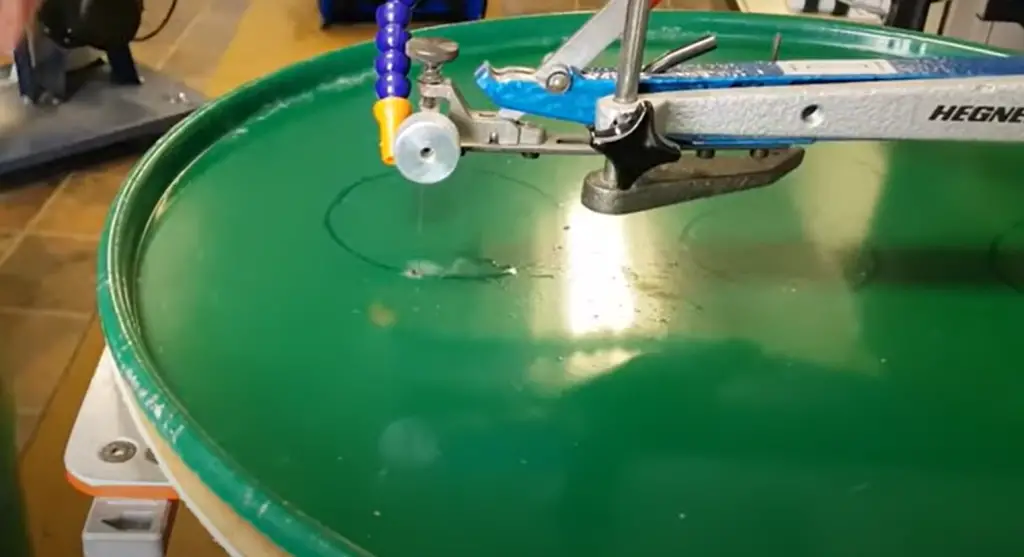

Scroll saws are a popular choice for woodworking projects, but can they be used to cut metal? The answer is yes – scroll saws can be used to cut through a variety of materials, including metal. However, there are some things you need to keep in mind when using a scroll saw to cut metal. In this blog post, we will discuss the basics of using a scroll saw to cut metal, as well as some tips for getting the best results. Let’s get started!

What is a Scroll Saw?

A scroll saw is a type of power saw that is typically used to cut intricate shapes and patterns in wood.

So, can a scroll saw cut metal? The answer is yes, but there are a few things you need to keep in mind. Before beginning, ensure you have a blade that can cut through metal. Second, you will need to go slowly and be very careful not to overheat the metal or damage the blade. With these things in mind, let’s take a closer look at how to cut metal with a scroll saw. [1]

What Blade Do I Need to Use for Sawing Metals?

You need to use a blade that is specifically designed for cutting metal. These blades are made from high carbon steel and have a very thin kerf. The teeth on these blades are also much sharper than those on general purpose blades, which allows them to cut through metal more easily.

Some scroll saws come with a special metal cutting blade, but if yours doesn’t then you can purchase one separately. Be sure to get the right size blade for your saw, as using a blade that is too big or too small can damage your saw or make it difficult to control.

Cutting Metal With A Scroll Saw: 5 Factors

Speed

The scroll saw speed is one of the biggest factors when it comes to whether or not it can cut through metal. If the scroll saw has a low speed, then it’s likely that it won’t be able to cut through metal. The higher the speed, the more likely it is that the scroll saw will be able to handle metal.

Blade Type

The type of blade that is being used on the scroll saw can also make a big difference. If you’re using a standard wood-cutting blade, then it’s unlikely that it will be able to cut through metal. However, if you’re using a special metal-cutting blade, then the scroll saw will be much more likely to be able to handle it. Thinner metals will be easier to cut than thicker metals.

Feed Rate

The feed rate is another important factor. If the scroll saw is being fed too slowly, then it’s likely that the blade will get stuck in the metal. If the scroll saw is being fed too quickly, then it’s possible that the blade will break. The best way to find the perfect feed rate is to experiment with different rates and see what works best. [2]

Pressure

The amount of pressure that you’re putting on the scroll saw can also make a difference. If you’re putting too much pressure on the saw, then it’s possible that the blade will break. However, if you’re not putting enough pressure on the saw, then it’s likely that the cut will be uneven. The best way to find the perfect amount of pressure is to experiment with different levels and see what works best.

Angle

The angle at which you’re holding the scroll saw can also influence whether or not it can cut through metal. If you’re holding the scroll saw at too shallow of an angle, then it’s likely that the blade will slip. If you’re holding the scroll saw at too steep of an angle, then it’s possible that the blade will break. Test out different angles to see which one works best for you.

Metal Type

The type of metal that you’re trying to cut can also make a difference. Softer metals, such as aluminum, will be easier to cut than harder metals, such as steel. Thinner metals will also be easier to cut than thicker metals.

Noise

The noise level of the scroll saw can also be a factor. If the scroll saw is too loud, then it’s possible that it will damage your hearing. If the scroll saw is too quiet, then it might not be able to cut through metal. The best way to find the perfect noise level is to experiment with different levels and see what works best for you.

As you can see, there are a lot of factors that go into whether or not a scroll saw can cut metal. By taking all of these factors into consideration, you’ll be able to choose the right scroll saw for your needs. [3]

Metal Cutting Scroll Saw Tips

Sandwich Method

The sandwich method is the best way to cut metal if you’re using a scroll saw. The method entails placing the metal between two pieces of wood. The top piece of wood will have a hole drilled in it that is slightly smaller than the size of the scroll saw blade.

The bottom piece of wood will have a hole drilled in it that is slightly larger than the size of the scroll saw blade. By sandwiching the metal between these two pieces of wood, you can guide the scroll saw blade through the metal without having to worry about it getting stuck.

Tension Method

The tension method is another great way to cut metal with a scroll saw. This method involves tensioning the metal so that it is taught when you start cutting. To do this, you will need to clamp one end of the metal to the table of the scroll saw. Then, you will need to feed the other end of the metal through the scroll saw blade. As you start cutting, the tension in the metal will keep it from moving around too much.

Tapping Method

The tapping method is a great way to cut small pieces of metal with a scroll saw. This method involves tapping the metal onto the scroll saw blade. To do this, you will need to hold the piece of metal against the scroll saw blade with one hand. Then, you will need to use a hammer to tap the other end of the metal onto the scroll saw blade. The metal will then be cut as you operate the scroll saw.

Safety Precautions

When cutting metal with a scroll saw, there are a few safety precautions that you should take. First, always wear eye protection. The metal can fly off of the scroll saw blade and into your eyes. Second, always wear gloves. The metal can be sharp and can cut your hands if you are not careful. Third, be aware of the sparks that are created when cutting metal. These sparks can cause fires if they land on flammable materials.

Hearing Protection

When cutting metal with a scroll saw, you will also need to wear hearing protection. The scroll saw can be very loud when it is cutting through metal. If you do not wear hearing protection, you could damage your hearing. [4]

Gloves

As mentioned above, always wear gloves when cutting metal with a scroll saw. The metal can be sharp and can cut your hands if you are not careful.

Lubrication

It is also a good idea to lubricate the scroll saw blade when cutting metal.

The best way to lubricate the scroll saw blade is to use a cutting oil. You can find cutting oil at most hardware stores.Margin of Error

When cutting metal with a scroll saw, you need to be aware that there is a margin of error. The metal can be very thin and can easily bend or break if you are not careful.

When cutting metal, always err on the side of caution and make the cuts as slowly and carefully as possible.

Supplement With Handsaw

If you are having trouble cutting metal with a scroll saw, you can supplement the scroll saw with a handsaw. This will help to make the cuts more precise.

Use a Jig

If you are having trouble keeping the metal straight while cutting it with a scroll saw, you can use a jig. A jig is simply a piece of wood that is attached to the scroll saw table. The jig will help to keep the metal in place while you are cutting it.

Mark the Metal

When cutting metal with a scroll saw, always mark the metal before you start cutting. This will help to ensure that you make the cuts in the right place. You can use a pencil or a felt-tip marker to mark the metal.

How Does Cutting Various Metals Differ?

Different metals will present different challenges when cutting with a scroll saw. Softer metals like aluminum or brass will be easier to cut than harder metals like steel. The type of metal you are trying to cut will also dictate the type of blade you need to use.

For example, if you are cutting stainless steel, you will need a blade that is specifically designed for cutting stainless steel. These blades are usually made from high carbon steel or bi-metal construction and have more teeth per inch than a standard scroll saw blade. This helps the blade move through the metal more easily and results in a cleaner cut. [5]

What Types of Metal Can Scroll Saws Cut?

In general, any metal that is soft enough to be cut with a saw can be cut with a scroll saw. This includes metals like aluminum, brass, and copper.

Some scroll saws come with a built-in plate that allows you to attach the workpiece directly to the scroll saw table. This can be helpful when cutting metal, as it prevents the workpiece from moving around while you are cutting it.

How Do I Protect My Metal While Sawing?

When cutting metal with a scroll saw, it is important to use a blade that is designed for cutting metal. This will help to prevent the blade from becoming damaged while cutting. It is also important to use a lower speed setting when cutting metal, as this will help to prevent the metal from overheating and becoming damaged.

It is also a good idea to clamp the workpiece down before beginning to cut. This will help to prevent the workpiece from moving around while you are cutting it and will also help to protect your hands from getting cut on the sharp edges of the metal.

How Do I Ensure My Safety When Sawing Metals?

Working with any type of metal can be dangerous, so it is important to take safety precautions when using a scroll saw to cut metal. Always wear gloves and eye protection when working with metal.

Clamp the workpiece down before beginning to cut, and use a lower speed setting to prevent the metal from overheating.

Keep your hands away from the blade at all times and be careful not to touch the hot metal after you have cut it.

FAQ

What material can you cut with a scroll saw?

Scroll saws can cut a variety of materials, including wood, metal, plastic, and even tile. However, some scroll saws are designed specifically for cutting one type of material. For example, there are scroll saws that are designed specifically for cutting metal.

Can a scroll saw cut metal?

Yes, a scroll saw can cut metal. However, you will need to use a blade that is designed for cutting metal. Scroll saw blades for metal are available at most hardware stores. You may also need to use a lubricant to help the blade glide through the metal.

What saw is best for cutting metal?

There are a few different types of saws that can be used for cutting metal. A scroll saw is one option. Another option is a band saw. A band saw is a type of saw that has a blade that is continuous, meaning it does not have teeth. The blade on a band saw is also much wider than the blade on a scroll saw.

This makes a band saw better suited for cutting thicker pieces of metal.A jigsaw can also be used to cut metal. Jigsaws have blades with teeth, but they are not as fine as the teeth on a scroll saw blade. This means that a jigsaw can cut through metal faster than a scroll saw, but the cuts will not be as precise.

What can you not do with a scroll saw?

A scroll saw is not designed for cutting through metal. If you try to cut metal with a scroll saw, the blade will quickly become dull and the cuts will be very rough. Additionally, scroll saws are not designed for making long straight cuts. For this type of cut, you would need to use a different type of saw, such as a jigsaw or a band saw.

Which is better: a scroll saw or jigsaw?

Both scroll saws and jigsaws have their own advantages and disadvantages. Scroll saws are better for making precise, detailed cuts. Jigsaws are better for making faster, rougher cuts. If you need to cut metal, a jigsaw is the better option.

Should scroll saw teeth up or down?

The teeth on a scroll saw blade should be pointing up. This will help to prevent the blade from getting caught on the material you are cutting. Additionally, when the teeth are pointing up, they will cut on the upstroke of the saw, which is when the blade is moving towards the handle. This helps to prevent the blade from becoming bound in the material.

What is the best scroll saw speed for cutting metal?

The best scroll saw speed for cutting metal is around 100-150 strokes per minute. This will help to prevent the blade from overheating and becoming damaged. Additionally, a lower speed will help to prolong the life of the scroll saw blade.

Why do I keep breaking blades on my scroll saw?

There are a few reasons why blades may break on a scroll saw. One reason is that the blade may be dull. If the blade is dull, it will need to be replaced. Another reason is that the scroll saw may be overloaded. This can happen if you are trying to cut too thick of a piece of metal. Thescroll saw may also be overloaded if you are trying to make too tight of a turn. Finally, the blade may break if it becomes bent. If this happens, you will need to replace the blade.

How do I prevent my scroll saw from overheating?

One way to prevent your scroll saw from overheating is to use a lower speed setting. Additionally, you can use a blade with fewer teeth per inch. This will help to reduce the amount of friction the blade experiences as it cuts through the metal. Finally, you can use a lubricant to help cool the blade and prevent it from overheating.

Useful Video: Cutting Metal With a Scroll Saw, How To Do It Right! EthAnswers

Conclusion

Yes, a scroll saw can cut metal. However, there are a few things you need to keep in mind in order to do it safely and effectively. First, you need to use a blade that is specifically designed for cutting metal. Second, you need to make sure that the metal you are trying to cut is not too thick. And finally, you need to go slowly and be very careful when cutting metal with a scroll saw. If you follow these guidelines, you should be able to safely and successfully cut metal with a scroll saw.

References:

- https://www.familyhandyman.com/article/what-is-a-scroll-saw/

- https://www.finepowertools.com/saws/scroll-saw/

- https://northernnester.com/can-scroll-saw-cut-metal/

- https://www.ccohs.ca/oshanswers/safety_haz/woodwork/band_saw.html

- https://www.sansmachining.com/what-is-the-difference-in-cutting-different-metal-materials/