If you ever wanted to machine aluminum but didn’t know how, this post is for you. It can be difficult to know what tools to use and how to start. But don’t worry, we will explain the machinery you need, some helpful tips and the best practices for working with aluminum in this post.

Whether you are just starting out or have been machining metal for years, we guarantee that there will be something here for everyone! Let’s get started learning about how to machine aluminum!

Why Can Aluminum Be Challenging?

Aluminum is a difficult material to work with for many reasons.

- First, it is a soft metal that can bend and dent easily if not handled properly.

- It also has a low melting point which means the cutting tools need to be sharpened regularly.

- In addition, aluminum is more likely to chip and break when machined so it takes more skill to use properly. [1]

What Machinery Do You Need?

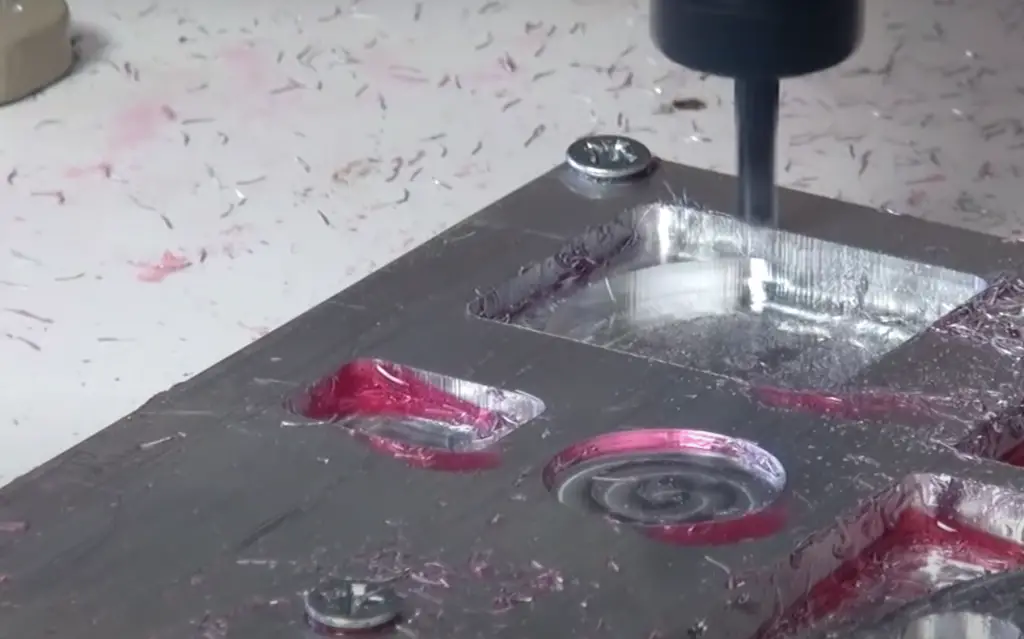

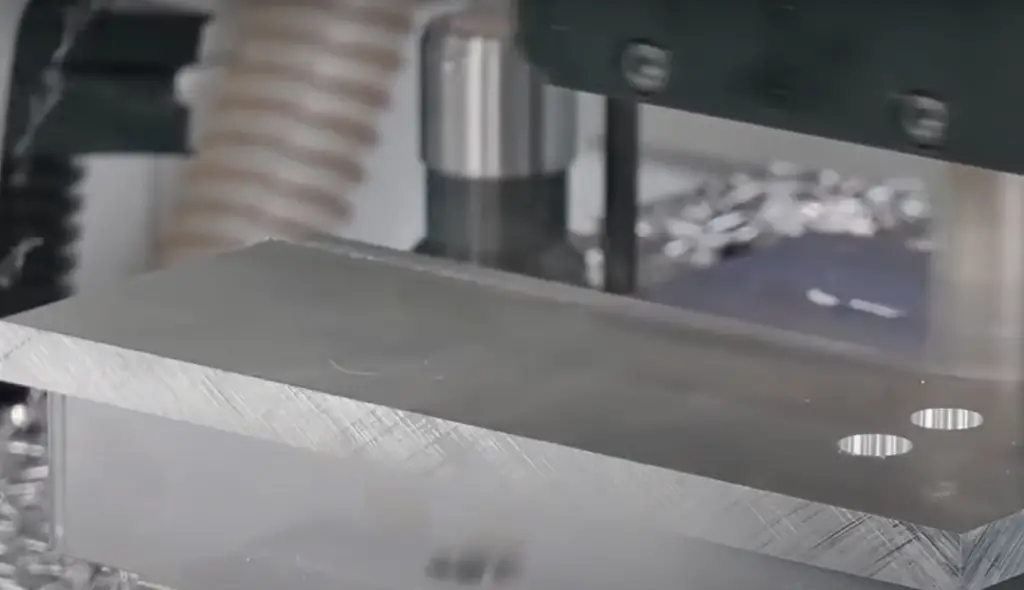

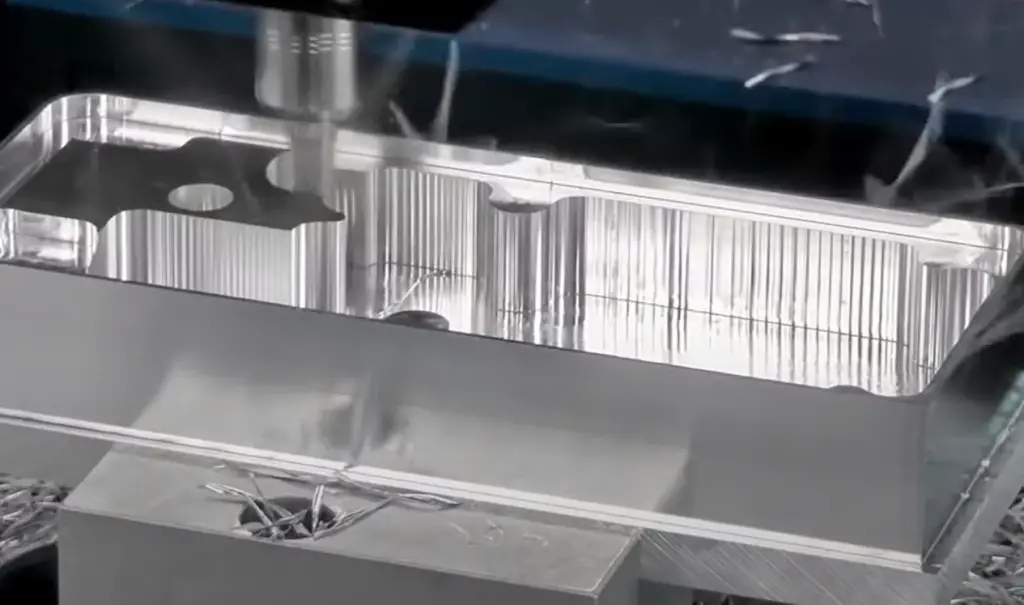

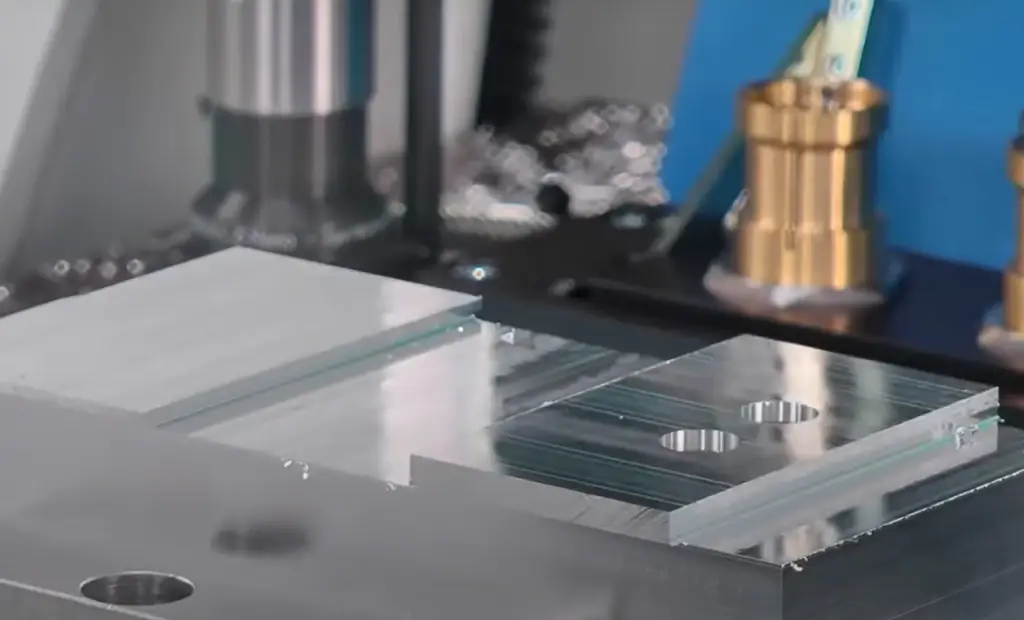

The first step to success is choosing the right machinery for your project. The most popular type of machine used for machining aluminum is a CNC mill.

With a CNC mill, you can program it to cut shapes and curves that would be difficult to make with other types of cutting tools. They are also more precise than other types of machines, making them great for detailed projects.

If you need to make large and/or simple-shaped parts, then a CNC lathe is probably a better option. This type of machine can quickly and easily create symmetrical parts from aluminum. It also makes it easier to create threads or grooves in the metal.

Both machines will need special tools to cut aluminum. The tools come in different sizes and can be made from high-speed steel or carbide for extra strength.

Different Kinds of Aluminum Machining

There are several different machining processes that can be used to work with aluminum. In general, milling and lathe turning are the two main types of machining processes used for aluminum.

- Milling is a process where tools are used to remove material from a block of metal in order to create a flat surface.

- Lathe turning is a process where the workpiece is rotated and cutting tools remove material from the outside diameter to create round shapes.

Other processes such as drilling, tapping, reaming and grinding can also be used when machining aluminum.

Cutting Tools for Aluminumu Need?

Cutting Tool Material

The material of the tool you use to cut aluminum is very important. Often, people use high-speed steel (HSS) tools for general purpose machining because they are good for most applications.

Carbide tools are better at not wearing down, but they require you to cut faster and need more skill to use them correctly.

Cutting Fluids

Using cutting fluids or lubricants is important when machining aluminum. They help reduce friction between the tool and workpiece which can cause heat build-up and decrease the life of the cutting tools.

Flutes

The number of flutes on the cutting tool can also make a difference. More flutes mean that the tool can remove more material at once, but it also means that there is less room for chips to escape.

Helix Angle

The helix angle helps determine how the cutting tool interacts with the workpiece.

A higher helix angle is better for machining aluminum because it can reduce chatter and vibration.

Worthwhile Features

There are some good things about machining aluminum. It is a lightweight material that is easy to work with and won’t rust. Also, it can be machined into complex shapes which is good for making parts for cars, planes, boats and more!

Feeds and Speeds

Feed rate and speed are important when machining aluminum.

The correct combination of these two parameters helps reduce heat build-up and increase tool life.Balancing and Harmonics

When machining aluminum, it is also important to balance and use harmonics. Balancing means making sure the cutting tool does not vibrate or chatter.

Harmonics refer to the frequency of vibration that can occur, which can be reduced by using a damping lubricant. [1]

Machining Strategies for Aluminum

When machining aluminum, it is important to use the right strategies. Start with small cuts and a slow feed rate. Increase the depth of your cut gradually as you become more familiar with the material and its properties.

Your cutting tools will work better if they are sharp. You should also use cutting fluid or lubricant to help reduce heat and prevent chips from sticking to the tool. Using a balance and harmonic damping lubricant will help you make smoother cuts.

Common Operations for Machining Aluminum

Facing

Facing is a common operation where you cut off extra material from the top or bottom of a workpiece. You can do this with either a lathe or milling machine. To get the best finish, you need to have good tool control.

Turning

Turning is another machining process used for aluminum. It involves rotating the workpiece and removing material to create a round shape. You can use either a lathe or milling machine for this operation.

Pocketing

Pocketing is when you cut pockets into the workpiece. You can do this with a milling machine or lathe. The cutting tool should have multiple flutes so that it removes material quickly and smoothly.

Slotting

Slotting is when you cut a groove into the workpiece. You can do this with either a milling machine or lathe. It is important to make sure that the cutting tool has enough flutes so that it does not chatter.

Drilling

Drilling means making a hole in the workpiece. You can use a milling machine or lathe.

Aluminum needs sharp tools and lubricant to stop heat build-up and tool wear.

Tapping

Tapping means cutting threads into the workpiece. This is usually done with a tap and die set.

Best Strategies and Tips for Aluminum Machining

When machining aluminum, you need to use the right tools and strategies. This means that your cutting tools should be sharp and you should use plenty of lubricant or coolant. You also need to adjust the feed rate and speed for the material.

Also, think about using a balance and harmonic damping lubricant to reduce chatter and vibration. Finally, it is important to start with small cuts and increase the depth gradually as you become more familiar with the material. [2]

Tips for Working with Aluminum

Now that we know what machinery is needed let’s get into some helpful tips for working with aluminum:

- Use sharp cutting tools – Dull cutting tools can cause the aluminum to chip or break easily so make sure that your tools are sharpened regularly.

- Wear protective gear – Aluminum particles can cause irritation and even respiratory problems so it is important to wear a dust mask, gloves, and safety glasses when working with aluminum.

- Reduce the speed of the cutting tool – Slower speeds allow for cleaner cuts and less waste.

- Take adequate cooling measures – Aluminum should be kept cool while machining to avoid damage to the material.

- Use the right lubricant – Lubricants can help reduce friction and make cutting easier but be sure to use a lubricant that is compatible with aluminum.

Precautions

Aluminum is a delicate material and needs to be handled with care. Here are some important safety tips for machining aluminum:

- Ensure the proper setup – Make sure that the proper tools and equipment are used for each operation.

- Use sharp cutting tools – Dull tools can cause excessive wear on the material and lead to poor results.

- Wear protective gear – Always wear safety glasses, gloves, and a dust mask when operating machinery.

- Clean up regularly – Metal chips can be hazardous so make sure to clean up any messes promptly.

- Follow all machine safety rules – Read the manual for any machinery you are using and follow the safety rules listed.

FAQ

Is aluminum easy to machine?

Yes, aluminum is relatively easy to machine. However, it needs to be handled with care and requires sharp cutting tools.

Can you use a milling machine for aluminum?

Yes, a milling machine can be used for aluminum machining operations such as pocketing, slotting, and drilling.

What type of lubricants are best for machining aluminum?

The best type of lubricant to use when machining aluminum is a balance and harmonic damping lubricant. This type of lubricant helps reduce chatter and vibration.

It is also important to make sure that the lubricant you use does not damage aluminum. We suggest using a water-soluble cutting fluid specifically designed for aluminum machining.

What type of tools are used for machining aluminum?

Common tools used for machining aluminum include drill bits, taps, reamers, countersinks, milling cutters, and end mills. It is important to use sharp cutting tools when working with aluminum. Dull tools can cause excessive wear on the material and lead to poor results.

Can Aluminium be machined?

Yes, aluminium can be machined. Aluminium can be cut into different shapes using machines. To machine aluminium, you need sharp cutting tools, lubricants or coolant, adjustable feed rate and speed for the material, a balance and harmonic damping lubricant to reduce chatter and vibration, and starting with small cuts before increasing depth gradually.

Additionally, it is important to make sure that you are wearing protective gear such as a dust mask, gloves, and safety glasses when machining aluminium.

Why is aluminum difficult to machine?

Aluminum is a soft metal and can be difficult to machine because it has a tendency to stick or weld itself to the cutting tool.

Additionally, aluminum tends to require higher cutting speeds than other metals, so it can be challenging to set up the machines correctly.

Does Aluminum corrode?

Aluminum can corrode if exposed to certain environmental conditions, such as salt water or certain acids.

Corrosion can cause the aluminum to become weak and brittle, so it is important to protect aluminum from corrosion if you are going to be using it in a corrosive environment. Protective coatings, such as anodizing, can be applied to aluminum to help prevent corrosion.

Is aluminum hard to mill?

No, aluminum is relatively easy to mill. However, it needs to be handled with care and requires sharp cutting tools.

Additionally, it is important to make sure that the speed settings are correct for the material and that a balance and harmonic damping lubricant is used to reduce chatter and vibration.

What aluminum is easiest to machine?

Aluminum alloys that are easy to machine include 6061-T6 and 7075-T6. These alloys are strong and durable, and can be machined at high speeds.

Can you machine aluminum with a CNC?

Yes, aluminum can be machined with a CNC machine. The CNC machine is very precise and needs to be programmed correctly. The speed of the machine also matters. If it is set too fast, it could ruin the project.

Lubricant also helps to reduce vibration and makes sure the project turns out well. When working with aluminum, it is best to go slowly so that it does not stick to the cutting tool.

How can I machine aluminum without sticking?

If you want to machine aluminum without it sticking, you need to use the correct cutting tools and make sure they are sharp. You should also use coolant or lubricants to reduce friction.

Additionally, you should adjust the feed rate and speed for the material according to how fast you want to cut, and use a balance and harmonic damping lubricant to reduce chatter and vibration.

Finally, it is important to start with small cuts before increasing depth in order to avoid sticking.

Why is it important to use sharp cutting tools when machining aluminum?

It is important to use sharp cutting tools when machining aluminum because it will help you make more precise cuts. Additionally, using a dull tool can cause the aluminum to warp and distort.

Sharp cutting tools also reduce the risk of the tool sticking to the material, as well as reduce vibration and chatter. Finally, using a sharp tool will result in better quality cuts with less effort.

How can I prevent vibrations when machining aluminum?

To stop vibrations when using a machine on aluminum, you should use adjustable feed rate and speed for the material. You should also use a balance and harmonic damping lubricant to reduce chatter and vibration.

Additionally, it is important to make sure that you are using sharp cutting tools, coolants or lubricants to reduce friction.

Why is it important to wear protective gear when machining aluminum?

When you work with aluminum, it is important to wear a dust mask, gloves and safety glasses. This will help protect you from the metal filings and sparks.

It is also important to wear protective gear so that you can stay focused on your work and reduce the risk of getting hurt.

Does aluminum need to be machined with a coolant?

Yes, it is important to use coolants or lubricants when machining aluminum. This will help reduce friction and keep the tool from sticking to the material.

Additionally, using coolant or lubricant will also help reduce vibration and chatter. It is important to make sure that you are using the right type of lubricant for your project.

Do I need to use a balance and harmonic damping lubricant when machining aluminum?

It is important to use a balance and harmonic damping lubricant when machining aluminum. This will help reduce vibration and chatter while ensuring that the tool does not stick to the material.

Additionally, using this type of lubricant can also improve the quality of the cut and reduce strain on the machine.

Is there a certain type of coolant or lubricant I should use when machining aluminum?

It is important to use the right type of lubricant when machining aluminum. You should use an oil-based coolant or lubricant for non-ferrous metals such as aluminum.

This will help reduce friction and keep the tool from sticking to the material. Additionally, it is important to make sure that you are using the right type of lubricant for your project.

Are there any other tips for machining aluminum?

There are some other useful tips to keep in mind when machining aluminum. Make sure that you are using sharp cutting tools and coolants or lubricants to reduce friction.

Additionally, adjust the feed rate and speed for the material according to how fast you want to cut, and use a balance and harmonic damping lubricant to reduce chatter and vibration.

Finally, it is important to start with small cuts before increasing depth in order to avoid sticking. It is also important to wear protective gear such as a dust mask, gloves, and safety glasses when machining aluminum.

Does machining aluminum require any special skills?

Machining aluminum requires some skill and experience. You need to know how to use the machine correctly and safely. You also need to know how to adjust the feed rate and speed for the material according to how fast you want to cut.

Additionally, you need to choose the right type of lubricant for your project and wear protective gear when machining aluminum.

Why is it important to use coolants or lubricants when machining aluminum?

Coolants or lubricants help reduce friction when machining aluminum. This helps the cutting tool move smoothly across the material, which can make the finished product more accurate and precise.

Additionally, it prevents heat build up on the tool, which can damage it. It is also important to use a balance and harmonic damping lubricant to reduce chatter and vibration.

How often should I sharpen my cutting tools when machining aluminum?

This depends on the type of cutting tool you are using. Generally, it is best to sharpen your cutting tools every few hours or after a certain number of cuts have been made.

It is also important to use the right lubricant for your project and adjust the feed rate and speed according to how fast you want to cut. This helps ensure that your cutting tools last longer and produce the best results.

What should I do if my aluminum part comes out rough?

If your aluminum part is not smooth, it might be because the cutting tools are dull. Or there might be too much friction because of using the wrong kind of lubricant or feeding it too fast. To fix this, you can try sharpening the cutting tools.

You can also use the right lubricant and adjust the feed rate and speed to reduce friction. Another way to help avoid this problem is to start by making small cuts before increasing depth.

What is the best type of lubricant for machining aluminum?

The best type of lubricant to use when machining aluminum depends on the project and your needs. Generally, it is best to use a balance and harmonic damping lubricant, which helps reduce chatter and vibration.

Additionally, it is important to choose the right type of lubricant for your project and adjust the feed rate and speed according to how fast you want to cut. This helps ensure that your cutting tools last longer and produce the best results.

What protective gear should I wear when machining aluminum?

When machining aluminum, it is important to wear the right protective gear. This includes a dust mask, gloves, and safety glasses to protect your eyes and lungs from particles created by the machine.

Additionally, you should also consider investing in long sleeve shirts and pants to minimise contact with hot metal shavings. Lastly, be sure to wear hearing protection if your machining area is particularly noisy.

Aluminum is a material that can be shaped into different things using CNC machines. If you use the right tools and follow the correct steps, you can make sure your project turns out well.

How to Machine Aluminum?

To machine aluminum, you will need a CNC milling machine and cutting tools. You should use coolants or lubricants when machining to reduce friction and heat buildup on the tool, which can damage it.

Adjust the feed rate and speed according to how fast you want to cut. Lastly, wear the proper protective gear, such as a dust mask, gloves and safety glasses. Following these steps will ensure your aluminum project is successful.

Is machining aluminum difficult?

Machining aluminum does not have to be hard, but it does take practice. The most important thing to remember is to use the right tools, coolants, and lubricants for your project.

You should also wear the proper protective gear to keep yourself safe from hot metal shavings. With the right information and preparation, machining aluminum can be a good experience.

Useful Video:Extreme Fast Milling Machines in Action – DATRON CNC Machines

Conclusion

Whether you’re looking to machine aluminum for a new product or prototype, there are a few things you need to know about the process. With the right tools and understanding of aluminium machines, you can create just about anything.

Thanks for reading and we hope this article was helpful. If you have any further questions feel free to contact us anytime or visit our website for more information.

References:

- https://makeitfrommetal.com/how-to-machine-aluminum-all-you-need-to-know/

- https://ecoreprap.com/how-to-machine-aluminum/