Metals, with their myriad forms and compositions, never fail to captivate us with their diverse range of properties and capabilities. From the towering skyscrapers that define modern cityscapes to the sleek smartphones that have become extensions of ourselves, metals are truly integral to our day-to-day existence.

This comprehensive document takes you on an exhilarating journey into the fascinating world of metals, delving deep into their strengths, weaknesses, and unique characteristics. We will explore the exceptional properties of specific metals such as Tungsten, known for its remarkable density and strength, Chromium, renowned for its corrosion resistance and brilliant shine, and Titanium, celebrated for its exceptional strength-to-weight ratio and biocompatibility. We will even venture into the realm of fiction, examining the mythical metal Vibranium from the Marvel Universe, renowned for its extraordinary energy-absorbing properties.

Prepare yourself for an immersive and enlightening experience that will not only deepen your understanding of the metals that shape our world but also empower you to make informed decisions when choosing the right metal for your projects. Consider factors such as strength, durability, weight, corrosion resistance, cost, and availability, and embark on a quest to unlock the full potential of these remarkable materials. Get ready to embark on a captivating journey that will ignite your passion for the wonders of metallurgy and leave you with a newfound appreciation for the metals that shape our lives.

Types of Metal Bending

Metal Bending, an age-old technique that has stood the test of time, has undergone significant evolution and transformation with the advancements in technology. Today, there are types of metal bending techniques employed, each offering its own unique set of benefits and applications.

From the precise and intricate artistry of press brake bending to the raw power of roll bending, these techniques enable the shaping and manipulation of metal in ways that were once unimaginable. Whether it’s for architectural masterpieces or industrial machinery, metal bending continues to play a vital role in various fields, pushing the boundaries of what is possible in engineering and design.[1]

Air Bending

Air Bending is a fascinating technique that falls under the umbrella of metal bending. Unlike other methods that rely on direct contact with the metal to create a bend, air bending introduces a unique approach. In this process, the sheeting material is not clamped; instead, it is delicately placed on the die, while the punch is gradually lowered towards it. As a result, the material bends under the pressure exerted by the punch, without the punch itself making physical contact with the die.

One of the remarkable advantages of air bending lies in its exceptional flexibility. By simply adjusting the position of the punch, the angle of the bend can be easily modified. This versatility allows for precise and intricate bending operations, making air bending a preferred choice in various industries. Its applications stretch across sectors such as automotive, aerospace, and construction, where accuracy and the ability to exert relatively low force are paramount.

The significance of air bending cannot be overstated, as it revolutionizes the way metal fabrication is approached. With its innovative technique and wide-ranging benefits, air bending continues to shape and elevate the standards of metalworking in countless industries.

Bottom Bending

Bottom Bending is a highly effective metal bending technique that offers distinct advantages over other methods. In contrast to air bending, which relies on air pressure to achieve desired angles, bottom bending utilizes a punch to exert more force and achieve precise angles with strict tolerances.

During the bottom bending process, the punch pushes the sheet metal into the die until it makes contact with the bottom surface. This action forces the sheet metal to conform to the angle of the die, resulting in a precisely bent piece. The method’s high accuracy and repeatability make it the preferred choice for applications that demand precise angles and strict tolerances.

It is worth noting that while bottom bending offers exceptional accuracy, it does require more force compared to air bending. As a result, the use of robust equipment may be necessary to ensure efficient and reliable bending operations.

Coining

Coining, a prominent technique in the world of metal bending, is known for its high precision and accuracy. This process involves stamping a piece of metal with a die, similar to a coin press, to create a specific shape or pattern.

One of the remarkable advantages of coining is its ability to produce highly detailed and intricate shapes, making it an ideal choice for industries requiring complex designs and high-volume production.

The precision and consistency offered by coining make it a popular technique in sectors such as electronics, automotive, and aerospace.

Despite this, the exceptional level of detail and accuracy achieved by coining continues to make it a sought-after method in various industries.V-bending

V-bending is a widely employed technique in metal bending, known for its versatility and precision. In this process, a piece of sheet metal is carefully positioned between a V-shaped die and a punch. As the punch exerts pressure on the metal, it gradually takes on the shape of the die, resulting in a clean and accurate bend. This method finds extensive application across industries like aerospace, automotive, and electronics manufacturing, where intricate shapes and precise angles are paramount. It offers the ability to create sharp and well-defined bends, making it an ideal choice for projects that demand meticulous attention to detail.

It is important to note that due to the substantial forces involved in V-bending, it is crucial to utilize robust and durable machinery and equipment to ensure safety and efficiency in the process. By employing this technique, professionals can achieve exceptional results while maintaining the integrity and quality of the metal workpiece.

Roll Bending

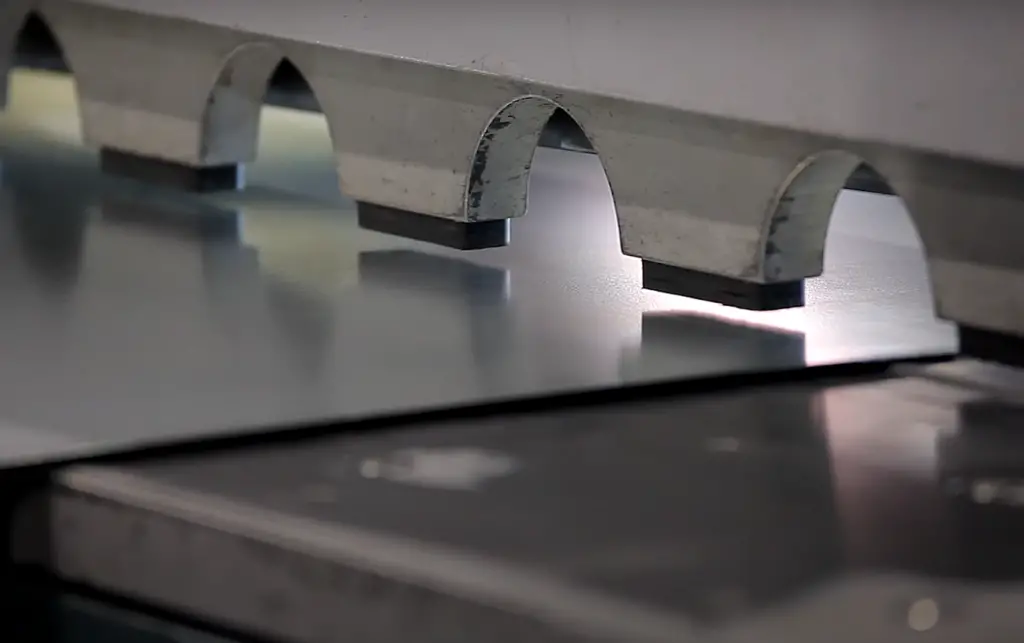

Roll Bending is a distinctive and versatile metal bending technique that offers a wide range of possibilities. Principally used to form smooth curves and precise arcs in metal, this method employs a specialized machine with three rollers arranged in a pyramid formation. As the metal passes through these rollers, carefully applied pressure causes it to gracefully curve, resulting in elegant and seamless bends.

One of the key advantages of roll bending is its adjustable bend radius. By changing the distance between the rollers, operators can achieve a variety of shapes and curvatures, providing endless design possibilities. This flexibility makes roll bending particularly useful for bending large pieces of metal, making it a popular choice in the construction of tanks, pipelines, and even wind turbine structures.

However, it is important to note that while roll bending offers great flexibility and creativity, it does require skilled operators to ensure precision and accuracy. The expertise and experience of these operators are crucial in achieving consistent and high-quality results, especially when working with complex designs or tight tolerances.

U-Bending

U-bending is a highly important and widely utilized technique in the realm of metal bending. This intricate process involves bending a strip of metal into a precise U shape by skillfully applying force using a punch and die.

The remarkable aspect of this technique lies in its versatility, as the depth of the bend can be precisely adjusted by varying the amount of force applied. Due to its simplicity and the ability to achieve consistent repeatability, U-bending finds extensive applications in various industries, including automotive and HVAC. It plays a crucial role in the fabrication of essential components such as brackets, clamps, and heat exchangers. This process not only ensures the creation of intricate and accurate bends but also contributes to the overall efficiency and quality of the final products.Wipe Bending

Wipe Bending is a technique that finds its significance in the world of metal bending. In this method, the sheet metal is held in place by a clamping die while a wiping die forces the metal over a form block, creating the bend. The force applied by the wiping die bends the overhanging part of the sheet into the desired angle. Wipe bending is particularly beneficial when dealing with thinner materials or when a sharp, clean bend is required.

It is also used when the precision of the bend angle is critical. Therefore, it finds wide applications in various industries, including the automotive and aerospace sectors, for manufacturing parts that demand high precision and sharp angles. However, the process requires a well-maintained tool setup to ensure accuracy and prevent the formation of undesired bends or distortions in the metal.

Rotary Bending

Rotary Bending is a unique and advanced metal bending technique. This method employs a rotary bending machine, which uses rotating movements to bend the metal, reducing or eliminating the risk of marking the material. As a result, the method is especially suitable for bending polished, coated, or sensitive materials that require a high-quality surface finish. The machine has two dies which rotate and draw the metal inwards, creating a bend. The bend angle may be controlled by adjusting the rotation angle of the dies, allowing for high flexibility and precision. Rotary bending is extensively used in industries such as automotive, aviation, and household appliances, where the aesthetic quality of the product is important. The technique, though requiring specially designed machinery, offers the advantage of a mark-free bending process, enabling high-quality and precision-finished products.

5 Tips for Bending Steel Plates

Watch out for springback

In the process of metal bending, there is a fascinating phenomenon known as springback that you should be aware of. Springback refers to the inherent tendency of the metal to return to its original shape after the bending force is removed. This behavior can be influenced by various factors such as the type of metal being used, the specific bending process employed, and even the bend radius. It is important to note that the amount of springback can vary significantly depending on these factors.

To account for the unpredictable nature of springback, it is often necessary to employ a technique called overbending. This involves bending the material slightly beyond the desired shape and angle, ensuring that once the springback occurs, the final product achieves the precise shape and angle that is desired. By accurately predicting and compensating for springback, you can achieve remarkable precision and high-quality bends in your metal bending projects.

Remember, understanding and effectively managing springback is an essential skill for any metal bender. It requires careful consideration of the material properties, the bending process, and the desired outcome. By mastering the art of accounting for springback, you can elevate the quality of your metal bending work and achieve impressive results.

Is the sheet metal malleable enough?

One of the key factors to consider when bending sheet metal is its malleability. Malleability refers to the metal’s ability to be bent and shaped without breaking or cracking. Highly malleable metals, such as aluminum and copper, exhibit excellent ductility and can be formed into intricate designs and precise bends. Their flexibility allows for creative possibilities in metalworking.

On the other hand, less malleable materials, like high Carbon steel, pose challenges in the bending process. These materials are more prone to cracking or breaking under the pressure of bending. However, with the right techniques, such as heat treatments or annealing processes, the malleability of these materials can be improved. This opens up opportunities to work with a wider range of metals and achieve desired shapes and forms.

It is crucial to choose a metal with suitable malleability for the specific bending project. This consideration helps avoid costly mistakes and ensures high-quality results. By understanding the malleability of different metals and implementing appropriate techniques, metalworkers can achieve incredible precision and finesse in their sheet metal bending endeavors.

Always use a press brake

A press brake is a machine pressing tool for bending sheet and plate material, most commonly sheet metal. It’s a crucial tool for metal bending and should be used whenever possible. It offers high precision and control over the bending process, making it ideal for projects that require specific angles or shapes.

Additionally, press brakes come with a range of dies that can be swapped out according to the specifications of the project, further increasing their versatility. When used correctly, a press brake can greatly enhance the accuracy and quality of your bends, leading to an overall improved final product. However, remember to use it safely – always follow the manufacturer’s guidelines and wear the appropriate safety gear while operating the machine.

Do not forget the process position holes

When working with metal bending, it is crucial to take into consideration any process position holes that need to be integrated into your design. These holes play a significant role as guides or reference points during the manufacturing process, ensuring proper alignment and assembly of parts. It is imperative to meticulously place these holes before the bending process begins, as any distortion during bending can result in inaccuracies in the final product. By meticulously placing these process position holes, you can greatly enhance the precision of your project, leading to high-quality assembly and impeccable fit. Taking the time to account for every detail in the design process ensures optimal results and a successful outcome.

Bend Allowance

Bend allowance is a fundamental and critical concept in metal bending, referring to the precise length of the metal that undergoes bending during the fabrication process. It plays a pivotal role in determining the final length of the bent metal, making it imperative to calculate the bend allowance accurately. Any miscalculation can result in detrimental errors in the final product, leading to either an excessively shortened or elongated metal component, rendering it unsuitable for its intended purpose.

The bend allowance is influenced by various factors, such as the type of material being bent, the angle at which the bend is made, and the specific method employed for bending. Each of these factors contributes to the overall accuracy and precision of the bending process. By gaining a comprehensive understanding of bend allowance and meticulously calculating it, you can ensure impeccable precision in all your metal bending projects, guaranteeing optimal results and meeting the highest standards of quality and craftsmanship.[2]

FAQ

What is the bending process?

The bending process is a manufacturing procedure where force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. This technique is often used in industries such as automotive, aerospace, and construction for its ability to create sturdy, reliable, and precise metal components. The process involves several steps, starting with a thorough assessment of the project requirements and the malleability of the sheet metal. The metal is then carefully measured and marked before being placed in a press brake or other bending tool.

The tool applies force to the sheet metal, causing it to bend at the predetermined points. During this process, care must be taken to account for phenomena like springback and to ensure the accurate placement of process position holes. Understanding the bend allowance is also crucial for maintaining precision in the final product. With thorough planning and careful execution, the bending process can effectively transform flat sheet metal into a variety of shapes and forms, capable of serving numerous functional purposes.

What is the process of bending metals?

The process of bending metals involves a series of steps that leverage the malleability and ductility of the metal to achieve the desired shape. It begins with the selection of the appropriate material that can withstand the bending process. Once the metal is chosen, it’s crucial to measure and mark the areas where the bends are required. These measurements should account for the bend allowance, which refers to the elongation of the metal during the bending process. Then, the metal is carefully positioned within a bending tool or a press brake, which applies controlled force to the marked areas. The bending tool or press brake utilizes various dies suitable for different bend angles and radii. Once the force is applied, the metal bends at the predetermined points, taking on the desired shape. It’s crucial during this stage to account for springback, a phenomenon where the metal tends to unbend slightly after the force is removed. To ensure the final product maintains the correct angle, the metal is often overbent. Lastly, any process position holes are incorporated into the design before the bending process, serving as vital guides during manufacturing. With careful planning and execution, metal bending can produce highly precise and complex shapes for a wide range of applications.

What metal is used for bending?

The choice of metal for bending largely depends on the specific requirements of the project. Typically, malleable metals like aluminum, copper, brass, and low-carbon steel are popular choices because they bend easily without cracking or breaking. Aluminum, for instance, is widely used due to its excellent formability, light weight, and resistance to corrosion. Copper and brass, on the other hand, are preferred for their aesthetic appeal in decorative applications. Low-carbon steel is a common choice for structural applications, given its strength and durability. However, it’s essential to remember that each metal has its unique properties and may require specific bending techniques or treatments to achieve the desired results.

What is the method of bending steel?

Steel, a common material in metal bending, has its unique bending process due to its strength and rigidity. The process begins with carefully measuring and marking the steel, considering the bend allowance.

The Steel is then positioned in a specially designed bending tool or press brake, which applies a controlled force. Since Steel is harder than many other metals, it requires a higher amount of force to bend. To counter the phenomenon of springback, which is more pronounced in Steel, the metal is often over-bent. Throughout the process, it’s crucial to ensure that any process position holes are accurately placed before applying the bending force. With the right tools and techniques, Steel can be successfully bent into highly precise and durable structures, serving a variety of purposes in construction, automotive, and many other industries.

Useful Video: Incredible Super Hard Metal Bending Process – Amazing Modern Metal Processing Methods Technology

Conclusion

In conclusion, metal bending is a highly versatile and essential manufacturing process prevalent in a multitude of industries. The technique relies on careful planning and precise execution, with particular attention to factors such as material selection, bend allowance, and correct placement of process position holes. Varieties of metals, from Aluminum and Copper to Brass and Steel, each with their unique attributes, can be skillfully manipulated into precise and durable structures. Understanding the intricacies of metal bending can help ensure the production of high-quality, functional components that meet the exact specifications of any project. With continued advancements in technology, the possibilities in the field of metal bending are boundless, paving the way for more complex and intricate designs in the future.

References:

- https://markhammetals.com/what-is-metal-bending/

- https://www.delahenty.com.au/bend-steel-plates/