Choose the Best Respirator for Metal Grinding

Customer’s Choice: the Best Rated Respirators for Metal Grinding

131 users answered this survey. Please help us improve this review!

Do you need a respirator for metal grinding? If so, which one is best for you? In this article, we will answer these questions and more. We will also provide product reviews and useful tips to help you choose the right respirator for your needs. Whether you are a professional metal grinder or just a hobbyist, we have the information you need to make the right purchase!

KISCHERS Reusable Half Face Cover – Choose The Perfect Fit and Comfort!

KISCHERS’s Reusable Half Face Cover is made of premium quality silicone, which is soft, comfortable and safe to wear. It is designed to provide superior protection against organic vapors, fumes, pollen and other particles in the air.

KISCHERS’s Reusable Half Face Cover is made of premium quality silicone, which is soft, comfortable and safe to wear. It is designed to provide superior protection against organic vapors, fumes, pollen and other particles in the air.

So, if you’re looking for a respirator that will provide you with superior protection against organic vapors, fumes, pollen and other particles in the air, then the KISCHERS Reusable Half Face Cover is the perfect choice for you!

NORTH 550030 L HALF MASK RESPIRATOR – Strong Protection!

The North 550030 L Half Mask Respirator is a reliable and comfortable option for anyone in need of respiratory protection. Made of an extremely soft non-allergenic elastomer, it is gentle on the skin and provides a snug and comfortable fit.

The North 550030 L Half Mask Respirator is a reliable and comfortable option for anyone in need of respiratory protection. Made of an extremely soft non-allergenic elastomer, it is gentle on the skin and provides a snug and comfortable fit.

Overall, the North Half Mask Respirator is a great option for anyone in need of respiratory protection. It is comfortable, durable and easy to use.

JO STORE Half Facepiece Reusable Respirator – Comfort First!

The JO STORE Half Facepiece Reusable Respirator is a quality respirator that offers reliable protection from airborne particles and contaminants. Featuring a breathing valve and filter valve, this respirator can maintain internal and external air circulation while also keeping you comfortable with its soft, skin-friendly materials.

The JO STORE Half Facepiece Reusable Respirator is a quality respirator that offers reliable protection from airborne particles and contaminants. Featuring a breathing valve and filter valve, this respirator can maintain internal and external air circulation while also keeping you comfortable with its soft, skin-friendly materials.

So, if you are looking for a respirator that is both comfortable and effective, the JO STORE Half Facepiece Reusable Respirator is a great option for you!

AUWOD Full Face Lightweight Respirator – Perfect Protection!

The AUWOD Full Face Lightweight Respirator is perfect for workers who need a reliable, durable respirator that won’t weigh them down. This respirator features a wide field of view and two adjustable straps to help keep it in place, making it perfect for painting, welding, or other work where you need protection from dust or fumes.

The AUWOD Full Face Lightweight Respirator is perfect for workers who need a reliable, durable respirator that won’t weigh them down. This respirator features a wide field of view and two adjustable straps to help keep it in place, making it perfect for painting, welding, or other work where you need protection from dust or fumes.

So, if you are in the market for a good respirator for metal grinding, the AUWOD Full Face Lightweight Respirator is definitely worth considering.

6900 Series Full Facepiece Respirator – Editor’s Choice!

The 6900 Series Full Facepiece Respirator is a top-of-the-line mask that provides optimal protection against a variety of hazardous airborne contaminants. This Mask is sold as 1 Each and features a unique center adapter, Cool Flow Valve, and lightweight, well-balanced design.

The 6900 Series Full Facepiece Respirator is a top-of-the-line mask that provides optimal protection against a variety of hazardous airborne contaminants. This Mask is sold as 1 Each and features a unique center adapter, Cool Flow Valve, and lightweight, well-balanced design.

Whether you’re working in a hazardous environment or simply want to be prepared for any potential emergencies, the 6900 Series Full Facepiece Respirator is an excellent choice.

The Buyer’s Guide

When do I Need a Respirator for Metal Grinding

You need a respirator any time you are working with or around airborne pollutants and particulate matter. This is especially true if you are doing any kind of grinding, as the process can create a lot of dust. Some other activities that might require a respirator include sanding, painting, and cleaning. [1]

If you have asthma or another respiratory condition, it is even more important that you take precautions when working with or around airborne particles. Even healthy people can be affected by exposure to certain materials, so it’s always better to be safe than sorry.

Types of Respirators For Metal Grinding

The first thing you need to know is that there are three main types of respirators: air-purifying, supplied-air and self-contained breathing apparatus (SCBA). All three types can be used for metal grinding, but they each have their own advantages and disadvantages.

Air-Purifying Respirators (APRs)

Air-purifying respirators (APRs) are the most common type of respirator. They work by drawing air through a filter that captures harmful particles, like dust and metal fumes.

APRs are available in two different styles: half-mask and full-face. [2]

One downside of APRs is that they only work as long as the filters remain effective. The filters can become clogged with particles after extended use, which reduces their effectiveness. For this reason, it’s important to check the filters regularly and replace them when necessary.

Supplied Respirators

Supplied-air respirators (SARs) are another type of respirator that can be used for metal grinding. SARs provide clean, breathable air from an external source, like a compressor or air cylinder. There are two main types of SARs: positive pressure and negative pressure.

Positive pressure SARs constantly pump air into the mask, which prevents contaminants from entering.

Negative pressure SARs work by drawing air through filters into the mask.

SARs are more expensive than APRs, but they offer several advantages. First, they don’t rely on filters, so they can be used for extended periods of time without worrying about clogged filters. Second, the air supply is unlimited, so you don’t have to worry about running out of air. Finally, SARs provide a higher level of protection against contaminants. SARs are also available in two different styles: half-mask and full-face.

Self-Contained

The final type of respirator is the self-contained breathing apparatus (SCBA). SCBAs are the most expensive type of respirator, but they offer the highest level of protection. SCBAs provide a constant supply of clean, breathable air from an external source, like an air cylinder. They also have a full-face mask that covers your entire face, which provides better protection against flying debris and chemicals. One downside of SCBAs is that they can be bulky and difficult to wear for extended periods of time.

The Four Face Styles of Respirators

Mouth Bit Respirator

A mouth bit respirator is the most basic type of respirator and covers your mouth and nose. This type of respirator will protect you from inhaling dust particles but will not protect your eyes.

You can find mouth bit respirators at most hardware stores or online.

Pros:

- inexpensive

- easy to find

Cons:

- does not protect your eyes

- can be uncomfortable to wear for long periods of time

This type of respirator is best for short exposure to metal grinding dust or occasional use.

Quarter Mask Respirator

The most common type of respirator is the quarter mask respirator. This covers your nose and mouth and is usually fitted with a single strap that goes around your head.

One advantage of quarter masks is that they’re less likely to fog up your glasses or goggles than a full-face respirator. Another advantage is that quarter masks tend to be less expensive than full-face models. However, they don’t provide as much protection since they don’t cover your eyes.Half-Face Mask Respirators

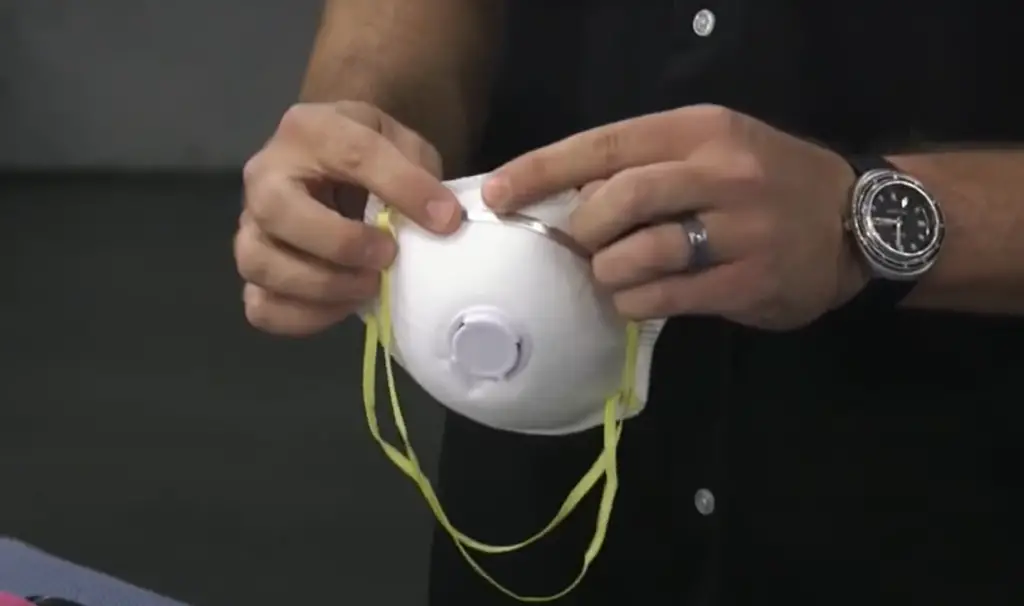

One of the most popular types of respirators is the half-face mask respirator. This type of respirator covers your mouth and nose, and it has two straps that go around your head. Some half-face mask respirators have a single strap that goes over your head, while others have two straps. This mask respirator is made of a soft material that is comfortable to wear. It is also easy to put on and take off. The half-face mask respirator can be used for a variety of applications, including welding, soldering, grinding, and sanding.

Full Facepiece Respirators

A full facepiece respirator, also called a gas mask, is very important for eye and respiratory protection while grinding metal. This type of respirator covers the entire face, including the eyes, to protect the wearer from flying metal particles and other potential hazards in the work environment.

Pros:

- Full facepiece respirators offer the highest level of protection against airborne contaminants

- Can be adapted to work with other personal protective equipment, like earplugs or safety glasses

Cons:

- May be uncomfortable to wear for long periods of time

- Can make it difficult to see and communicate while working

If you choose to use a full facepiece respirator, be sure to read the manufacturer’s instructions carefully before use, and follow all OSHA guidelines for fit testing and proper use.

How to Choose the Best Respirator for Metal Grinding

When it comes to choosing the best respirator for metal grinding, there are a few things you need to take into consideration. Here are some factors that you should keep in mind when making your decision:

- The type of metal you will be grinding: Some metals produce more dust than others. For example, aluminum produces a lot of fine dust that can be dangerous to breathe in. If you will be grinding aluminum, you need a respirator that is specifically designed for that purpose.

- The size of the particles: The smaller the particles, the more harmful they can be. A respirator with a high filtration rate will help to remove more of the small particles from the air.

- The environment: If you will be grinding in a dusty environment, you need a respirator that can filter out the dust. A disposable mask is not going to be enough in this case. You need something more durable that can withstand repeated exposure to dust.

- Your budget: Respirators can range in price from around $20 to over $100. It is important to find one that fits your budget and provides the features you need.

Keep these factors in mind when choosing a respirator for metal grinding and you will be sure to find one that fits your needs.

How to Wear Respirators for Metal Grinding

Most people don’t know how to correctly wear a respirator for metal grinding. Make sure you do!

Incorrectly wearing a respirator can actually do more harm than good. When not worn correctly, gaps can form around the edges of the mask, allowing contaminants to enter through them.

To avoid this, follow these simple steps:

- Before putting on the mask, wash your hands with soap and water or alcohol-based hand sanitizer.

- Inspect the mask for damage. If it is damaged, do not use it and dispose of it properly.

- Put the straps over your head and position the mask so that it covers your nose and mouth completely.

- Press down on the edges of the mask to create a seal around your face.

- Once you have put on the mask, do not touch it. If you do, wash your hands with soap and water or alcohol-based hand sanitizer again.

By following these steps, you can be sure that you are correctly wearing your respirator and that it will provide the protection you need.

How to Change a Filter on a Respirator

The most common factors that will necessitate a filter change are time and exposure. Depending on the environment you’re in, you’ll want to keep an eye on both of these things. If you’re in a particularly dusty or dirty area, it’s going to be more important to change your filters more frequently.

You’ll also want to change your filters if they become damaged or wet. If you notice that your filters are starting to look dirty, it’s time for a change. And if they get wet, it’s definitely time for a change – water can damage the filters and make them less effective. [3]

Changing your filters is a quick and easy process, so there’s no excuse not to do it when necessary. Your respirator will work better and you’ll be better protected if you change the filters on a regular basis.

To change the filters:

- Open the respirator so you can access the inside. On most models, this will involve removing the face piece.

- Locate the old filter(s) and remove them. Make sure to dispose of them properly according to your local regulations.

- Insert the new filter(s). Make sure they’re inserted in the correct orientation – consult your owner’s manual if you’re unsure.

- Close up the respirator and make sure all the parts are securely in place.

With some types of filters, it’s important to remember to pre-wash them before using them for the first time. This will remove any chemicals used in the manufacturing process that could be harmful if inhaled. Follow the instructions on the packaging for pre-washing instructions.

Respirator maintenance

If you’re going to be doing any metal grinding, it’s important to keep your respirator in good working order. This means regularly cleaning and replacing the filters. It’s also a good idea to have a couple of spare filters on hand, just in case. [4]

And of course, make sure you’re wearing the right type of respirator for the job. Some jobs will require a dust mask, while others will need a full-face respirator. Finally, always read the safety instructions that come with your respirator and follow them carefully. By taking these simple precautions, you can help keep yourself safe while you’re working.

FAQ

What is the difference between a mask and respirator?

Masks are loose-fitting, whereas respirators form a tight seal around your face. Masks typically protect against large particle droplets, while respirators also protect against small particles that can be inhaled. Masks can vary in design, but most of them have a pleated front with different levels of filtration. Respirators, on the other hand, have cartridges or canisters that filter out contaminants from the air you breathe. When it comes to metal grinding, both masks and respirators can offer protection from the harmful airborne particles created by this type of work. However, if you want the best possible protection for your lungs, it is important to choose a high-quality respirator specifically designed for this purpose.

What is required before using a respirator?

You’ll need to have a good understanding of the following before using a respirator for metal grinding:

- The type of metal you’re grinding

- The size and shape of the particles you’re dealing with

- How much exposure you’re likely to have

- What kind of ventilation is available

If you’re not sure about any of these factors, it’s best to err on the side of caution and consult with a professional.

Which respirator has the highest protection factor?

The answer to this question is a little complicated. The protection factor of a respirator depends on many factors, including the type of filter used, the fit of the mask, and how well it seals to your face. In general, N95 masks have the highest protection factor, followed by P100 masks. However, there are many different types and models of each type of mask, so it’s hard to say definitively which is the best.

Can I use alcohol wipes to clean my respirator?

Yes, you can use alcohol wipes to clean your respirator. However, you should only use them if the manufacturer recommends them. Some manufacturers do not recommend using alcohol wipes because they can damage the material of the respirator.

Is it OK to share respirators?

The answer is no. You should never share your respirator with anyone, even if they seem healthy. It’s possible to spread germs through close contact, and a respirator can only protect you if it’s clean. Also, sharing respirators can lead to a poor fit, which reduces the protection they offer. So if you’re thinking about sharing your respirator with someone, just don’t do it. If you’re in a situation where you can’t avoid sharing a respirator, make sure to clean it before and after use. You should also perform a fit test on yourself and the other person to make sure the respirator is working properly.

How do you protect against metal dust?

When it comes to protecting against metal dust, there are a few key strategies you can employ. Firstly, make sure to wear the appropriate protective gear when working with metals – this should include safety glasses, gloves and a respirator mask. Secondly, keep the area clean and well-ventilated to minimize exposure to metal particles in the air. Finally, use an industrial vacuum cleaner with a high efficiency particulate filter (HEPA) for regular cleaning. These will help trap small metal particles before they enter your breathing space. By taking these measures, you can help protect yourself and others from the dangers of metal dust.

Do you need to wear a respirator when grinding metal?

It depends on the type of grinding you are doing and the environment you are in. If you’re working with metal grinders in an enclosed or poorly ventilated area, then it is recommended to wear a respirator. When dealing with airborne particles, fumes, mists, vapors and dusts that may be present during metal grinding operations, a respirator can protect your lungs from inhaling harmful materials. It’s always best to check with your employer or safety program manager for specific recommendations regarding any required personal protective equipment (PPE) related to your particular job tasks. For example, some employers may require personnel using power tools such as grinders to use both hearing protection and a face shield or goggles along with a respirator if they are exposed to hazardous materials.

Remember, it’s always important to check with your employer or safety program manager regarding any required personal protective equipment (PPE) when working with metal grinders. Even if a respirator isn’t required for the work you’re doing, you may still want to consider wearing one for added protection and peace of mind.

Which mask is best for welding fumes?

For welding fumes, it’s important to use a mask designed specifically for the job. This would typically be an air-purifying respirator with an N95 or P100 filter cartridge. In more extreme cases, a powered air-purifying respirator (PAPR) may be needed. It’s important to always refer to the manufacturer’s instructions on how to properly wear and care for your mask. Additionally, OSHA has guidelines regarding respiratory protection that should be followed. Be sure to check them out before starting any welding projects. Safety is key!

Is N95 good for grinding metal?

No, N95 masks are not good for grinding metal. They do not provide full-face protection and the small particles of metal could be inhaled through the mask, leading to potential health risks. Instead, opt for a full-face respirator mask with appropriate filters when you are working in such an environment. These masks offer better protection from airborne particles and dust generated by grinding metal. Make sure to fit your respirator properly before use to ensure that it is providing adequate coverage for your face and mouth. Also, replace or clean your respirator’s filter regularly to maximize its effectiveness. Safety should never be compromised so take precautions whenever you are engaging in activities that involve removing or grinding metals!

Is N95 OK for welding?

For most welding applications, it is recommended to use an N95 class filter because welding fumes are able to be filtered relatively easily. Another common factor, oil mist, is seldom present. The presence of oil mist means that a P100 class filter should be used instead. Both types of filters are available from most welding supply stores, so it is important to consult with the shop to determine which type of filter will provide the best protection for your specific application. Generally speaking, an N95 filter can protect you from welding fumes and other airborne particles, but may not offer adequate protection against oil mist or other hazardous materials. Therefore, it is important to take all precautions and choose the right filter for your needs.

It’s also important to remember that no matter which type of respirator you use, proper fit is essential in order to ensure maximum safety and effectiveness. Always make sure that the respirator fits tightly on your face so that there are no gaps or air leaks. This is especially important when using an N95 filter, as even a small gap can allow hazardous particles to enter the respirator and cause harm. Additionally, the filter should be replaced or cleaned regularly in order to maintain its effectiveness over time.

What respirator should I use for melting metal?

The Center for Disease Control and Prevention (CDC) recommends respirators with an N-100, R-100, or P-100 rating. These types of respirators are designed to filter out harmful particles from the air, including metal fumes and other airborne contaminants. It is important to select a respirator that fits properly so it can effectively protect you from inhalation hazards when melting metal. Be sure to read and follow the manufacturer’s instructions carefully for proper use and cleaning. You may also want to consider purchasing additional filters or cartridges as needed, since these need to be replaced on a regular basis depending on usage. If you have any questions about which type of respirator is best for your situation, contact an occupational safety professional for help selecting the appropriate product. Safety should always be a priority when working with hazardous materials!

Should I wear a respirator when grinding aluminum?

Yes, it is always recommended to wear a respirator when grinding aluminum. Aluminum oxides are known to be harmful if inhaled and can cause irritation of the respiratory tract. A respirator will act as a barrier against these airborne particles. It should also fit properly and be securely fastened so that no air can leak in or out. You may also want to consider wearing eye protection while grinding aluminum as sparks from the grinder could cause potential harm to your eyes. It’s better to be safe than sorry!

What respirator is needed for welding galvanized steel?

Half-Masks are the best option for when you’re welding galvanized steel. A half-mask respirator will provide you with respiratory protection, and it will filter out the fumes and particles released during welding. Look for a respirator that has a P95 or better rating to make sure that you are getting the highest level of protection possible. Make sure that the mask fits snugly and securely around your face, as any gaps can allow in dangerous vapors and particles. Additionally, be sure to replace filters on your respirator regularly for continued safety when welding galvanized steel.

Do most welders wear respirators?

Yes, most welders wear respirators while working. This is because welding involves burning gases and particles that can be hazardous to your health if inhaled. Respirators help protect welders from potentially dangerous fumes and keep them safe while they work. Additionally, they often come with replaceable filters to ensure that the air you breathe remains clean and healthy. Furthermore, OSHA regulations require welders to use respirators when welding in certain environments, ensuring their safety while they do their job. So whether it’s for personal comfort or regulatory compliance, wearing a respirator is an important part of a welder’s safety protocol!

What happens if you inhale metal dust?

Breathing in metal dust can cause a variety of health problems, including an increased risk of cancer, respiratory problems such as asthma, lung inflammation and even heart disease. Long-term exposure to metal dust can also lead to other serious medical conditions, like neurological damage. Inhaling large amounts of metal dust could be extremely hazardous to your health and should be avoided at all costs. If you are exposed to metal dust, it’s important to seek medical attention quickly in order to minimize the potential damage. Additionally, wearing protective gear when working with metals will help keep you safe from any potential harm caused by inhaled particles.

What happens if you inhale aluminum dust?

Inhaling aluminum dust can be dangerous and has been linked to an increased risk of developing a range of health issues. It may cause inflammation in the lungs, respiratory illnesses, difficulty breathing, coughing, lung damage and even death in extreme cases. Ingesting aluminum dust can also lead to gastrointestinal irritation, kidney damage and neurological symptoms such as headaches and memory problems. People with pre-existing respiratory or cardiovascular conditions should be especially mindful of not inhaling aluminum dust as it might worsen their condition. It is important to wear protective masks when handling aluminum dust and follow safety protocols when working with this material. Additionally, if you think you have inhaled too much aluminum dust it’s best to seek medical attention immediately for proper diagnosis and treatment.

Useful Video: Protect Yourself! Do you know when to use each style of Respirator? Plus More Safety Equipment!

Conclusion

If you work with metal grinding on a regular basis, it’s important to have the right respirator for the job. In this guide, we’ve reviewed some of the best respirators for metal grinding and provided some useful tips to help you choose the right one for your needs. We hope this information has been helpful and that you can find the perfect respirator to keep you safe while you work. Thanks for reading!

References:

- https://www.cdc.gov/niosh/npptl/topics/respirators/factsheets/respfact.html

- https://mybreathbuddy.com/blogs/blog/understanding-respirator-selection-full-face-half-mask-or-hood-respirator

- https://worksafegear.com.au/blog/when-to-change-your-respirator-filters-or-cartridges

- https://blog.rmiwyoming.com/how-to-clean-and-maintain-your-respirator

- https://www.amazon.com/Reusable-KISCHERS-Painting-Polishing-Protection/dp/B08BWQL1R9

- https://www.amazon.com/NORTH-550030L-HALF-MASK-RESPIRATOR/dp/B06XVQ41RL

- https://www.amazon.com/Facepiece-Reusable-Respirator-Replaceable-Protection/dp/B08719GSRF

- https://www.amazon.com/Respirator-Lightweight-Painting-Decoration-Woodworking/dp/B085XTGGYC

- https://www.amazon.com/6000-Full-Facepiece-Respirator-Size/dp/B0761395MM