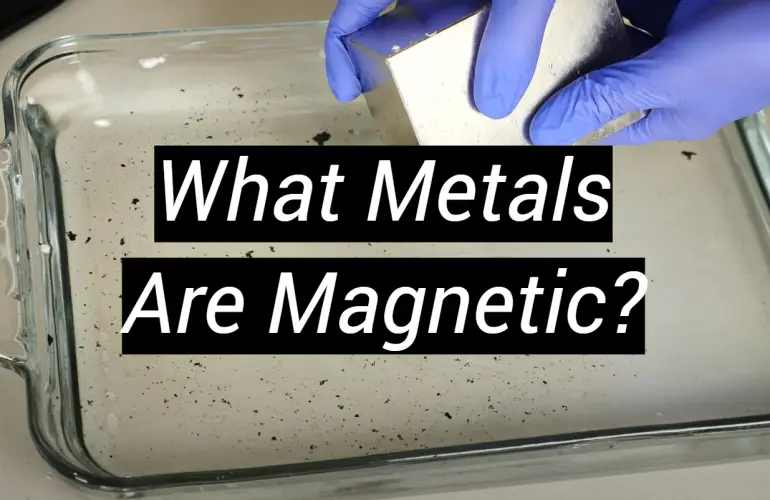

What Metals Are Magnetic?

If you’re like most people, you probably think of magnets as being made of metal. But did you know that there are actually only a few metals that are naturally magnetic? In this blog post, we’ll take a look at the metals that are attracted to magnets, and explain why they behave this way. After reading this post, you’ll have a better understanding of how magnets work and which materials can be used to create them. So let’s get started!

Magnetism: What Is It?

Magnetism is a phenomenon that occurs when certain metals are exposed to an external magnetic field, causing them to become magnetized.

This means that they produce their own magnetic field, which can attract and repel other objects. The most commonly known example of this is the refrigerator magnet, which uses iron filings as its core material.

What Creates Magnetism In Metals?

Metals can be magnetic due to the presence of unpaired electrons in their atomic structure. When a metal has an atomic number with an uneven amount of paired electrons, it creates imbalances that leave one or more unpaired electrons. As a result, this causes the metal to be attracted to magnets.

Apart from ferromagnetic materials, permanent magnets also consist of gadolinium and neodymium.Magnetism is also created when two different types of metals (magnetic substances) come into close contact with each other due to cold welding, which is a kind of diffusion bonding process at room temperature. This process welds together the atoms on the surface of both objects and creates strong and permanent magnetic properties.

Still other metals may become temporarily magnetized when they come into contact with an existing magnet. This is because the magnetic force of the external field induces a weak internal field in the metal, causing it to become attracted to magnets. However, this effect only lasts as long as the magnet is present; once it is removed, the metal’s internal field dissipates quickly and it loses its magnetic properties. [1]

Which Metals Are Magnetic?

While the majority of metals lack magnetic properties, a small number of them do possess these qualities. Iron, cobalt, and nickel are the most common magnetic metals. These elements are ferromagnetic, meaning they can be magnetized to become strongly attracted to a magnetic field. Other metals that may show weak magnetism include gadolinium, neodymium and samarium. Certain alloys such as steel also contain iron and cobalt which makes them naturally magnetic.

However, it is important to note that a material may be considered “magnetic” even if it only exhibits weak properties when exposed to an external magnetic field. This is due to the fact that these materials are still able to induce a small current in nearby electrical wires when an external field is applied to them.

The magnitude of magnetism observed in a metal is related to the degree of its ferromagnetism. This property can be tested by exposing the material to an external magnetic field, and measuring the strength of attraction or repulsion that it experiences. The magnetomotive force (MMF) is a measure of magnetism, relating the current through a wire wound around a solid rod, or other ferromagnetic material, to the amount of magnetization within the material itself. To assess MMF for a metal object, one would typically expose it to an electric current and then measure its response using sensitive instruments such as Hall probes.

In summary, some metals are more magnetic than others. Generally, metals that contain iron, cobalt and nickel are the most magnetic. However, even metals without these elements can exhibit weak magnetic properties when exposed to an external field. By measuring the magnetomotive force of a metal object, one can assess its degree of ferromagnetism. Knowing which metals are magnetic can be useful in many practical applications such as electronic device design and engineering projects. [2]

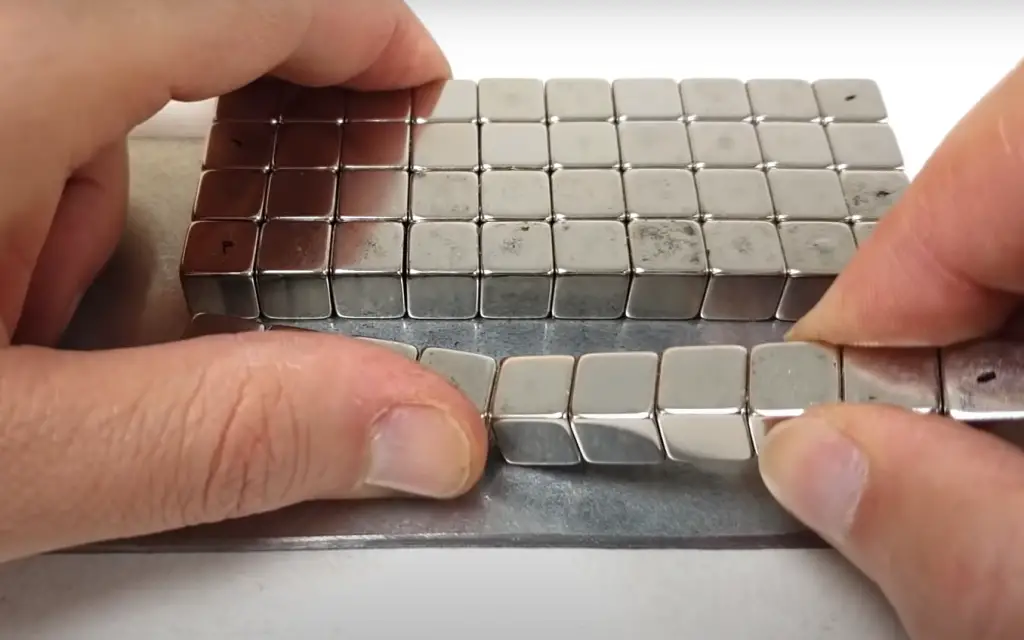

Permanent Magnets

Permanent magnets are made from materials that retain their magnetic properties when exposed to a magnetic field.

The strongest permanent magnets are usually made of an alloy of two or more different metals.Magnets can also be made using a process called “electroplating,” where the metal is plated onto a ferromagnetic material like steel. Permanent magnets are known for having high coercivity, meaning they can resist an external magnetic force without losing their own magnetism. This makes them ideal for use in applications where strength and durability are important, such as motors and generators. Furthermore, permanent magnets can have a variety of shapes and sizes, making them useful for a wide range of applications. [3]

Electromagnets

Magnets made of iron, steel, cobalt, and nickel are all magnetic. However, not all metals are magnetic; for example, aluminum, brass, copper, gold and silver are not attracted to a magnet. Metals that can be magnetized usually have the ability to become an electromagnet when electricity is passed through them.

An electromagnet is created by passing an electric current through a wire that is wrapped around a core material composed of iron or other metal with magnetic properties. When this occurs the electrons align with their surrounding atoms and create a strong electrical field which produces its own magnetic field. This type of magnet has much more strength than one just composed of ferromagnetic metal alone because it combines both electrical and magnetic fields together to create a stronger force.

The strength of an electromagnet also depends on how many turns of wire are used in the coil and the material that makes up the core. This type of magnet is often used for lifting heavy objects such as scrap metal, in motors to create motion, and in medical instruments to help with imaging processes. Electromagnets can be turned on and off depending on whether or not electricity is passed through them which makes them a versatile tool for many applications.

Overall, while some metals like iron and steel have natural magnetic properties, other metals can be made into magnets by creating an electromagnet which has great practical use both in industry and medicine. It’s important to remember that not all metals are magnetic, so it’s important to pay attention to the material when considering whether or not a magnet will be attracted to it.

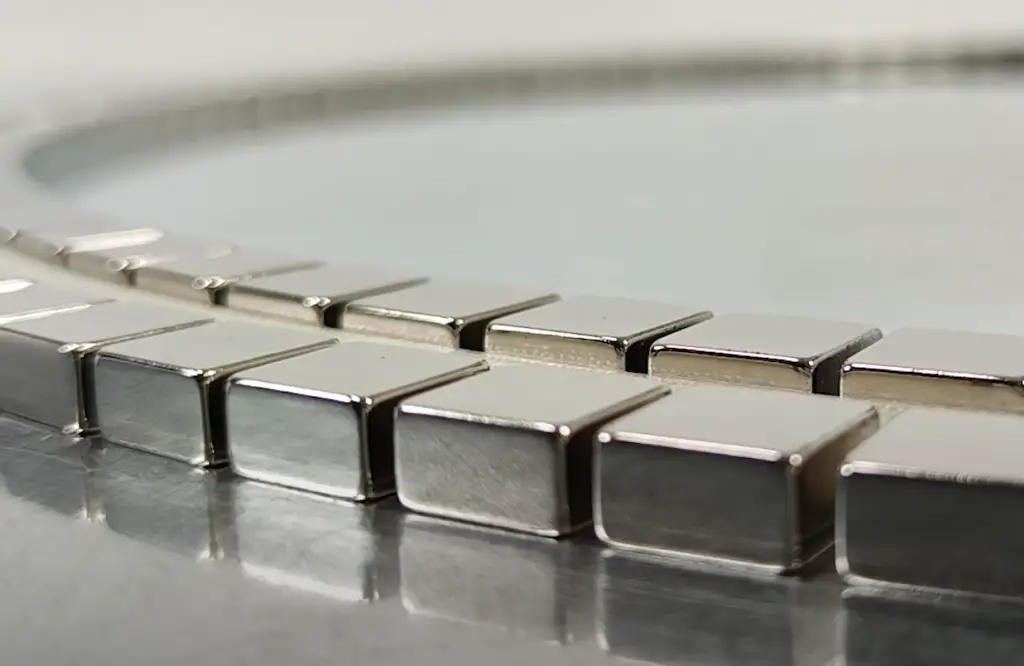

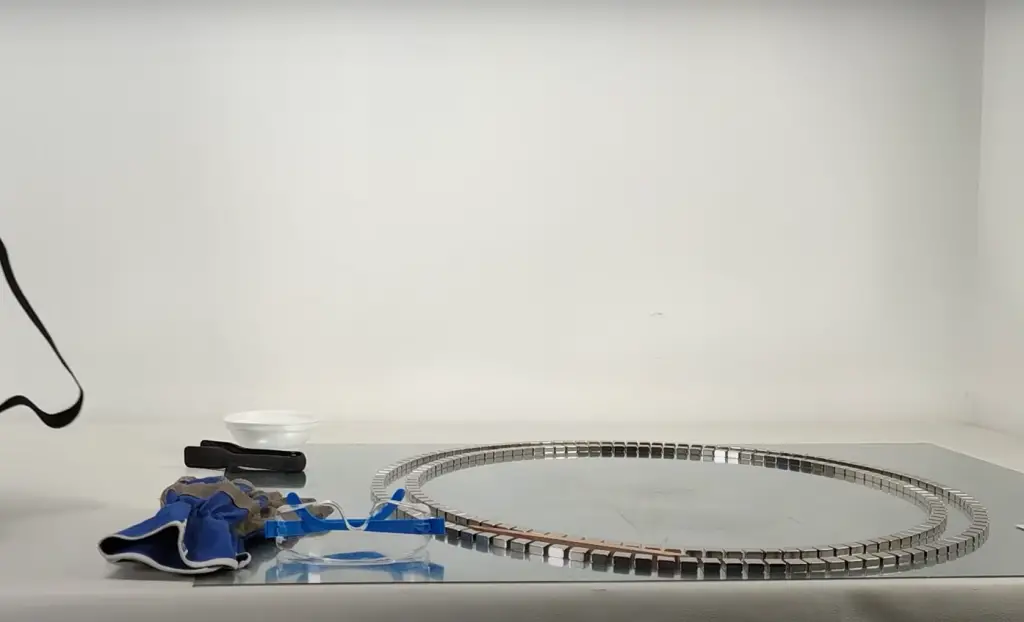

Neodymium Magnets

Neodymium magnets are the strongest permanent magnetic materials available and are composed mainly of neodymium, iron, and boron. They also have a high coercivity which makes them difficult to demagnetize and can be found in many applications such as hard drives, electric motors, speakers, sensors, medical devices, and more. Other metals that can be magnetized include cobalt and nickel.

Alnico (an alloy made from aluminum, nickel and cobalt), steel alloys such as stainless steel, and rare earth metals like samarium-cobalt also become magnetized when exposed to strong external magnetic fields.

By understanding what metals are magnetic it is possible to create products with higher performance than those without magnetic properties. This can be beneficial in many industries, from manufacturing to aerospace. With ever-evolving technology, magnetic materials are becoming increasingly important for a variety of applications.

Turning Non-Magnetic Metals Into Magnets

Though some metals are naturally magnetic, others can be magnetized by using a process called inductive charging. This process creates a current through the metal object and rearranges its molecules in such a way that it acquires magnetic properties. One of the most common ways to create an inductive charge is with electricity, though it can also be done with electromagnetic fields or chemical treatments. Metals like iron, nickel, cobalt and certain rare earth alloys are particularly susceptible to this process and as a result, they’re often used in industrial applications where strong magnets are needed.

By contrast, other materials like aluminum do not respond well to induction charging and so they will not usually become magnets no matter how hard you try. That said, with enough electrical current, aluminum can be made magnetic in some cases. It just won’t be nearly as strong or as reliable as a naturally occurring magnet.

Ultimately, there’s no one-size-fits-all answer when it comes to making non-magnetic metals into magnets. Some metals are easier to magnetize than others and the process itself varies depending on what kind of metal you’re working with. However, by understanding the principles involved in magnetic induction and applying them appropriately, even materials that are not normally magnetic can become powerful magnets in their own right! [4]

Are Magnetic Metals Stronger Than Non-Magnetic Metals?

The answer to this question is not a simple yes or no. Generally speaking, magnetic metals tend to be stronger than non-magnetic metals, but there are some exceptions. Magnetic metals usually have higher tensile strength, meaning they can resist breaking under heavy loads better than non-magnetic metals.

However, other factors like the composition of the metal and its alloying elements can also affect its strength. For example, aluminum alloys with low levels of iron may be stronger than ferromagnetic materials such as steel but still lack magnetism. Therefore, it is more accurate to say that magnetic and non-magnetic metals can both possess varying levels of strength depending on their individual compositions.

Can Metal Detectors Detect Non-Magnetic Metals?

No, metal detectors are designed to detect magnets and magnetic materials. They are not sensitive enough to detect non-magnetic metal alloys such as aluminum, copper, brass or stainless steel. However, certain types of metal detectors can be equipped with advanced technology that can detect certain non-magnetic metals such as gold or silver. These specialized detectors usually have a higher cost than regular metal detectors and require special training to use properly. Additionally, depending on the size of the target object and its depth beneath the surface, it may still be difficult for even these specialized detectors to find non-magnetic metals.

The best way to find any type of metal is to use a combination of different detection methods. By combining traditional metal detecting with ground-penetrating radar or a magnetometer, it is possible to locate non-magnetic metals with great accuracy. This method is used by professionals in mining operations and archaeology to detect buried objects that traditional methods may miss. [5]

Examples Of Ways To Utilize Magnetic Metals

Magnetic metals are highly valuable in many industries, including electronics and engineering. Here are a few ways they can be used:

- Motors: Motors often contain magnetic components, such as permanent magnets, electromagnets, and coils. Ferromagnetic materials like iron help create the powerful fields necessary for these motors to work.

- Magnetic resonance imaging (MRI) machines: These medical scanning devices use strong magnetic fields to generate images of the body’s internal organs. The field is created by large superconducting magnets made from metals like cobalt or nickel-iron alloys.

- Generators & alternators: Generators and alternators rely on magnetism to produce electrical current. They are usually made from steel and other magnetic metals such as iron or nickel.

- Telecommunications: Telecom networks use a variety of ferromagnetic materials due to their ability to transmit data without breaking down. They are often made from aluminum, cobalt, or nickel alloys that can be magnetized and demagnetized.

- Magnetic sensors: These devices sense changes in the environment by detecting fluctuations in magnetic fields. They are usually made of magnetic metals like iron or nickel-iron alloys. [6]

How Does Magnetization Affect Pricing?

The magnetization of a metal affects its price in two ways. Firstly, the process of turning a non-magnetic material into a magnetic one can be costly and time consuming. Depending on the type and size of the material, this transformation can require specialized tools and expertise.

Secondly, magnetic metals are often more valuable than non-magnetic materials because they can be used in a variety of applications that require specific properties or functionality—such as motors, computers, transformers, and MRI machines.

For example, steel is much less expensive than cobalt or nickel alloys because steel is not easily magnetized and therefore has fewer applications than these other metals.

This is because, in some cases, it may be more economical to purchase a non-magnetic metal and have it magnetized than it would be to buy an already magnetic material. Additionally, when selecting a magnetic metal for a specific application, its strength and functionality should also be taken into account—as these factors will affect both its price and performance.FAQ

What are the 4 magnetic metals?

The 4 magnetic metals are iron, cobalt, nickel and neodymium. Iron is the most available and by far the strongest of these magnetic metals. Cobalt and nickel are much rarer than iron but also have strong magnetic properties. Neodymium is a rare earth metal that has very strong magnetic properties; it is used in many modern technologies such as high-powered magnets and motors. All four of these materials will strongly attract other magnetic objects when placed near them.

Are all metals magnetic?

No, not all metals are magnetic. Some non-magnetic metals include aluminum, lead, copper, tin and brass. These materials do not attract a magnet or any other type of magnetized material when placed near them. However, they can become magnetized if placed within a strong magnetic field.

How do I test if a metal is magnetic?

The easiest way to test whether a material is magnetic or not is by using a simple magnet. If the metal attracts the magnet, it is likely that it contains at least some magnetic properties. For more precise results, you may want to use an electronic metal detector or other testing device to determine its exact composition and level of magnetization.

What are ferromagnetic metals?

Ferromagnetic metals are materials that have the strongest possible response to an applied magnetic field. These materials include iron, cobalt and nickel as well as alloys such as alnico, permalloy and mumetal. Ferromagnetic metals are commonly found in motors, electric generators and other electrical equipment where they are used to create a strong magnetic field.

What metals are not magnetic?

Non-magnetic metals include aluminum, lead, copper, zinc, tin and gold. These metals have an unpaired electron or have low magnetic permeability. Aluminum is the most commonly used non-magnetic metal in everyday life. Lead is also a very common non-magnetic metal that has many uses in construction and industrial applications. Copper, zinc, tin and gold are all non-magnetic but are rarely used for large scale engineering projects due to their relatively high cost. They do however find use as decorative items or electrical components such as wiring or connectors.

Some of these metals can be alloyed with other metals to increase their strength or corrosion resistance while still retaining their non-magnetic properties. For example, brass (an alloy of copper and zinc) often finds use in industrial valves or fixtures due to its high resistance to corrosion. Despite their lack of magnetism, these non-magnetic metals can still be affected by a magnetic field as they are able to conduct electricity.

Is aluminum magnetic?

No, aluminum is not magnetic. Aluminum is a non-magnetic metal that has an unpaired electron, making it unable to form a permanent magnetic field around itself. Therefore, it cannot be magnetized and will not attract magnets or other magnetic materials. However, aluminum can still interact with existing magnetic fields as it is able to conduct electricity. For this reason, aluminum should be avoided when selecting material for applications requiring complete immunity from external magnetic influences.

Useful Video: Are all metals magnetic?

Conclusion

In conclusion, many metals are magnetic, including iron, cobalt, nickel, steel and more. Magnets can be used to move objects in the same way that metal filings move around a magnet when it is placed on paper. Magnetic forces act in both directions between two magnets and even between metal items and a magnet. Therefore it is important to note that not all metals are magnetic; some non-magnetic metals include aluminum, copper, lead and tin. Knowing which metals are magnetic can help you decide whether an object will respond to a magnet or not. Understanding these concepts can aid with various projects or experiments involving magnets.

References:

- https://www.meadmetals.com/blog/what-metals-are-magnetic

- https://www.metalsupermarkets.co.uk/which-metals-are-magnetic/

- https://www.eclipsemagnetics.com/resources/a-quick-guide-to-magnets-magnetic-metals-and-non-magnetic-metals/

- https://fractory.com/magnetic-metals-non-magnetic-metals-with-examples/

- https://www.asm-recycling.co.uk/blog/which-metals-are-magnetic/

- https://www.twinkl.co.uk/homework-help/science-homework-help/magnets-facts-for-kids/what-are-some-everyday-uses-of-magnets