How to Extract Precious Metals From Catalytic Converters?

If you’ve been curious about how scrap metal recyclers extract valuable metals from catalytic converters, your curiosity can now be satisfied! In this blog post, we’ll give you a step-by-step guide on how it’s done. Our comprehensive guide will provide you with the necessary tools and information to identify the correct converter type as well as how to extract metals. So if you’re ready to learn about this interesting process, read on!

What Is A Catalytic Converter?

A catalytic converter is an invaluable part of the exhaust system that helps decrease harmful emissions from automobiles, benefiting our environment.

The process works by converting hazardous pollutants like hydrocarbons and carbon monoxide into harmless substances such as oxygen, nitrogen, and water vapor. Constructed from an amalgamation of various metals – including platinum, palladium, and rhodium – catalytic converters effectively reduce harmful emissions. These metals are rare and expensive, so it can be beneficial to extract them for reuse or recycling. [1]

How To Extract Precious Metals From Catalytic Converters?

The catalytic converter is an important part of a vehicle’s exhaust system, and it contains several precious metals that can be extracted for reuse. Precious metals, such as palladium, rhodium and platinum, are used in the construction of catalytic converters because they are able to reduce harmful emissions from vehicles. When a car reaches its end of life or needs a new converter, these precious metals must be extracted from the converter before it can be disposed of safely.

There are two main ways to extract the precious metals from a catalytic converter: chemical dissolution and mechanical separation.

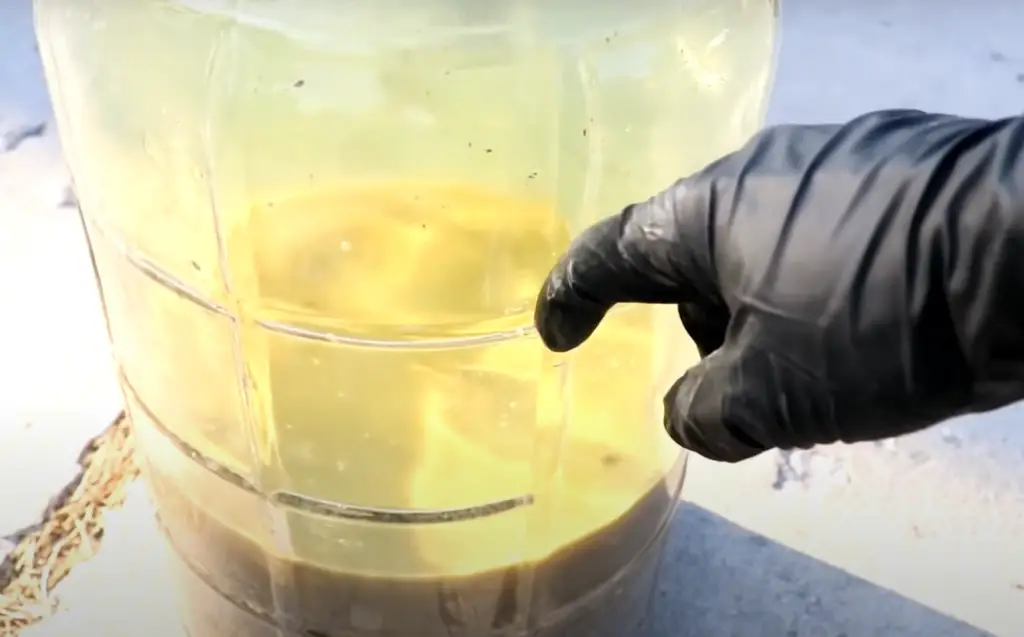

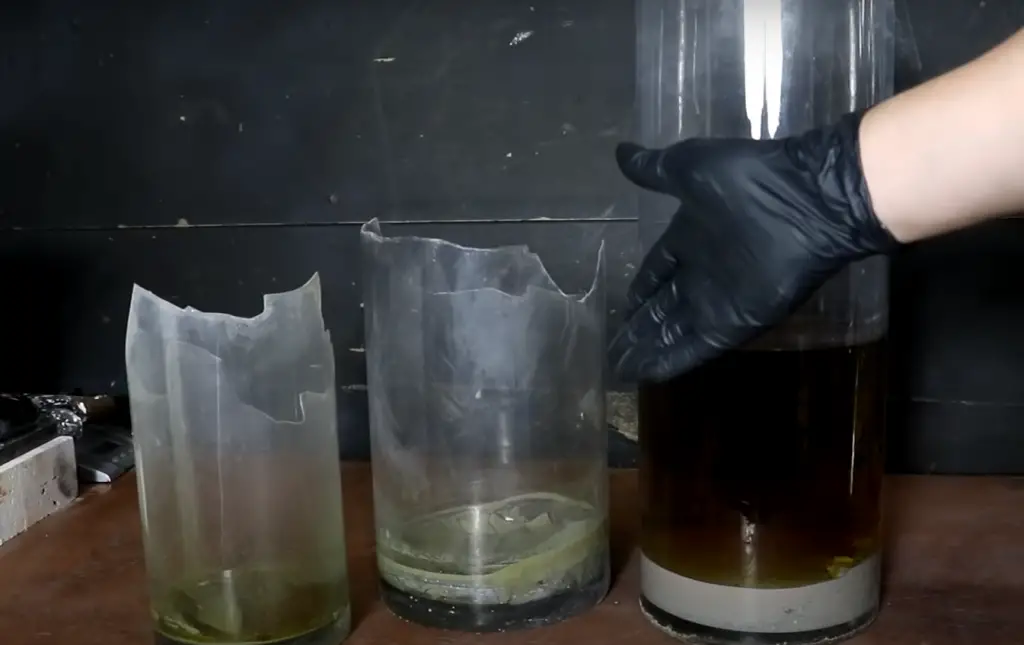

Chemical dissolution involves placing the catalyst into a hot solution containing specific acids (such as hydrochloric acid) and bases (like sodium hydroxide). This solution causes the metals to dissolve and separate into various forms, allowing them to be later recovered with a filtration system.

It involves cutting open the converter and separating out the individual components such as platinum, palladium, rhodium and other valuable elements. This can be done by hand or with specialized machinery, depending on what type of material needs to be separated.

Once these materials are extracted they can then either be recycled or sold for their scrap value. The amount of money that can be made depends on several factors including market prices and purity levels.

Overall, precious metals can be extracted from catalytic converters using a variety of methods, and these materials can then be reused or sold for scrap value. This helps to reduce the amount of waste created by end-of-life vehicles, as well as conserving valuable resources that may have otherwise been lost. [2]

What Precious Metals Are Found In A Catalytic Converter?

The valuable metals of platinum, palladium and rhodium can be found in the composition of catalytic converters.

Palladium and rhodium are also commonly found in catalytic converters; however, they usually make up smaller percentages than platinum. Other metals may be present as well, such as iridium and gold. Their concentrations will depend on the type of vehicle that the converter was removed from.

The proportion of each metal in a catalytic converter can vary greatly depending on where it comes from and its age. Older vehicles tend to have higher concentrations of these metals due to their decreased efficiency over time. Additionally, the type of vehicle will influence the types and amounts of metals present. For example, diesel vehicles can contain significantly more platinum than gasoline cars.

It is important to note that not all catalytic converters contain precious metals. Those that do typically have a much higher concentration; however, it is still possible for some catalytic converters to contain small amounts of these metals or even none at all. This means that if you are looking to extract and recover these materials from a catalytic converter, it is essential to first test the sample before attempting any extraction process. [3]

Why Recycle Catalytic Converters?

Recycling catalytic converters is an important part of helping to protect the environment. Catalytic converters help reduce air pollution by controlling harmful emissions from vehicle exhausts. Since these pollutants can be damaging to people’s health and the environment, it’s essential that we recycle them properly so that precious metals like platinum, palladium, and rhodium can be reused in a more sustainable manner.

The process of recycling catalytic converters involves extracting the valuable metals from within the converter itself. This extraction process requires specialized equipment and stringent safety protocols in order to do it safely and effectively. By using this method, recyclers are able to obtain around 95% of the total metal content of each catalytic converter. This allows them to make a profit from the sale of the extracted precious metals and re-use them in other products.

In addition to helping protect the environment, recycling catalytic converters also helps save money. With each recycled unit, up to $200 worth of valuable metals can be recovered and reused for other purposes. By removing these materials from circulation, it helps reduce the need for new sources of raw material – decreasing demand and saving resources in the long run. [4]

What Is The Platinum In A Catalytic Converter?

The platinum in a catalytic converter is typically found as a fine powder that coats the ceramics inside the converter. Platinum is used because of its ability to resist heat and oxidation, making it an ideal catalyst for reducing emissions from vehicles. Platinum is also one of the most expensive metals on the market today, so extracting it from catalytic converters can be quite lucrative.

Extracting precious metals, such as platinum, palladium, and rhodium from catalytic converters involves separating the ceramic material from the metal powders inside it.

How Are Precious Metals Mined?

The process of extracting precious metals from catalytic converters is a complex one that involves mining the raw material and then refining it. First, miners must locate deposits of platinum, palladium, and rhodium – the three most commonly found precious metals in catalytic converters. These deposits can be located through various forms of geophysical surveying and exploration techniques such as seismic surveys, magnetometers, and gravimeters. Once these materials have been identified within an orebody or deposit, miners will use heavy equipment to extract them from the earth in either open-pit or underground operations.

Once mined, the ore is transported to a refinery where it is melted down into a pure form called doré (gold-platinum alloy). Doré is further refined into pure metals, usually through a process of electrolysis. During this process, the metals are separated out from each other and then purified to their individual elements. The final product can take the form of bars, powder, or coins depending on the desired end-use.

Overall, mining and refining precious metals from catalytic converters is an intricate process that requires expertise in both geology and metallurgy. By understanding the basics of how it works, you will be able to make better informed decisions when coming across potential sources for these valuable materials. [5]

The Value Of Platinum and Palladium

Catalytic converters are some of the more valuable products that can be recycled as they contain precious metals such as platinum and palladium. Platinum is a rare metal with a variety of industrial applications, while palladium is used in electronics and medical instruments. Both of these metals have become increasingly valuable over time, so recycling them is an important way to both reduce landfill waste and generate profit.

The main process for extracting these metals involves pulverizing the catalytic converter and heating it with a series of acids, bases, and solvents to dissolve the nonmetallic components and separate out the desired elements. This method typically yields around 80-90% recovery rates for each metal, although different catalytic converters may vary in their yields depending on their make and model. The extracted metals are then purified and sold on the open market.

Recycling catalytic converters is an important source of revenue for scrap metal yards, as well as a great way to reduce waste that would otherwise end up in landfills. While it does require more effort than recycling other materials such as aluminum, the increased payout makes it worth the trouble. Companies can also take advantage of this opportunity by sorting through catalytic converters at auto dismantlers or junkyards, and reselling them to specialized recyclers who can extract the precious metals contained within.

How Much Gold In A Catalytic Converter?

The amount of gold in a catalytic converter varies based on the model and age of the vehicle, but typically ranges between 0.03 to 0.04 grams per converter. However, some catalytic converters contain up to 0.5 grams of gold or more! The presence of other precious metals such as palladium and rhodium can also affect the total value of the catalytic converter.

Extracting these valuable metals from a catalytic converter is not an easy task, since they are embedded in ceramic substrates. To extract them, one must use acids and heat at temperatures exceeding 1000°C to dissolve the metals in liquid form so that they can be recovered from solution. This process is known as smelting.

How Much Rhodium In A Catalytic Converter?

Rhodium is one of the rarest and most valuable precious metals found in catalytic converters. It is used to convert toxic pollutants from gasoline burning engines into harmless water vapor and carbon dioxide. The amount of rhodium in a catalytic converter can vary greatly depending on the car’s make, model, year, and condition. Generally speaking, newer cars will have higher amounts of rhodium than older ones due to advancements in engine technology over time. For example, some late model vehicles may contain up to 1 gram of rhodium per converter while an older vehicle could only have 0.05 grams or less.

To accurately estimate the total amount of rhodium present in a given catalytic converter it must first be removed from the vehicle and analyzed in a laboratory. This can be done by either disassembling the converter or using special extraction methods to remove it without damaging the converter itself. Once extracted, a spectrochemical analysis of the sample can be performed which will determine both the purity and total amount of rhodium present within the sample.

FAQ

How do you recover platinum from a catalytic converter?

The most common method for recovering platinum from a catalytic converter is to use an aqua regia process. This involves mixing the catalyst with a mixture of hydrochloric and nitric acid in order to dissolve the precious metals contained within. The mixture is heated, which causes the platinum and other metals to precipitate out as a solid that can be separated and collected. After the recovery process has been completed, any residual acids must be neutralized before being disposed of properly. It is important to note that this process requires specific safety protocols in order to protect workers from potential health risks associated with working with hazardous materials. Additionally, metallic residues from the process may need to be managed separately due to their toxicity or value.

How much precious metals can be recovered from a catalytic converter?

It depends on the size of the converter and the amount of precious metal it contains, but typically about 0.4 to 2 grams of platinum, palladium and rhodium can be recovered from a single converter. That may not sound like much, but all three metals are very valuable due to their scarcity and industrial use as catalysts in many applications. In fact, most catalytic converters contain more rhodium than platinum or palladium because of its superior ability to convert pollutants into less harmful substances. Recovering these precious metals from catalytic converters is no small task and requires specialized equipment and professional knowledge.

What is the most valuable metal in a catalytic converter?

Rhodium, a member of the platinum group, is the most valuable metal contained in catalytic converters. Rhodium is more expensive than any other precious metals and has many industrial uses due to its ability to act as a catalyst and convert pollutants into less harmful substances. As such, it can be recovered from catalytic converters and sold for scrap prices on the market.

What metals do catalytic converters extract?

Catalytic converters extract three precious metals: palladium, rhodium and platinum. These metals are found as oxides in the catalysts of catalytic converters, which contain a ceramic honeycomb structure coated with these metal compounds. The catalytic converter works by converting pollutants from exhaust gasses into less-toxic substances before they are released into the atmosphere. The process of extracting these precious metals from catalytic converters involves breaking down the metal oxide compounds that make up the catalyst. This can be done through several methods including chemical leaching, thermal decomposition and electrolysis.

How much is raw rhodium worth?

Rhodium is currently one of the most expensive precious metals, with prices ranging from $750 to $2,500 per ounce. The rarity of rhodium further contributes to its high cost. It is estimated that there are about 0.001 parts per million of rhodium present in the Earth’s crust which makes it one of the rarest elements on Earth. Extraction and refining processes for this metal can be complicated and costly due to its scarcity. However, recycling catalytic converters for their precious metal content can offer an economical alternative to acquiring these metals from other sources such as mines or refineries.

What are the types of catalytic converters?

Catalytic converters come in several different types, depending on the type of vehicle and its engine size. The most common types are two-way catalytic converters, three-way catalytic converters, and diesel particulate filters. Two-way catalytic converters help to reduce hydrocarbons (HC) and carbon monoxide (CO) from vehicle exhaust. They are usually made up of a single chamber that contains a ceramic honeycomb coated with precious metals such as palladium, rhodium, and platinum. Three-way catalytic converters have an additional chamber that helps to reduce nitrogen oxide (NOx) emissions. They also contain ceramic honeycombs coated with precious metals. Diesel particulate filters are designed specifically to reduce the amount of soot and other particles released from diesel engines. They contain a ceramic or stainless steel filter that is coated with precious metals such as palladium, platinum, and rhodium.

How much gold is in a catalytic converter?

The amount of gold in a catalytic converter varies depending on the type and age of the converter. A newer model may have more precious metals than an older one, but generally speaking, most catalytic converters contain only small amounts of gold. On average, a standard catalytic converter will contain about 0.03 grams of gold per unit. While this isn’t much in terms of pure weight, it is still worth extracting as the price for recycled gold is high. If you are looking to extract gold from your catalytic converter, you should be aware that there are several different methods available to do so.

Useful Video: Precious Metal From Catalytic Converter

Conclusion

Extracting precious metals from catalytic converters is a complex and time-consuming process that requires specialized equipment and knowledge. Despite the difficulty and cost associated with extracting these metals, it can be a lucrative business endeavor. Understanding the different methods of extraction, their advantages and disadvantages, as well as safety precautions can help ensure success when attempting to extract these valuable materials. The use of environmentally friendly recovery processes such as those used in hydrometallurgy are also important for maintaining sustainability and preserving resources for future generations. With the right approach and careful planning, anyone can take advantage of this unique opportunity to make money from scrap catalytic converters.

References:

- https://www.krosfou.com/blog/63_how-to-recover-precious-metals-in-a-catalytic-converter.html

- https://www.hindawi.com/journals/jchem/2019/2318157/

- https://www.researchgate.net/publication/259338467_Possible_ways_of_refining_precious_group_metals_PGM_obtained_from_recycling_of_the_used_auto_catalytic_converters

- https://www.sciencedirect.com/science/article/abs/pii/S0921344920302093

- https://www.911metallurgist.com/recovering-platinum-group-metals-in-catalytic-converters/