Do you need to drill a hole in stainless steel? Whether you’re working on a DIY project or need to make a repair, it’s important to know the best way to drill stainless steel. In this blog post, we will teach you the basics of drilling stainless steel and provide some tips for getting the job done right.

What Is Stainless Steel?

Stainless steel is a type of steel that contains at least 10.5% chromium by mass. It is highly corrosion-resistant and wear-resistant, making it ideal for many industrial and household applications.

While stainless steel is generally resistant to rusting, it can still occur in some cases. If rust does form on stainless steel, it is important to remove it as soon as possible to prevent further damage.

Fortunately, there are a few different ways to remove rust from stainless steel without damaging the material. In most cases, a little elbow grease and a few common household items are all you need. [1]

Types of Stainless Steel

There are a few different types of stainless steel, each with its own properties and uses. The three most common types are austenitic, ferritic, and martensitic.

Austenitic stainless steel is the most common type used in both industrial and household applications. It contains chromium, nickel, and other alloying elements to improve corrosion resistance and mechanical properties.

It contains less chromium than austenitic stainless steel but can be heat-treated to improve strength.Martensitic stainless steel is not as commonly used but can be heat-treated for a high hardness. It is often used in knives, cutting tools, and other applications where a hard, durable material is needed. [2]

How to Drill Stainless Steel Properly?

Step 1. Drill bit selection

When choosing a drill bit for stainless steel, it is important to consider the type of metal being drilled and the desired finish. In general, twist drills are the best choice for drilling stainless steel. However, there are a few other options to consider depending on your project.

Type of Drill Bit:

- Twist Drill: The most common type of drill bit. It has a tapered point that helps it start drilling into the material and flutes that create chips as it drills. The angle of the twist drill is usually between 118° and 135°.

- Step Drill: A type of drill bit that can be used for making large holes in thin materials. It has a conical point that starts drilling at a small diameter and then enlarges the hole as it is turned.

- Carbide Drill Bit: A type of drill bit that is made from carbide, a material that is harder than high-speed steel and cobalt. These bits are used for drilling into hard materials such as stainless steel.

Finish:

- Bright: A shiny finish that is achieved by using a high-speed steel drill bit.

- Black Oxide: A black finish that is achieved by using a cobalt or high-speed steel drill bit with a black oxide coating.

- Titanium Nitride (TiN): A gold or blue finish that is achieved by using a titanium nitride coated drill bit. This coating helps to extend the life of the drill bit.

Step 2. Speed and Feed

The speed and feed of the drill bit are important to consider when drilling stainless steel.

The feed rate should be slow at first and then increased as the drill bit breaks through the material.Step 3. Pressure

Applying the right amount of pressure is important when drilling stainless steel. Too much pressure can cause the drill bit to wander and produce an uneven hole. Too little pressure will cause the drill bit to overheat and wear out quickly.

The best way to find the right amount of pressure is to experiment on a scrap piece of material first.

Step 4. Lubrication

It is important to use a cutting oil or lubricant when drilling stainless steel. This will help to cool the drill bit and prevent it from overheating. Apply a small amount of oil to the drill bit before starting to drill.

Step 5. Clearing Chips

As the drill bit breaks through the material, it will create chips that need to be removed from the hole. Use a chip brush or other tool to clear the chips from the hole as you drill. This will help to prevent the drill bit from becoming clogged and overheating.

Step 6. Drill Depth

When drilling through stainless steel, it is important to control the depth of the hole. This can be done by using a depth stop on the drill bit or by making a mark on the drill bit with a permanent marker. Drill slowly and stop frequently to check the depth of the hole.

Step 7. Cooling

It is important to keep the drill bit cool when drilling through stainless steel. This can be done by using a cutting oil or lubricant, as well as by allowing the drill bit to rest in between drilling. If the drill bit becomes too hot, it will lose its temper and become brittle.

Step 8. Finishing

Once the hole has been drilled, remove the drill bit from the material and inspect the hole. If the hole is not clean or if the edges are jagged, use a deburring tool to remove any sharp edges.

Step 9. Take a break

After drilling a few holes, it is important to take a break to allow the drill bit to cool down. If the drill bit becomes too hot, it will lose its temper and become brittle.

Step 10. Drill Another Hole

Repeat steps 2-8 to drill another hole. Remember to keep the drill bit cool and lubricated while drilling.

By following these steps, you will be able to drill through stainless steel without damaging the material. With a little practice, you will be able to drill through stainless steel quickly and easily.[3]

Safety Tips

When drilling stainless steel, always take the following safety precautions:

- Wear proper eye and ear protection.

- Use a dust mask to avoid inhaling any metal particles.

- Wear gloves to protect your hands from sharp edges.

- Work in a well-ventilated area.

- Secure the workpiece so it doesn’t move while you’re drilling.

General Tips

Here are some general tips for drilling stainless steel:

- Start with a smaller drill bit and then gradually increase the size until you reach the desired hole diameter. With this helpful tip, your drill bit will be less likely to slip, giving you more control over the drill.

- Use plenty of lubrication. This will help keep the drill bit cool and will prevent it from overheating.

- Use a lower speed setting on your drill. This will help prevent the drill bit from slipping and will make it easier to control the drill.

- Take your time. Drilling stainless steel can be difficult, so it’s important to go slowly and be careful.

How to Store Stainless Steel Items?

When it comes to storing stainless steel items, there are a few things you need to keep in mind.

First, always store your stainless steel in a dry place. If the area is damp, it can cause the steel to rust.

Second, if you’re going to be storing the steel for an extended period of time, make sure to wrap it in a breathable material. This will help prevent the formation of condensation on the surface of the steel.

Lastly, avoid storing stainless steel near chemicals or other materials that could cause it to corrode.

By following these simple tips, you can ensure that your stainless steel stays in good condition for years to come. [4]

How to Clean Stainless Steel?

Stainless steel is known for its ability to resist staining and corrosion, but it still needs to be cleaned on a regular basis.

The best way to clean stainless steel is with a mild detergent and warm water. Simply mix the two together and use a soft cloth to wipe down the surface of the steel.

If there are any stubborn stains, you can try using white vinegar or baking soda. Just apply either one of these directly to the stain and then wipe it away with a damp cloth.

Once you’re finished cleaning, make sure to dry the stainless steel completely. This will help prevent water spots from forming.

With just a little bit of care, you can keep your stainless steel looking like new for years to come. [5]

How to Cut Stainless Steel?

If you need to cut stainless steel, there are a few things you need to keep in mind.

First, always use a sharp blade when cutting stainless steel. A dull blade will cause the steel to tear and could even lead to injuries.

Second, take your time when cutting the steel. rushing through the process can result in an uneven or jagged cut.

Lastly, be sure to wear protective gear when cutting stainless steel. This includes gloves, safety glasses, and a dust mask.

By following these simple tips, you can safely and easily cut stainless steel.

How to Remove Rust from Stainless Steel?

Stainless steel is a popular choice for many household appliances and fixtures because it has a very long lifespan and is very easy to clean. However, one of the drawbacks of stainless steel is that it can be susceptible to rusting, especially if it’s not properly maintained. If you have stainless steel that is starting to show signs of rust, there are a few things you can do to clean it up and prevent further rusting.

One way to remove rust from stainless steel is to use a commercial rust remover. These products are designed specifically for removing rust and will usually do a good job of getting rid of it without damaging the underlying metal. Just be sure to follow the instructions on the product carefully so you don’t end up doing more harm than good.

One popular DIY rust removal solution is to mix equal parts white vinegar and water in a spray bottle and then spraying it on the affected area. Let it sit for a few minutes before scrubbing at the rust with a stiff brush. Once you’ve removed as much rust as possible, rinse the area with clean water and dry it off.Another option for removing rust from stainless steel is to use a paste made from baking soda and water. Just mix together enough of each ingredient to form a thick paste and then rub it into the rust using circular motions. Let it sit for a few minutes before wiping it away with a clean cloth. If there’s still some rust remaining, you can repeat the process until it’s all gone.

Once you’ve removed the rust from your stainless steel, it’s important to take steps to prevent it from coming back. One of the best ways to do this is to regularly clean and dry the metal after use. This will help remove any residue that could lead to rusting in the future. You should also avoid storing stainless steel in humid environments since moisture can promote rusting.

If you follow these tips, you should be able to keep your stainless steel looking like new for many years to come.

Alternatives to Stainless Steel

There are a few materials that can be used as substitutes for stainless steel. These include: titanium, hastelloy, nickel alloys, aluminum, zinc alloys, and copper alloys. While each of these materials has its own set of benefits, they also come with their own set of drawbacks. For instance, titanium is much more expensive than stainless steel and is not as corrosion resistant. Hastelloy is also quite expensive and is not as strong as stainless steel. Nickel alloys are susceptible to pitting and corrosion and are not as strong as stainless steel. Aluminum is not as strong as stainless steel and is also susceptible to corrosion. Zinc alloys are not as strong or durable as stainless steel. Copper alloys are the weakest of the bunch and are also susceptible to corrosion.

So, if you need a material that is strong, durable, and corrosion resistant, stainless steel is the way to go. Drill bits for stainless steel are available in a variety of sizes and styles to fit your needs. When choosing a drill bit for stainless steel, make sure to select one that is made from high-quality materials and is designed for use with stainless steel. With the right drill bit, you will be able to easily drill through stainless steel without any issues.

FAQ

Do you need a special drill bit for stainless steel?

No, you don’t need a special drill bit for stainless steel. However, using a standard high-speed steel (HSS) drill bit will cause the drill bit to wear out quickly. For best results, use a cobalt or carbide-tipped drill bit designed for drilling hard metals.

How do you keep stainless steel from rusting?

Stainless steel is an alloy that contains chromium. This element forms a thin layer of oxide on the surface of the metal that protects it from corrosion. In order for this to work effectively, there must be at least 10.5% chromium present in the alloy.

What is the best way to drill a hole in stainless steel?

The best way to drill a hole in stainless steel is to use a cobalt or carbide-tipped drill bit. These bits are designed specifically for drilling hard metals and will stay sharp longer than standard HSS bits.

How do you prevent stainless steel from rusting?

Stainless steel is an alloy that contains chromium.

This element forms a thin layer of oxide on the surface of the metal that protects it from corrosion. In order for this to work effectively, there must be at least 10.5% chromium present in the alloy.

Can you weld stainless steel to carbon steel?

Yes, you can weld stainless steel to carbon steel. However, you will need to use a filler material that is compatible with both metals. This is because stainless steel and carbon steel have different melting points.

What are the benefits of using stainless steel?

Some of the benefits of using stainless steel include its durability, corrosion resistance, and ability to be cleaned easily. Stainless steel is also a recyclable material, which makes it an environmentally friendly option.

What are some disadvantages of using stainless steel?

Some potential disadvantages of using stainless steel include its high initial cost, as well as the fact that it can scratch easily. Additionally, stainless steel is not compatible with certain other metals, such as aluminum.

Do you need a special drill bit for stainless steel?

If you’re drilling through stainless steel thicker than 1/8 inch, then you’ll need a specialized drill bit. These are available at most hardware stores. For thinner sheets of stainless steel, you can use standard metal drill bits, but they may not last as long as the specialized ones.

Step by step guide on how to drill through stainless steel:

- Start with a smaller drill bit and work your way up to the desired size. This will extend the life of your drill bit and make the job easier.

- Use cutting oil or WD-40 to lubricate the drill bit and work area. This will help keep the drill bit from overheating and make drilling easier.

- Use a slow speed and steady pressure when drilling. This will prevent the drill bit from overheating and breaking.

- Start the hole in the center of the stainless steel sheet. This will prevent the drill bit from wandering off course.

- Drill through the stainless steel sheet slowly and steadily, using short strokes.

- Once you’ve reached the other side, back the drill bit out slowly to avoid breaking it.

- Inspect your work and remove any burrs with a file or sandpaper.

- Repeat these steps if necessary to enlarge the hole to the desired size.

Is it hard to drill stainless steel?

Drilling through stainless steel is not difficult, but it does require a bit of patience and the right tools. With the proper preparation and techniques, you can drill through stainless steel without too much trouble. When drilling through stainless steel, it’s important to use a sharp drill bit and go slowly to avoid overheating the metal. It’s also helpful to lubricate the drill bit with cutting oil or WD-40 before starting. If you take your time and work carefully, you should be able to drill through stainless steel without any major problems.

What speed should you drill stainless steel?

When drilling through stainless steel, it’s best to use a slow speed and apply steady pressure. This will help prevent the drill bit from overheating and breaking. Start with a smaller drill bit and work your way up to the desired size. This will extend the life of your drill bit and make the job easier.

Can you drill stainless steel with a regular drill bit?

For thinner sheets of stainless steel, you can use standard metal drill bits, but they may not last as long as the specialized ones. If you’re drilling through stainless steel thicker than 1/8 inch, then you’ll need a specialized drill bit. These are available at most hardware stores. Use cutting oil or WD-40 to lubricate the drill bit and work area. This will help keep the drill bit from overheating and make drilling easier.

How do you soften stainless steel for drilling?

If the stainless steel is too hard for drilling, you can try annealing it. This involves heating the metal until it’s red-hot and then cooling it rapidly. This will make the metal softer and easier to drill through. However, this process also makes the metal more brittle, so you’ll need to be careful not to break it while drilling.

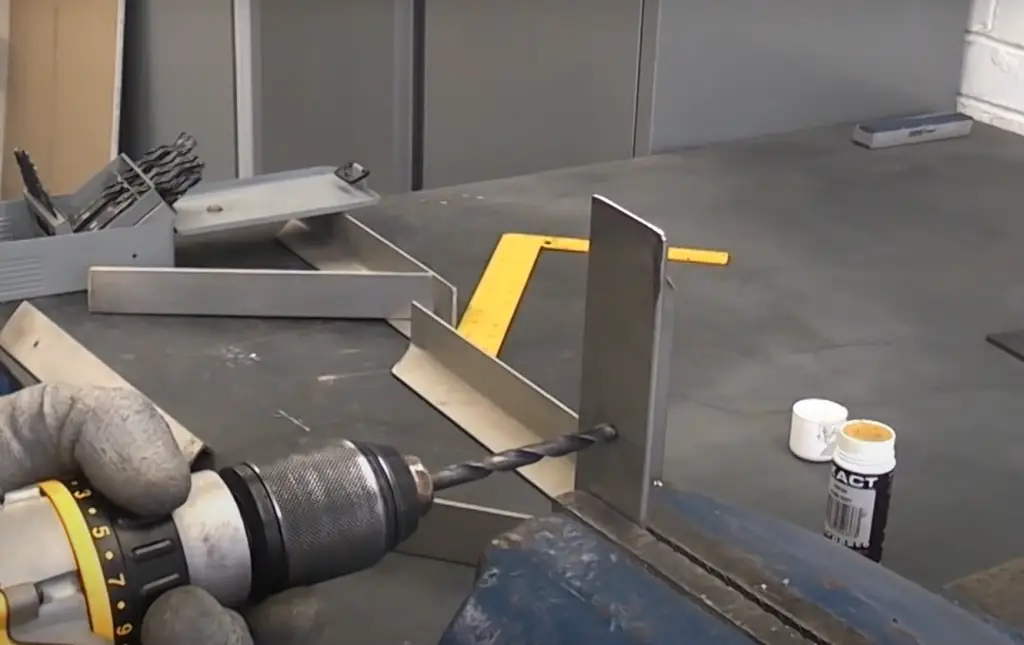

Useful Video:How to drill stainless steel

Conclusion

With the right drill bit and some care, it is possible to drill through stainless steel. Be sure to use a sharp bit and work slowly to avoid overheating the steel. Use coolant if necessary to keep the bit from overheating. When drilling larger holes, or when working with thicker stainless steel, it may be necessary to use a pilot hole to get started. With a little patience and the proper tools, even a beginner can learn how to drill through stainless steel like a pro!

No matter what type of project you are working on that requires stainless steel drilling, following these tips will help ensure success. Remember to use the right type of drill bit for your application, take your time, and avoid overheating the material.

References:

- https://www.unifiedalloys.com/blog/what-is-stainless-steel

- https://www.accu.co.uk/p/112-what-is-the-difference-between-ferritic-austenitic-martensitic-stainless-steels-accu

- https://www.sailmagazine.com/diy/know-drilling-stainless-steel

- https://www.webstaurantstore.com/guide/542/how-to-clean-stainless-steel.html

- https://www.maids.com/blog/cleaning-stainless-steel/