Choose the Best Angle Grinder Wheel for Cutting Metal

Customer’s Choice: the Best Rated Angle Grinder Wheels for Cutting Metal

49 users answered this survey. Please help us improve this review!

So you want to get yourself an angle grinder? Great! It’s important that the right one is selected for your needs and preferences. In this article, we’ll discuss some popular products so they might help guide future purchases.

DEWALT Cutting Wheel, General Purpose Metal Cutting

Expanded metal comes in different sizes, thicknesses, and weights. It’s important to choose the right size for your project, as using the wrong size can be dangerous.

Expanded metal comes in different sizes, thicknesses, and weights. It’s important to choose the right size for your project, as using the wrong size can be dangerous.

DEWALT’s answer to every project is made of two sheets of aluminum oxide grains, fiberglass sandpaper that can cut through tough materials with precision and speed. These wheels are thin and fast. They don’t leave any marks or residue behind, making them perfect for DIY projects. [1]

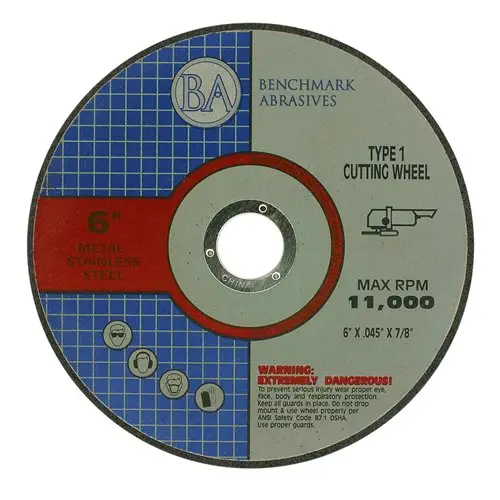

Benchmark Abrasives Quality Thin Wheel

These discs are made to be used with steel, iron, plastic, stainless steel, and other ferrous metals. They are designed with a special blend of premium abrasive grains that stay sharp for an aggressive cut.

These discs are made to be used with steel, iron, plastic, stainless steel, and other ferrous metals. They are designed with a special blend of premium abrasive grains that stay sharp for an aggressive cut.

However, be aware that this product wears out very fast – you’ll only get a few cuts before it needs to be replaced. Unfortunately, this makes it quite expensive in the long run. Nonetheless, it’s a good product for anyone who needs to do some light metal cutting. [2]

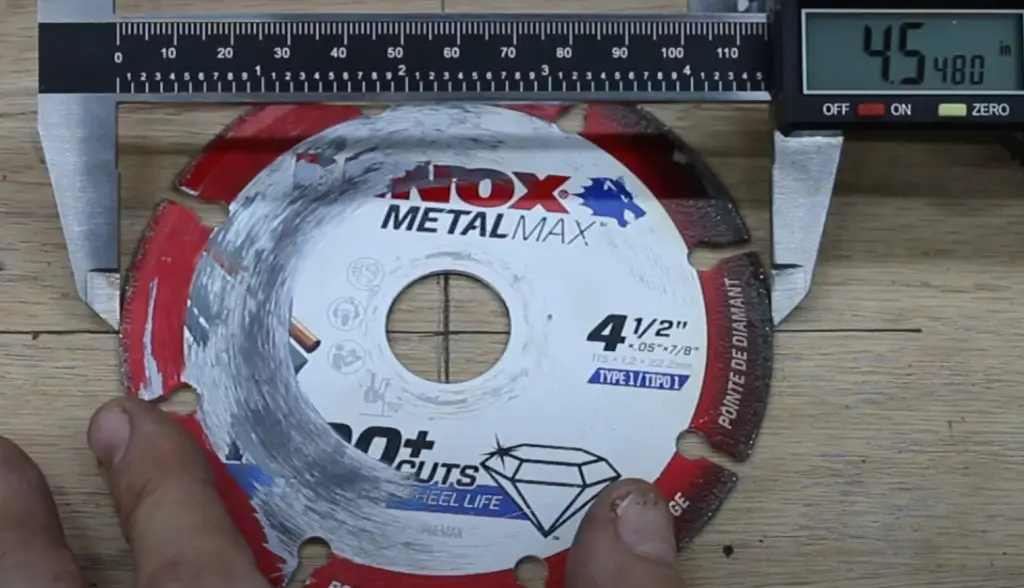

LENOX Tools Cutting Wheel

The LENOX Tools Cutting Wheel is the best angle grinder wheel for cutting metal. It is made of diamond which makes it ideal for cutting through hard metals. The wheel has a diameter of four and a half inches with a thickness of one eighth inch.

The LENOX Tools Cutting Wheel is the best angle grinder wheel for cutting metal. It is made of diamond which makes it ideal for cutting through hard metals. The wheel has a diameter of four and a half inches with a thickness of one eighth inch.

Made with a diamond edge, this wheel can easily cut through thick material without any hassle. Just be careful not to apply too much pressure, as it may cause the wheel to jump off the material. [3]

Benchmark Aluminum Oxide Quality Thin Wheel for Metal

These wheels are made from aluminum oxide, which is one of the most durable materials available. They’re also 0.045 inches thick, so they can withstand a lot of wear and tear. They come in a pack of 25, so you’ll have plenty to last you for a while.

These wheels are made from aluminum oxide, which is one of the most durable materials available. They’re also 0.045 inches thick, so they can withstand a lot of wear and tear. They come in a pack of 25, so you’ll have plenty to last you for a while.

Makita 10 Pack Cut Off Wheels For Grinders

These wheels are designed for hard and continuous use, and can quickly and effortlessly cut through even the toughest materials. Plus, they are contaminant-free and contain less than 0.1% iron, sulfur or chlorine, making them perfect for use on stainless steel.

These wheels are designed for hard and continuous use, and can quickly and effortlessly cut through even the toughest materials. Plus, they are contaminant-free and contain less than 0.1% iron, sulfur or chlorine, making them perfect for use on stainless steel.

Buyer’s Guide

How To Choose The Best Angle Grinder Wheels For Cutting Metal?

Size

The most common sizes are four inches and five inches. The larger the disc, the more power it will have. However, a larger disc is also more difficult to control.

Almost all models come with a 5/8″ arbor, but some have a 3/4 inch or 1 inch barrel. Make sure the wheel you purchase fits your model before buying it, to avoid wasting money.[6]

Disc quality

The discs that you purchase should be of the highest quality. Not only will this make your life easier, but it will also save you money in the long run. Cheap discs break easily and can cause damage to your tools.

Look for those that are labeled “high-quality” or “industrial grade.” These discs are made to withstand heavy use and will last much longer than the cheap ones.

Quantity

On average, there are four to seven discs.

If you’re new to using an angle grinder, it’s best to start with a model that has four discs.Be sure to take extra care when operating a machine with more power and speed.

Material compatibility

It is important to make sure that the wheel is strong enough to handle the type of metal you will be working with. Otherwise there’s risk in damaging both parts and potentially ruining whatever task needs doing!

Metal is a type of material that can be used to make tools and weapons. People have used it for centuries, but only in the last century or so have people discovered all its many uses!

Ferrous metals contain iron and are not as strong as other types of metal. Nonferrous metals do not rust easily and stainless steel does not rust at all, even when it is exposed to the outdoor environment.

Wheels for grinding non-ferrous metals can be difficult to find if you’re not sure what kind of material your project will need them on. Different types work better with different alloys. It is important to match them up correctly so that the alloy is not damaged. [7]

Easy to assemble/disassemble

The cutting wheel is very easy to attach and remove from the grinder. The whole process takes less than a minute.

Another great thing about this product is that it comes with a storage case. This way, you can keep the wheels in good condition and avoid losing them.

The high-quality materials make this cutting wheel durable and long lasting. You can be sure that you are making an investment with our money back guarantee, so go ahead.

How To Cut Metal With An Angle Grinder Wheel?

Choose your required tools

The abrasive cut-off wheel is one of the most common types used for metal cutting. These wheels can help you do your job quickly and easily, whether you are working with thick or thin materials.

Next, put on safety goggles or protective eyewear before starting this process. This will protect you in case anything gets thrown into your eye.

As you’re cutting, keep your hands away from the path of the blade to avoid injury. Once you have finished cutting, release the trigger and let the blade come to a complete stop before moving it away from the metal. [8]

Prepare safety gears

Always wear protective gear, including gloves, safety glasses and a dust mask. Ear protection is also a good idea if you’ll be using the grinder for extended periods of time.

Most angle grinders have a guard that can be adjusted to different positions. Depending on the type of metal you’re working with, you may need to adjust the guard to provide more or less coverage. For example, when cutting thin pieces of metal, you’ll want to use a higher setting so the sparks don’t scatter as much. When you are using a thicker piece of material, you can use a lower setting so that more of the wheel is exposed.

Before you begin, it’s also important to make sure that the angle grinder is properly balanced. Many models have an adjustable weight system that allows you to fine-tune the balance. It is important to balance your grinder because if it is not balanced, the wheel might start vibrating. This can make it harder for you to control the grinder.

Install the disc onto your grinder

First, you need to make sure that the disc guard is in place and secure.

Next, twist the release nut onto the spindle of your grinder clockwise until it’s tight.

Now you can take your Angle Grinder Wheel for Cutting Metal and line up the arbor hole with the release nut.

Once you have them lined up, push the wheel onto the spindle until it is snug against the release nut. Now you can use your wrench to tighten the nut by turning it to the left. [9]

Mark your cut line

Use a sharpie or scribe to mark your cut line on the metal. This will give you a visual guide to follow as you make your cut. If you’re not comfortable drawing a straight line freehand, you can use a measuring tape or ruler to help make a straighter line.

Now that you have your safety gear on and your metal cut line marked, it’s time to get started.

Turn on the tool and start cutting carefully

Now that you know how to change the angle grinder wheel, it’s time to get started on your project. Make sure you have all the necessary safety gear before you begin. Once you’ve got everything ready, turn on the tool and start cutting carefully.

This will help you understand how the tool works and how much pressure you need to apply.When you’re ready to start cutting the metal, it’s important to go slowly at first. Apply light pressure and make sure the wheel is straight before you start increasing speed. Once you get the hang of it, you can start moving faster. [8]

It is important to keep the angle grinder wheel in good condition. Inspect it often and replace it if needed. With proper care, your angle grinder will last for many years.

Extra tips

You should never exceed the maximum speed that’s specified on the grinder or the wheel.

Wear gloves when using an angle grinder.

If the wheel shatters, make sure you have a firm grip on the unit and position your body and arms in a way that the wheel will not hit you.

Do not use an angle grinder on materials that are not meant to be cut with this type of power tool. [8]

FAQ

Can an angle grinder wheel be used to cut metal?

A grinder wheel will cut through metal until it meets with resistance or finishes its job- whichever comes first. There are different blades that can be used at an angle. One of these blades is a disc that can reduce the surface until there is no more room left to cut.

The discs are very sharp and can cut through anything in their way. This allows them to shave more than one layer of material off their target object before being ground down themselves. This way, you will get a more even surface.

Diamond blades work by slowly wearing down the metal surface until it is cut through.

What type of wheel is used for cutting steel?

Abrasive wheels are made of carbon steel or diamond. They are used to grind away the surface of metal.

You need to consider how the wheel will be used paying attention at the following factors:

- The type of steel you will be cutting

- The size of the wheel

- The shape and hardness

- The speed of the grinder

If you need a wheel that can be used on many types of metal, then you should choose an abrasive wheel made from carbon steel. If you know you will only be working with one type of metal, then you can select a wheel made from diamond.

The size of the wheel is determined by the diameter of the grinder. The most common sizes are four, five, and six inches. The shape of the wheel is also important. You will want to choose a wheel that is comfortable to hold and that will not slip out of your hand while you are using it. The wheel should feel good in your hand and it should not move around.

The hardness of the wheel is important because it will determine how quickly the wheel wears down. If you are working with a soft metal, then you will want to choose a harder wheel. If you are working with a hard metal, then you will want to choose a softer wheel.

The speed of the grinder is also important. The faster the speed, the more quickly the wheel will wear down.

When you are choosing an abrasive wheel for cutting steel, you need to consider all of these factors. With a little bit of research, you can find the perfect wheel for your needs.

What disc do I need to cut metal?

There are different discs for different materials. If you need to cut aluminum, make sure you get a disc that is meant for cutting aluminum.

Steel might not seem as tough as some of the other metals, but it is actually very hard to work with. Unless someone has experience working with it or knows exactly where every tooth is on their tool, they will probably end up with a lot of bent and broken teeth.

The size is usually decided by whether or not you need a four-inch, five inch (or bigger), and six inch model. Make sure that the dimensions of the treadmill work for your needs before buying it. If the dimensions are not right, it might be hard to use it and you might not be able to do what you want with it.

How do I choose an angle grinder disc?

Angle grinders come with different disc types and sizes. The most common size is four and a half inches, but there are also models that use three-inch discs.

When choosing a disc for your lathe, it’s important to think about what material you’ll be using. The type of metal and power level will dictate which kind is right!

There are different discs that are available depending on the weight and shape of the object you need to reproduce with accuracy. If you’re using a high-powered machine, then you’ll need tough equipment to do the job. So don’t waste time guessing when buying new tools – just go ahead and buy them today.

How do you cut metal with a grinding wheel?

One way is to use a standard cutting wheel that is made out of abrasive materials. Another way is to use a diamond cutting wheel.

Metal cutting is a skill that requires experience to do right. If you’re not sure which wheel will work for your needs, it’s always a good idea to check the tool’s rating for metal types like steel or aluminum before starting any project.

First, you will need to make sure that the area that you are working in is well-ventilated. This is because the grinding process can create a lot of dust and debris.

Next, you should clamp the metal in place so that it does not move while you are working.

Once the metal is clamped in place, you can begin to cut it with the grinding wheel. Start by making shallow cuts, and then make deeper cuts as you go.

You will need to apply pressure to the grinding wheel as you are cutting. The amount of pressure you need to apply to a metal cutter will depend on the type of metal and how thick it is.

How do I choose a cutting wheel?

The most important thing to think about is the type of material you will be cutting. Other factors to consider include the size and shape of the wheel, as well as the speed at which you will be grinding.

If you are going to be making very thick cuts, then you will want to choose a thicker wheel. However, if you only need to make shallow cuts, then a thinner wheel will suffice.

The type of cut you need to make will determine what kind of blade is best for your situation. If it is just a straight task, use a straight blade. If the task is not straight, use a blade with curves to help guide it.

How thick of steel can an angle grinder cut?

The most common type of angle grinder can cut through steel that is about ¼ inch thick. If you need to shave off more metal or clean up a rough edge, it is best to get a tool with a motor and blade system that is strong enough to handle thicker pieces of metal, like 1/2″ – 3″.

It’s important to consider both the thickness of your steel as well as its hardness when deciding which angle grinder will be best for cutting it. If you have ¼ inch thick metal but it’s extremely hard, then even a high-quality tool may struggle with what needs doing here.

If you’re looking for an angle grinder that can cut through thicker metal, you may want to consider a tool with a more powerful motor. This will help you get the job done more quickly and easily. The best way to find out if a tool is good is to read reviews from people who have used it for similar projects.

Can I use a stone cutting disc on metal?

Stone discs are a great way to cut through softer materials like tile, brick and stone but they’re not so good on metal. The electrodes will wear down quickly if they are used too much or if there is a lot of heat buildup. This can be dangerous!

Diamond cutting discs are a great choice for metal cutting. They can handle the tough stuff. The sparks and heat buildup will be less with this than if you were to use a stone disc, so it’s better in many ways.

Can you cut steel with a stainless steel blade?

Stainless steel is a great option choice when durability matters. Carbide or diamond blades will last longer and provide better results in most cases!

The blades gum up easily, which can cause excessive wear on your tooling. That’s why it’s important to keep them in good condition if you’re using one for this purpose.

You need a very high-quality blade that is specifically designed to cut metal in order to use a stainless steel blade effectively.

A good quality blade should have a lot of teeth and be able to withstand the heat that is generated when cutting through metal.

The downside to using a stainless steel blade is that they are more expensive than other options.

If you are looking for a cheaper option, consider using a carbide or diamond blade.

Is stainless steel harder to cut than steel?

The difference in hardness between stainless steel and regular cast iron means you’ll need to take extra care when cutting with a dull knife. Stainless steel is harder than regular cast iron, so if you’re not careful, you could damage the knife or the surface of the metal.

It is important that your grinders match up well so that they do not damage either type of material- especially if they are made from different metals! Only use wheels that are specifically designed for SS appliances. This is because Wheels that are not specifically designed for SS appliances could potentially scratch or mar your appliance.

How do you cut thick metal?

The easiest way to cut thick metal is with an angle grinder and a specially designed disc. This thin, circular piece of diamond or abrasive coated steel can quickly grind away most substances. If you can’t take the door off its hinges, you can use a hacksaw or reciprocating saw. But remember that these tools might take more time than necessary, so don’t get overwhelmed by them at first.

Useful Video: Which angle grinder blade / disk for concrete, plastic, tiles and metal

Conclusion

When it comes to choosing the best angle grinder wheels for cutting metal, there are a few things you need to take into account. The first is the type of wheel – there are two main types, grinding and cutting discs. Grinding discs are used for roughing down surfaces, while cutting discs can be used for more detailed work. The second consideration is the material that the disc is made from. There are three main materials – aluminum oxide, silicon carbide, and diamond – each of which has different properties. Finally, you’ll need to consider the size and shape of the disc in order to find one that will fit your angle grinder.

References:

- https://www.amazon.com/DEWALT-DW8062B5-0-045-Inch-Stainless-Cutting/dp/B005B8LZCI

- https://www.amazon.com/50-Pack-Quality-Wheels-Stainless/dp/B015VOMD5E

- https://www.amazon.com/Lenox-Tools-1972921-METALMAX-Diamond/dp/B01HSJ1A2M

- https://www.amazon.com/Premium-Cut-Off-Wheel-Metal-Stainless/dp/B008KYUVCK

- https://www.amazon.com/Makita-10-Pack-Aggressive-Stainless/dp/B019QYUFX2

- https://ronixtools.com/en/blog/the-best-angle-grinders-to-cut-metal/

- https://reviewerguides.com/best-angle-grinder-wheel-for-cutting-metal/

- https://www.weilerabrasives.com/6-Tips-for-Improving-Cutting-Performance-With-Angle-Grinders

- https://jag10tools.com/blog/how-to-choose-the-right-cut-off-wheel-for-the-job/