Choose the Best Metal Lathes

Customer’s Choice: the Best Rated Metal Lathes

77 users answered this survey. Please help us improve this review!

Finding the best metal lathe for your needs can be a daunting task. There are so many different brands, models, and features to choose from! How do you know which one is right for you? In this article, we will answer some of the most common questions about metal lathes. We will also review some of the best models on the market and provide tips on how to use them effectively. So whether you are just starting out in metalworking or you are a seasoned pro, read on for information that will help you make the right purchase decision!

BestEquip Metal Lathe 7″ x 14″,Mini Metal Lathe

Looking for a high-quality mini metal lathe that can handle a variety of projects? Look no further than the BestEquip Metal Lathe! This top-of-the-line product offers variable speeds that range from 0 to 2500 RPM, making it perfect for any hobby use.

Looking for a high-quality mini metal lathe that can handle a variety of projects? Look no further than the BestEquip Metal Lathe! This top-of-the-line product offers variable speeds that range from 0 to 2500 RPM, making it perfect for any hobby use.

This metal lathe is a compact metal lathe machine and it’s perfect for hobbyists and DIYers. It has a 7″ x 14″ capacity, so it can handle small projects with ease. Keep in mind that this machine doesn’t come with any tool holders, so you’ll need to purchase those separately. It’s also off center, so you’ll need to adjust it to get accurate results. Unfortunately, the build quality is poor overall and the speed doesn’t switch smoothly. Plus, it’s very noisy when in use. Overall, this metal lathe, while being cheap, will definitely use some of your time trying to fix its issues.

Grizzly G9972Z Bench Lathe

The Grizzly G9972Z 26-inch Bench Lathe is a powerful and accurate machine that is perfect for both hobbyists and professional machinists alike. This lathe features six speed choices, an impressive spindle with no runouts, and tightness and accuracy that are second to none.

The Grizzly G9972Z 26-inch Bench Lathe is a powerful and accurate machine that is perfect for both hobbyists and professional machinists alike. This lathe features six speed choices, an impressive spindle with no runouts, and tightness and accuracy that are second to none.

The Grizzly G9972Z Bench Lathe is a great tool for anyone who loves to work with their hands. Even though it has some minor flaws, like a badly positioned switch and no variable speed motor, it’s still a great lathe that can help you create beautiful pieces of art. The speeds don’t change smoothly, but with a little patience, you can still get the perfect finish on your project. Sometimes the bolt holes might not line up, but that just adds to the challenge. This lathe is on the pricier side, but it’s definitely worth the price tag.

Jet 321360A BDB-1340A Bench Metalworking Lathe

The Jet 321360A BDB-1340A Bench Metalworking Lathe is perfect for smaller projects that don’t require a lot of heavy-duty power. With its 13-inch swing and smooth speed changes, this lathe is perfect for many metalworkers.

The Jet 321360A BDB-1340A Bench Metalworking Lathe is perfect for smaller projects that don’t require a lot of heavy-duty power. With its 13-inch swing and smooth speed changes, this lathe is perfect for many metalworkers.

If you’re looking for a high-quality bench metalworking lathe, the Jet 321360A BDB-1340A is not the machine for you. With a maximum speed of only 1250 RPM, it’s not suitable for anyone who wants to do serious work with metal. The equipment that comes with the lathe is also of poor quality, and customer support won’t be enthusiastic to help you with the problems you might encounter. So if you’re a beginner who won’t understand the limitations of this machine, we suggest you look elsewhere.

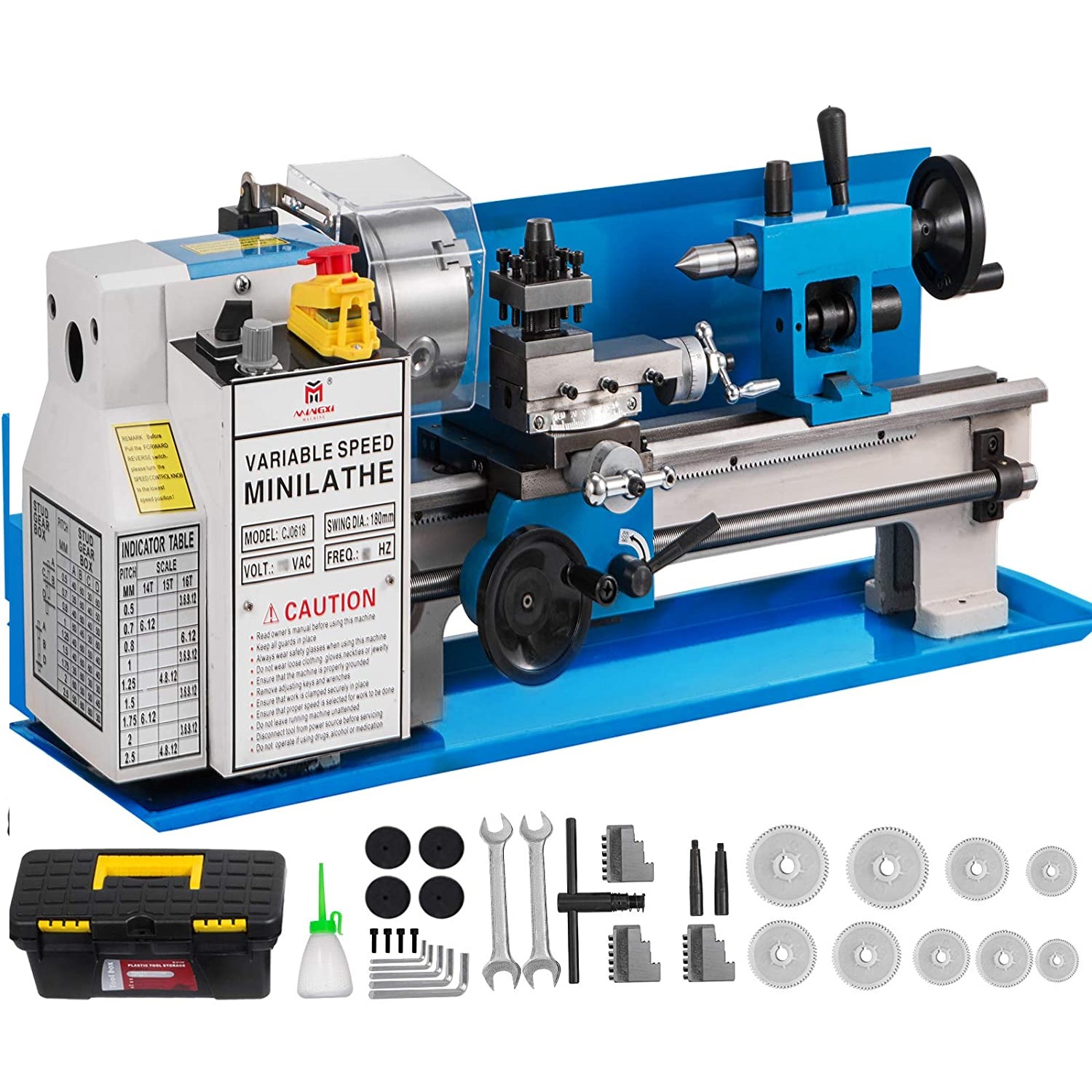

Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe

Are you looking for a versatile and easy-to-use mini metal lathe? If so, the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe is a great choice.

Are you looking for a versatile and easy-to-use mini metal lathe? If so, the Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe is a great choice.

The Erie Tools 7 x 14 Precision Bench Top Mini Metal Milling Lathe is a versatile and powerful machine that can handle a wide range of metalworking tasks. Its small size makes it perfect for use in cramped spaces, and its precision controls allow you to achieve accurate results. However, there are a few things to keep in mind when using this lathe. First, the plastic gears may need to be replaced with metal ones if you plan to do heavy-duty work. Second, the instructions can be unclear, so it’s important to read them carefully before beginning any project. Finally, the lathe may require some adjustments and cleaning before it’s ready to use. Overall, this is a pretty good lathe if you are willing to put some work setting it up.

Shop Fox M1112 12-Inch by 36-Inch Gunsmithing Lathe

The Shop Fox M1112 12-Inch by 36-Inch Gunsmithing Lathe is perfect for the serious hobbyist or gunsmith. With a wide range of speeds, this lathe can accommodate any project you might be working on.

The Shop Fox M1112 12-Inch by 36-Inch Gunsmithing Lathe is perfect for the serious hobbyist or gunsmith. With a wide range of speeds, this lathe can accommodate any project you might be working on.

This beast of a machine can handle any project you throw at it, but be warned: it can be quite hard to unbox. It’s also pretty sloppy in terms of the cross feed screw. The supplied jaw is also pretty small, so it might not be suitable for all projects. It also doesn’t come with a chip guard, so you’ll need to be careful when using it. But despite these cons, it’s still one of the best options out there.

Buyers Guide

What are the Metal Lathes?

Metal lathes are some of the most versatile and powerful machines in any workshop. They are capable of shaping an enormous variety of parts, from small precision components to large objects such as car engine blocks.

There is a huge range of different metal lathes available on the market, from simple bench-top models to massive floor-standing ones. Below, we will take a look at some of the best metal lathes in each category. [1],[2]

How Do Metal Lathes Work?

Metal lathes work by rotating a workpiece while a cutting tool is applied to it. The cutting tool removes material from the workpiece, shaping it into the desired form.

The speed at which the workpiece is rotated, and the speed and feed rate of the cutting tool, are carefully controlled to avoid damaging the workpiece or breaking the cutting tool.

Metal lathes can be used to drill and sand as well as cut, and many have attachments that allow them to perform other operations such as tapping and reaming.

It’s also used for shaping. All kinds of shapes can be produced with a high degree of accuracy, making metal lathes essential tools for many engineering applications.

In addition to shaping parts, metal lathes can also be used to create threads. This is done by holding the workpiece in a chuck and rotating it while a threaded cutting tool is moved along its length. The resulting thread can be used to screw parts together or to hold them in place.

Threads can also be cut onto the outside of cylindrical objects such as pipes. This is known as external threading. [1],[2],[3],[4]

Advantages and Disadvantages of Metal Lathes for Metalworking

There are many advantages to using metal lathes for metalworking. They are highly versatile and can be used to create a wide variety of shapes and threads. Metal lathes are also very accurate, making them ideal for engineering applications.

However, there are some disadvantages to using metal lathes. They require a high level of skill and experience to operate safely and effectively. They also require regular maintenance and care in order to stay in good condition.

They offer a great deal of versatility and accuracy, making them perfect for a wide range of projects. However, they should only be used by experienced operators who understand the risks involved in operating them and the limits they have. With proper care and maintenance, metal lathes can provide years of reliable service. [1],[2],[4]

Types of Metal Lathes

There are several different types of metal lathes available on the market. Each type has its own advantages and disadvantages, so it is important to choose the right one for your needs.

Bench Lathe

A bench lathe is a small, portable lathe that can be mounted on a workbench. Bench lathes are perfect for small projects and precision work. They are usually less powerful than floor-standing models and have smaller capacities.

However, bench lathes are much easier to set up and use, and they take up far less space in your workshop. If you only need to occasionally use a metal lathe, then a bench model might be the best choice for you.

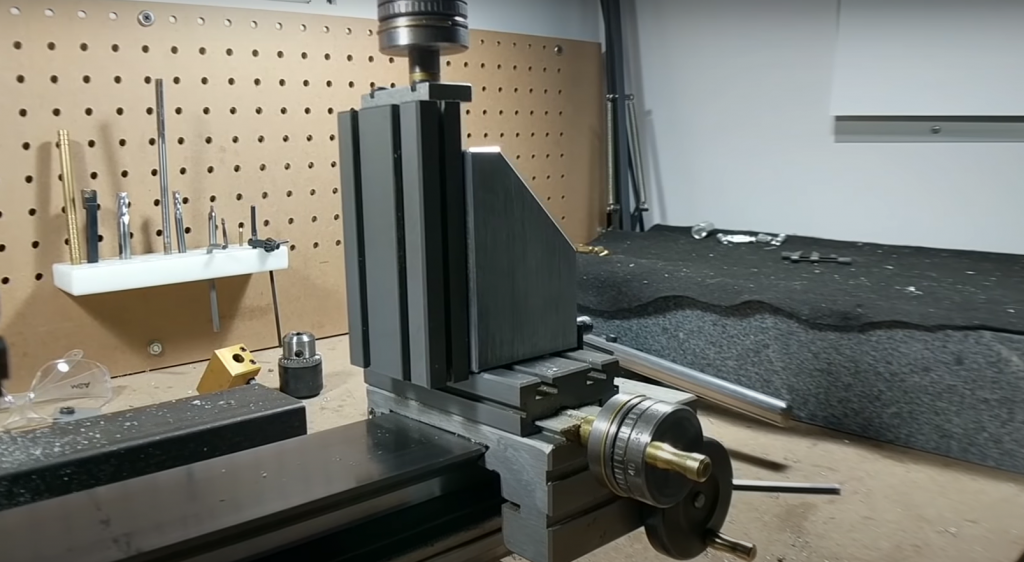

CNC Machine

A CNC machine is a computer-controlled lathe that can be used to create highly accurate parts. CNC machines are often used in production settings where large numbers of identical parts need to be produced quickly and accurately.

CNC machines are very expensive, so they are not typically found in home workshops. However, if you need to produce high-quality parts on a regular basis, then a CNC machine might be the right choice for you.

High-Speed Lathe

A high-speed lathe is a specialized type of metal lathe that is designed for use with very hard metals. High-speed lathes rotate the workpiece at much higher speeds than other types of lathes, allowing them to cut through even the toughest materials.

High-speed lathes are usually floor-standing models with large capacities. They are also very expensive, so they are only worth considering if you regularly work with extremely hard metals.

If you need to cut threads into extremely hard metals, then a high-speed lathe might be the best choice for you. However, if you only occasionally need to cut hard metals, then a less expensive model would be more suitable.

Engine Lathe

An engine lathe is a large, heavy-duty lathe that is designed for use in an industrial setting. Engine lathes are capable of machining large and complex parts. They are also very accurate and offer a high degree of versatility. They can do tasks like threading, grooving, turning etc.

However, engine lathes are expensive and require a great deal of space to operate. They also require a high level of skill to use effectively. If you need to regularly machine large parts, then an engine lathe might be the right choice for you.

Turret Lathe

A turret lathe is a type of lathe that has a turret instead of a chuck. The turret holds a number of different cutting tools, which can be quickly swapped out as needed. This makes turret lathes very versatile and efficient.

Turret lathes are often used for high-volume production work, where the same parts are being produced over and over again. They are also often used for complex shapes that require multiple operations to create. However, they are more expensive than other types of lathes and require more skill to operate effectively.

Overall, turret lathes offer a great deal of versatility and efficiency, making them perfect for high-volume production work, but that versatility comes at a premium price.

Automatic Lathe

An automatic lathe is a type of lathe that is operated by a computer. Automatic lathes are capable of producing very complex shapes and threads. They are often used in high-volume manufacturing applications where accuracy and repeatability are essential.

Automatic lathes are more expensive than manual models, but they can greatly reduce the amount of time and labor required to produce parts. If you need to produce large quantities of parts with tight tolerances, then an automatic lathe might be the best choice for you.

Special Lathes

Some lathes are designed for specific tasks or materials. These include T-lathes, which are designed for turning tubular parts; duplex lathes, which can turn two parts at once; and gear-cutting lathes, which are used to cut gears.

If you need to perform a specific task or work with a specific material, then you might want to consider a special lathe.

Tool Room Lathe

A tool room lathe is a larger and more powerful version of a bench lathe and is similar to the engine variant in terms of functionality. Tool room lathes are designed for heavier work, they have much higher capacities than bench models and better precision than engine lathes.

Yes, tool room lathes are also much more accurate, making them perfect for precision engineering applications. However, they are much more expensive than other lathes and require a higher level of skill to operate effectively.

Used tool room lathes can be found for sale online or at industrial auctions. [2]

As you can see, there are many different types of metal lathes available on the market. Each type has its own advantages and disadvantages, so it is important to choose the right one for your needs.

How Different Are Lathes and Mini-Lathes?

The main difference between lathes and mini-lathes is size. Lathes are much larger than mini-lathes, and they are designed for use in an industrial setting. Mini-lathes, on the other hand, are smaller and more portable.

Mini-lathes are also less powerful than lathes, meaning that they can only be used for light machining tasks. However, mini-lathes are much cheaper than lathes and offer a high degree of portability. If you need a machine that can be easily moved from one location to another, then a mini-lathe is the best choice for you.

Safety Tips For Using a Metal Lathe

When using a metal lathe, it is important to follow some basic safety guidelines.

Protection Yourself is Important

Most importantly, you should always wear protective clothing when using a lathe. This includes gloves, goggles, and ear protection. Proper equipment will help you avoid injuries from the flying debris.

That’s why in this guide we will answer some common questions about best metal lathes, provide reviews of popular products, and offer some tips on how to choose the right model for your needs. Let’s get started!

Sharpen Your Tools Properly

Another important safety tip is to make sure that your cutting tools are properly sharpened. Dull tools can cause the lathe to chatter, which can lead to dangerous conditions. Always use a sharpening stone or file to keep your cutting tools in good condition.

In addition, you should always use the correct tool for the job at hand. Using the wrong tool can damage the workpiece, as well as cause injuries. Make sure to consult the owner’s manual before using any attachments or accessories on your lathe.

Make Sure the Workpiece is Secure

A workpiece that is not properly secured can fly off of the lathe and cause serious injuries. Always use clamps or a vise to secure the workpiece before beginning any machining operation.Avoid Wearing Loose Clothing

Last safety tip is to avoid wearing loose clothing while using the lathe. Loose clothing can easily get caught in the moving parts of the machine and cause serious injuries. Always wear close-fitting clothing when working with a lathe. Same goes for jewelry, take it off before starting to work on your project!

Now that you know some basics about metal lathes and how to safely use them, let’s see the best lathes that are available on the market today! [1],[5]

Buyers Guide for the Best Metal Lathes

Having provided you with five great options for metal lathes, we now want to help you further with a buyer’s guide. This guide will help you understand what to look for when purchasing a metal lathe!

Budget

The first factor you need to consider is your budget. Metal lathes can range in price from a few hundred dollars to several thousand. It’s important to know how much you’re willing to spend before beginning your search.

The price will depend on the features you need. Some metal lathes come with more features than others. If you’re looking for a basic model, you won’t need to worry about all the bells and whistles. However, if you want a lathe that has more advanced features, you’ll need to be willing to pay more. [6],[7],[9]

Wattage

The wattage of the lathe will determine how much power it has. The higher the wattage, the more powerful the lathe. If you plan on doing a lot of heavy duty work, then you will want to look for a lathe with a high wattage. However, if you only plan on using the lathe for light duty work, then you can get away with a lower wattage.

For most home users, a lathe with a wattage between 600 should be plenty. But, keep in mind that the higher the wattage, the more expensive the lathe will be. [8],[10]

Spindle Speed

The spindle speed is how fast the spindle of the lathe turns. This is measured in revolutions per minute (RPM). The faster the spindle speed, the faster you can work. However, you also need to be careful not to overheat the metal you are working with. If you are working with very thin metal, then you will want a lower spindle speed so that you do not overheat the metal and cause it to warp.

In general, you will want a spindle speed between 30 and 2500 RPM. This will give you a good range to work with different types of metals. [7],[8],[10]

Project Size

One of the main things you need to consider when purchasing a metal lathe is the size of projects you’ll be working on. If you’re only going to be working on small projects, then a mini metal lathe would be a great choice. However, if you’re planning on working on larger projects, then you’ll need to purchase a full-size metal lathe.

Another thing to keep in mind is the space you have available for your lathe. Metal lathes can be quite large and bulky, so make sure you have enough room in your workshop before making your purchase! [6],[8],[9],[10]

Weight

The weight of the lathe is going to be one of the most important factors in your decision. If you’re looking for a portable lathe that can be easily transported, then you’ll want to pay close attention to the weight.

However, if you’re looking for a lathe that will be staying in one spot, then they may not be as big of a factor.

A heavier lathe will be more rigid, and less likely to vibrate than a lighter one. Heavier lathes are usually made with thicker walls which also adds to their rigidity.

Of course, there are trade-offs to everything, and the heavier weight will make it more difficult to move around. Portability too is going to be one of the main factors to consider when purchasing a metal lathe. So keep all this in mind. [6][8]

The Design of the lathe

One of the most important aspects of choosing a lathe is the design. The design will determine how easy the lathe is to use and how accurate it can be. If you are looking for a lathe that is easy to use, then you should look for one with a simple design. On the other hand, if you are looking for a lathe that is more accurate, then you should look for one with a more complex design. [9]

Type of Headstock Bearings

There are two main types of bearings that you’ll find on a metal lathe: ball bearings and roller bearings. Ball bearings are the more common type, and they’re typically found on lower-end models. Roller bearings, on the other hand, are usually only found on higher-end models. They provide smoother operation and higher precision than ball bearings.

Both of these will work well. On the other hand you should avoid lathes with plain bearings. These are the least precise and will give you the roughest finish. [8],[9],[10]

Overall Build Quality

The build quality of a lathe is very important. After all, you want your machine to last for years, and even decades with proper care. A metal lathe should be made mostly of cast iron. This will give the lathe more rigidity, and dampen vibrations. Vibrations can cause poor finishes on your workpieces.

The best metal lathes will also have a gearbox made of strong material. This is important because the gears in a gearbox are under a lot of stress. If the gearbox is not made durable, it is more likely to fail prematurely.

Gears are also an important consideration when looking at the build quality of a lathe. The gears should be made of hardened steel, and they should mesh together smoothly. There should be no play in the gears, and they should not make any noise when the lathe is running.

You also want to make sure that any moving parts are well lubricated. This includes the spindle bearings, cross slide ways, and lead screw. Lubrication helps to reduce friction and heat, which can damage metal surfaces over time. [8],[9],[11]

Easiness of Use

What you definitely want to check when purchasing a metal lathe is how easy it is to use. You want to make sure that the lathe you purchase is user-friendly and easy to operate. The last thing you want is to purchase a lathe that is difficult to use and frustrates you every time you try to use it. It mostly comes down to user experience at the end of the day. [9],[10]

DBC

One of the most important aspects of a metal lathe is the distance between centers or DBC. This is the measurement from the center of the spindle to the center of the tailstock. This is important because it will determine how long of a piece you can work with. If you are working with very long pieces, then you will want a lathe with a longer distance between centers.

The average distance between centers is about 20 inches. However, some lathes can have a distance bigger than that! This is something to keep in mind if you are planning on working with very long pieces of metal.

If you know you will only be working on small projects, then it stands to reason that you won’t need as large of a distance between centers. Conversely, if you plan on tackling large projects, make sure your model can accommodate that.

Another thing to keep in mind is that some models have the ability to extend their distance between centers with the use of an extension bed. If you think you may need this feature in the future, be sure to check and see if the model you are interested in offers it. [9],[10]

SOD

You also need to take into account the switch over distance. The switch over distance is the measurement from the center of the spindle to the point where the carriage can be reversed. This will give you an idea of how big of a work area you have to work with and if it will be able to accommodate the diameter of projects you want to complete. A larger switch over distance means that you’ll be able to work on projects with a bigger diameter!

Warranty

One important factor is the warranty. You want to make sure that the metal lathe you purchase has a solid warranty. This way, if anything goes wrong with your purchase, you will be covered!

Warranty can range from one year to five years, so be sure to do your research before making a purchase. [8],[9],[10]

FAQ

Are Atlas metal lathes any good?

Atlas metal lathes are some of the most popular on the market and for good reason. They’re well-made, durable, and easy to use. However, they can be a bit pricey. If you’re on a budget, there are other options available that may be more suitable for you. If you have the money to spend however, an Atlas lathe is definitely worth the investment. You won’t be disappointed with the quality or performance of these machines.

What is a good size metal lathe?

There is no definitive answer to this question as the size that is “good” for one person may not be sufficient for another person’s needs. It is important to consider the types of projects you will be working on and the amount of space you have available when deciding on a lathe size.

But usually, larger lathes typically have more power and can handle heavier projects than smaller lathes. If you are unsure about what size would be best for you, it is always a good idea to consult with a professional or someone who has experience with metal lathes before making your purchase.

Are myford lathes still made?

No, Myford lathes are no longer in production. However, you may be able to find a used one for sale if you look hard enough. Myford was a British company that manufactured high-quality metal lathes. They were known for their precision and durability.

What is a good beginner metal lathe?

If you are a beginner, you might be wondering what is the best metal lathe for you. There are a few things to consider when purchasing your first lathe. First, think about the size of the projects you will be working on. A smaller lathe will be less expensive and easier to maneuver, but it may not have all the features that a larger lathe has. Second, think about your budget and what features are most important to you. You won’t need that many features if you’re only starting, so there’s no point in spending extra cash on something you won’t use.

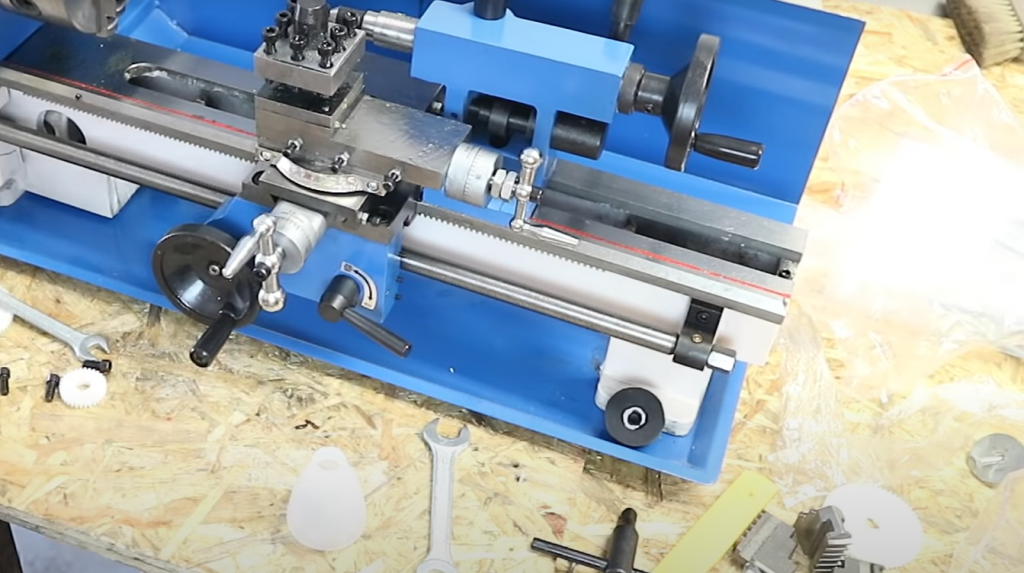

Useful Video: 7×14 MINI LATHE CHINESE COPY CLONE 550W

Conclusion

If you’re in the market for a metal lathe, it’s important to understand the different types available and what each can do. With so many options on the market, it can be tough to choose the best metal lathe for your needs. That’s why we’ve put together this comprehensive guide – to help make your decision easier.

Keep in mind that what’s most important when choosing a metal lathe is considering the size of the project, how durable it is, how user-friendly it is and overall build quality. And don’t forget to factor in price – because let’s face it, we all want the best possible machine without breaking the bank. Happy turning!

References:

- https://www.ametals.com/post/what-is-a-lathe-and-how-does-it-work

- https://machineryfuture.weebly.com/knowledge/lathe-machine-04

- https://openoregon.pressbooks.pub/manufacturingprocesses45/chapter/unit-6-lathe-threading/

- https://machinefanatic.com/what-does-a-lathe-do/

- https://littlemachineshop.com/images/gallery/info/MiniLatheUsersGuide.pdf

- https://homemakerchic.com/best-metal-mini-lathe/

- https://www.lathematters.com/best-mini-metal-lathes/#Where_Can_We_Use_Mini_Lathe_and_How_Does_it_Work

- https://handymansworld.net/best-mini-metal-lathes/

- https://www.architecturelab.net/best-metal-lathe/#Mini_Metal_Lathe_vs_Metal_Lathe

- https://www.electronicshub.org/best-metal-lathes/

- https://www.sharpen-up.com/best-metal-lathe-money-top-5-reviewed/#Metal_Lathe_Buyers_Guide