Choose the Best Dry Cut Metal Saw

Customer’s Choice: the Best Rated Dry Cut Metal Saws

33 users answered this survey. Please help us improve this review!

When it comes time to buy a new saw for your workshop, the options can be overwhelming. Do you need a circular saw? A miter saw? What about a band saw or jigsaw? If you’re looking to cut metal, then you’ll definitely want to check out dry cut metal saws. In this article, we’ll discuss the benefits of using a dry cut metal saw and provide reviews of some of the best models on the market. We’ll also give you some tips on how to choose the right saw for your needs and how to get the most out of it.

PORTER-CABLE Chop Saw – The Right Tool for the Right Application!

Introducing the PORTER-CABLE Chop Saw, the perfect tool for all your metal cutting needs. With a powerful 15 amp motor and a quick-release material clamp, this chop saw is designed for easy, efficient cutting.

Introducing the PORTER-CABLE Chop Saw, the perfect tool for all your metal cutting needs. With a powerful 15 amp motor and a quick-release material clamp, this chop saw is designed for easy, efficient cutting.

So, if you’re in the market for a dry cut metal saw, the PORTER-CABLE Chop Saw is a great option. It’s powerful, easy to use, and perfect for all your metal cutting needs.

Makita LC1230 12″ Metal Cutting Saw – A Treasure for a Metal Worker!

The Makita LC1230 12″ Metal Cutting Saw is the perfect tool for anyone who needs to make clean, accurate cuts with minimal burr formation. The carbide-tipped blade is designed for long-lasting durability, and the quick release vise ensures secure material retention and fast, repeated cut-offs.

The Makita LC1230 12″ Metal Cutting Saw is the perfect tool for anyone who needs to make clean, accurate cuts with minimal burr formation. The carbide-tipped blade is designed for long-lasting durability, and the quick release vise ensures secure material retention and fast, repeated cut-offs.

Overall, the Makita LC1230 12″ Metal Cutting Saw is an excellent tool for anyone who needs to make clean, accurate cuts with minimal burr formation.

DEWALT Metal Cutting Saw – Unsurpassed Speed!

The DEWALT Metal Cutting Saw is a high-performance industrial tool that is built to last. It comes with a powerful 15 AC/DC amps motor and a no-load speed of 1,300 rpm, making it ideal for heavy-duty projects. It also features a quick-lock vise and a spindle lock for added convenience.

The DEWALT Metal Cutting Saw is a high-performance industrial tool that is built to last. It comes with a powerful 15 AC/DC amps motor and a no-load speed of 1,300 rpm, making it ideal for heavy-duty projects. It also features a quick-lock vise and a spindle lock for added convenience.

Overall, the DEWALT Metal Cutting Saw is a great choice for those who need a powerful and durable tool for their projects. It comes with all the necessary features and accessories, and it even has a warranty package that will give you peace of mind.

Fein Slugger Metal Cutting Chop Saw – Enjoy Clean Cuts!

The Fein Slugger Metal Cutting Chop Saw is a versatile and precision tool that is perfect for a range of applications. With a quick release table/base clamp, it is easy to make cuts at different angles, and the well-balanced handle design provides better control.

The Fein Slugger Metal Cutting Chop Saw is a versatile and precision tool that is perfect for a range of applications. With a quick release table/base clamp, it is easy to make cuts at different angles, and the well-balanced handle design provides better control.

So if you’re looking for a versatile and precise dry cut metal saw, the Fein Slugger Metal Cutting Chop Saw is a great option. And if you want a saw that is easy to use and has all the features you need, this is the one for you!

MK Morse Metal Cutting Saw – Editor’s Choice!

The MK Morse Metal Cutting Saw is the ideal tool for anyone who needs to quickly and efficiently cut through metal. With its innovative cutting system, the Metal Cutting Saw can cut through 6 inches x ¼ inch thick steel in just 12 seconds – significantly faster than traditional abrasive wheels.

The MK Morse Metal Cutting Saw is the ideal tool for anyone who needs to quickly and efficiently cut through metal. With its innovative cutting system, the Metal Cutting Saw can cut through 6 inches x ¼ inch thick steel in just 12 seconds – significantly faster than traditional abrasive wheels.

Overall, the MK Morse Metal Cutting Saw is an excellent choice for anyone who needs a reliable and powerful tool for cutting through metal. It’s well-built, cuts quickly and efficiently, and is sure to last for a long time.

The Buyer’s Guide

What is a Dry Metal Cutting Saw

A dry cut metal saw uses a frictional cutting process to slice through metals. The cutting blade on these types of saws is typically coated with abrasive materials like diamond or carbide. This type of saw is ideal for making quick, clean cuts through tougher materials like stainless steel and cast iron.

Dry cut metal saws are available in both stationary and portable models. Stationary models are typically larger and more powerful, while portable models are more compact and easier to transport.

How to Choose the Best Metal Cutting Saw?

There are a few factors you need to consider before purchasing the best metal cutting saw for your needs. Below, we will go over what those factors are so that you can make an informed decision.

First and foremost, you need to think about the types of materials you will be cutting most often. If you only ever cut soft metals, then a lower end model should suffice. However, if you plan on cutting tougher alloys or even concrete occasionally, then you will need to spend a bit more money on a higher end model that is up for the task.

Next, consider how much power you need. The amount of power required varies depending on the type of metal being cut as well as the thickness. Again, if you only ever cut soft metals then a lower end model should be just fine. But if you find yourself constantly cutting tougher alloys or working with thicker materials, then you will want to consider spending a bit more money on a saw with more power.

Finally, take into account the size of the projects you typically work on.

However, if you regularly work on larger commercial projects, then you will need to get a larger saw that can handle those bigger jobs.Keep these factors in mind when shopping for the best metal cutting saw and you are sure to find the perfect one for your needs.

Types of Metal Cutting Saw

There are four types of metal cutting saws:

Chop Metal Saw

A chop metal cutting saw is a type of dry cut metal saw that uses a downstroke blade to make quick, clean cuts in light gauge metals. These saws are typically used by plumbers and electricians to cut pipe and conduit.

Circular Metal Saw

A circular metal cutting saw is a type of dry cut metal saw that uses an abrasive disc to make cuts in metals. These saws are typically used to cut rebar, angle iron, pipe, and conduit.

Reciprocating Metal Saw

The reciprocating metal saw is one of the most versatile and commonly used tools in a metalworker’s toolkit. It can be used for a variety of tasks, from cutting through thick metal pipes to making intricate cuts in sheet metal.

Band Metal Saw

A band metal saw is a specialized tool that is designed for cutting through very thick metal. It usually has a much larger blade than a reciprocating saw, and it runs on a continuous loop of blade. [3]

Things to Consider before Buying Dry Cut Metal Saws

Dry cut metal saws are a great tool for anyone who regularly works with metal. They offer many benefits over traditional wet saws, including faster cutting and less mess. However, there are a few things you should keep in mind before purchasing one of these saws.

Power Source

One of the most important things to consider when purchasing a dry cut metal saw is the power source. There are 3 types of power sources for these saws: gas powered, electric powered and battery powered.

Gas Powered

Gas powered dry cut metal saws are the most powerful type of saw. They can easily cut through thick metal without any issues. However, they are also the most expensive type of saw.[2]

Electric Powered

Electric powered dry cut metal saws are not as powerful as gas powered saws, but they are still able to cut through most types of metal. They are also less expensive than gas powered saws.

Battery Powered

Battery powered dry cut metal saws are the least powerful type of saw.

They can only cut through thin metals. However, they are the most convenient type of saw since you don’t have to worry about a power source.

What are Metal Cutting Saw Blades

Dry cut metal saws have blades that are specially designed to cut metals. The blades are made out of different materials such as high-speed steel, tungsten carbide, and diamond.

Types of Blades

Abrasive Blades

Abrasive blades are the most common type of blade used on dry cut metal saws.

Abrasive blades are designed to cut through a wide range of materials, including metals, plastics, and composites.Cold Saw Blades

Cold saw blades are made of high-speed steel or carbide. They are designed to cut through metals, including stainless steel and cast iron. Cold saw blades are available in a variety of sizes and can be used with a wide range of saws. [1]

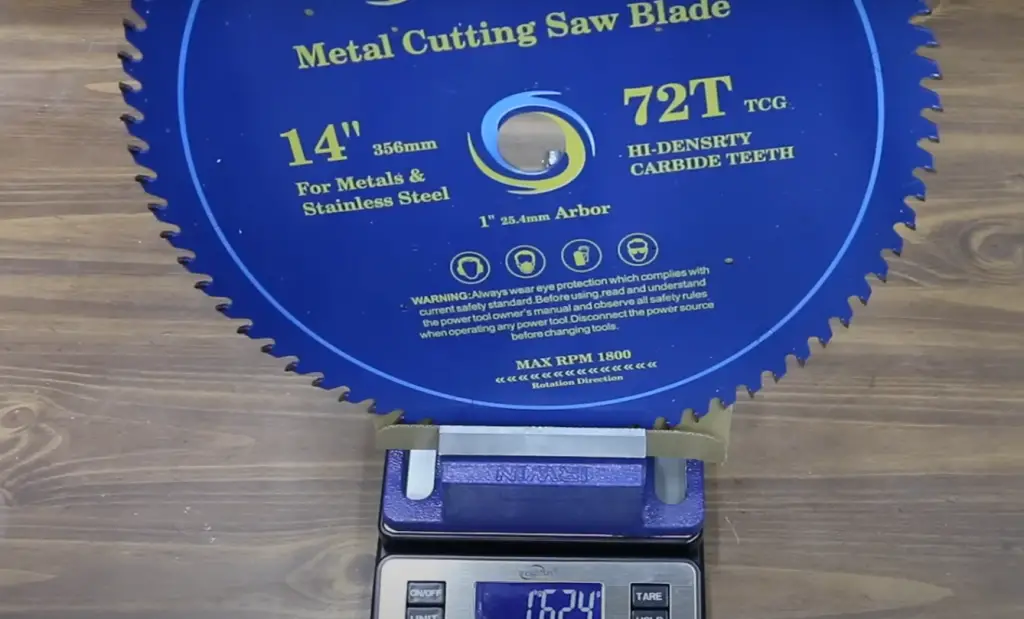

Blade Tooth Count

The number of teeth on the blade is important because it determines how fast or slow the cut will be. More teeth mean a slower cut, while fewer teeth mean a faster cut.

Blade Size

The next thing you need to consider is the size of blade you’ll need.

The most common sizes are six, seven, and eight inches.Blade Rotation Speed

The speed of the blade is also important. You’ll want to choose a saw with a blade that rotates between two thousand and four thousand RPM. If you’re unsure about which size or speed is right for your needs, it’s best to consult with an expert. Otherwise, you could end up damaging your material or even injuring yourself.

Motor Power

The saw’s motor power is also an important consideration. The higher the voltage, the more powerful the motor will be. However, you don’t want to choose a saw with too much power. Otherwise, you’ll find it difficult to control. Look for a saw with between two and four horsepower.

Angled Cuts / Fence Adjustment

Some saws also have the ability to make angled cuts. If you think you might need this feature, then be sure to choose a saw that has it. You’ll also want to make sure that the fence is adjustable. This will allow you to make precise cuts.

Vise Adjustment

Another feature to look for is vise adjustment. This will allow you to clamp your material in place, ensuring that it doesn’t move while you’re cutting.

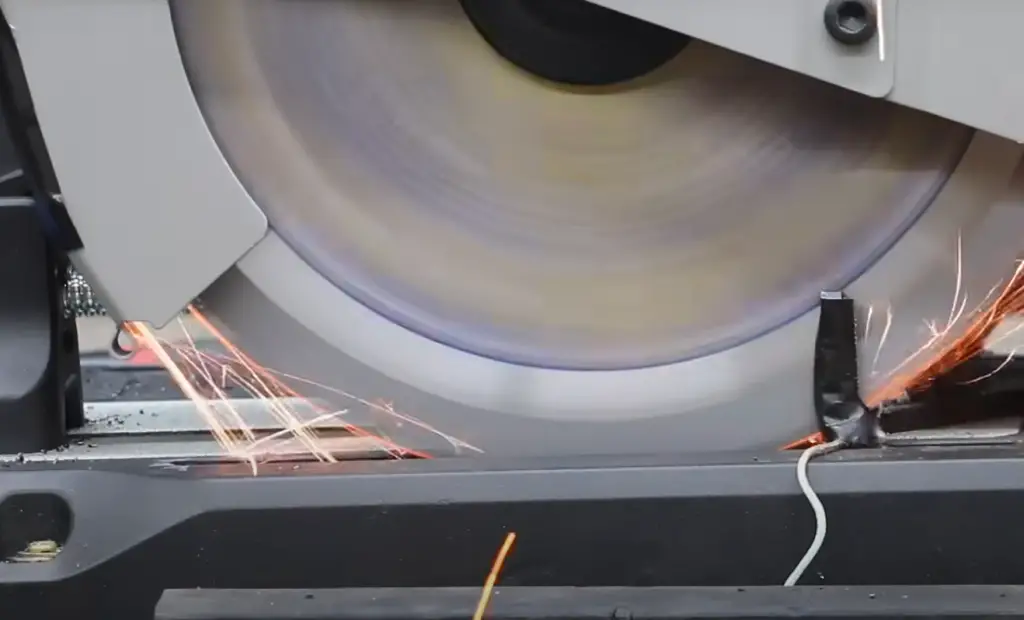

Spark Deflectors

Spark deflectors are a must-have if you’re going to be cutting metal. They help to keep the sparks from flying into your eyes.

Portability

Finally, you’ll want to consider the saw’s portability. If you plan on using it at home, then portability might not be an issue. However, if you need to take it with you to job sites, then you’ll want to choose a saw that’s easy to transport.

Warranty

When choosing a saw, be sure to look at the warranty. You want to choose a saw that comes with a good warranty. This way, if anything goes wrong, you’ll be covered.

Dry Cut Metal Saw – Safety Tips

When working with any type of power saw, safety is always the number one priority. That’s why we’ve put together a list of safety tips for you to keep in mind when using your dry cut metal saw.

Wear proper eye and ear protection. This is non-negotiable.

- Read the manual before using the saw. This seems like a no brainer, but you’d be surprised how many people don’t do this! Make sure you understand how the saw works and what all the safety features are before using it.

- Use gloves when handling the blade. The last thing you want is to accidentally cut yourself on the blade while changing it or doing other maintenance on the saw.

- Be aware of your surroundings. This is important with any power tool, but especially so with a saw. Keep an eye out for people or objects that could be in danger if you were to lose control of the saw.

Following these simple safety tips will help ensure that you have a safe and productive experience when using your dry cut metal saw.

Dry Cut Metal Saw Maintenance

It is important to keep your dry cut metal saw in good working order. This will help ensure that your cuts are accurate and safe. Here are some tips for maintaining your saw:

- Clean the air filters regularly. This will help prevent dust and debris from clogging the motor.

- Lubricate the moving parts regularly. This will help keep the saw running smoothly and prevent premature wear. [4]

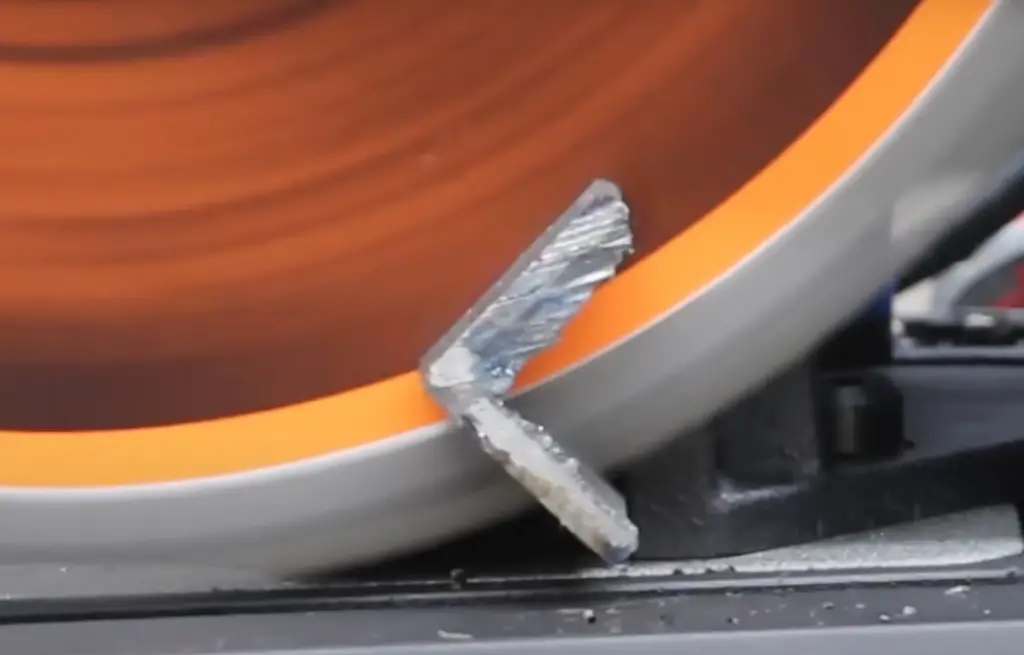

- Check the blade regularly for damage. If the blade is damaged, it can cause the saw to vibrate and produce inaccurate cuts.

Following these simple tips will help you get the most out of your dry cut metal saw.

FAQ

Can we use a metal cutting saw to cut wood?

No, you should not use a metal cutting saw to cut wood. Metal cutting saws are designed for cutting metal, and they will not work well on wood. If you try to use a metal cutting saw to cut wood, the blade will get stuck in the wood and damage the saw. If you need to cut both metal and wood, you should get a saw that is designed for both.

Are Some Metals Easier to Cut Than Others with Dry Cut Metal Saw

The answer to this question is both yes and no. Some metals are more difficult to cut than others, but there are ways to make the process easier. One way is to use a saw with a higher blade speed. Another way is to use a saw with a carbide-tipped blade.

Some of the most difficult metals to cut include stainless steel, aluminum, and cast iron. These materials require a lot of heat to be generated in order to cut through them. This is why using a saw with a higher blade speed is often recommended.

How long do chop saw blades last?

This is a difficult question to answer because it depends on so many factors, such as the type of metal you’re cutting, how often you’re using the saw, and how well you’re maintaining the blade. However, in general, you can expect a good-quality chop saw blade to last for several hundred cuts. If you’re cutting a lot of metal or very thick metal, you may need to replace the blade more frequently.

How many times can you sharpen a table saw blade?

You can sharpen your table saw blade around 20 to 30 times before it needs to be replaced. Of course, this number will differ depending on how often you use the saw and what type of materials you’re cutting. If you’re using your saw regularly, it’s a good idea to invest in a good quality sharpener.

There are two types of sharpeners: handheld and benchtop. Handheld sharpeners are more portable, but they can be tricky to use and may not produce as consistent of results as a benchtop sharpener. Benchtop sharpeners are larger and require more setup, but they’re much easier to use and will give you a more precise sharpening.

What is a no melt blade?

A no melt blade is a saw blade that is specifically designed to cut through metal without causing the metal to melt. This is accomplished by using a carbide or diamond-tipped blade that stays cool even when cutting through hot metals. No melt blades are available in both circular and reciprocating saws.

How do you know when a chop saw blade is dull?

One of the most common questions we get asked is how do you know when a chop saw blade is dull? The best way to tell if your blade is getting dull is by the quality of your cuts. If you notice that your cuts are becoming more jagged and less precise, it’s time to change your blade. Another way to tell if your blade is dull is by the amount of sparks it’s producing. If you’re not sure whether or not your blade is dull, it’s always better to err on the side of caution and replace it. A dull blade will not only produce subpar cuts, but it can also be dangerous. So, if you’re unsure, just replace your blade to be safe.

Can metal be cut with chop saw?

The answer is yes, a chop saw can cut metal. However, it is important to use the right blade and take precautions to avoid sparks.

What type of saw is best for cutting metal?

If you’re looking for a saw that can cut through metal quickly and easily, then you’ll want to choose a dry cut metal saw. These types of saws use an abrasive disc or blade to cut through metal, and they don’t require any coolant or water to keep the blade from overheating.

What is the difference between a metal chop saw and a wood chop saw?

A metal chop saw is designed to cut through tougher materials, like metal or concrete, whereas a wood chop saw is designed for cutting softer materials, like wood or plastic. Metal chop saws typically have stronger blades and motors than wood chop saws. Another difference between these two types of saws is that metal chop saws usually create more sparks and dust than wood chop saws.

Can I use a miter saw as a chop saw?

The quick answer is yes, you can use a miter saw as a chop saw – but we wouldn’t recommend it. Miter saws are designed for making precise cuts at different angles, whereas chop saws are designed for making quick, rough cuts. So if you’re looking to make clean, accurate cuts in metal, stick to using a dry cut metal saw.

Useful Video: Best Dry Cut Metal Saws (Top 5 in 2020)

Conclusion

So, what is the best dry cut metal saw?

The answer may not be as simple as you think. It depends on a variety of factors, such as the type of material you’re cutting, the thickness of the metal, and your own personal preferences.

There are a few things to keep in mind when choosing a dry cut metal saw:

- The higher the amps, the more powerful the saw.

- A blade with more teeth will make cleaner cuts, but it will also cause the saw to work harder and overheat more easily.

- A lower speed setting is better for thicker materials, while a higher speed setting is better for thinner materials.

We hope this guide has been helpful in finding the best dry cut metal saw for your needs! If you have any questions or comments, please feel free to leave them below. Thanks for reading!

References:

- https://www.electronicshub.org/best-metal-cutting-saws/

- https://www.homedit.com/metal-cutting-saw/

- https://toolscritics.com/best-metal-cutting-saw/#Types_of_Metal_Cutting_Saw

- https://blog.dakecorp.com/en-us/7-tips-for-maintaining-your-cold-saw

- https://www.amazon.com/PORTER-CABLE-PCE700-Amp-Chop-Saw/dp/B00NI2CF28

- https://www.amazon.com/Makita-LC1230-12-Inch-Metal-Cutting/dp/B00004YOLV

- https://www.amazon.com/DEWALT-DW872-14-Inch-Multi-Cutter-Saw/dp/B0000302QS

- https://www.amazon.com/Slugger-MCCS14-Metal-Cutting-Diameter/dp/B00C102URI

- https://www.amazon.com/dp/B000IHXOKI