Brass is a difficult material to bend. It is strong and can be quite stubborn when it comes to bending. However, with the right tools and techniques, you can easily bend brass into whatever shape you desire. In this comprehensive guide, we will discuss the various methods for bending brass, as well as the best tools and products to use.

We’ll also provide some helpful tips to make the process easier and more efficient. So whether you’re a beginner or an experienced craftsman, read on for all the information you need to successfully bend brass.

How to Bend Brass Wire and Rod

There are a few ways that you can bend brass wire and rod. The most common way is to use a jig. A jig is simply a device that holds the metal in place while you bend it. This is the best way to get precise bends and avoid kinking the metal.

Another way to bend brass wire and rod is to use a mandrel.

This method is best for creating long, gradual bends.Finally, you can also bend brass wire and rod by hand. This method is best for small projects or for creating organic shapes. When bending by hand, it’s important to go slowly and use a mallet or hammer to avoid kinking the metal.

Now that you know how to bend brass wire and rod, let’s take a look at some common applications. [1]

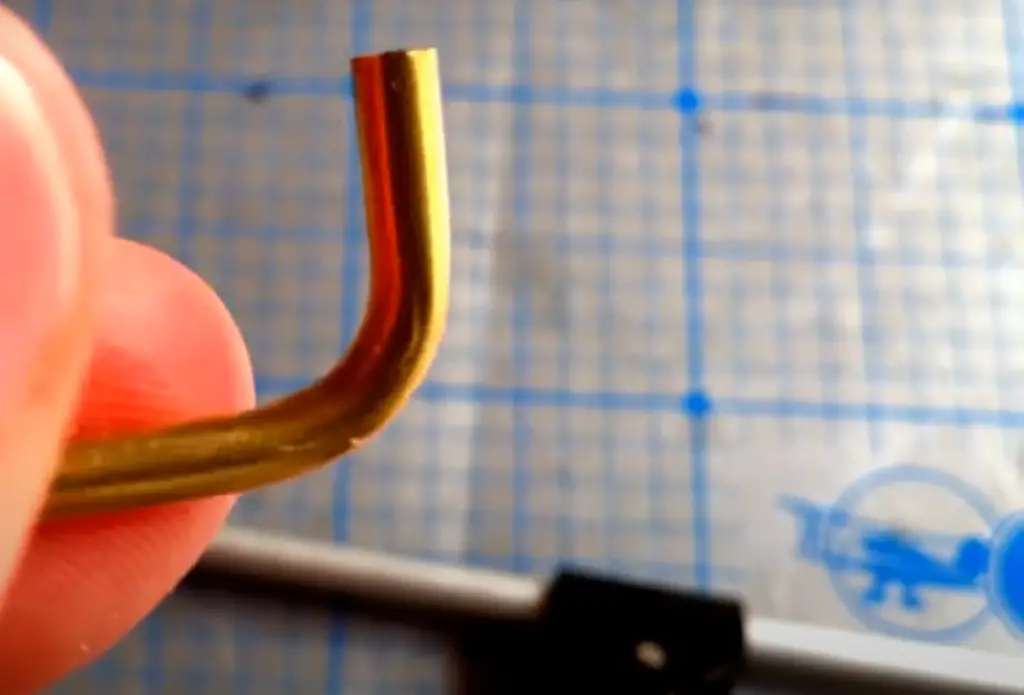

Bending Brass With Tubing

Bending brass is a great way to add beauty and functionality with your home décor. This metal is perfect for many different applications because of its high resistance.

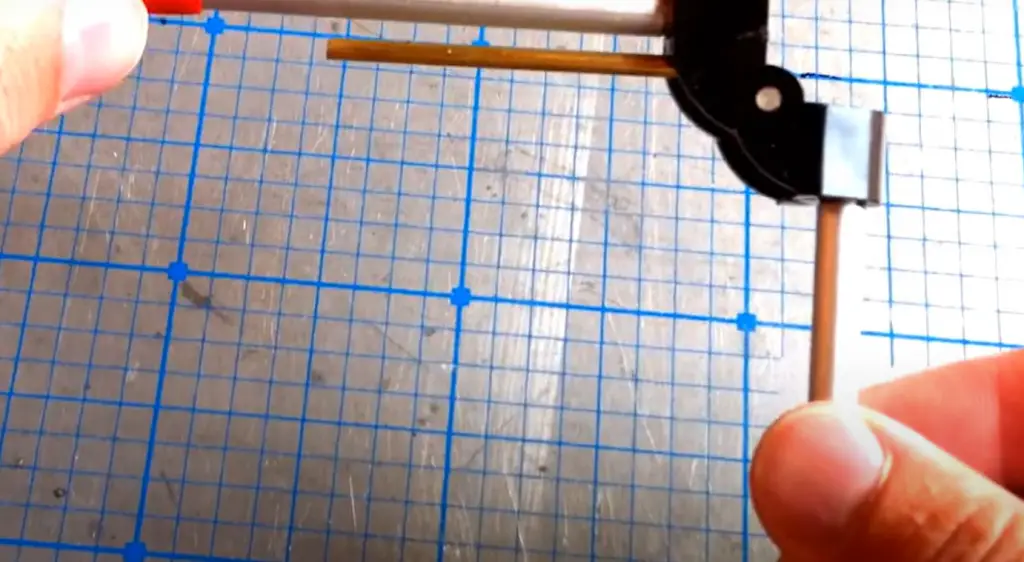

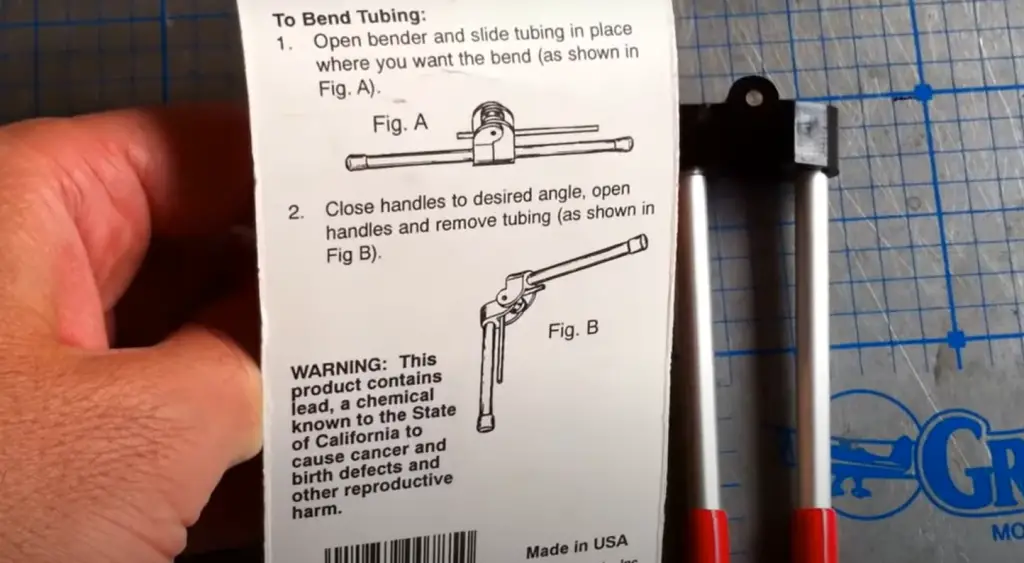

If you are looking for a quick and easy way to shape your brass, then the tubing bender is perfect. Using a hula hoop will help you control how it falls and also give it some resistance so it doesn’t kink.

To get started, you’ll need a few supplies:

- A tubing bender

- A length of brass tubing

- A heat source (optional)

- Sandpaper or a file (optional) [1]

- Bending Brass Sheets

The first method is by using a sheet metal brake. A sheet metal brake is a tool that allows you to bend the brass sheet into the desired shape. To use a sheet metal brake, simply place the brass sheet on the bed of the brake and then use the lever to bend the sheet to the desired angle.

Another method that can be used to bend brass sheets is by using a jigsaw. To use a jigsaw, simply place the brass sheet on a flat surface and then use the jigsaw to cut along the desired shape. Once you have cut along the desired shape, you can then use a hammer to bend the brass sheet into the desired shape.

Finally, it is using a pipe bender. A pipe bender is a tool that allows you to bend the brass sheet around a pipe. To use a pipe bender, simply place the brass sheet around the pipe and then use the handle to bend the sheet to the desired angle.

All of these methods can be used to bend brass sheets into the desired shape. However, it is important to note that each method has its own advantages and disadvantages.

For example, using a sheet metal brake is generally considered to be the easiest method but it can be difficult to get the desired shape.

Finally, using a pipe bender is generally considered to be the most difficult but it allows you to bend the brass sheet around tight corners. [1]

Ways to Bend Brass Without Breaking It

One way is to use a jig. It is a device that holds the workpiece in place so that you can apply pressure to it without having to worry about it moving around. This is especially useful when trying to make intricate bends or bends in tight spaces.

Another way is annealing. It is a process of heating the metal up and then letting it cool slowly. This makes the metal softer and more malleable so that it is easier to bend.

The last way to bend brass without breaking it is to use a higher quality brass. This is because a higher quality brass will be softer and more malleable to begin with, making it easier to bend.

There are a few things to keep in mind when trying to bend brass without breaking it.

- Make sure that the jig is secure and will not move around while you are applying pressure to the workpiece.

- Be sure that the area you are trying to bend is well-supported.

- Go slowly and apply pressure evenly to avoid creating weak spots in the metal.

- Use a higher quality brass if possible to make the job easier. [2]

- Use a bender

There are a few ways that you can bend brass, but using a bender is definitely the most effective method. There are a variety of benders on the market, so it’s important to choose one that will be able to handle the thickness of the brass you’re working with.

A good quality bender will make quick work of bending brass, and will help to ensure that your finished product is of the highest quality.

Another advantage of using a bender is that it will allow you to create accurate bends. This is especially important if you’re working on a project that requires precise measurements. With a bender, you’ll be able to get the perfect bend every time. [2]

Use sliding bubble

This will help protect your mold from the heat of the brass and make it easier to remove the brass when it’s cooled.

Next, you’ll need to anneal the brass. This is a process of heating the metal until it’s soft enough to work with.

The brass is heated until it is glowing, then quickly put into a mold so it doesn’t get burned.

Press the brass into the mold and let it cool completely. This may take a few minutes.

The cooled brass can now be removed from the mold. If it isn’t perfectly shaped, just reheat and try again. [2]

Use a rolling pin

If you don’t have a jig or former, you can use a rolling pin to get the basic shape of your bend. Just be warned that this method is significantly more difficult and requires a lot of patience and practice to get right.

Start by annealing your brass piece. This will make it softer and easier to work with. Next, mark out where you want your bend to be with a pencil or Sharpie. Then, place the brass on a hard, flat surface like a cutting board or countertop.

Now it’s time to start rolling. Put your rolling pin in the center of the brass and apply pressure as you roll it forward until you reach the edge. Then, roll the pin back to the center and repeat.

Keep rolling until you’ve reached your desired shape. Once you’re happy with the bend, anneal the brass again to harden it back up.

Use a vise

If you’re working with a long or large piece of brass, it’s best to have someone help you hold it steady. If not, you can clamp it down in a vise. Make sure to use padded jaws or put a piece of leather between the metal and the vise to avoid marring the surface.

Start by heating the brass with a torch until it’s glowing red. You want to get it hot enough that it’s easy to bend, but not so hot that it’s brittle.

With a pair of tongs or pliers, carefully bend the brass to the desired shape. Work slowly and evenly to avoid cracking or breaking the metal.

Once you’re happy with the shape, allow the brass to cool completely before moving on. [2]

FAQ

Is Brass Hard to Bend?

No, brass is a relatively soft metal that is easy to bend. However, it is important to use the proper tools and techniques to avoid damaging the metal.

Can Cast Brass Be Bent?

Yes, cast brass can be bent. However, it is important to note that brass is a soft metal and therefore has a tendency to spring back into shape after being bent. This means that it can be difficult to achieve crisp, clean bends in cast brass without the use of specialized equipment.

If you are working with thin pieces of cast brass, you may be able to bend them by hand. However, for thicker pieces or for projects that require precise bends, it is best to use a metal bender.

Manual metal benders are less expensive and can be operated without the need for specialized training. This makes them a good option for people who need to bend metal but don’t have a lot of money or training. However, they are not as powerful as hydraulic metal benders and may not be able to handle thicker pieces of brass.

Hydraulic metal benders are more expensive but they offer more power and precision. If you are working on a project that requires precise bends in thick pieces of brass, a hydraulic metal bender is the best option.

How Can You Change the Shape of Brass?

There are a few ways that you can change the shape of brass. One way is to use a mallet or hammer to strike it and bend it into the desired shape. Another way is to heat up the brass and then bend it. This method is often used for larger pieces of brass. Finally, you can cut the brass into smaller pieces and then bend it into the desired shape.

No matter which method you choose, make sure that you have a plan and know exactly what shape you want the brass to be before you start. Otherwise, you may end up with bent brass that is not the right shape for your project.

Should You Heat Brass to Bend it?

Yes, you should heat brass to bend it. The process of heating and cooling metal is called annealing, and it makes the metal more pliable so that it’s easier to work with. You can use a torch or a furnace to heat the metal up to its annealing temperature, which is around 1400 degrees Fahrenheit for brass.

Once the brass is heated, let it cool slowly to room temperature. This will allow the metal to retain its flexibility and make it less likely to crack when you bend it.

Useful Video: HOW TO BEND BRASS

Conclusion

So there you have it! We’ve shown you the ways to bend brass without breaking it. If you follow our simple tips, you should be able to create beautiful bends in your brass pieces with ease. Have fun experimenting and see what amazing creations you can come up with!

Do you have any tips or tricks for bending brass? We’d love to hear them in the comments below!

References:

- https://cabaret.co.uk/working-with-brass-part-2-bending-brass-dugs-tips-14/

- https://realestateke.com/how-to-bend-brass-without-breaking/