Glowforge is a powerful laser cutter that has been making waves in the crafting and DIY communities since it was first released. People have been asking if it can cut metal, and we’re here to give you a definitive answer. In this article, we’ll discuss the capabilities of Glowforge when it comes to cutting metal, as well as some helpful tips on how to get the best results. So can a Glowforge cut metal? The answer is yes – read on to find out more!

What are Proofgrade materials?

If you’re new to the world of laser cutting, you may be wondering what Proof Grade materials are. In short, Proofgrade materials are those that have been tested and proven to work well with Glowforge’s laser cutter. This means that they are of a high enough quality to produce consistent results, and that they are compatible with the laser cutter’s settings.

There are a variety of different Proofgrade materials available, including both metals and nonmetals. This means that you can use your Glowforge to cut a wide variety of different materials, including stainless steel, aluminum, brass, wood, acrylic, and more.[2]

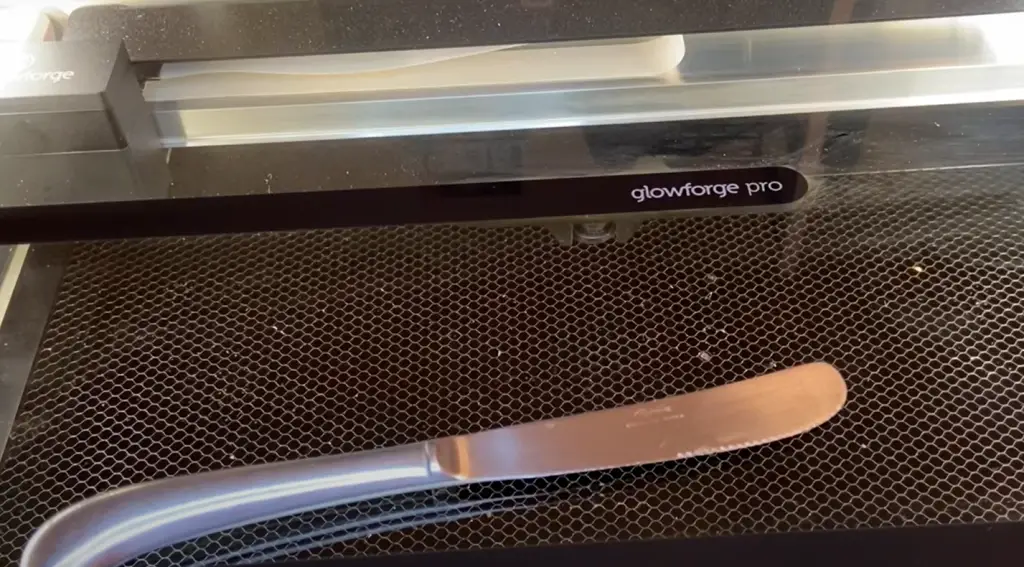

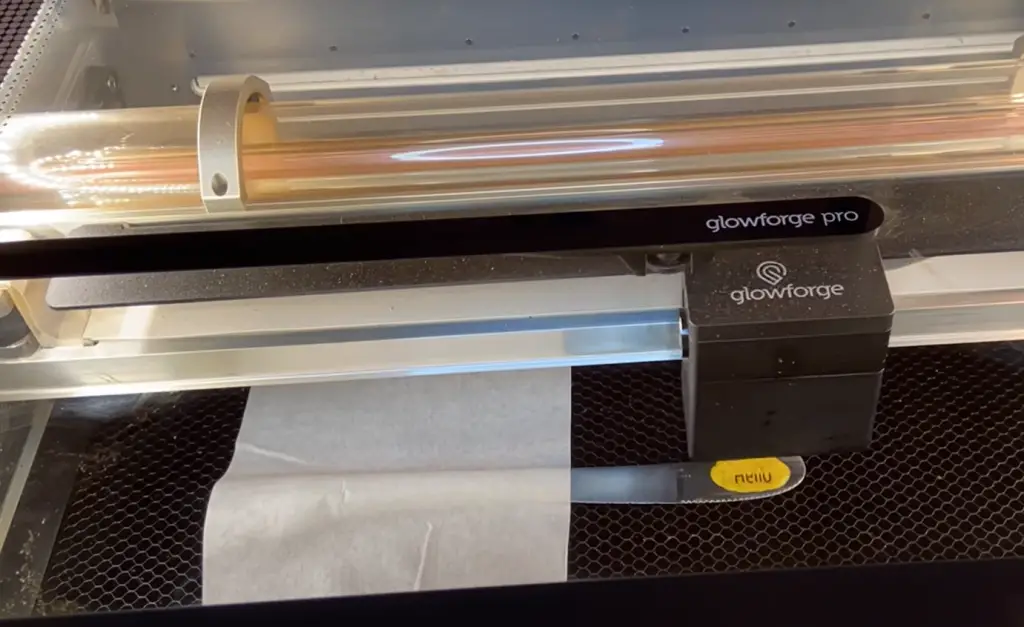

Cut Metal with Glowforge

If you’re wondering whether you can cut metal with your Glowforge, the answer is yes! However, there are a few things to keep in mind when working with metal. In this article, we’ll cover some common questions about cutting metal with Glowforge and provide some helpful tips.[3]

How Do I Etch Metal with the Glowforge?

Etching metal with the Glowforge is a two-step process. First, you’ll need to create a stencil of your design using the Glowforge software. Then, you’ll place the stencil on your metal surface and use the Glowforge to etch your design into the metal.

To get started, you’ll need to gather a few materials. In addition to the Glowforge and your computer, you’ll need:

- Metal sheet (copper, brass, or stainless steel work best)

- Glowforge air filter

- Stencil material (vinyl or kraft paper)

- Utility knife

- Masking tape

- Scissors

Once you have your materials, you’re ready to start creating your stencil. The first step is to open the Glowforge software and upload your design. Then, select “stencil” as your material type. The software will automatically adjust the settings for cutting a stencil out of vinyl or kraft paper.

Next, use the utility knife to cut out your design from the stencil material. Be sure to leave a border around your design so that the etching cream doesn’t leak under the stencil.

Now it’s time to place your stencil on the metal sheet. To keep it in place, use masking tape to secure the edges of the stencil. Once your stencil is in place, it’s time to etch!

Fill a bowl with etching cream and use a paintbrush to evenly coat the exposed areas of the metal sheet. Be sure to avoid any areas that are covered by the stencil.

Leave the etching cream on for the recommended amount of time (usually 5-15 minutes). Then, rinse off the cream and remove the stencil. Your etched design should now be visible on the metal surface![1]

How Thick of Material Can the Glowforge Cut?

The Glowforge Basic can cut through material up to 1/8 inch thick.

The Pro model can cut through material up to 1/4 inch thick.[3]

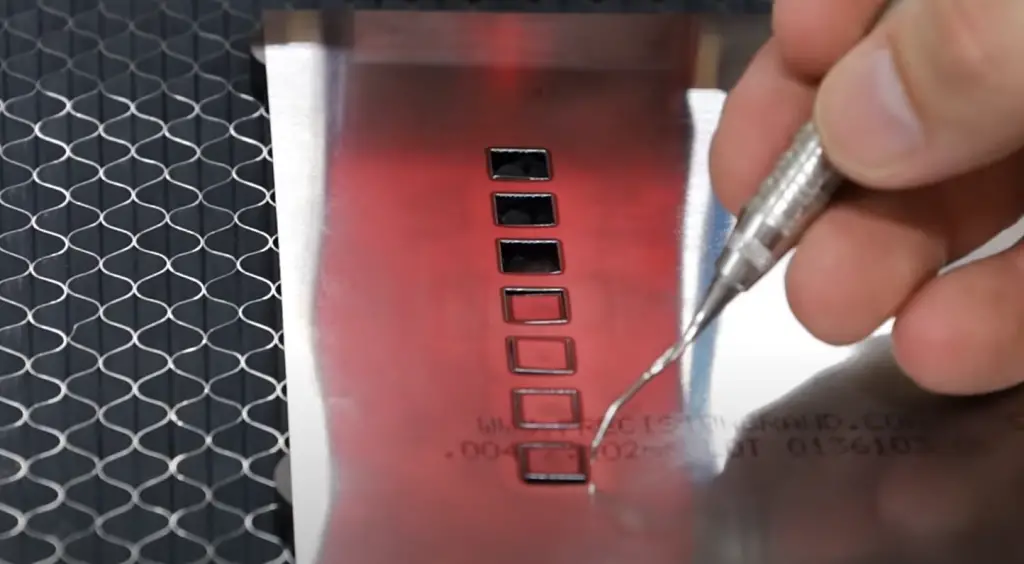

How Does Cermark Work?

Cermark is a special coating that can be applied to metals. When lasered, this coating turns black, allowing the laser to engrave or cut the metal beneath. Not all metals can use Cermark, and not all colors of Cermark work with every type of metal.

You can purchase pre-coated blanks from many different sources, or you can apply the coating yourself using a brush or spray bottle. You’ll need to allow the coating to dry completely before lasering.[1]

What Metals Can the Glowforge Models Etch?

The Glowforge Basic and Pro can etch the following metals:

- Anodized aluminum

- Bare stainless steel

- Painted metals[1]

What materials are NOT safe to cut?

Not all materials are safe to cut with a Glowforge. The list of safe and unsafe materials is always growing as we test more substances, so be sure to check the list before beginning a project. But generally speaking, anything that’s flammable, corrosive, or reactive should not be cut.

This includes:

- Acrylic (flames spread quickly on this material)

- Cardboard (releases harmful chemicals when heated)

- Chlorine (releases hazardous chlorine gas when heated)

Highly reflective materials like mirror or metalized Mylar (reflects too much heat back into the machine)[2]

Where Can I Get Custom Metal Shapes Cut?

If you’re looking for a place to have custom metal shapes cut, there are a few different options available to you. One option is to use a service like Glowforge. Glowforge is a 3D laser printer that can cut and engrave a variety of materials, including metal.

Another option is to use a CNC plasma cutter.

This method can be used to create custom shapes and designs in metal.If you’re not sure which method is best for you, it’s worth considering the pros and cons of each before making a decision. Here’s a look at some of the key factors to consider:

- Cost: One of the main considerations when choosing a method for cutting metal is cost. Glowforge offers a subscription-based service that starts at $7 per month. CNC plasma cutters can be purchased for around $500.

- Speed: Another important consideration is speed. Glowforge is designed to be fast and easy to use, with most users reporting that it can cut through metal quickly and easily. CNC plasma cutters are generally faster than Glowforge, but they can be more difficult to set up and use.

- Precision: When it comes to precision, both methods are capable of creating accurate cuts. However, CNC plasma cutters tend to be more precise than Glowforge.

- Ease of Use: When it comes to ease of use, Glowforge is the clear winner. It’s simple to set up and use, and there’s no need for special training or expertise. CNC plasma cutters can be more difficult to use, and they often require specialized training.[1]

What Type of Laser is Best to Cut Through Metal?

Fiber Lasers

Fiber lasers are the newest technology when it comes to cutting through metal and they are quickly becoming the preferred choice for many fabricators. Fiber lasers offer a number of advantages over CO2 and YAG lasers including:

- Increased accuracy

- Faster cutting speeds

- The ability to cut thicker materials

- Low operating costs[3]

Utilizing Oxygen

One way to increase the cutting speed of a fiber laser is to utilize oxygen assisted cutting. In this process, oxygen is injected into the cut area which oxidizes the metal and helps the laser to cut through it more quickly. The downside to this method is that it can cause burrs and other imperfections in the cut edge.

If you are looking for a fast, accurate, and cost-effective way to cut through metal, a fiber laser is the best option. And, if you need to increase your cutting speed even more, oxygen assisted cutting may be the right solution for you.

Nitrogen assist

If you need to cut through metal quickly and don’t mind sacrificing some edge quality, nitrogen assist cutting is a great option. In this process, nitrogen is injected into the cutting area which helps to cool the metal and allows the laser to cut through it more quickly. The downside to this method is that it can cause burrs and other imperfections in the cut edge.

If you are looking for a fast way to cut through metal, nitrogen assisted cutting may be the right solution for you. Just keep in mind that it may not produce the best results in terms of edge quality.

Trotec

The Trotec Speedy 400 is a high-powered fiber laser that is designed for fast, accurate, and cost-effective cutting of metals.

If you are looking for a fast, accurate, and cost-effective way to cut through metal, the Trotec Speedy 400 is a great option. And, if you need to increase your cutting speed even more, the oxygen assist pump is a great way to do it.

Glowforge Limitations

Glowforge can cut and etch many different materials, but there are a few limitations to keep in mind. For example, Glowforge can not cut metal thicker than 1/8 inch (3.2 mm). If you need to cut thicker metal, you will need to use another method such as a laser cutter or plasma cutter.

Additionally, Glowforge cannot engrave or mark anodized aluminum. This is because the anodized layer is too hard for the laser to penetrate.

Finally, keep in mind that some metals are reflective and can cause damage to the laser lens. For this reason, it’s important to use a material that is specifically designed for use with laser cutting machines like Glowforge.

One such material is Proofgrade™️ metal, which is available in a variety of thicknesses and finishes. Proofgrade metal has been tested to work well with Glowforge and includes a protective coating to help prevent damage to the laser lens.[2]

FAQ

Can Glowforge engrave metal jewelry?

The short answer is no, the Glowforge cannot engrave metal jewelry. However, with a few extra steps, you can create some beautiful and unique pieces using the Glowforge.

Here are a few things to keep in mind when working with metal:

- The thicker the metal, the more power it will take to cut through it. If possible, use a thinner piece of metal for best results.

- Be sure to use a cutting mat designed for metal cutting. This will help protect your table and extend the life of your blades.

- When engraving on metals like aluminum or stainless steel, we recommend using our High Power Lens. This lens will give you deeper, darker engravings.

How do you make metal in Glowforge?

With a few extra steps, you can create some beautiful and unique pieces using the Glowforge.

Here are a few things to keep in mind when working with metal:

- The thicker the metal, the more power it will take to cut through it. If possible, use a thinner piece of metal for best results.

- Be sure to use a cutting mat designed for metal cutting. This will help protect your table and extend the life of your blades.

- When engraving on metals like aluminum or stainless steel, we recommend using our High Power Lens. This lens will give you deeper, darker engravings.

What is the thickest material a Glowforge can cut?

The Glowforge can cut through materials up to ¼ inch (6.35 mm) thick. However, the thicker the material, the more power it will take to cut through it. If possible, use a thinner piece of metal for best results.

When engraving on metals like aluminum or stainless steel, we recommend using our High Power Lens. This lens will give you deeper, darker engravings.

Can Glowforge engrave guns?

The Glowforge can engrave guns, but we do not recommend it. The chemicals in the gun metal can be dangerous, and the fumes created during engraving can be toxic. We recommend taking your gun to a professional for engraving.

Can a Glowforge etch glass?

The Glowforge can etch glass, but we do not recommend it. The chemicals in the glass can be dangerous, and the fumes created during engraving can be toxic. We recommend taking your glass to a professional for engraving.

Can you make a living with a Glowforge?

Yes, you can make a living with a Glowforge. Many people use their Glowforge to start their own business or to supplement their income. The Glowforge is a powerful tool that can be used to create a wide variety of products. With a little creativity and hard work, you can make a great living with your Glowforge.

Can a Glowforge print color?

No, the Glowforge cannot print color. The machine uses a laser to cut and engrave materials. The laser is only capable of cutting and engraving in one color: black.

Useful Video: Laserbond & the Glowforge = Steel Openers! Mark Metal in Minutes

Conclusion

So, can a Glowforge cut metal? In short, yes! A Glowforge can cut thin sheets of aluminum, steel, brass, and more. However, there are a few things to keep in mind when working with metal on your Glowforge. First, always use a cutting mat designed for metal cutting. Second, use a low power setting and multiple passes to avoid damaging your material or your machine. Finally, be sure to test on a scrap piece of metal before cutting your final project.

With these tips in mind, you’ll be able to create beautiful metal projects on your Glowforge. So get out there and start creating!

References:

- https://cuttingwithlight.com/so-why-wont-the-glowforge-cut-metal/

- https://lasercutlife.com/what-can-you-cut-and-engrave-with-a-glowforge-materials-limitations/

- https://madewithforge.com/what-materials-glowforge/