typically less than 8%. This category encompasses a wide range of steel grades, each offering unique properties due to the varying combinations and quantities of alloying elements. Low-alloy steel exhibits higher strength, hardness, and toughness compared to carbon steel. It also demonstrates good ductility and improved resistance to wear. However, it is important to note that low-alloy steel has lower corrosion resistance compared to stainless steel. Therefore, when used in corrosive environments, additional protective measures are necessary.

On the other hand, high-alloy steel contains a significantly higher percentage of alloying elements, exceeding 8%. Stainless steel is a prime example of high-alloy steel. The precise composition of high-alloy steel varies widely depending on the specific grade, but it often includes elements such as chromium and nickel. These alloying elements contribute to enhanced corrosion resistance, making high-alloy steel ideal for use in harsh or corrosive environments. Additionally, high-alloy steels tend to have superior hardness, strength, and wear resistance compared to low-alloy steel.

However, it is important to consider that the benefits of high-alloy steel come at a higher cost compared to its low-alloy counterpart. The selection between low and high-alloy steels depends on the specific application and environment. Factors such as necessary strength, corrosion resistance, wear resistance, and cost should be carefully evaluated when making a decision.

In summary, both low and high-alloy steels have their own unique properties and benefits. The choice between the two depends on various factors, and it is crucial to consider the specific requirements of the application to ensure optimal performance and cost-effectiveness.

What are the 4 types of Low Alloy Steels?

High-Strength Low Alloy (HSLA) Steels: These steels are specifically engineered to provide superior mechanical properties and exceptional resistance to atmospheric corrosion when compared to conventional carbon steels. They achieve these enhanced characteristics by incorporating small quantities of alloying elements such as copper, nickel, and chromium. These alloying elements contribute to improved strength, toughness, and wear resistance, making HSLA steels highly suitable for demanding applications where durability and performance are paramount.

Quenched and Tempered Steels: This particular type of low alloy steel undergoes a specialized heat treatment process to further enhance its hardness and toughness. The process involves heating the steel to a high temperature, followed by rapid cooling (also known as quenching) to achieve a hardened structure. Subsequently, the steel is reheated (tempered) to reduce brittleness and optimize its mechanical properties. This combination of quenching and tempering imparts exceptional strength and toughness to the steel, making it ideal for applications that require high resistance to impact and wear.

Low Alloy Steels with Improved Formability: These steels possess outstanding forming and welding properties, making them highly suitable for fabricating complex shapes and structures. They are formulated with small amounts of alloying elements such as vanadium, titanium, and niobium. These alloying elements significantly enhance the formability and weldability of the steel, allowing it to be easily shaped and joined without compromising its mechanical integrity. This makes low alloy steels with improved formability an excellent choice for industries that require intricate and customized components.

Low Alloy Steels with High Temperature and Corrosion Resistance: Engineered to withstand extreme temperatures and corrosive environments, these steels are alloyed with elements like molybdenum, silicon, and chromium. These alloying elements impart exceptional resistance to oxidation and corrosion at elevated temperatures, making the steels highly suitable for applications in industries such as aerospace, power generation, and chemical processing. With their ability to maintain structural integrity and performance in demanding conditions, low alloy steels with high temperature and corrosion resistance offer a reliable solution for critical applications.

What is Low Alloy Steel used for?

Low steel is a versatile material that finds extensive use across various industries, thanks to its remarkable strength, durability, and cost-effectiveness. In the field of construction, it plays a crucial role in the fabrication of heavy-duty structures like bridges and buildings due to its exceptional high strength-to-weight ratio. This enables the creation of robust and reliable structures that can withstand immense loads and harsh environmental conditions.

The automotive industry also heavily relies on low alloy steel for the manufacturing of vehicle bodies and parts. From gears and shafts to carabiners, this steel type offers excellent wear resistance and formability, ensuring long-lasting and efficient performance. It contributes to the overall safety and reliability of automobiles, making them more durable and capable of withstanding challenging operating conditions.

In the oil and gas sector, the application of low alloy steel is particularly significant. It is commonly used in pipelines and drilling equipment, where its toughness and ability to withstand high-pressure environments are paramount. This ensures the integrity and reliability of crucial infrastructure in the oil and gas industry, providing a safe and efficient means of transportation and extraction.

Apart from these prominent industries, low alloy steel finds application in various other sectors. Shipbuilding relies on its strength and durability to construct seaworthy vessels capable of enduring extreme conditions at sea. Power plants benefit from its robust properties, using it in critical components that withstand high temperatures and pressures. Additionally, heavy machinery manufacturers incorporate low alloy steel in their equipment, enhancing their performance and longevity.

It is important to note that in corrosive environments, additional measures such as coating or plating may be necessary to prevent rusting and degradation. These protective measures ensure the longevity and reliability of low alloy steel in challenging conditions, extending its service life.

Overall, the wide-ranging applications and exceptional properties of low alloy steel make it an indispensable material in numerous industries, enabling the creation of strong, durable, and cost-effective solutions.

What are the 4 classifications of Steel?

- Carbon Steel: This is the most widely used kind of steel due to its versatility and strength. Its carbon content is typically under 2%, and it is divided into three categories: low, medium, and high carbon steel. Low carbon steel, with less than 0.30% carbon, is commonly found in everyday items. Medium carbon steel, containing up to 0.60% carbon, strikes a balance between ductility, strength, and wear resistance. High-carbon steel, with up to 1.5% carbon content, is exceptionally strong, although less ductile.

- Alloy Steel: Alloy steel is characterized by the presence of other elements apart from iron and carbon. Common alloying elements include chromium, nickel, molybdenum, manganese, vanadium, silicon, and boron. These added elements impart specific properties to alloy steels, such as enhanced corrosion resistance, heat resistance, hardness, durability, and tensile strength.

- Stainless Steel: Stainless steel is a widely used type of steel known for its exceptional corrosion resistance. It contains a minimum of 10.5% chromium, which forms a protective layer on the steel’s surface, preventing rusting and staining. There are multiple grades of stainless steel, each with varying chromium and molybdenum contents, tailored to withstand specific environmental conditions.

- Tool Steel: Tool steels are a specialized type of carbon and alloy steels designed specifically for making tools. They are highly distinguished for their exceptional hardness, resistance to abrasion, and ability to maintain a cutting edge even at high temperatures. As a result, tool steel is extensively utilized in various applications, particularly in shaping and machining other materials.

Useful Video: What is Alloy Steel in Process Piping? Low alloy vs High alloy steel – Piping Training Video-4

Conclusion

The vast and fascinating world of steel is characterized by its remarkable diversity. Each type and category of steel is meticulously designed to meet specific needs across a wide range of sectors. For instance, low alloy steel, with its exceptional balance of strength, ductility, and cost-effectiveness, has gained prominence in industries such as construction, automotive, and oil and gas.

While low alloy steel may not possess the same level of corrosion resistance as stainless or high-alloy steel, it can still be effectively protected through various measures. Understanding the nuances and applications of different types of steel, including carbon steel, alloy steel, stainless steel, and tool steel, becomes crucial in selecting the most suitable material for a given application. Factors such as required strength, corrosion resistance, wear resistance, and budget ultimately play a significant role in making the ideal choice.

Delving deeper into the world of steel uncovers a fascinating array of possibilities and considerations. By exploring the intricacies of this versatile material, we gain a deeper appreciation for its role in shaping the world around us.

References:

- https://www.corrosionpedia.com/definition/7059/low-alloy-steel

- https://blog.thepipingmart.com/metals/low-alloy-steel-vs-stainless-steel-whats-the-difference/

- https://www.ispatguru.com/low-alloy-steels/

- https://www.sciencedirect.com/science/article/abs/pii/S1005030211601667